Manufacturing method of wind power sliding bearing

A technology for sliding bearings and manufacturing methods, which is applied in the direction of metal material coating process and coating, can solve the problems that cannot satisfy the wear resistance and corrosion resistance of sliding bearings, coarse grains in casting process, poor bonding force of copper alloys, etc., and achieve Save material consumption, cladding in large quantities, and improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

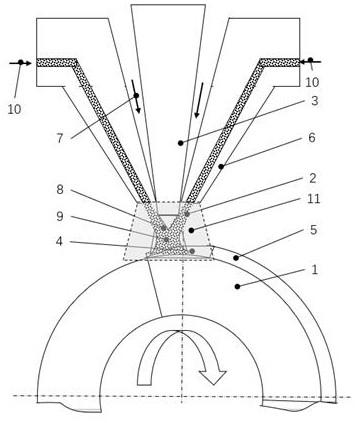

[0028] like figure 1 As shown, the manufacturing method of the wind power sliding bearing of this embodiment includes the following steps:

[0029] 1) Make the bearing base 1, place the bearing base 1 horizontally, and rotate the bearing base 1 around the central axis of the bearing base 1;

[0030] 2) Simultaneously spray tin bronze powder 2 and laser beam 3 on the surface of bearing base 1, and intersect tin bronze powder 2 and laser beam 3 before spraying onto the surface of bearing base 1 to form cladding in the cladding area 4 of bearing base 1 layer 5;

[0031] 3) Moving the cladding area 4 along the axial direction of the bearing base 1 , and repeating step 2), until the cladding layer 5 is formed on the entire surface of the bearing base 1 .

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com