Automobile air-conditioner fixed torque driver

An automobile air conditioner and constant torque technology, which is applied in the field of automobile air conditioner compressor system and automobile air conditioner constant torque driver, can solve the problems of short service life and complex structure, and achieve the effects of long service life, simple structure and reliable torque fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

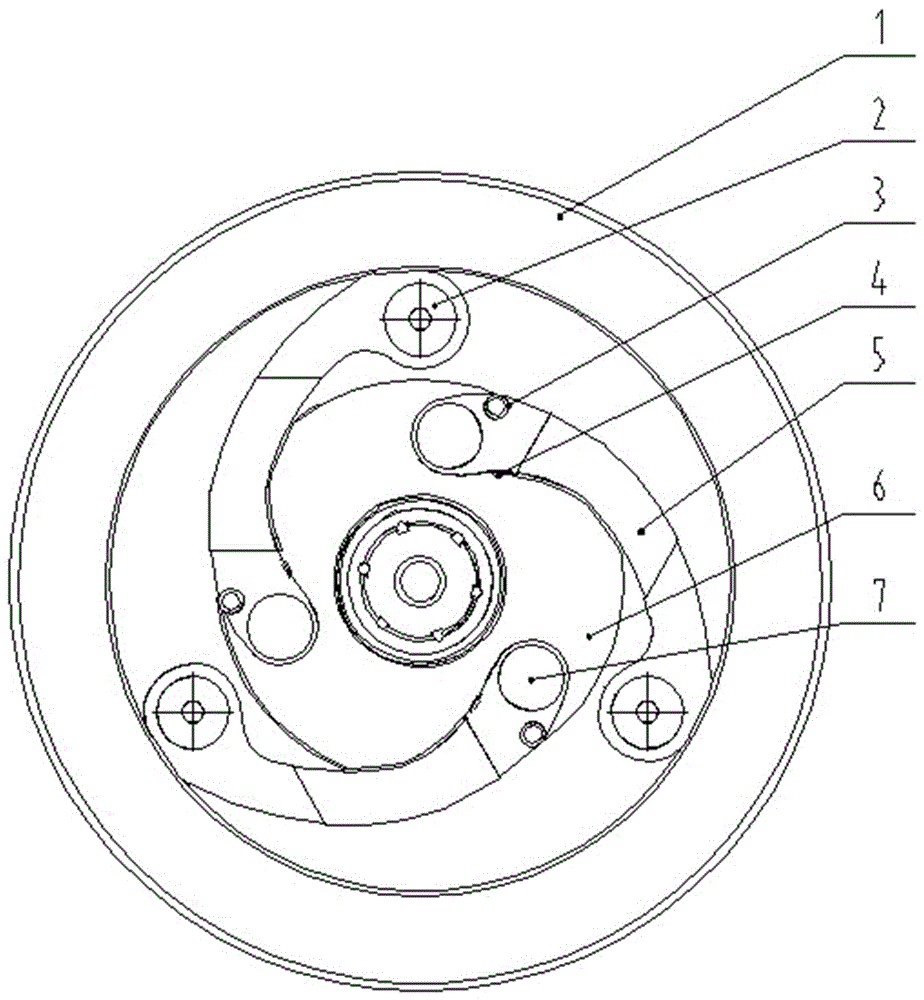

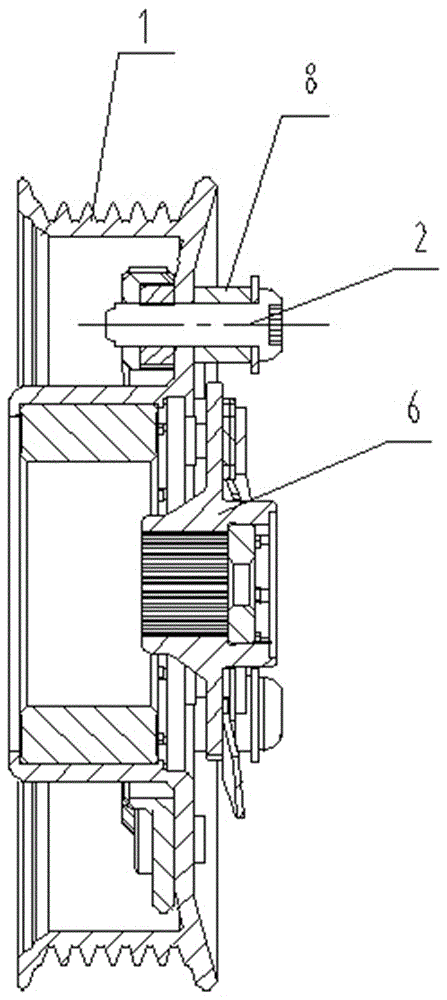

[0027] like figure 1 As shown, the present invention provides a constant torque driver for an automobile air conditioner, which includes a pulley 1 and a spline 6, and a set of three reeds 5, bolts 