Driving mechanism of electric vehicle

A driving mechanism and electric vehicle technology, which is applied to electric vehicles, motors, electric components, etc., can solve the problems of inability to realize variable speed and low utilization rate of motors, and achieve the effect of prolonging service life and increasing mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

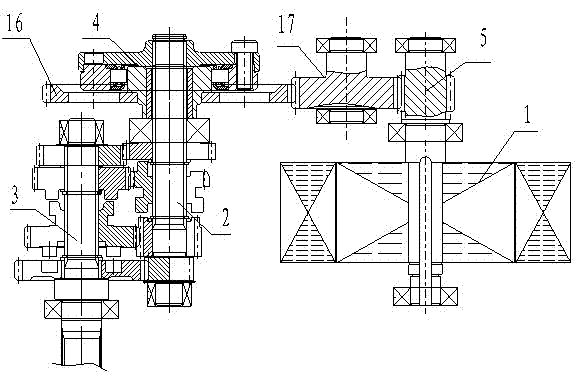

[0017] Embodiment 1, an electric vehicle drive mechanism, including a drive motor 1, the drive motor is connected to a transmission system with different gears through a clutch, and the transmission system is connected to the rear wheel, thereby driving the electric vehicle to run.

Embodiment 2

[0018] Embodiment 2, an electric vehicle drive mechanism, including a drive motor 1, the drive motor 1 is connected to a transmission system with four gears through an overrunning clutch 4, and the transmission system is connected to the rear wheels to drive the electric vehicle. The transmission system includes the transmission main shaft 2 and the transmission sub-shaft 3 and engages them. The start plate of the overrunning clutch 4 is sleeved on the transmission main shaft 2 and engages with the motor shaft 5 of the drive motor 1 through the driven teeth 19 and the bridge teeth 17. The overrunning clutch , The one-way cover of 4 is set on the transmission main shaft 1 through the rectangular spline.

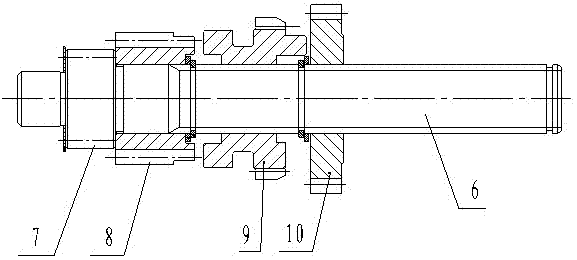

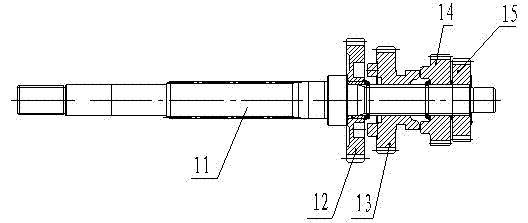

[0019] The transmission main shaft 2 comprises the main shaft mandrel 6 and the first speed gear 7, the second speed gear 8, the third speed gear 9 and the fourth speed gear 10 which are arranged on the main shaft mandrel 6 and are connected with the countershaft mandrel 11 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com