A processing method for bonding between titanium or titanium alloy watch parts with high finish

A technology with high finish and processing methods, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven joint surfaces, achieve uniform joints, low vacuum pressure, and improve the appearance of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

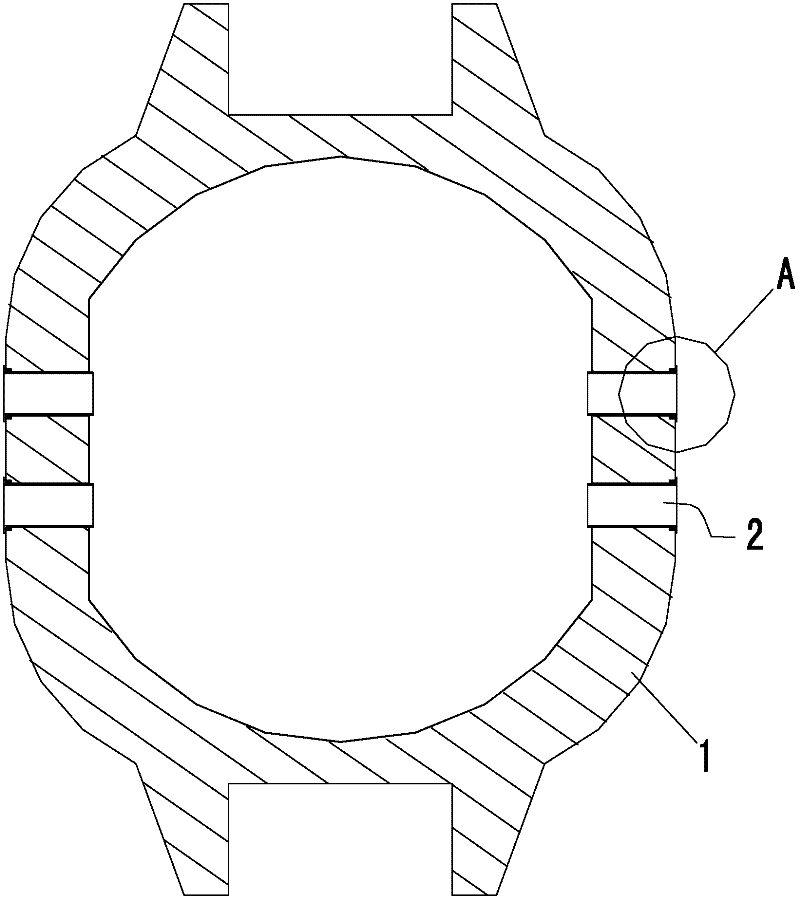

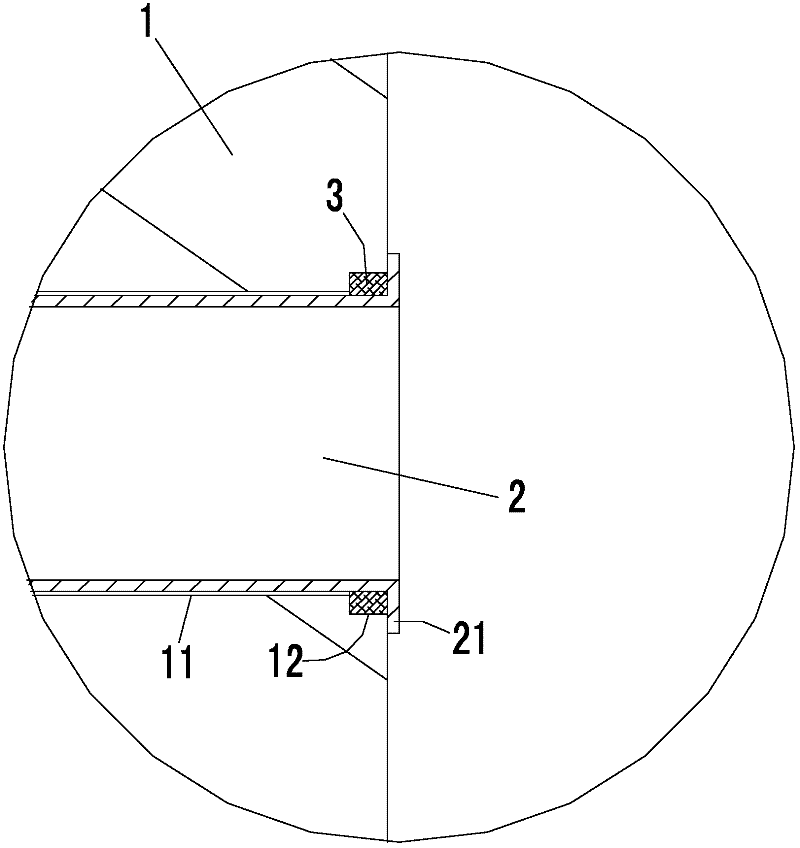

[0029] Such as Figure 1 to Figure 3 As shown, a treatment method for joining parts of high-gloss titanium or titanium alloy watches, the watch parts include a watch case 1 and a guide sleeve 2, the outer wall of the case 1 is provided with at least one