Safety protection system and safety protection method for preventing container truck from being hoisted

A technology for container trucks and safety protection, applied in the field of safety protection systems for preventing container trucks from being hoisted

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

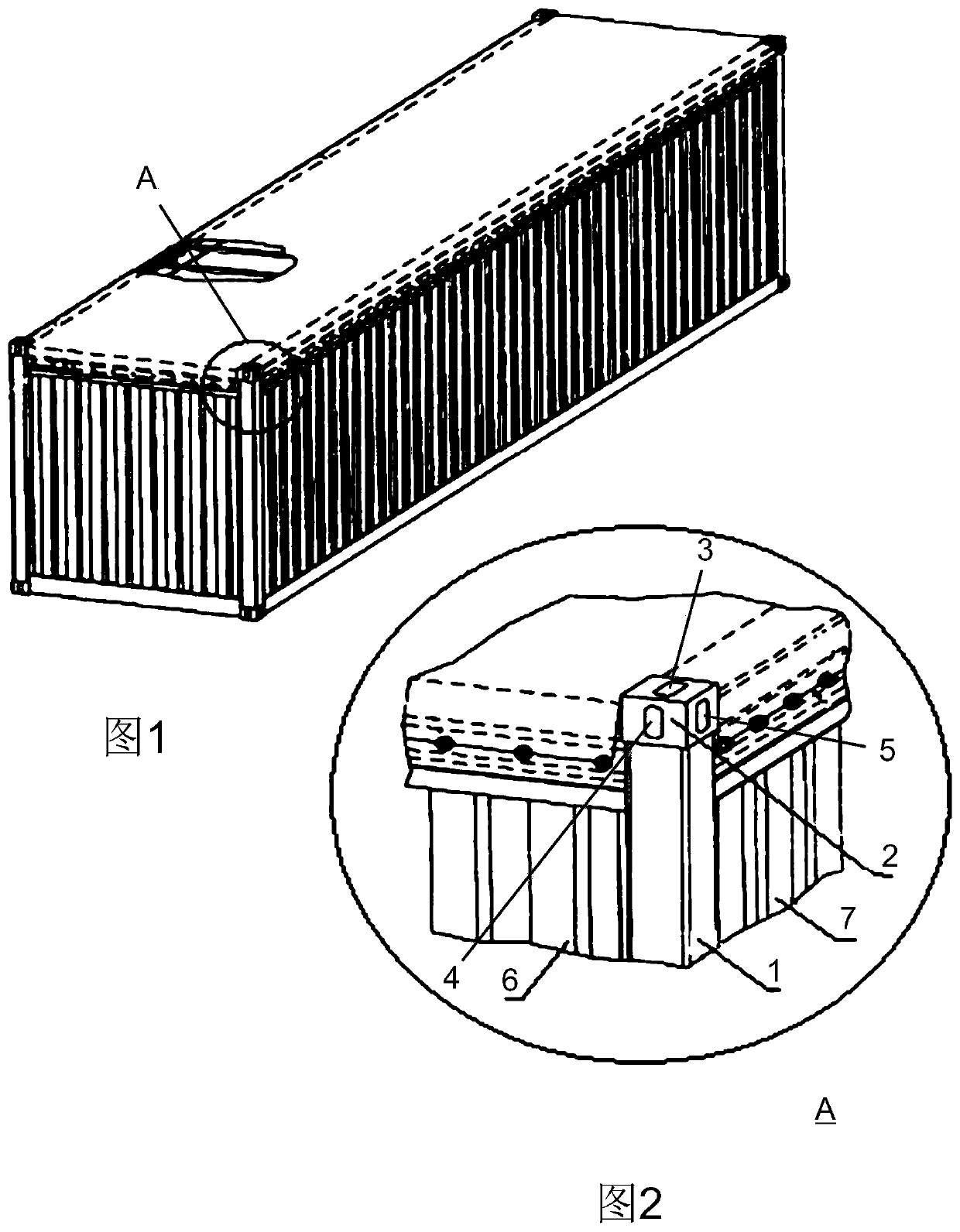

[0039] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

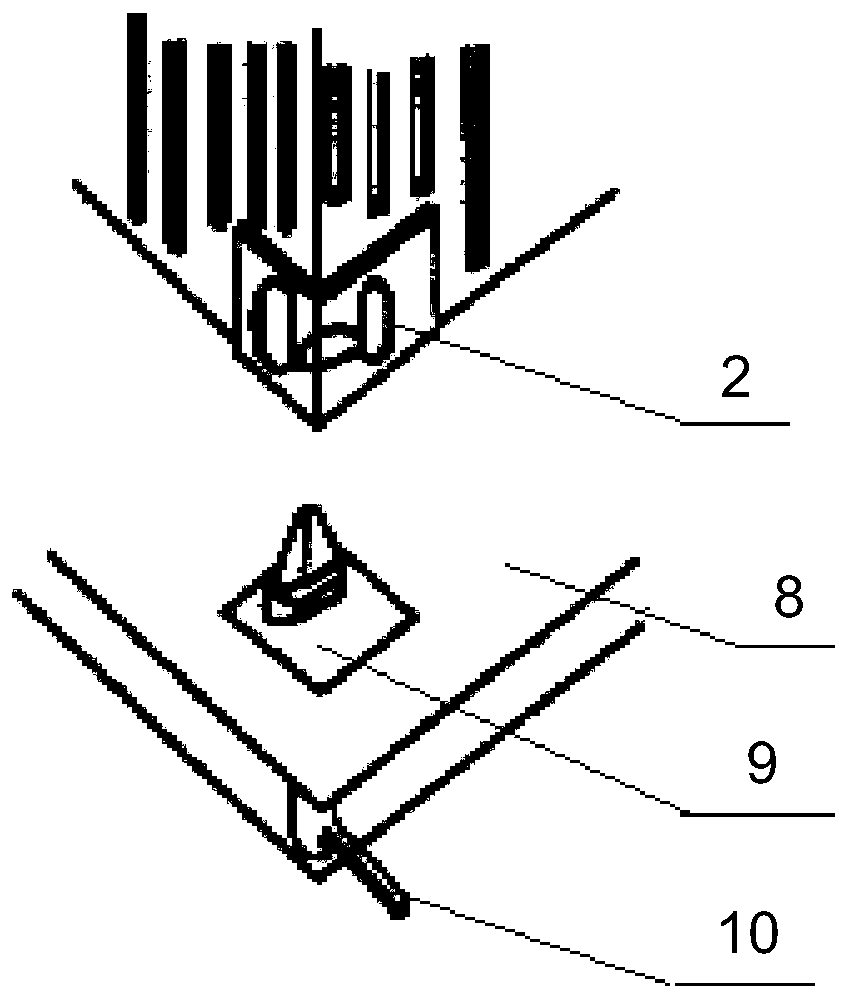

[0040] Please combine Figure 4 to Figure 7 As shown, a safety protection system for preventing container trucks from being hoisted provided by the present invention includes a twist lock 11 on the pallet of the truck, a truck scale 12 for weighing the truck, and a spreader for lifting the container 13.

