Ultrasonic flowmeter

A flowmeter and ultrasonic technology, applied in the field of fluid flow measurement equipment, can solve the problems of limited measurement range and low measurement accuracy of ultrasonic flowmeters, and achieve the effect of improving measurement accuracy and overcoming flow measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

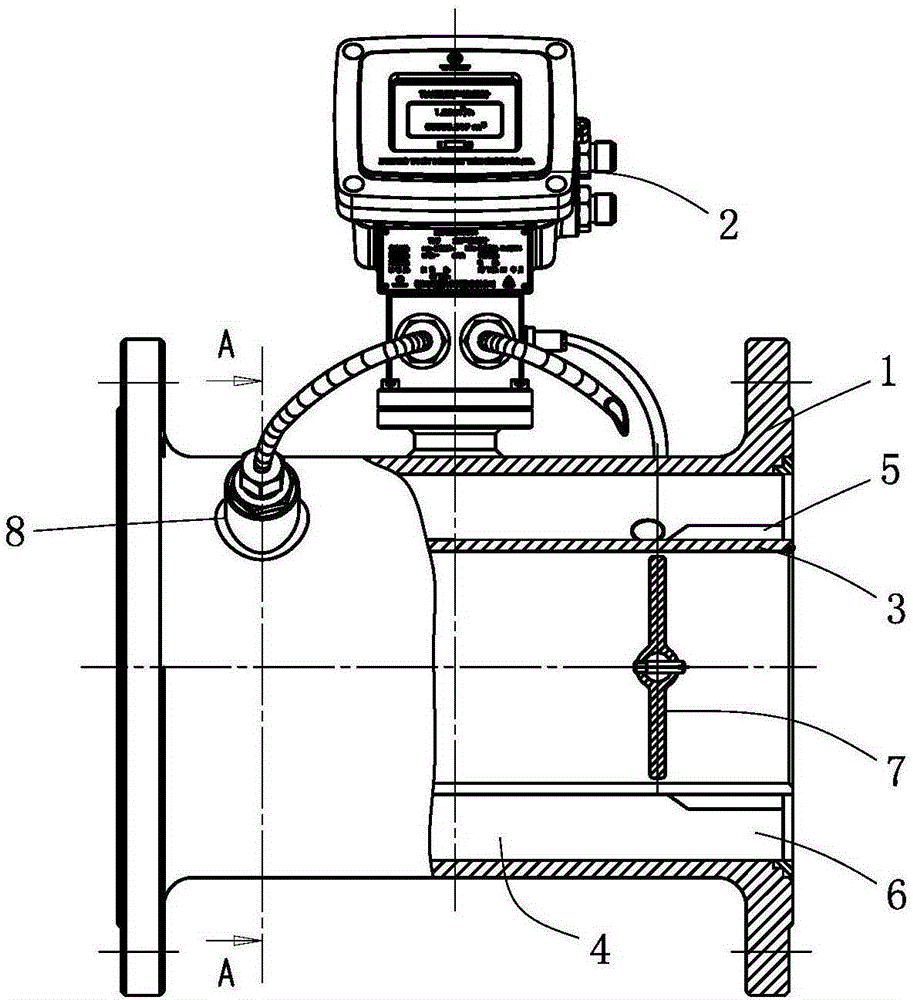

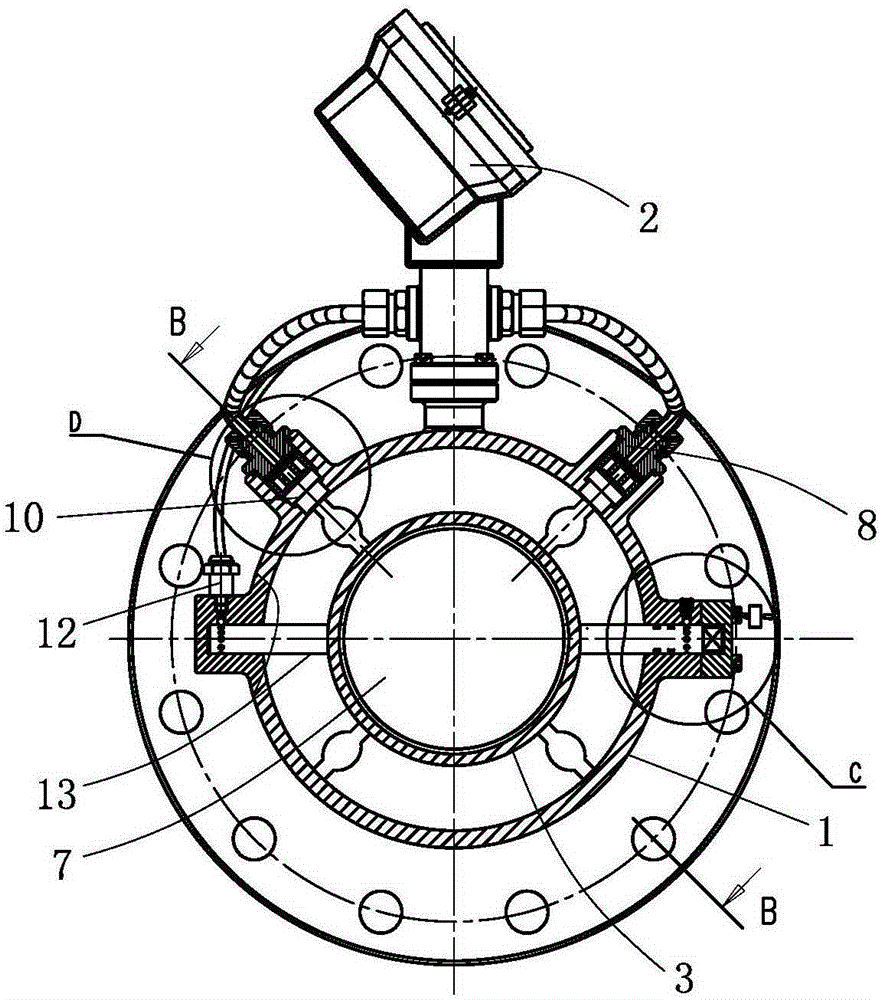

[0037] Such as Figure 1 to Figure 7 Commonly shown, the present invention discloses an ultrasonic flowmeter, which includes a cylindrical outer shell 1, a meter 2 is arranged outside the outer shell 1, and a control and conversion chip is arranged inside the meter 2, which are different from the traditional The principle is the same, so I won’t go into details here. The inner shell 1 is coaxially provided with the inner shell 3, and the inner shell 3 is also set as a linearly extending rotary structure. There is a communication between the outer shell 1 and the inner shell 3. The gap 4 and the circulation gap 4 are equidistantly arranged, and the two ends of the circulation gap 4 are respectively provided with a first reflection sheet 14 and a second reflection sheet 5, and the first reflection sheet 14 and the second reflection sheet 5 are cylindrical structures and are fixed on Between the outer shell 1 and the inner shell 3, the outer surfaces of the first reflective sheet...

Embodiment 2

[0043] Such as Figure 1 to Figure 7 Commonly shown, the present invention discloses an ultrasonic flowmeter, the structure of which is basically the same as that of Embodiment 1, the difference is that the ends of the first probe 8 and the second probe 9 are correspondingly provided for removing the attachment