Gear tooth type crusher tooth roller

A crusher and toothed roller technology, applied in grain processing and other directions, can solve the problems of high maintenance cost, shortened machine life, reduced work efficiency, etc., and achieve the effect of reducing manufacturing cost, convenient replacement and maintenance, and simple and reasonable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

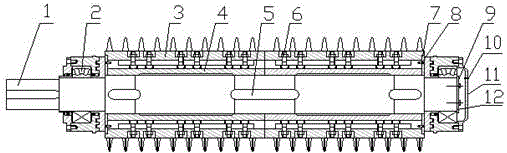

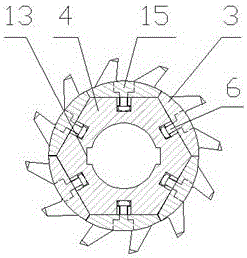

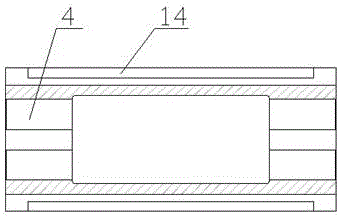

[0017] Such as Figure 1-5 As shown, a toothed roller of a toothed crusher includes a main shaft 1, a self-aligning roller bearing 2, a tooth plate 3, and a hexagonal cylinder 4. Both ends of the main shaft 1 are supported by a double-row self-aligning roller bearing 2. The bearing capacity is large, and it can be self-aligning, which is very suitable for the bearing position error and shaft deformation caused by the harsh working environment of the gear-tooth crusher; the main shaft 1 is connected to the hexagonal cylinder 4 through the flat key 5, and the tooth plate 3 Tightly connect the hexagonal cylinder 4 with the bolt 6 through the T-shaped slot; the signal generator 9 is installed on the shaft end retaining ring 12 at one end of the main shaft 1, and the signal receiver is installed on the blind cover 11 outside the spherical rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com