Bridge construction machine

A bridge construction and machinery technology, applied in the direction of cleaning hollow objects, removing smoke and dust, chemical instruments and methods, etc., can solve the problems of steel pipe oxidation and rust splashing of steel pipes, etc., to achieve the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

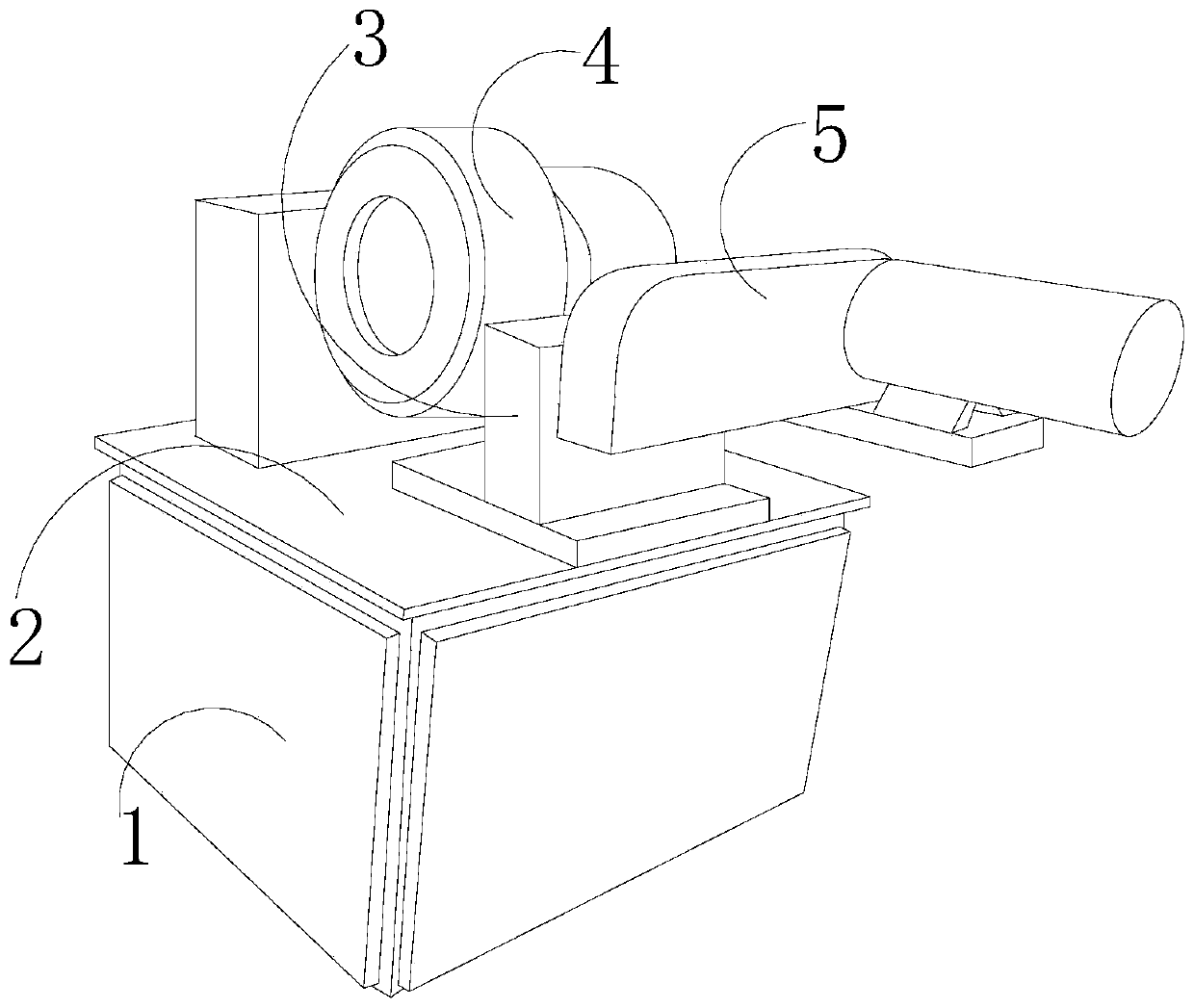

[0026] see Figure 1-Figure 5 , the present invention provides a kind of bridge construction machinery, and its structure comprises fixed seat 1, workbench 2, connecting seat 3, derusting device 4, connecting block 5, described fixing seat 1 is provided with workbench 2, and described workbench 2 is fixedly connected with the fixed seat 1, the workbench 2 is provided with a connection seat 3, the connection seat 3 is mechanically connected with the connection block 5, and the derusting device 4 is installed on the workbench 2;

