Screw-threaded joint for steel pipe

一种螺纹接头、钢管的技术,应用在螺纹连接、管子/管接头/管件、钻管等方向,能够解决无法修正、损伤外套接箍的密封面危险性等问题,达到保持气密性、避免局部显著损伤、刚性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

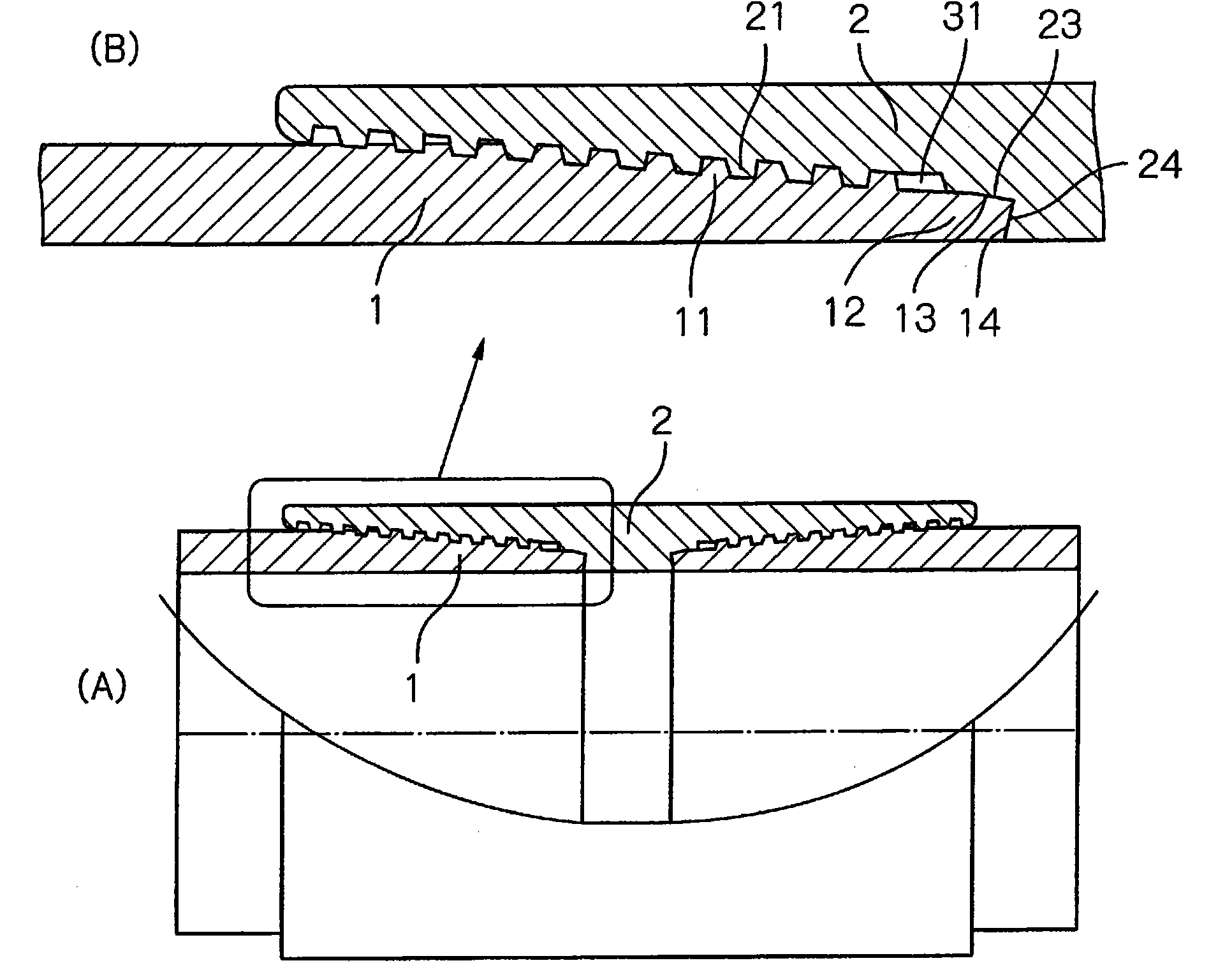

[0044] Below, while referring to the attached Figure 1 Embodiments of the threaded joint for steel pipes according to the present invention will be described.

