Audio Switch type AC induction motor

An induction motor, switch-type technology, applied in the direction of asynchronous induction motors, electrical components, electromechanical devices, etc., can solve the problems of manufacturing cost, speed range output torque can not meet, etc., to achieve low manufacturing cost, large speed range, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

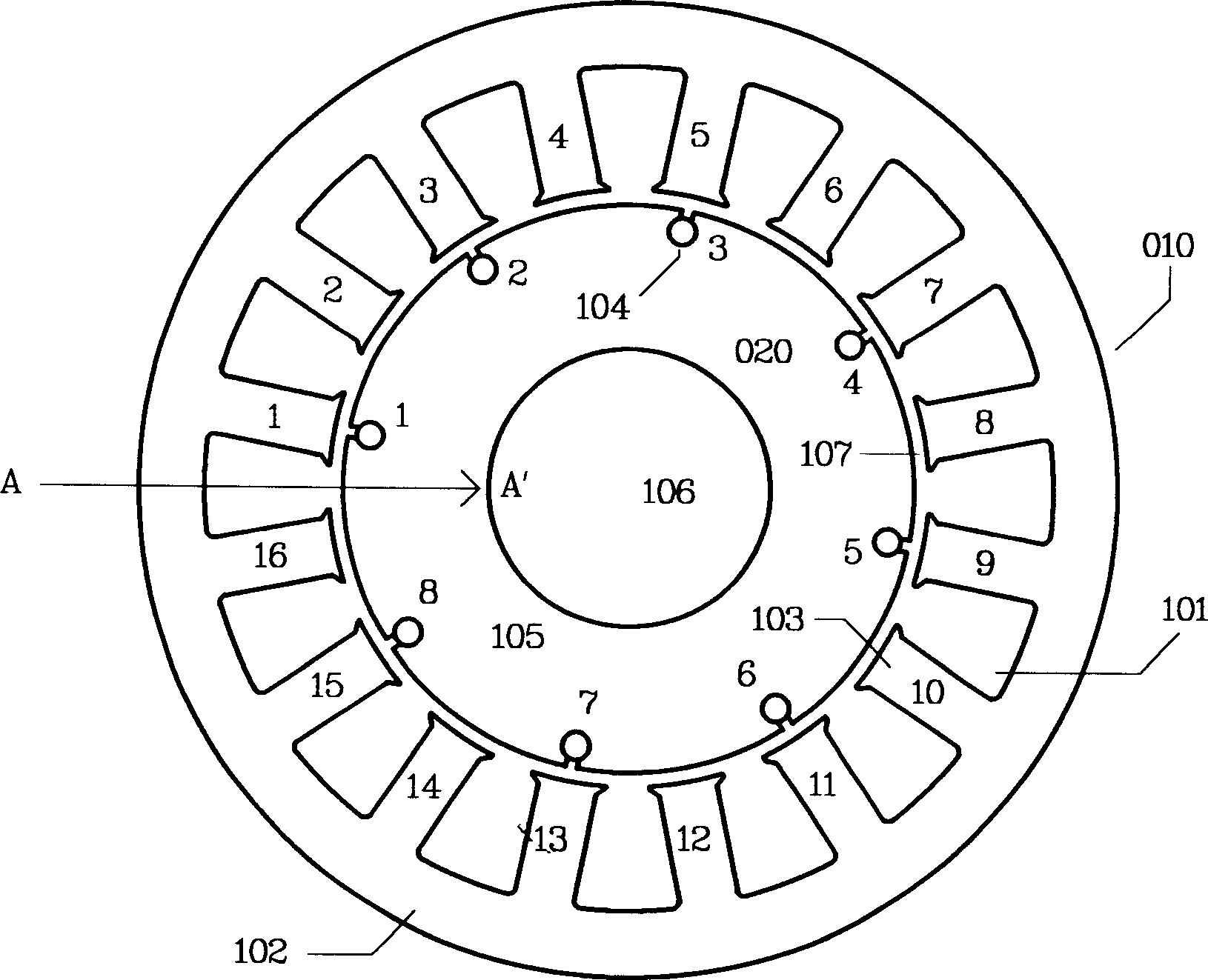

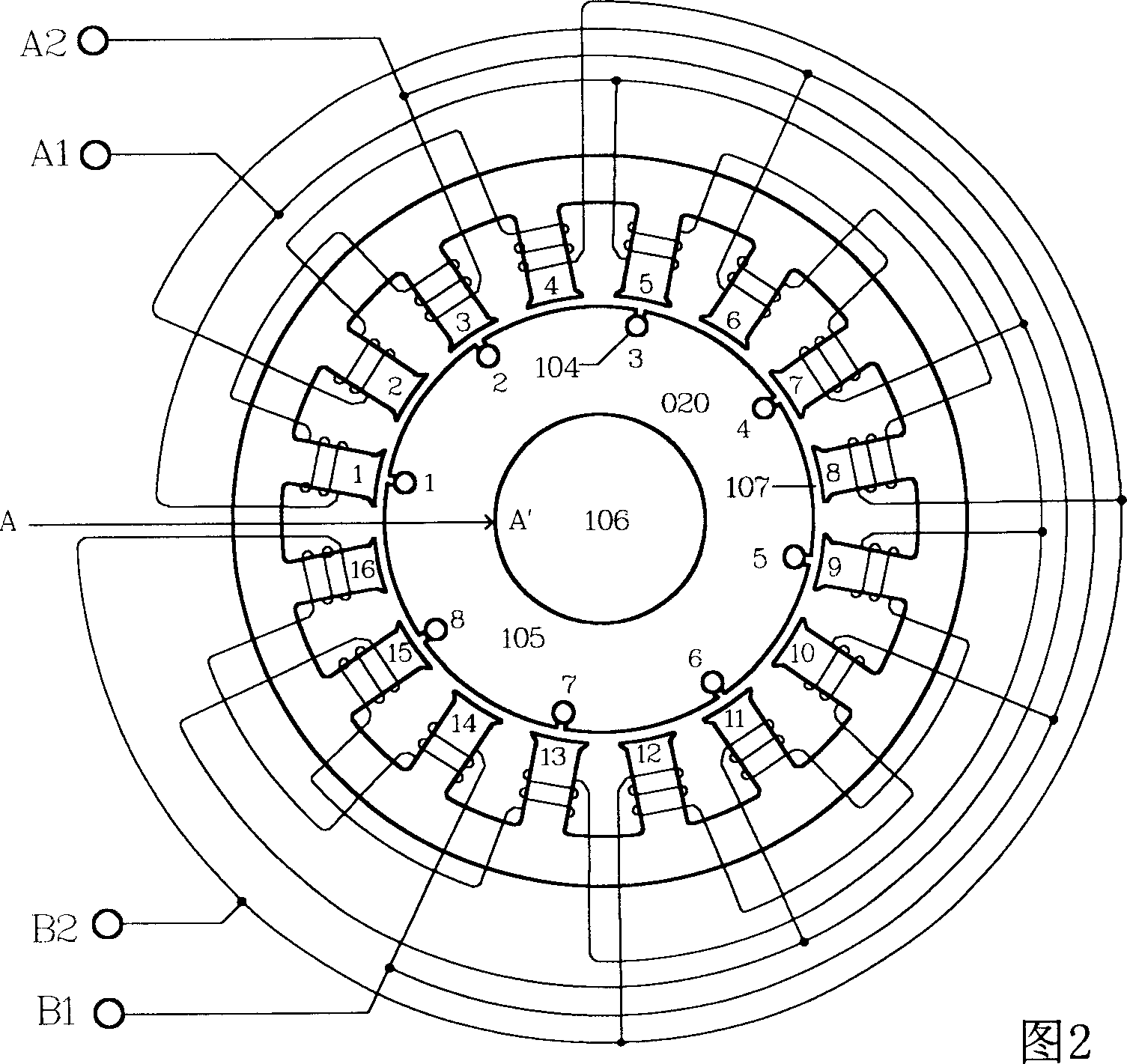

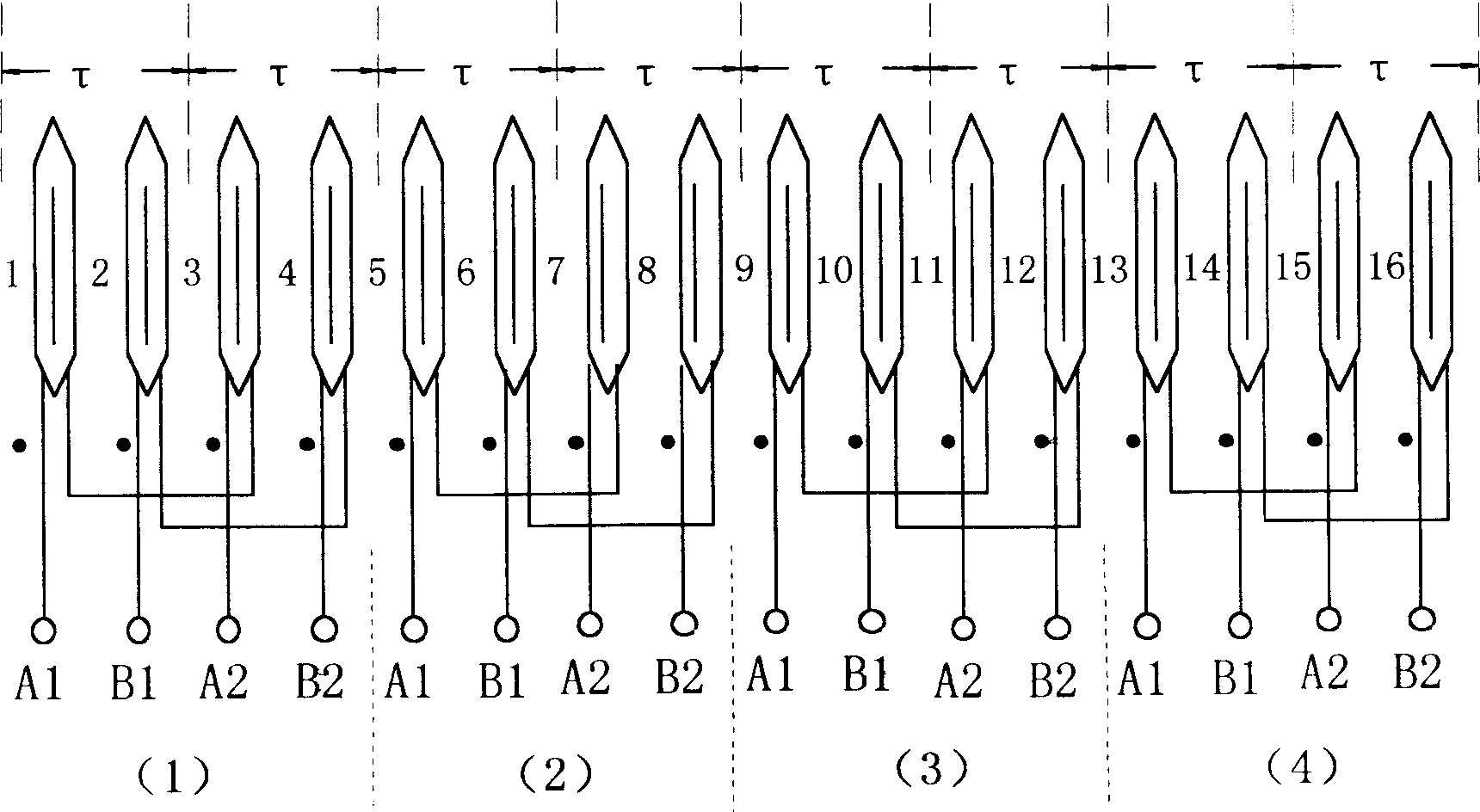

[0022] figure 1 Shown is a transverse section view of the stator and rotor of a 16-slot, 4-pole, two-phase motor. In the figure, "010" is a hollow cylindrical stator core, "101" is a stator slot penetrating in the axial direction, and "102" is a Stator yoke, "103" is the stator teeth extending radially inward and distributed at equal angles, the stator slots and the inner surface of the stator ring are arranged alternately, "020" is a rotor with a cylindrical surface, "104" is Along the cylindrical surface of the motor rotor core, the parallel conductive strips are distributed at equal intervals, and the conductive strips and the conductive rings (not shown) on the two end faces of the cylindrical body are fused to form a metal induction body similar to a squirrel cage structure. , "105" is the rotor core, "106" is the rotor shaft, and "107" is the air gap between the rotor and the stator. ) is supported. When the number Z of stator slots or teeth is constant, if the number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com