Sealing system for an internal combustion engine with a divided casting enclosure

A sealing system, a technology for a multi-cylinder internal combustion engine, which is applied to the sealing of the engine, the sealing device of the engine, mechanical equipment, etc., to achieve the effects of reliable sealing, simple structure and low component cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

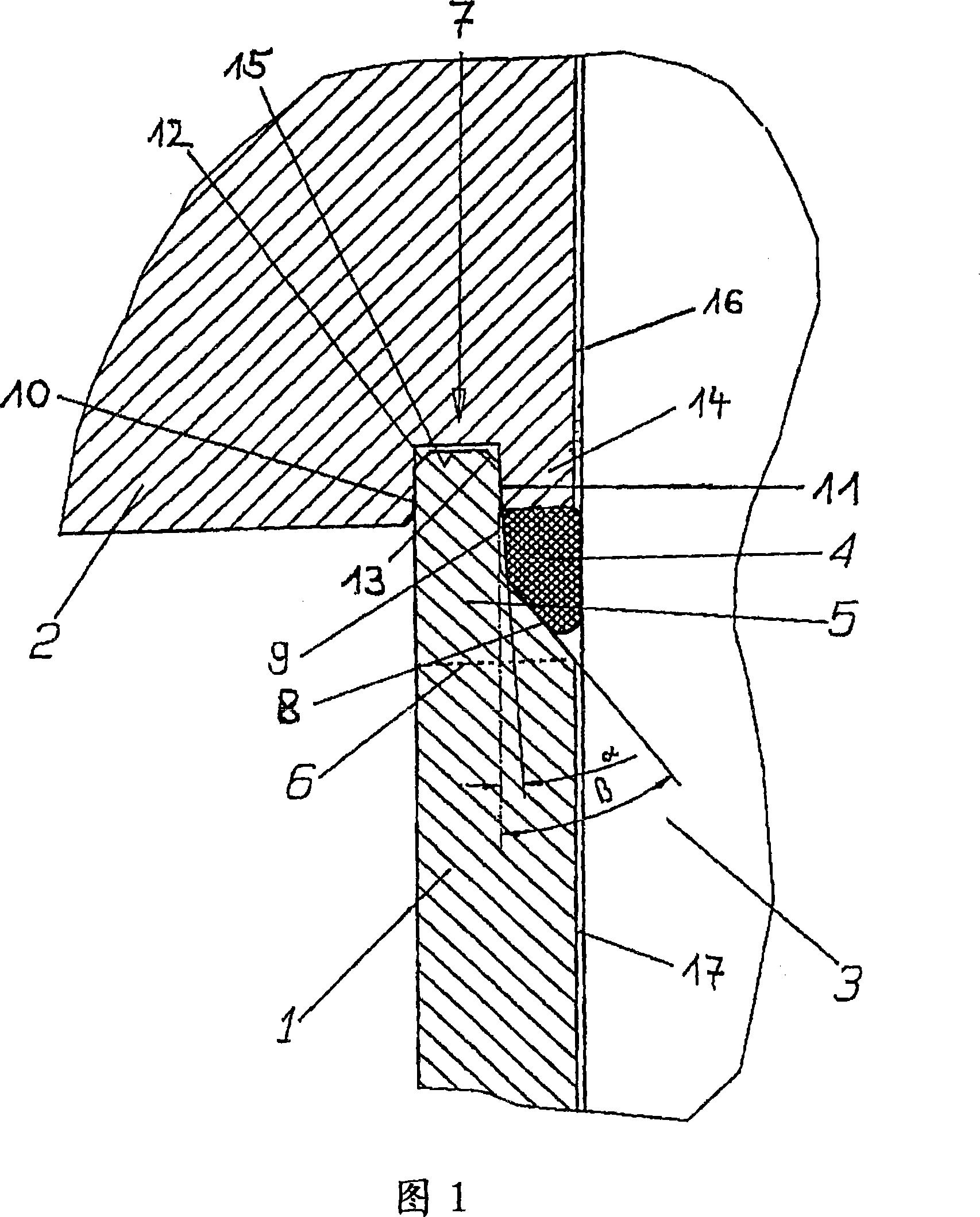

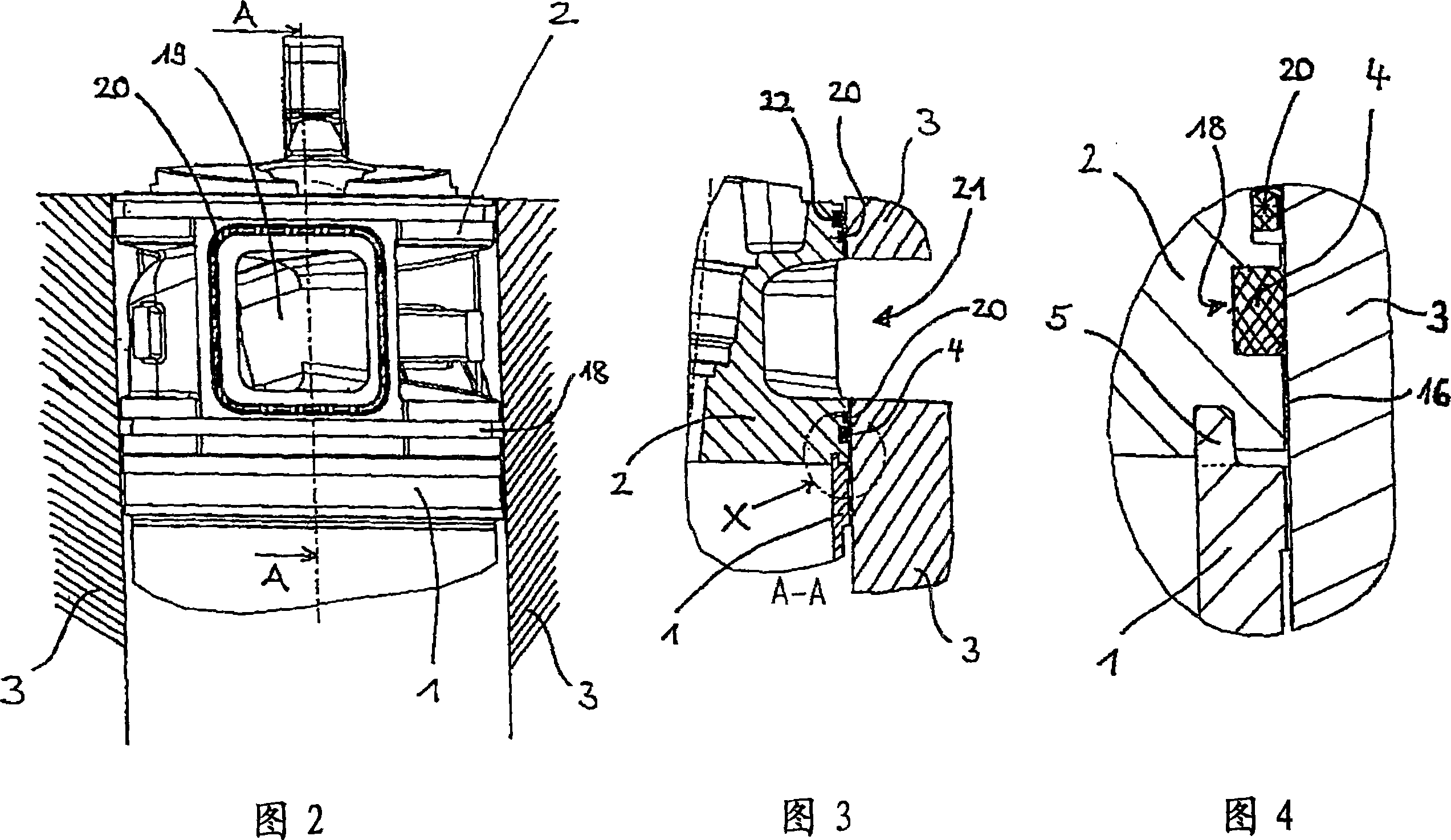

[0026] FIG. 1 shows a schematic sectional view of a first embodiment of the sealing system according to the invention along the half-shell parting plane of the housing. The arrangement of a cylinder liner 1 and part of the cylinder head 2 in the recess of a housing half-shell 3 can be seen in the sectional view shown.

[0027] The cylinder liner 1 has an extension above the dotted line 6 designed as a sealing flange 5 which is integral with the cylinder liner 1 . An annular sealing element in the form of a separate annular seal 4 bears against the sealing collar 5 . A portion of the sealing flange 5 of the cylinder liner 1 is received by an annular groove 7 of the cylinder head 2 forming a press fit.

[0028] The sealing flange 5 of the cylinder liner has a turned groove on its outer diameter, which consists of two tapered axially towards the cylinder head with different cone angles β or α and the outer surfaces 8 and 9 composed of conical sections. The annular seal 4 rests...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com