Double-feeding speed varying salient-pole synchronous motor

A synchronous motor, salient pole technology, applied in the direction of synchronous generator, etc., can solve the problem of unrealizable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

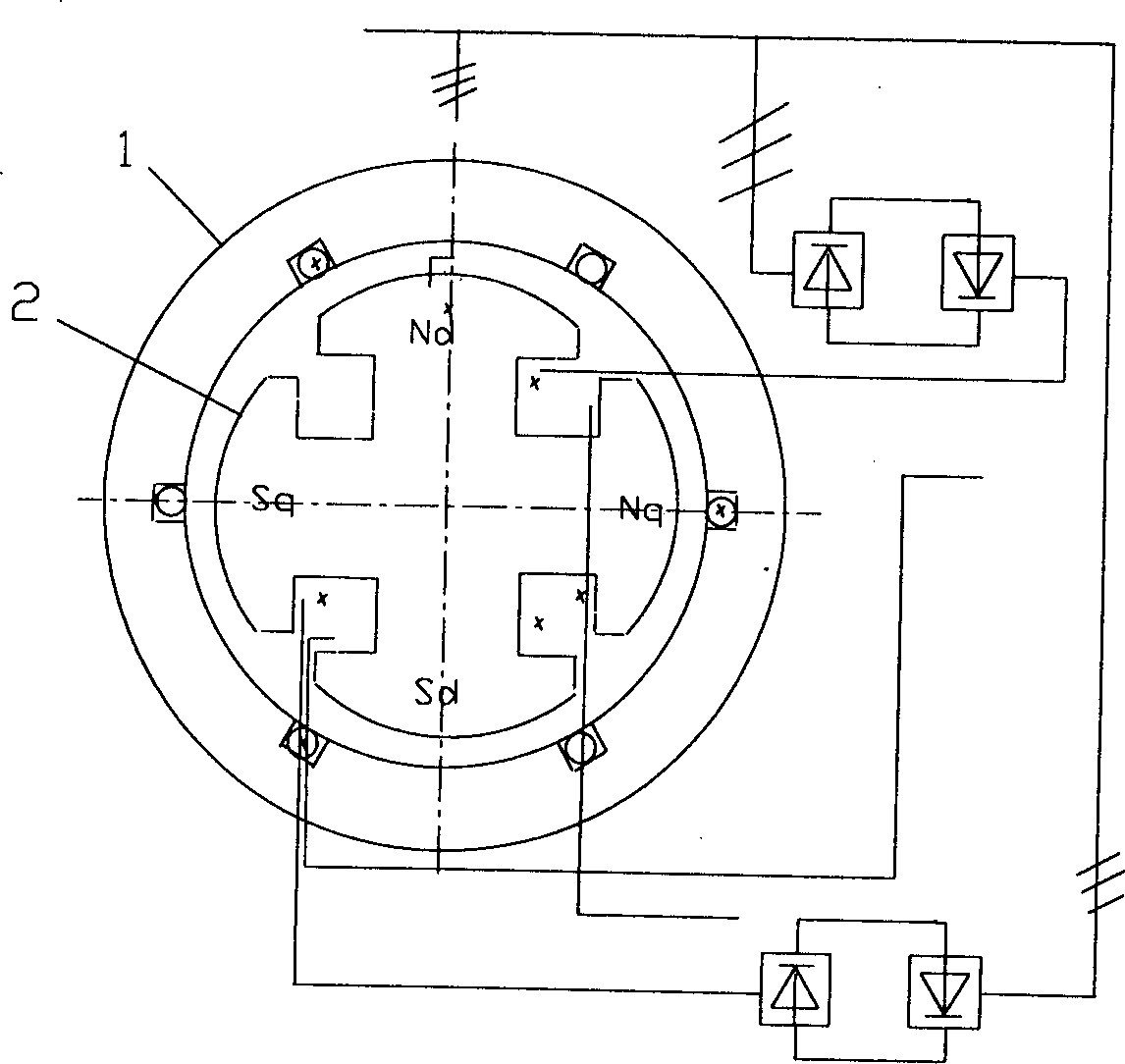

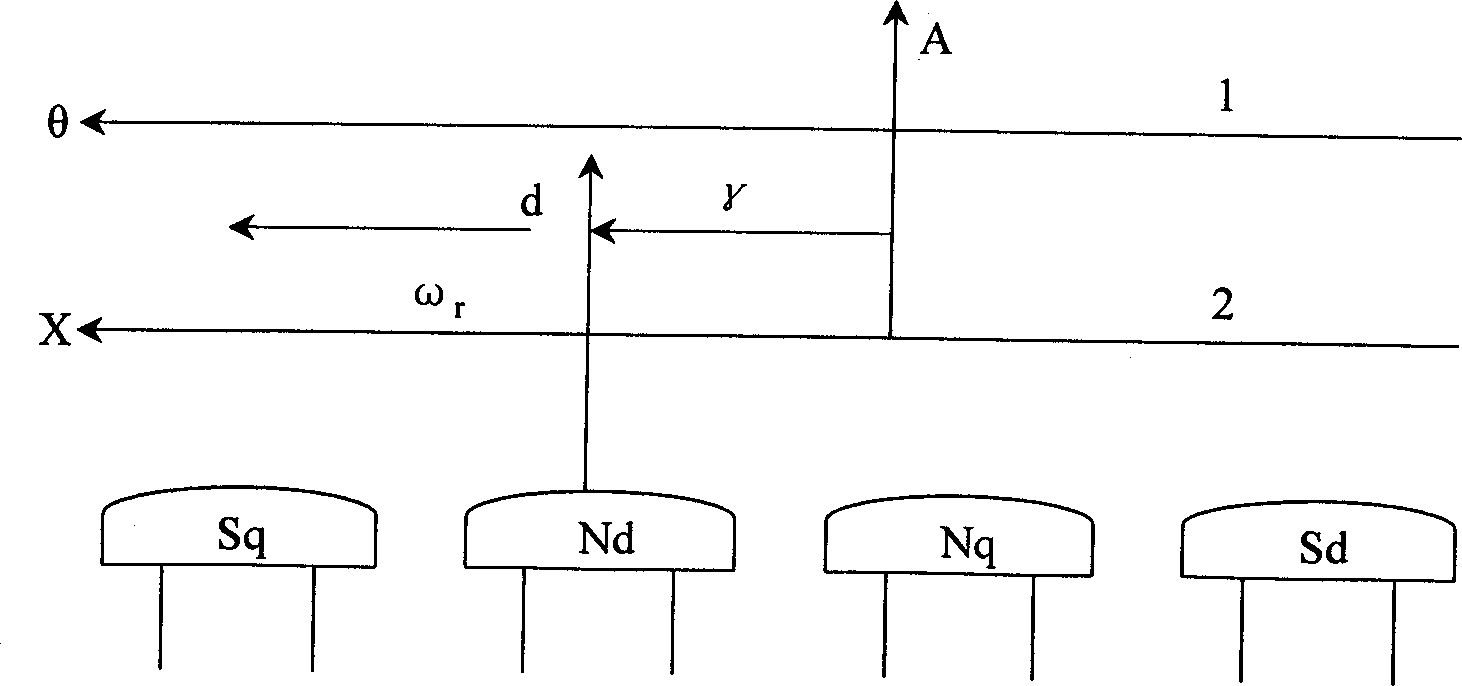

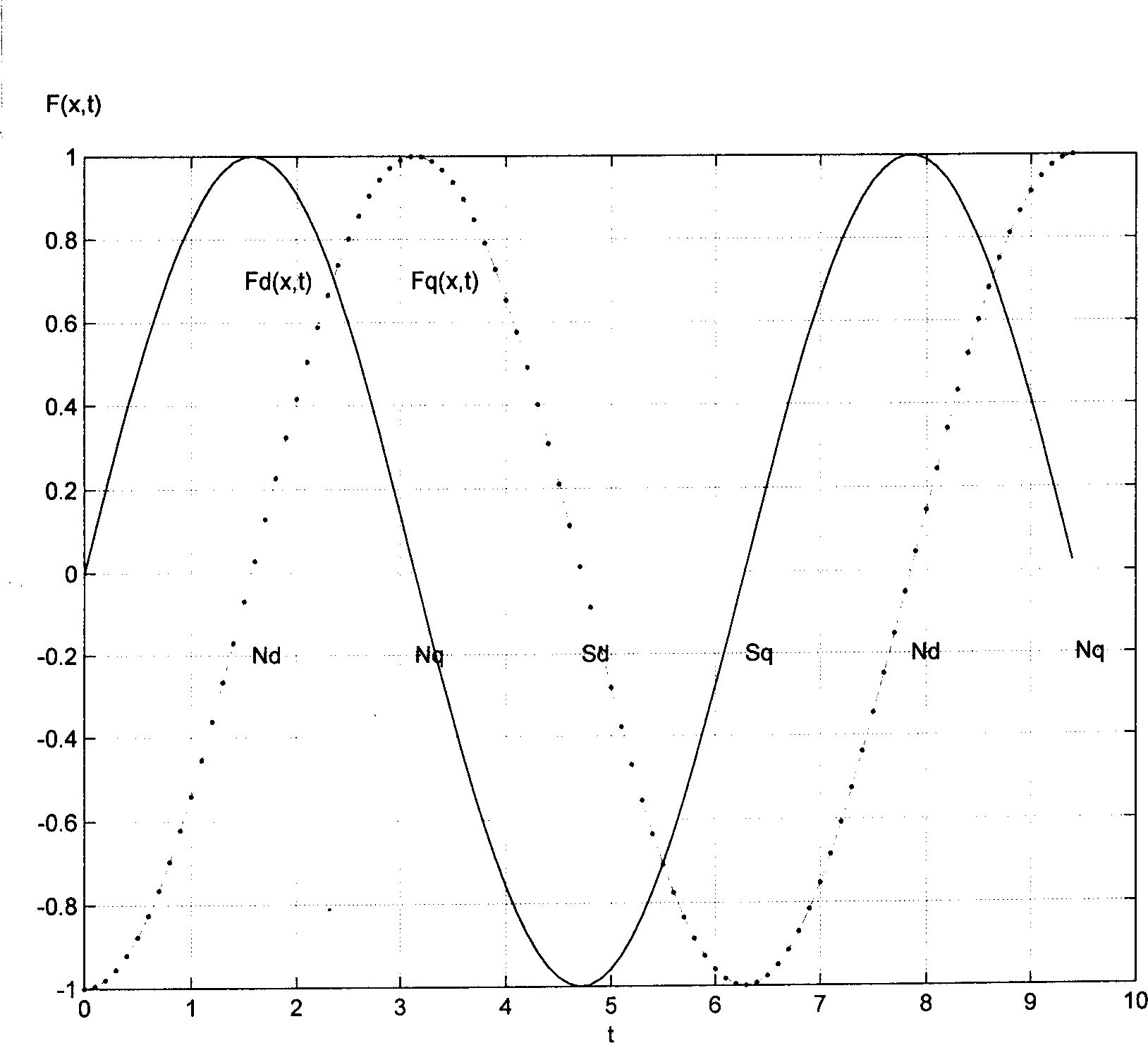

[0044] by Figure 4 The doubly-fed variable-speed salient-pole synchronous motor shown is taken as an example for implementation description. The number of pole pairs of the motor is P=2, the number of slots of the stator is Z=48, the stator is a three-phase symmetrical winding, and the number of parallel branches is a. The rotor has d, q two-phase windings, and the number of magnetic pole pairs is 2P=4, wherein the magnetic poles of the d-phase winding are Nd and Sd respectively, and the magnetic poles of the q-phase winding are Nq and Sq respectively, and the d and q two-phase excitation windings are in space The phase difference is 90° electrical angle, and the time difference is 90° electrical angle. The d and q two-phase excitation windings form an orthogonal winding, and corresponding damping windings are installed on the magnetic poles. The stator is powered by a symmetrical three-phase AC power supply, and the two-phase excitation windings of the rotor d and q are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com