[0045] image 3 (A) is a schematic axial cross-sectional view of a portion close to the front end of the inner sleeve of one embodiment of the threaded joint for steel pipes of the present invention.

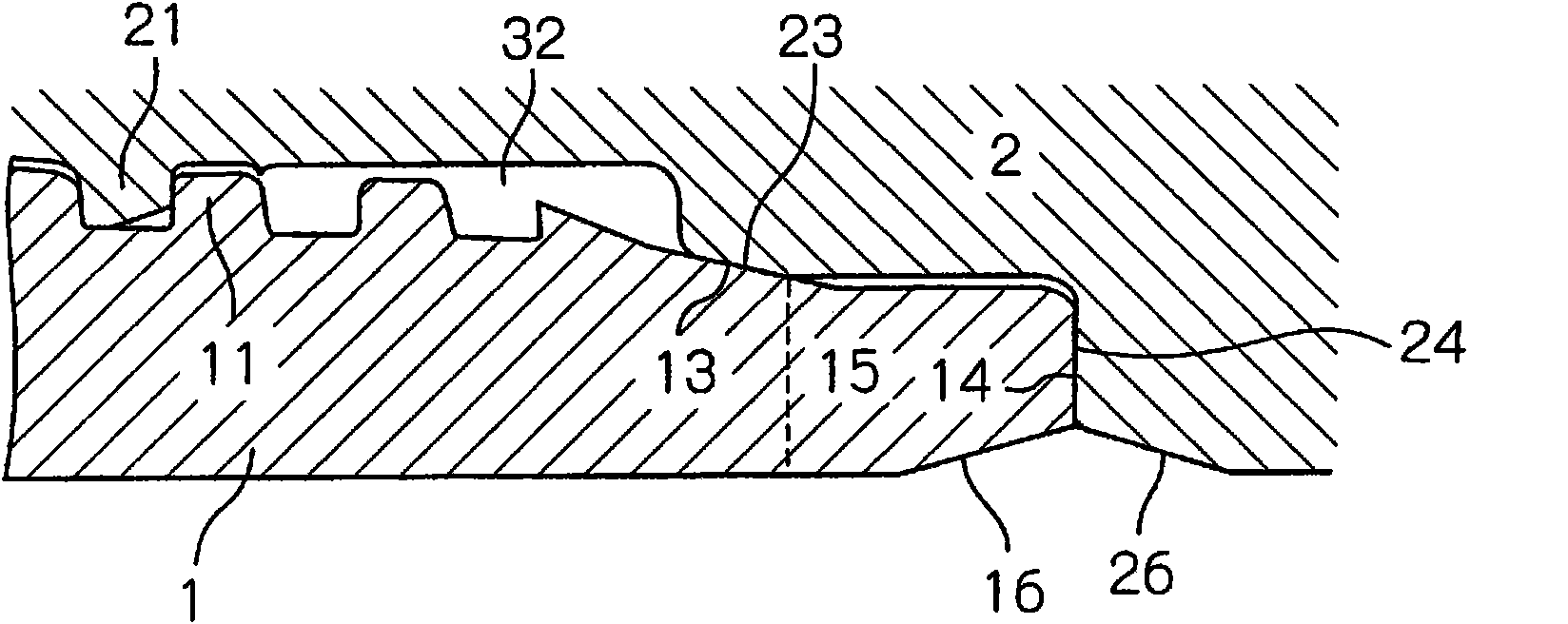

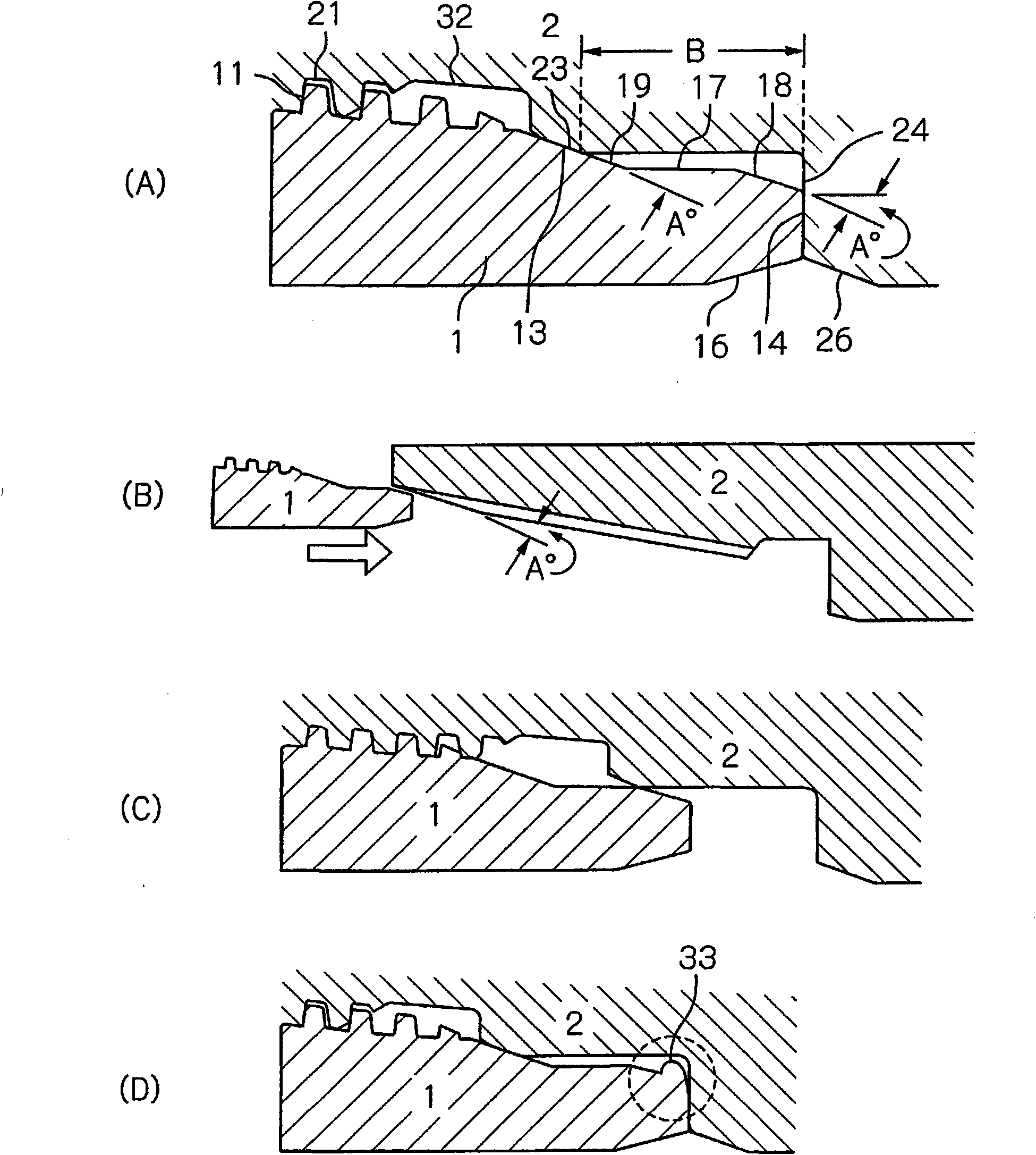

[0046] The threaded joint consists of an inner casing 1 and an outer collar 2, and is a high-grade joint type joint. From the inner side toward the front end of the inner casing, the inner casing 1 has an external thread 11, a sealing surface 13 and an end shoulder surface 14 in sequence, and the outer collar 2 has an external thread, a sealing surface and an end surface of the inner casing respectively in turn. The internal thread 21 , the sealing surface 23 and the shoulder surface 24 correspond to the shoulder surface (that is, engage, interfere or abut against the external thread, the sealing surface and the shoul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com