Novel valve core with spring seat

A spring seat, a new type of technology, applied in the hydraulic field, can solve the problems of low assembly success rate, short guiding effect of the valve stem, spring seat and valve stem falling off, etc., and achieve the goal of improving the assembly success rate, reducing assembly requirements, and increasing the guide length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

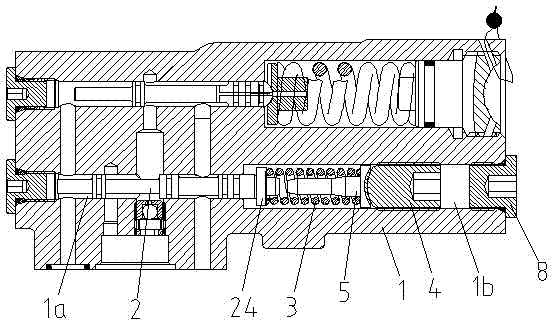

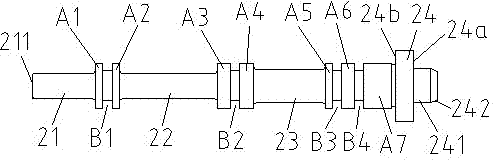

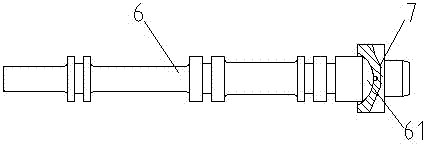

[0017] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] Figures 1 to 2 It is a structural schematic diagram of the present invention.

[0019] The reference signs are: the first annular sealing boss A1, the second annular sealing boss A2, the third annular sealing boss A3, the fourth annular sealing boss A4, the fifth annular sealing boss A5, the sixth annular sealing boss Sealing boss A6, seventh annular sealing boss A7, first annular groove B1, second annular groove B2, third annular groove B3, fourth annular groove B4, valve body 1, lower valve cavity 1a, Assembly cavity 1b, spool rod body 2, front rod section 21, front end surface 211, middle rod section 22, rear rod section 23, spring seat 24, positioning annular surface 24a, limiting annular surface 24b, spring guide rod 241, taper guide Inclined surface 242, compression spring 3, pressure regulating screw plug 4, spring back seat 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com