on the probe. The impurity removal device for impurities, the impurity removal device includes a sleeve 24 arranged in the flow gap 4, the cross-sectional shape of the sleeve 24 is shuttle-shaped, and the linear distance of the sleeve 24 in the fluid flow direction of the flow gap 4 is greater than that in the flow gap 4. The linear distance of the gap 4 perpendicular to the flow direction avoids the impact of the fluid and affects the measurement effect. One end of the sleeve 24 is open, and the other end is fixedly installed on the inner shell 3. The sleeve 24 is installed with a magnetic device sliding along the inside. The piston 25 and the end of the sleeve 24 near...

Embodiment 3

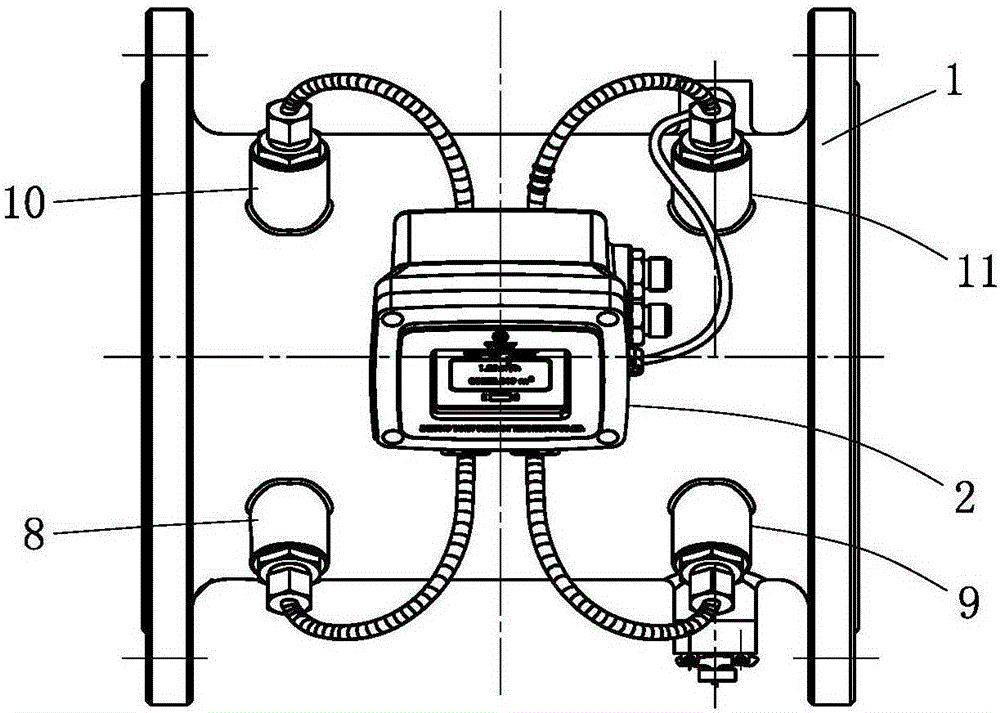

[0045] Such as Figure 1 to Figure 7 Commonly shown, the present invention discloses an ultrasonic flowmeter, the structure of which is basically the same as that of Embodiment 2, the difference being that a third probe 10 and a fourth probe 11 are installed at intervals on the outer shell 1, and the third probe 10 It is set on the same bus as the fourth probe 11 and the phase is staggered from the bus where the first probe 8 is located. As for the phase stagger angle, it is related to the diameter of the outer shell 1 and the measurement range. Those skilled in the art can set it according to professional knowledge. The third probe 10 is close to the first reflective sheet 14 and faces the first reflective slope 15 , the fourth probe 11 is close to the second reflective sheet 5 and faces the second reflective slope 16 , and both the third probe 10 and the fourth probe 11 are connected to the meter head 2 . The ends of the third probe 10 and the fourth probe 11 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com