Biaxially oriented polypropylene resin film

A polypropylene-based resin and biaxial orientation technology, which is applied to synthetic resin layered products, flexible coverings, packaging, etc., can solve the problems of unsmooth transportation of films, wrinkles of bags, etc., and achieve smooth automatic packaging processing , fewer wrinkles, and less air regurgitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0166] The resin composition constituting each layer used in Example 1 is as follows.

[0167] (1) Substrate layer (A) Constituent resin composition

[0168] Glycerin monostearate (Matsumoto Yuyu Pharmaceutical Co., Ltd., TB-123) 0.16% by weight, polyoxyethylene (2) stearylamine (Matsumoto Yuyu Pharmaceutical Co., Ltd.) as an antifogging agent was added to [PP-1]. Company, TB-12) 0.2% by weight, polyoxyethylene (2) stearylamine monostearate (Matsumoto Yushi Pharmaceutical Co., Ltd., ELEX 334) 0.6% by weight as [PP-4], the substrate layer ( A) Constituent resin composition uses 100% by weight.

[0169] (2) Intermediate layer (B) constitutes resin composition

[0170] In [PP-2], 1.5% by weight of organic polymer microparticles (CS30: Sumitomo Chemical Co., Ltd.: particle size 3.5 μm) and glycerin monostearate (Matsumoto Yushi Pharmaceutical Co., Ltd., TB) as an antifogging agent were melt mixed. -123) 0.45% by weight so that the resin temperature becomes 240° C., and it is fo...

Embodiment 2

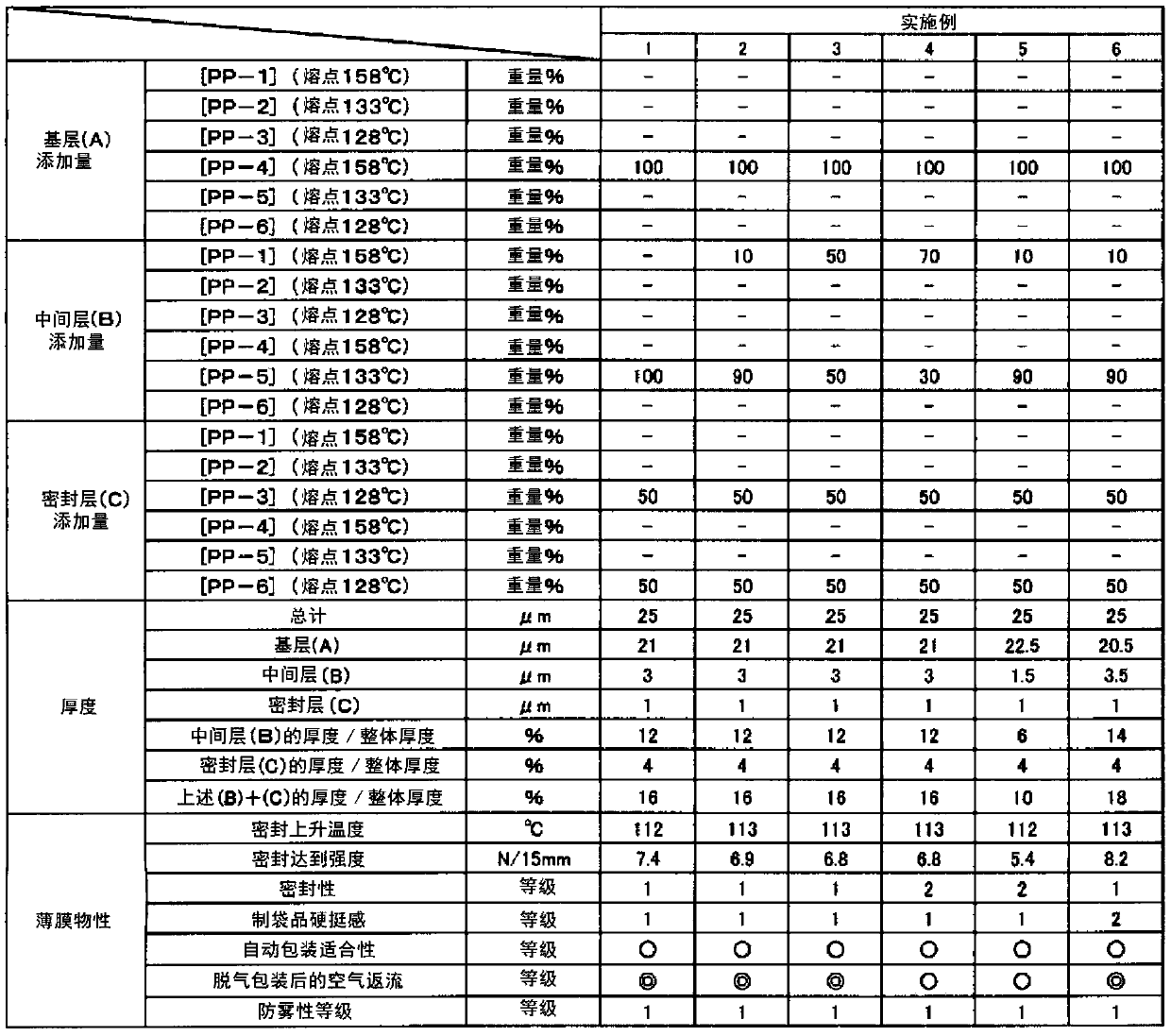

[0179] A laminated film was obtained in the same manner as in Example 1 except that the resin composition constituting the intermediate layer (B) was a mixture of [PP-1] 10% by weight and [PP-5] 90% by weight. The obtained laminated film had sufficient heat-sealing strength and attainment strength at low temperatures as in Example 1, and was compatible with airtightness, suitability for automatic packaging, stiffness of bag-making products, and air reflux after degassing packaging. And the anti-fogging property has also become a level that does not pose a problem to fruit and vegetable packaging. Table 1 shows the film composition and physical property results.

Embodiment 3

[0181] A laminated film was obtained in the same manner as in Example 1 except that the resin composition constituting the intermediate layer (B) was a mixture of 50% by weight of [PP-1] and 50% by weight of [PP-5]. The obtained laminated film had sufficient heat-sealing strength and attainment strength at low temperatures as in Example 1, and was compatible with airtightness, suitability for automatic packaging, stiffness of bag-making products, and air reflux after degassing packaging. And the anti-fogging property has also become a level that does not pose a problem to fruit and vegetable packaging. Table 1 shows the film composition and physical property results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com