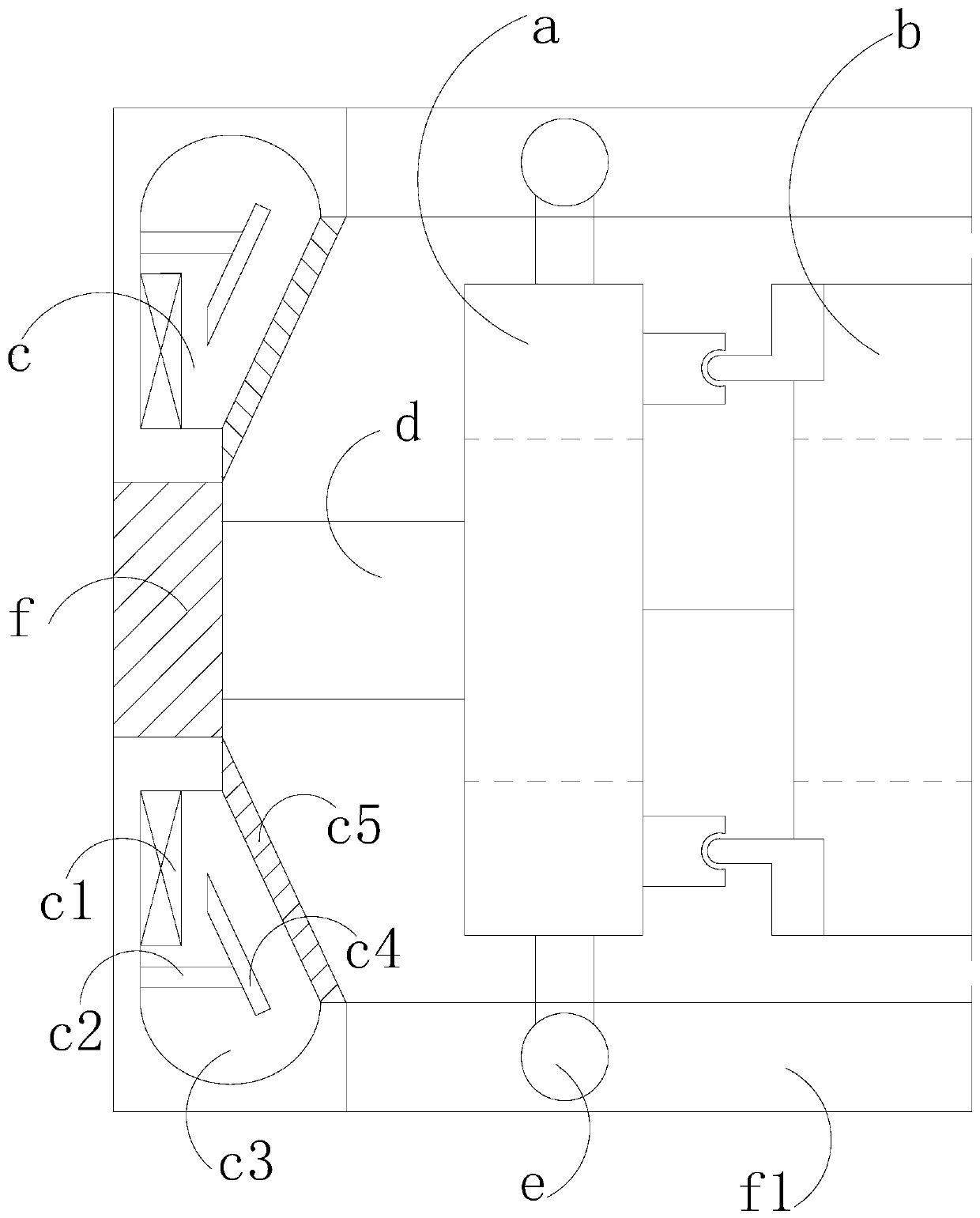

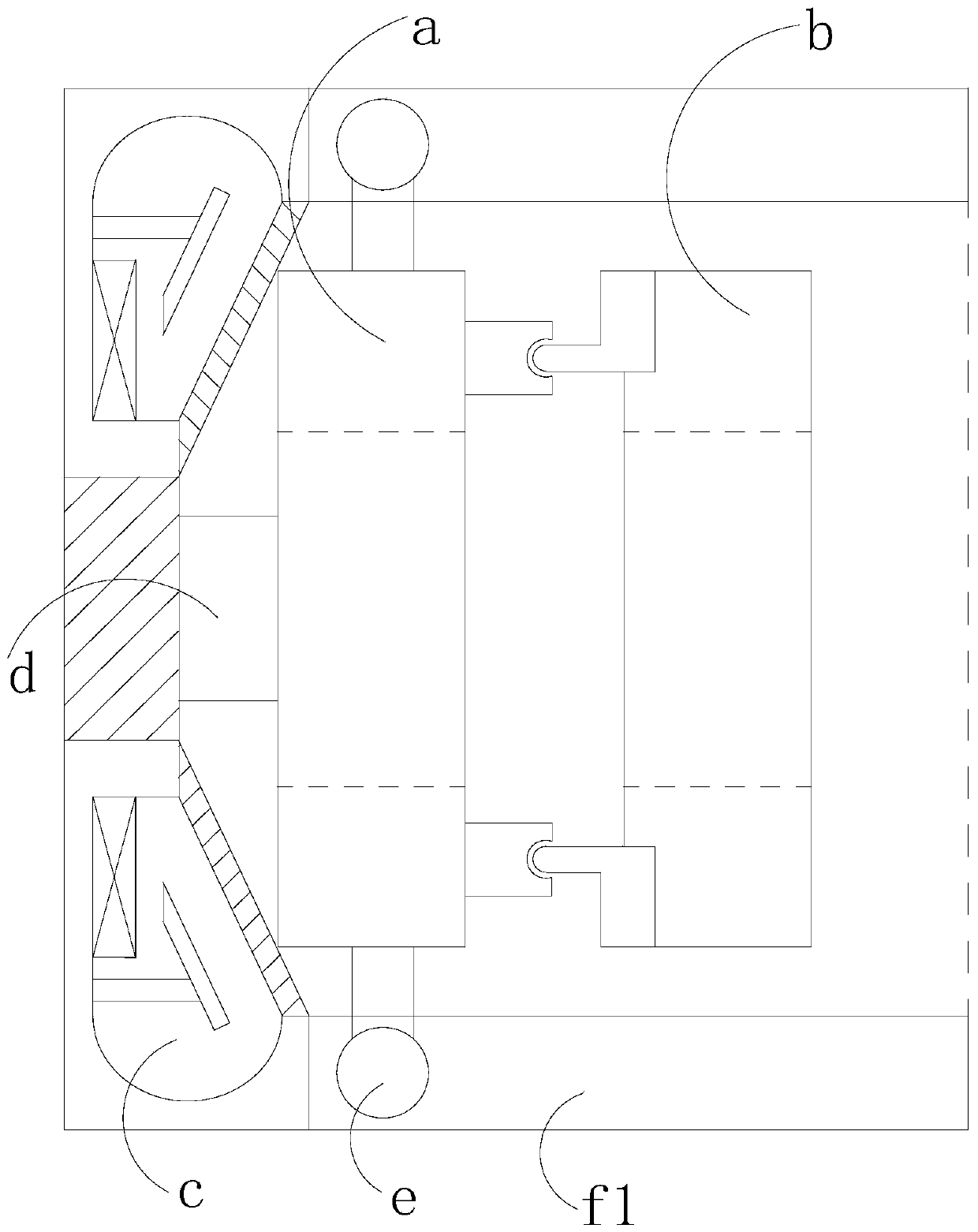

[0027] The rust removal device 4 is composed of a rust removal head a, an anti-rust head b, a recovery port c, a rotating shaft d, an extension rod e, and a rust removal chamber f. The rust removal head a and the anti-rust head b are matched, and the The derusting head a is mechanically connected to the rotating shaft d, the rotating shaft d is connected to the external mechanical force, the recovery port c is installed on the derusting chamber f, and ...

Embodiment 2

[0037] see Figure 1-Figure 2 , Figure 5, the present invention provides a kind of bridge construction machinery, and its structure comprises fixed seat 1, workbench 2, connecting seat 3, derusting device 4, connecting block 5, described fixing seat 1 is provided with workbench 2, and described workbench 2 is fixedly connected with the fixed seat 1, the workbench 2 is provided with a connection seat 3, the connection seat 3 is mechanically connected with the connection block 5, and the rust removal device 4 is installed on the workbench 2; the rust removal device 4. It is composed of rust removal head a, rust prevention head b, recovery port c, rotating shaft d, extension rod e, and rust removal chamber f. The rust removal head a is matched with the rust removal head b. Mechanically connected with the rotating shaft d, the rotating shaft d is connected with the external mechanical force, the recovery port c is installed on the derusting chamber f, the rotating shaft d is set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com