A cylindrical hybrid magnetic coupling

A magnetic coupling and coupling technology, applied in the direction of permanent magnet clutch/brake, asynchronous inductive clutch/brake, electric brake/clutch, etc., can solve the problem of unadjustable coupling and achieve large load torque , Solve the effect of switching asynchronous working conditions and realizing the effect of synchronous to asynchronous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

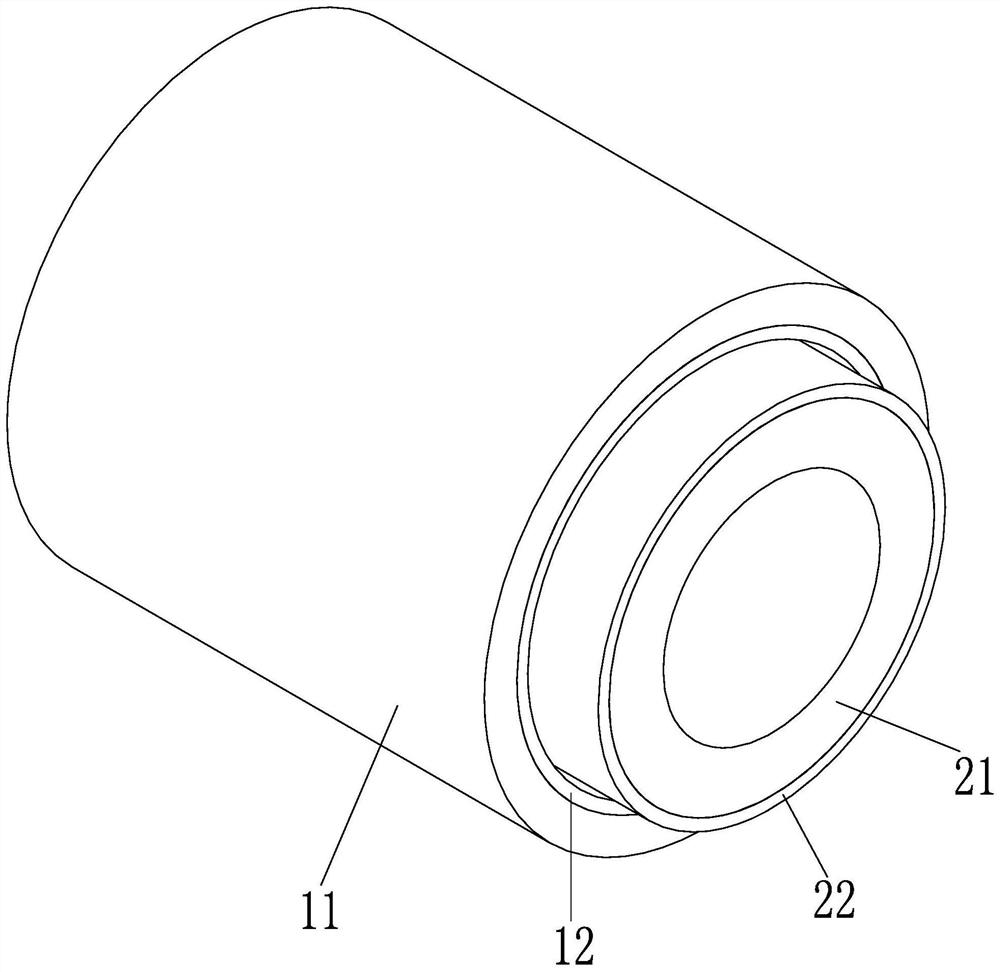

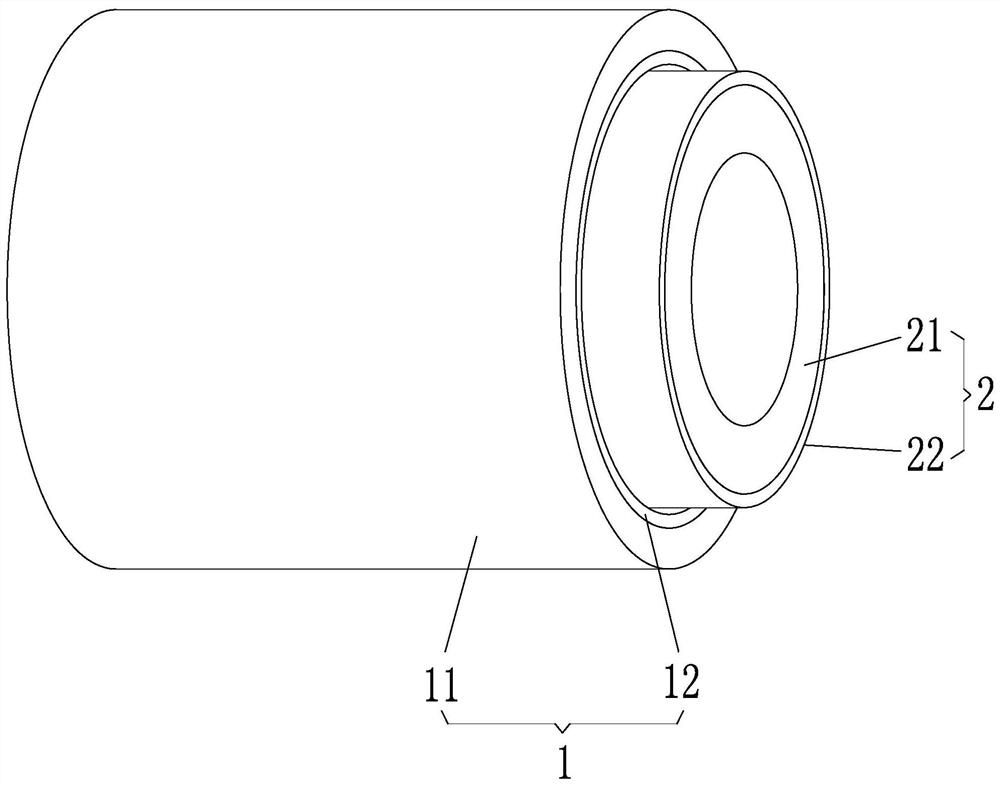

[0033] see figure 1 with figure 2 , this embodiment provides a cylindrical hybrid magnetic coupling, which includes a cylindrical structure 1 and a cylindrical structure 2 . The coupling is a cylindrical coupling, and the first cylindrical structure 1 and the second cylindrical structure 2 are the active part and the driven part of the coupling. These two cylindrical structures can be movably installed through other structures (such as the casing of the shaft coupling device), so as to ensure that no direct contact occurs between the two cylindrical structures, thereby realizing the combined effect of the driving and driven shafts.

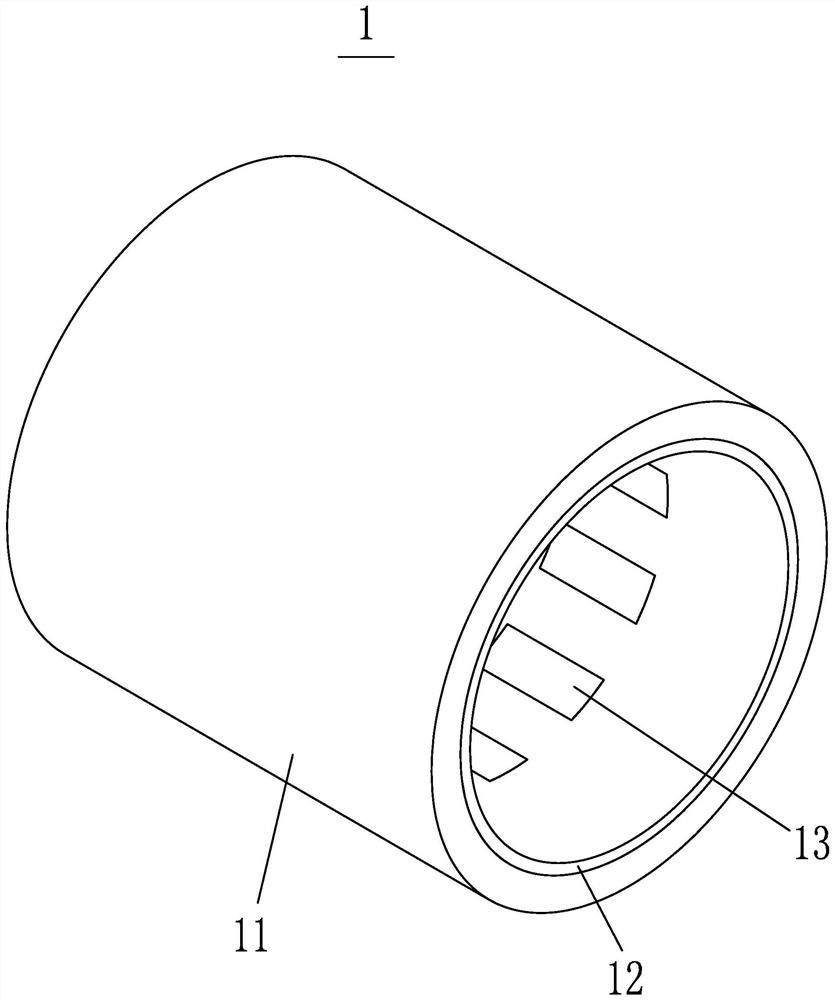

[0034] see image 3 , The cylindrical structure 1 includes an outer cylinder 11 , a mounting cylinder 12 and a plurality of magnets 13 . The outer cylinder 11 is arranged coaxially with the first installation cylinder 12 , and the first installation cylinder 12 is located in the outer cylinder 11 and connected with the outer cylinder 11 . A p...

Embodiment 2

[0043] This embodiment provides a cylindrical hybrid magnetic coupling, which is similar to the coupling in Embodiment 1, the difference is that the outer cylinder 11 and the installation cylinder 12 are integrally formed, and the inner cylinder 21 and the installation cylinder two 22 integrally formed. In this way, when the first magnet 13 or the second magnet 23 is installed, it is only necessary to directly install the magnets on the corresponding installation barrels, and the installation is very convenient. At the same time, in order to be able to generate eddy currents, the installation cylinder part can be made of copper material, while the outer cylinder 11 or inner cylinder 21 can be made of other materials, and an integrally formed material can be used for transition between the two, so that the two are connected more closely.

Embodiment 3

[0045] This embodiment provides a cylindrical hybrid magnetic coupling, which is based on Embodiment 1 with a housing added. Wherein, the cylindrical structure one 1 and the cylindrical structure two 2 are both movably installed in the casing. The casing can be the casing of the existing coupling, and the difference between the coupling of this embodiment and the existing coupling lies in the structure inside the casing. In this way, the housing can play a positioning role, and can also play a protective role, which can prevent dust from entering, and can also prevent other objects from colliding with the inner structure of the coupling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com