Single-motor multi-mode hybrid power system and automobile

A hybrid system and multi-mode technology, applied in the field of automobile transmission system, can solve the problems of slow response to speed changes, low transmission efficiency, difficult repairs, etc., achieve good power transmission and speed change, improve and electric transmission efficiency, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

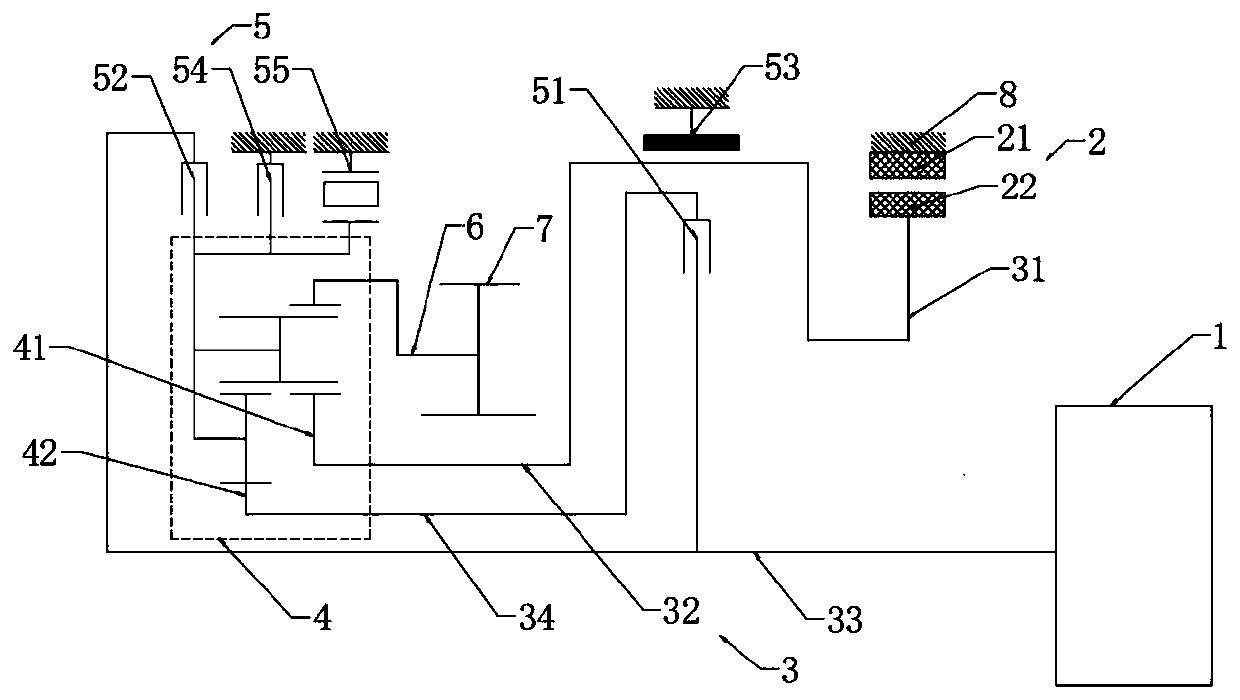

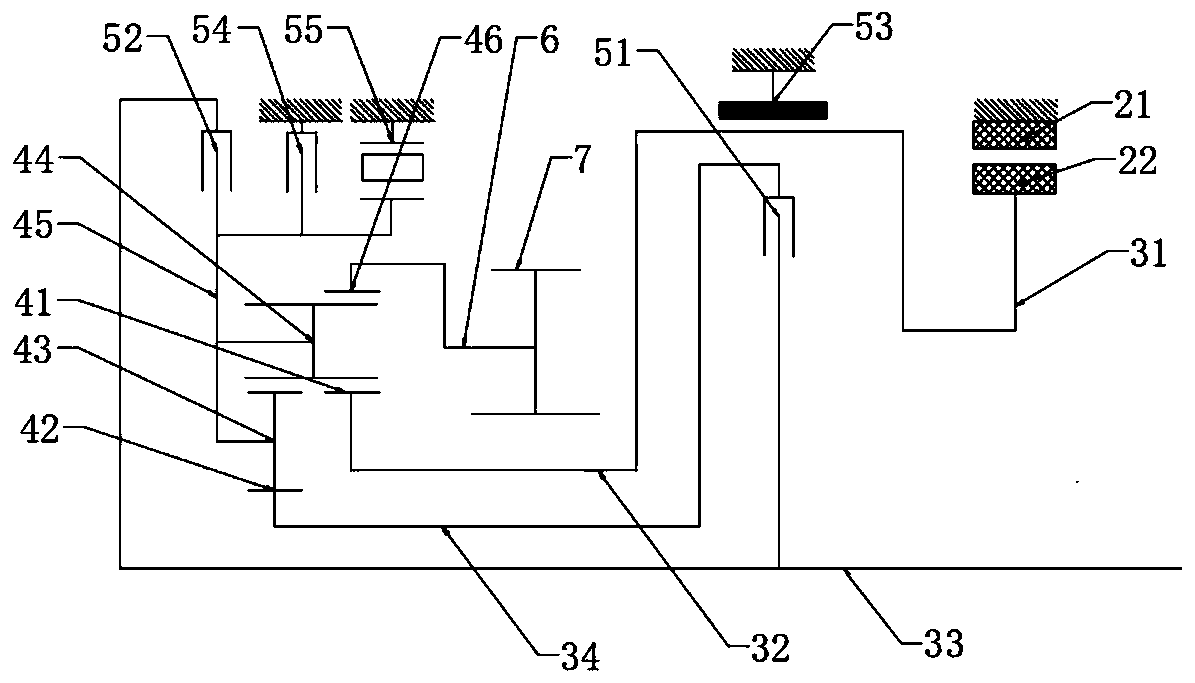

[0035] like figure 1 and 2 As shown, Embodiment 1 of the present invention is a single-motor multi-mode hybrid power system, including an engine 1, a motor 2, a first transmission system 3, a second transmission system 4 and a shift actuator 5, and the first transmission system 3 Including motor power input shaft 31, large sun gear connecting shaft 32, engine power input shaft 33 and small sun gear connecting shaft 34, the second transmission system 4 includes large sun gear 41 and small sun gear 42, in the embodiment of the present invention Among them, the second transmission system is a Ravina planetary gear mechanism, in which the large sun gear 41 and the small sun gear 42 adopt a segmented structure to make the shifting more smooth.

[0036] The shift actuator 5 includes a first clutch 51 and a second clutch 52 .

[0037]One end of the motor power input shaft 31 is connected to the motor rotor 22, the other end of the motor power input shaft 31 is connected to the big ...

Embodiment 2

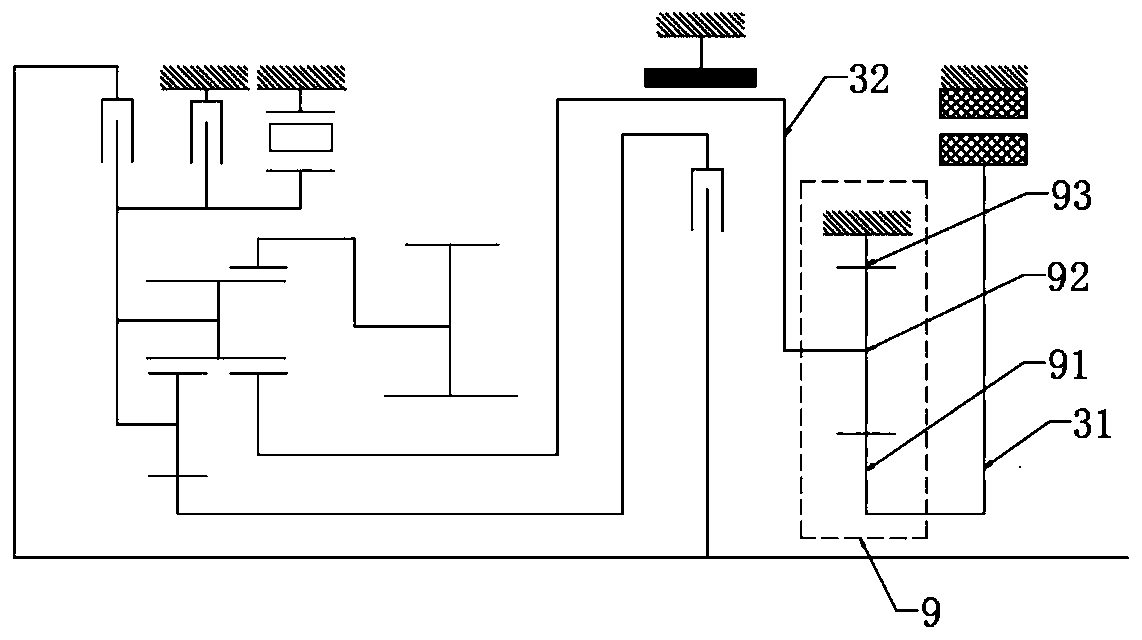

[0095] like image 3 As shown, Embodiment 2 of the present invention is a preferred embodiment of Embodiment 1, and the difference from Embodiment 1 is that a first planetary reduction mechanism is arranged between the motor power input shaft 31 and the large sun gear connecting shaft 32 9. The first planetary reduction mechanism 9 includes a first reduction sun gear 91, a first reduction planetary gear 92 and a first reduction ring gear 93,

