Connective building material and combined part used therewith

A technology for building materials and accessories, applied in the direction of connecting members, sheet connections, rod connections, etc., can solve the problems of long time period for brick partitions, long installation time, low efficiency, cloth wardrobes, etc., to facilitate the disassembly of the table. , The effect of shortened construction period and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

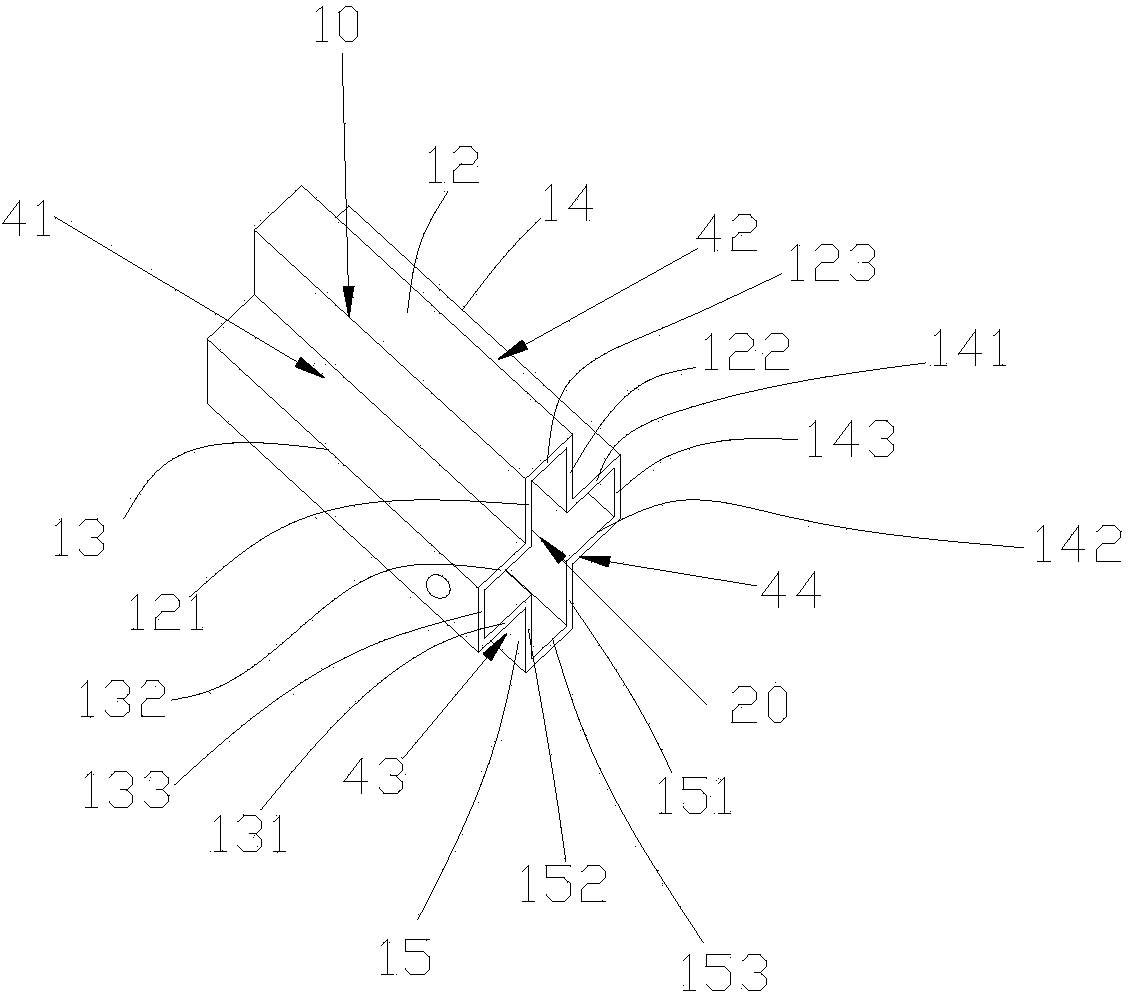

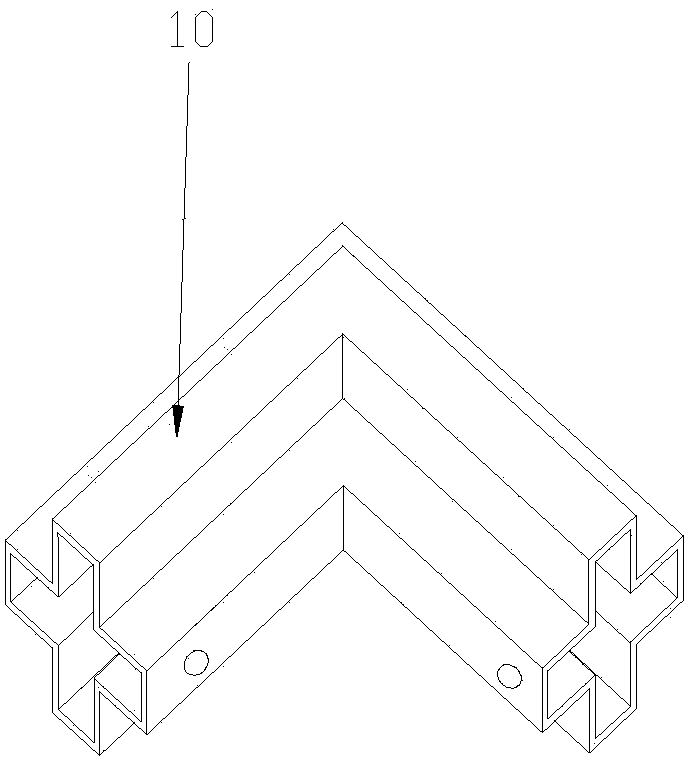

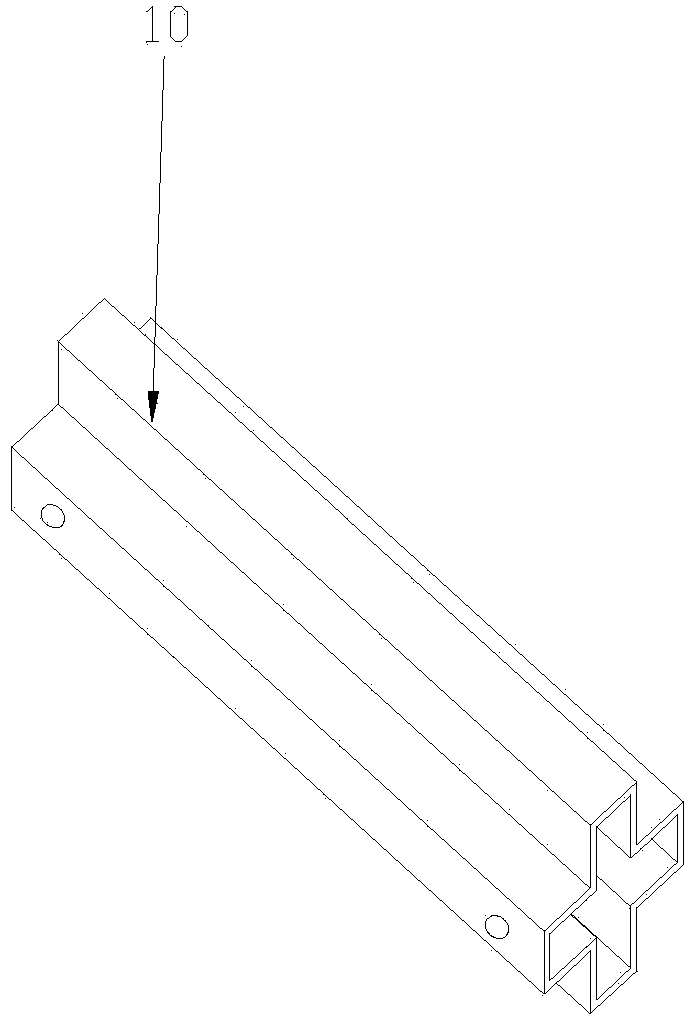

[0036] refer to figure 1, a connection building material, including at least one protruding pipe body 10. The outer end of each protruding tube body 10 is provided with a hollow insertion hole 20 with a cross-section in the shape of a "cross". Each protruding tube body 10 includes an upper protrusion 12, a left protrusion 13, a right protrusion 14 and a lower protrusion 15, and the upper protrusion 12, the left protrusion 13, the right protrusion 14 and the lower protrusion 15 form a The hollow socket 20. The two sides of upper projection 12 are respectively connected with one side of left projection 13 and one side of right projection 14, and the two sides of this lower projection 15 are connected with the other side of left projection 13 and right projection 14 respectively. Connect the other side. The upper bump 12, the left bump 13, the right bump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com