Synthetic resin cap

A technology of synthetic resin and container mouth, applied in the field of anti-theft lids, can solve the problems of difficulty in taking into account the sealing performance and opening performance, insufficient tamper-evidence, and easy tilting of the lid, and achieves excellent tamper-evidence performance, taking into account the opening performance, Achieving the effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

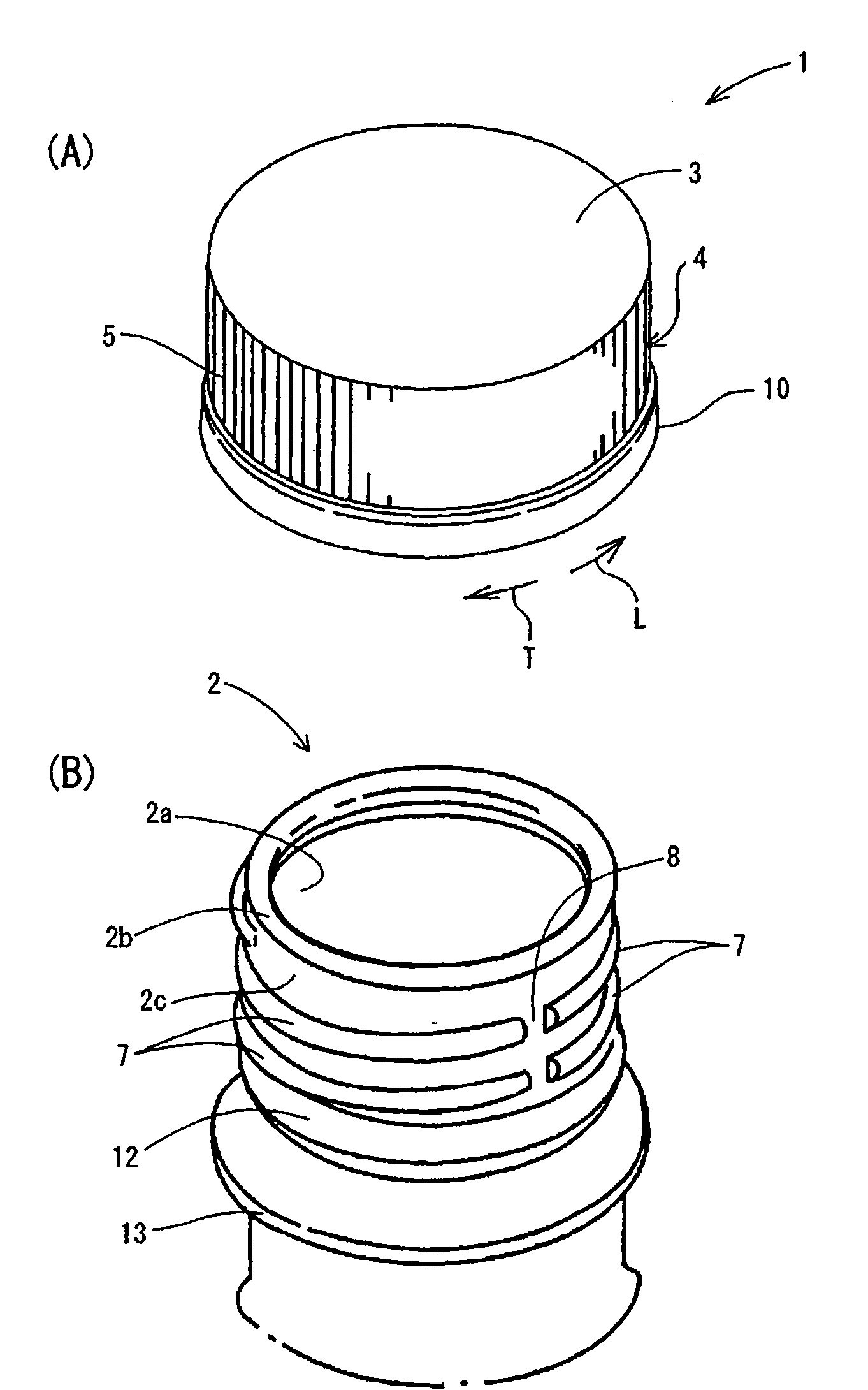

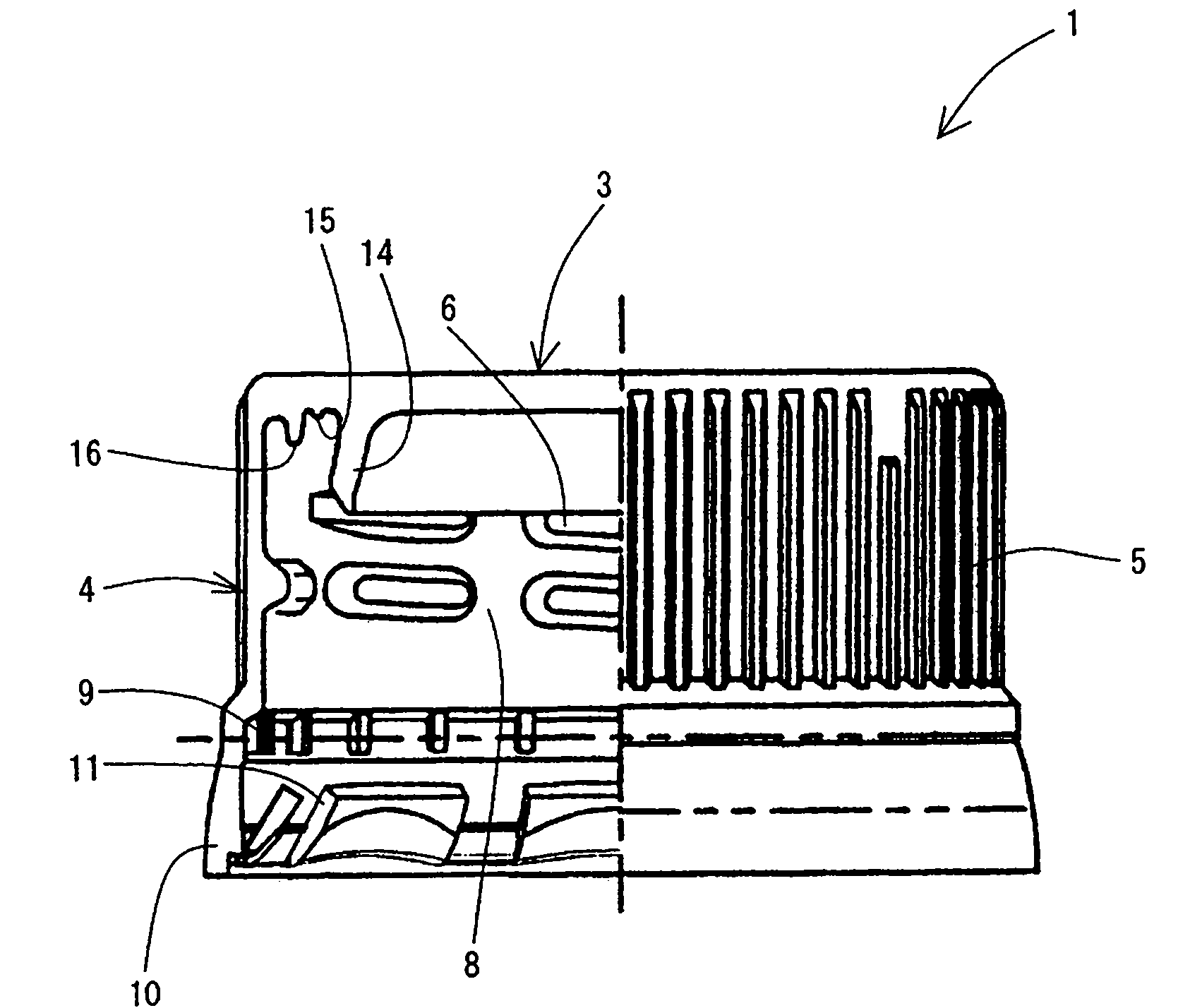