[0096] The first deceleration sun gear 91 is connected to the motor power input shaft 31, the first deceleration ring gear 93 is fixed on the housing 8, and the first deceleration planetary gear 92 is supported on the large sun gear through bearings. On the connecting shaft 32, the first reduction planetary gear 92 meshes with the first reduction sun gear 91 and the first reduction ring gear 93 respectively, and the first planetary reduction mechanism 9 is used to increase the motor drive torque and reduce Motor Power.

Embodiment 3

[0098] like Figure 4 As shown, Embodiment 3 of the present invention is a preferred embodiment of Embodiment 1. The difference from Embodiment 1 is that a second planetary reduction mechanism 10 is provided between the motor power input shaft 31 and the large sun gear connecting shaft 32, The second planetary reduction mechanism 10 includes a second reduction sun gear 101 , a second reduction planetary gear 102 , a second reduction ring gear 103 and a second reduction planet carrier 104 ,

[0099]The second deceleration sun gear 101 is connected to the motor power input shaft 31, the second deceleration ring gear 103 is connected to the large sun gear connection shaft 32, and the second deceleration planetary gear 102 is respectively connected to the first The second deceleration sun gear 101 meshes with the second deceleration ring gear 103, the second deceleration planetary gear 102 is supported on the second deceleration planet carrier 104 by bearings, and one end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com