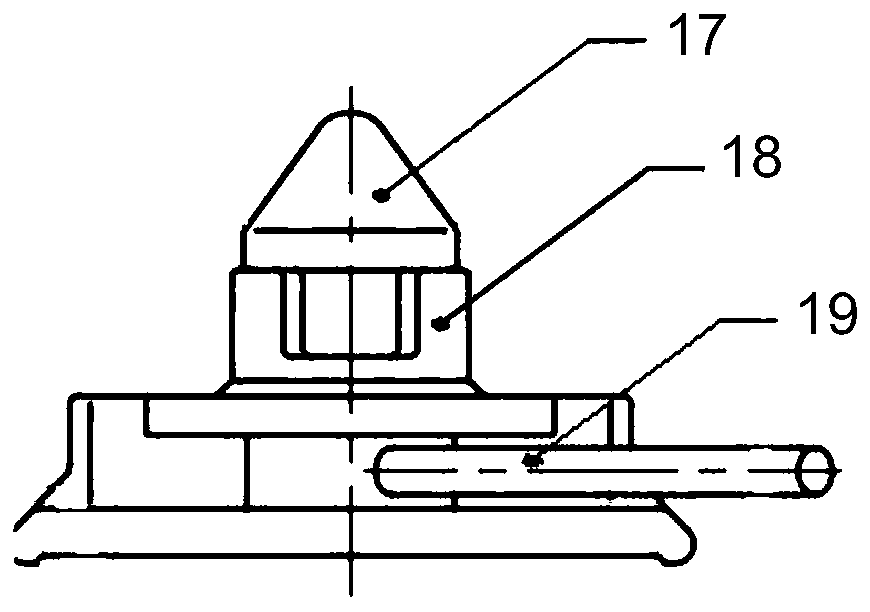

[0041] Preferably, the twist lock 11 is provided with a force sensor 14, the force sensor 14 can measure the magnitude of the force on the twist lock 11 when the container is hoisted.

[0042] Preferably, the spreader 13 is provided with four respin force sensors 15, the magnitude of the force measured by the four resell force sensors 15 can determine the weight of the container lifted by the spreader 13, and can also calculate The center of gravity of the container.

[0043] Preferably, it also includes a controller 16 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com