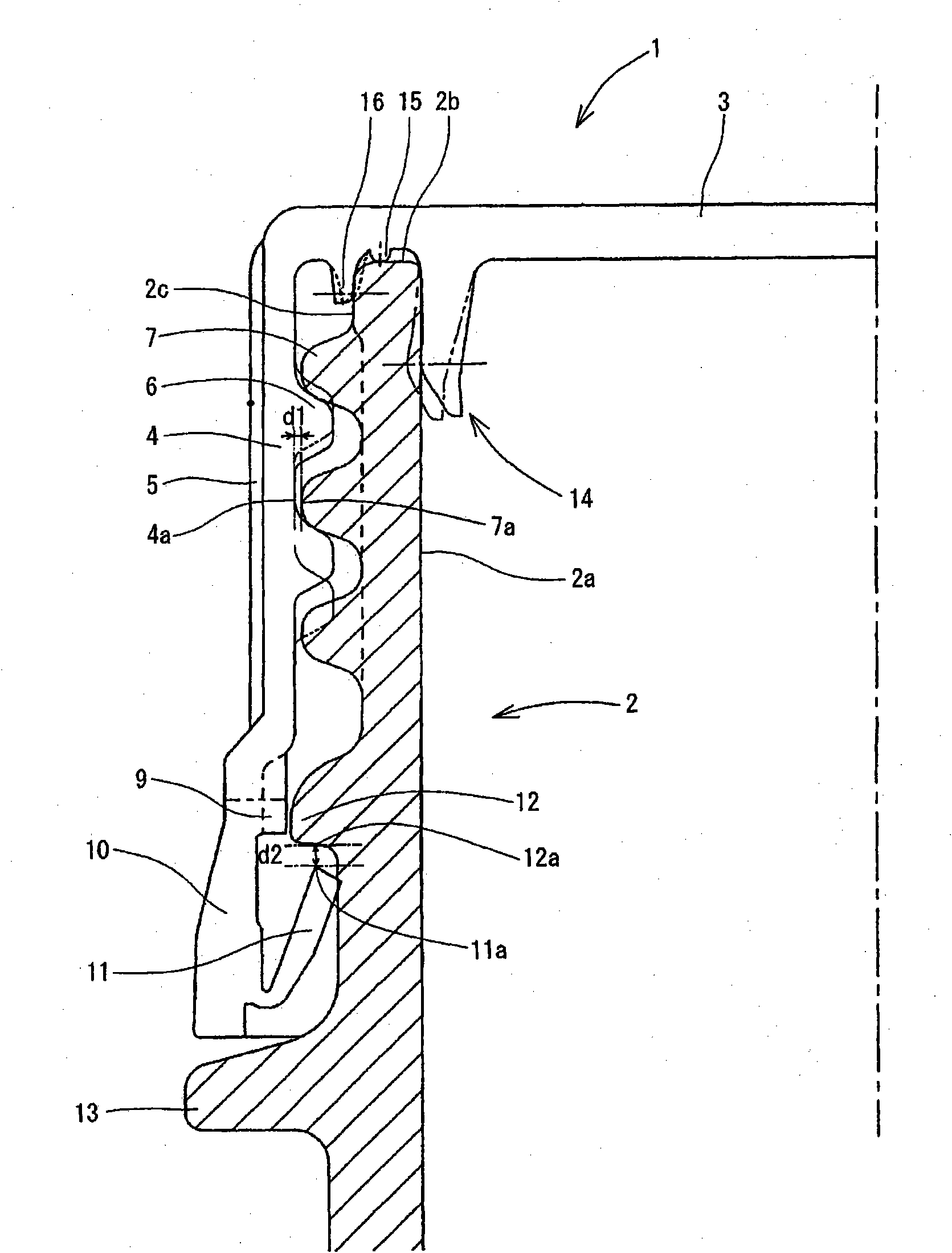

[0028] Below, while referring to the attached Figure 1 Embodiments of the present invention will be described. here, figure 1 (A) and (B) are perspective views schematically showing the structure of a main part of a synthetic resin cap (hereinafter simply referred to as a "cap") 1 and a container to which the cap is attached according to an embodiment of the present invention, figure 2 It is a partial perspective side view schematically showing the structure of the above-mentioned cover 1, image 3 It is a longitudinal sectional view schematically showing the structure of the left half of the lid 1 in a state assembled to the container, Figure 4 It is a partially enlarged vertical cross-sectional view schematically showing the structure of the main part of the above-mentioned cover 1 .

[0029] The cap 1 according to the present embodiment is mounted on the mouth 2 of a container (such as a PET bottle) manufactured separately from the cap 1 (see figure 1 (B)) is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com