shaft hole 11, the The guide sleeve 2 is installed in the shaft hole 11, and the shaft hole 11 is provided with an annular weld bead gap 12 along the circumference at one end close to the flange 21 of the guide sleeve. A filler accommodating space 3 is formed between the wall and its flange 21, which is characterized in that it includes the following steps:

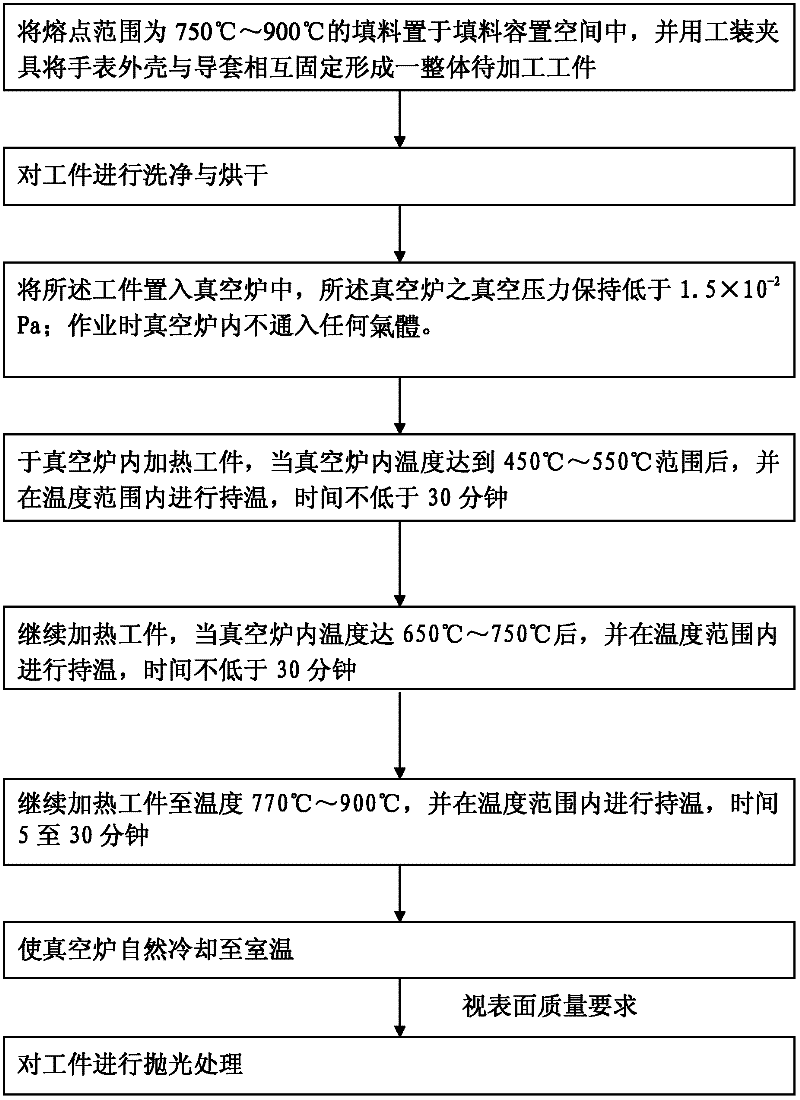

[0030] (1) Put an alloy filler with a melting point range of 750°C to 900°C in the filler accommodating space 3, and fix the watch case 1 and the guide sleeve 2 to each other with a fixture (not shown in the figure) to form an in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com