Peripheral transmission concentration mud scraper

A peripheral transmission and mud scraper technology, applied in chemical instruments and methods, separation methods, sedimentation separation, etc., can solve the problems affecting the normal operation of the mud scraper, uneven distribution of sludge, and a large amount of concentrated sludge. The effect of increasing sludge compactness, good sludge scraping effect and reducing operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

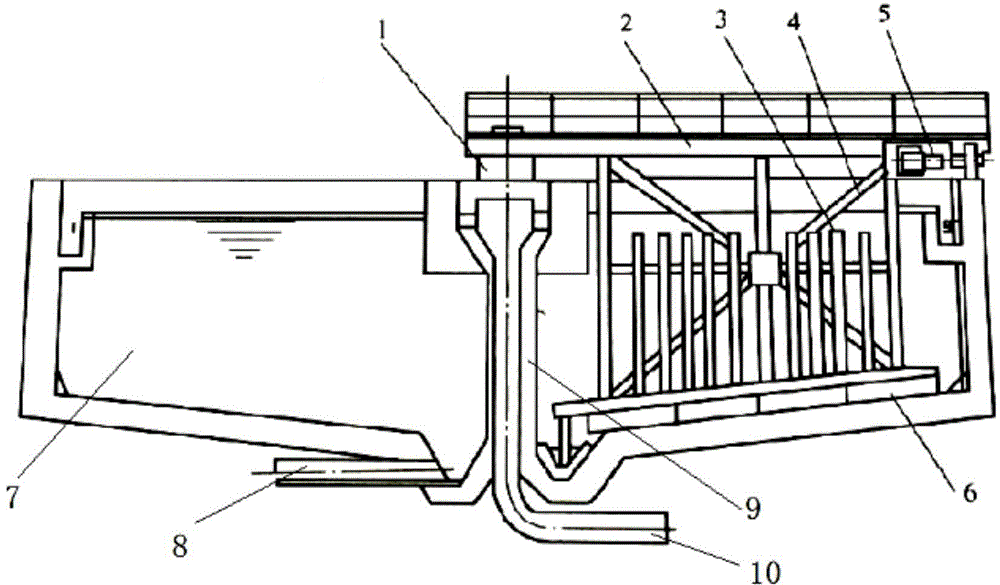

[0012] Such as figure 1 The peripheral transmission concentrated mud scraper shown includes a pool body 7, a central rotating support 1, a main beam 2, a transmission device 5 and a scraper 6. The bottom of the pool body 7 is conical, and the pool body 7 The bottom of the body 7 is provided with a mud outlet pipe 8, the pool body 7 is a half-span structure, the center column 9 and the water inlet pipe 10 are arranged in the middle of the pool body 7, and the water inlet pipe 10 is parallel to the center column 9 Set, the upper end of the central column 9 is provided with a central rotating support 1, one end of the main beam 2 is connected to the central rotating support 1, and the other end is equipped with a transmission device 5, and the transmission device 5 is connected to the hinged scraper The arm 4 is connected, and the bottom of the hinged scraper arm 4 is connected to the scraper 6, and the vertical grid bar 3 is also arranged on the scraper 6. The scraper 6 has a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com