2, sleeves 8, cotter pins A3, and cotter pins B4 that are matched and connected. , rivet 7, preload plate 9 (see Figure 5 )as well as. When the engine rotates, the belt drives the pulley 1 to rotate. When the pulley 1 rotates, it also drives the reed 5 to rotate, thereby pushing the spline 6 to rotate, thereby driving the compressor shaft to rotate, and finally driving the entire compressor system to work.

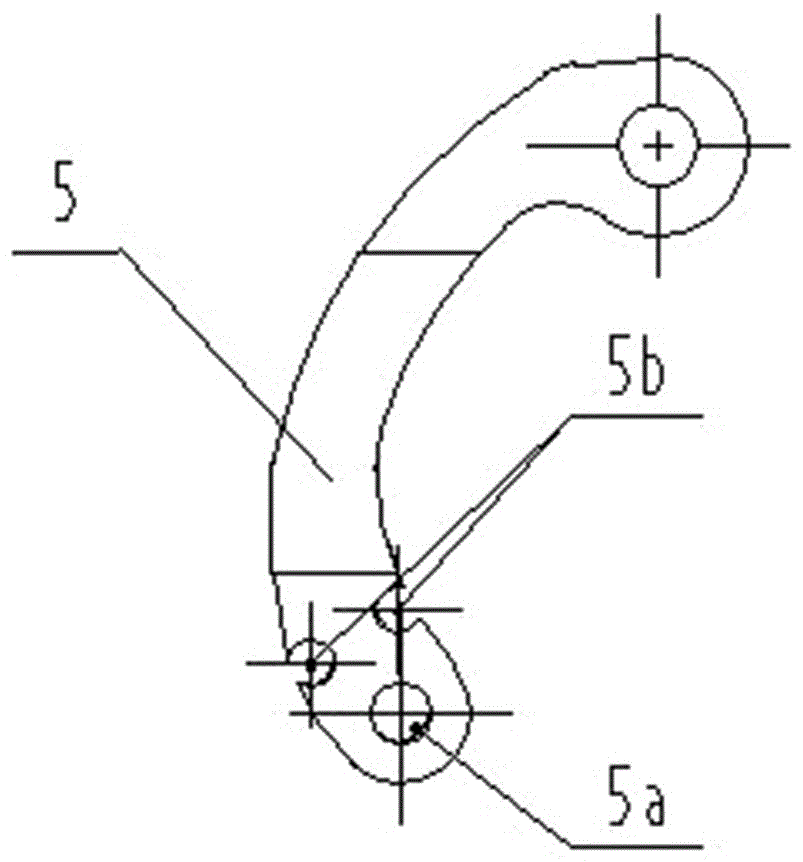

[0028] like figure 1 , Figure 5 As shown, one end of the reed 5 is provided with a section of pre-tensioning plate 9 , and the reed 5 and the pre-tensioning plate 9 are directly fixed on the spline 6 by rivets 7 . The other end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com