A Torque Overload Protection Method for Transmission Shaft Based on Carbon Fiber Composite Materials

A composite material and overload protection technology, which is applied in the field of mechanical transmission, can solve problems such as damage to related components, broken transmission shafts, and complex anti-overload structures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

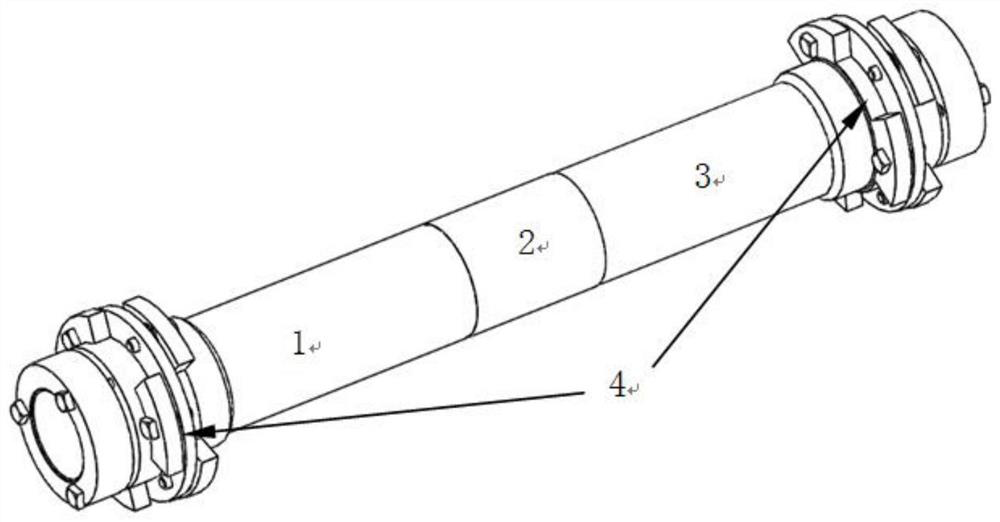

[0027] Embodiment 1: Torque overload protection method for a multi-material integrated drive shaft containing two metal material drive shafts

[0028] The multi-material integrated drive shaft containing two metal material drive shafts, such as image 3 As shown, it is composed of metal material transmission shaft 1, carbon fiber composite material shaft tube 2 and metal material transmission shaft 3 connected in sequence, and the protection method is: at the joint of metal material transmission shaft 1 and carbon fiber composite material shaft tube 2 and At least one of the joints between the shaft tube 2 of carbon fiber composite material and the transmission shaft 3 of metal material adopts an interference connection.

[0029] The two ends of the multi-material integrated transmission shaft including two sections of metal transmission shafts, ie, the ends of the metal transmission shaft 1 and the metal transmission shaft 3, are respectively provided with couplings 4 connect...

Embodiment 2

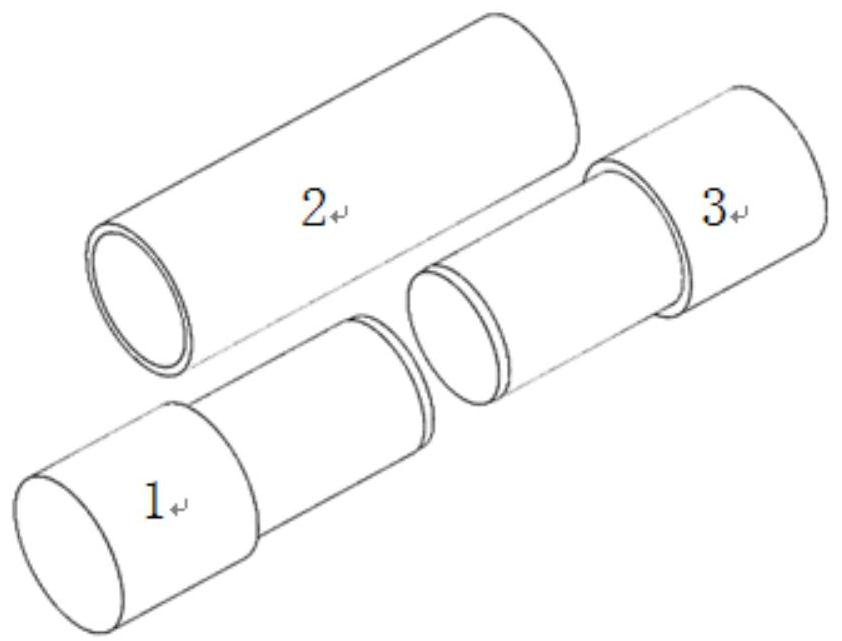

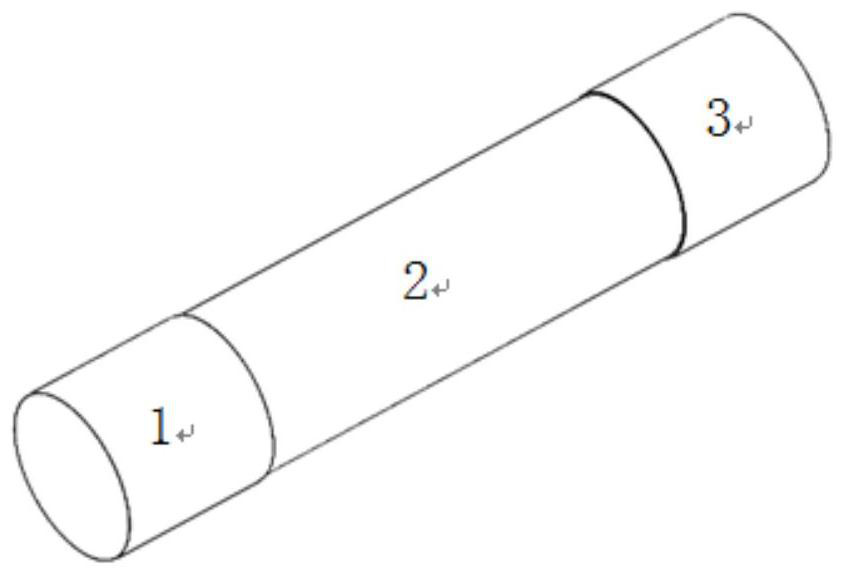

[0031] Embodiment 2: Overload protection method of a multi-material integrated transmission shaft containing a section of metal material transmission shaft

[0032] The multi-material integrated drive shaft containing a section of metal material drive shaft, such as Figure 4 As shown, it is composed of a metal transmission shaft 1 and a carbon fiber composite shaft tube 2 connected in sequence. The protection method is: the connection between the metal transmission shaft 1 and the carbon fiber composite shaft tube 2 adopts an interference connection.

[0033] The two ends of the multi-material integrated transmission shaft including a transmission shaft made of metal material, that is, the ends of the transmission shaft 1 made of metal material and the shaft tube 2 made of carbon fiber composite material, are respectively provided with couplings 4 connected thereto.

[0034] When the transmission torque is greater than the rated torque, there will be slippage between the meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com