Thin film extraction tank transmission device

A transmission device and extraction tank technology, which is applied in the field of film extraction tank transmission devices, can solve the problems of lengthening of the extraction tank, expensive perfluoroether, leakage, leakage, etc., and achieve the effect of simple structure, convenient maintenance, and avoiding vibration transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

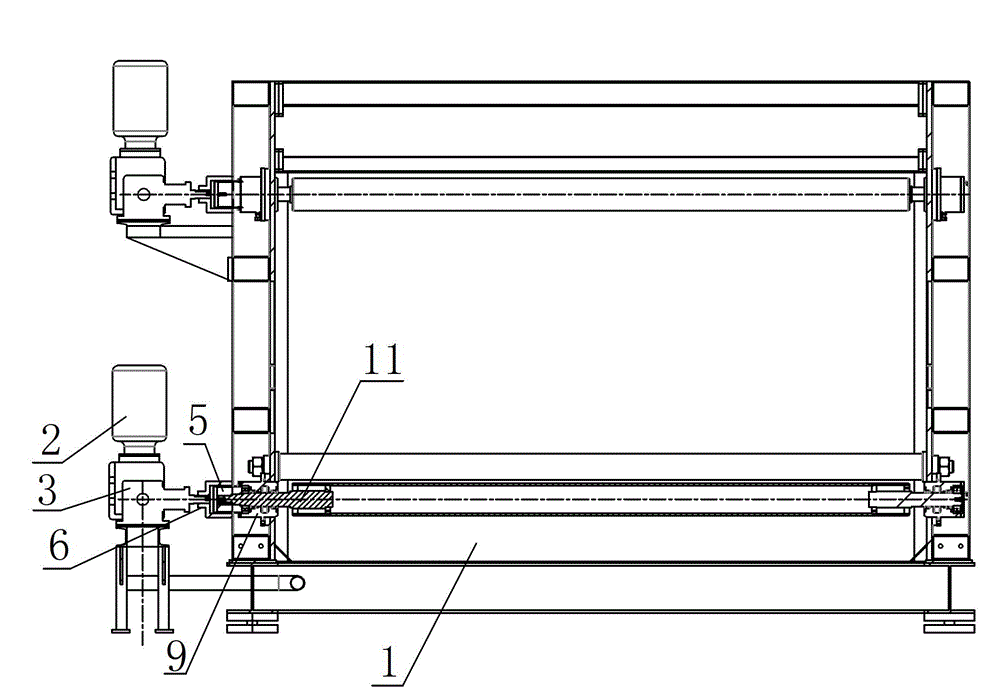

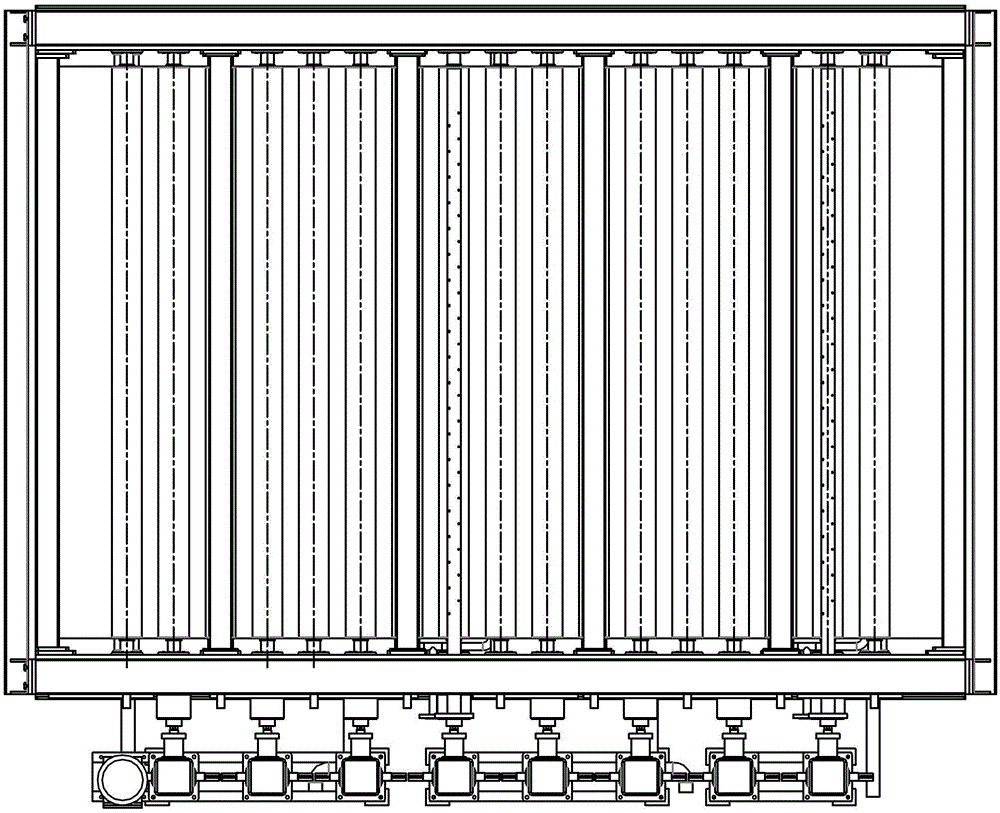

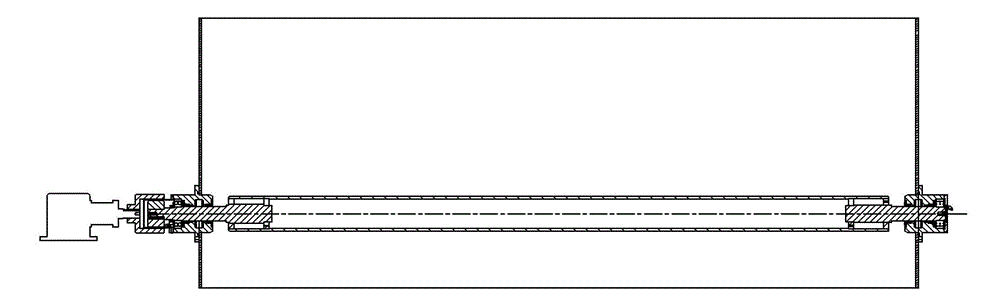

[0022] In conjunction with the accompanying drawings, a transmission device for a thin film extraction tank includes an extraction tank 1. In the extraction tank 1, an upper row of roller shafts and a lower row of roller shafts are alternately arranged. The upper row of roller shafts and the lower row of roller shafts pass through a motor and a reducer respectively. 2. The T-type commutator 3 and the magnetic driver drive the rotation. The T-shaped commutator 3 is fixed on the commutator bracket 4 . The magnetic drive includes an inner magnetic drive 5 and an outer magnetic drive 6, the outer magnetic drive 6 is installed on the T-shaped commutator 3, the T-shaped commutator 3 is connected with the motor and the reducer 2, and the inner magnetic drive 5 is installed on the roller shaft output. The internal magnetic drive 5 is coated with stainless steel (FeNdB) to ensure resistance to methylene chloride. A spacer 7 is arranged between the inner magnetic drive 5 and the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com