Automatic and manual integrated clutch

A clutch device and integrated technology, applied in clutches, friction clutches, mechanical drive clutches, etc., can solve the problems of affecting the escape of pilots, unable to adjust the seat, affecting the pilot's operation of entering and exiting the aircraft, etc., to achieve reliable work, significant effect, and ensure safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

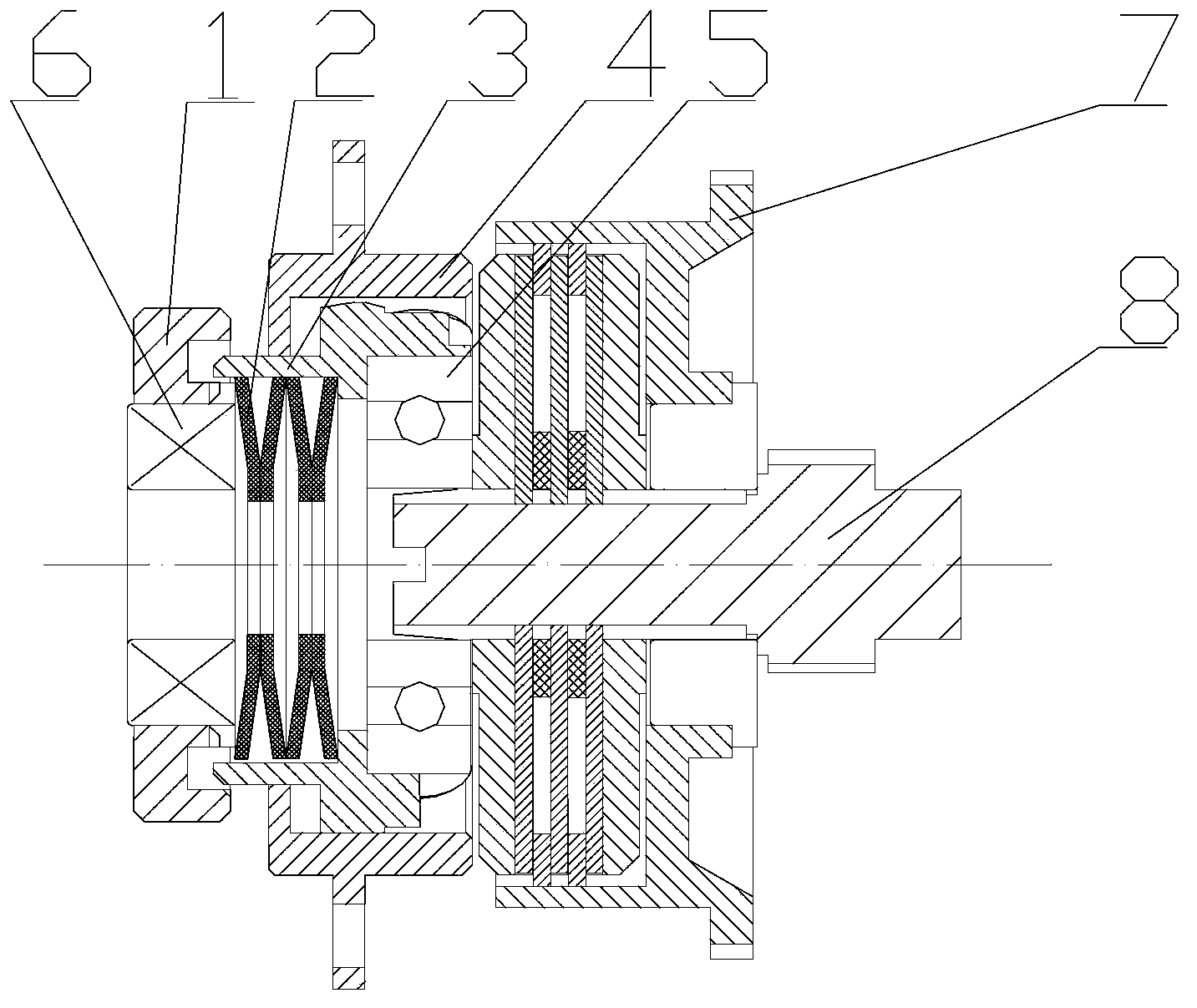

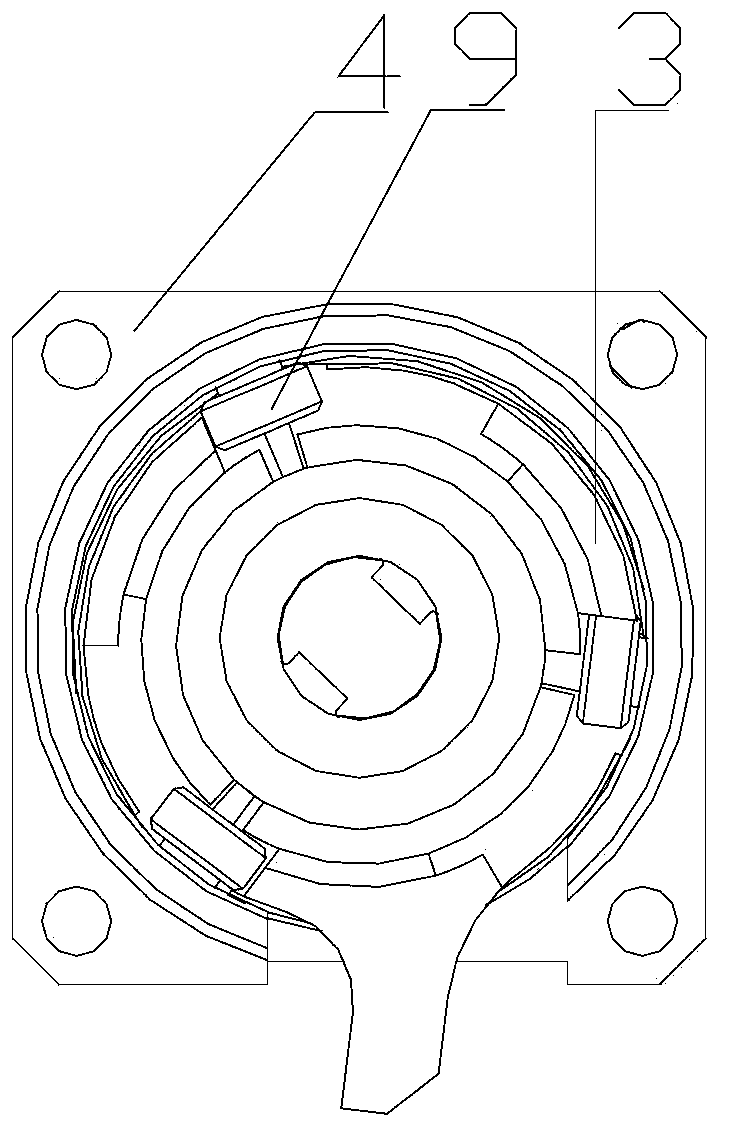

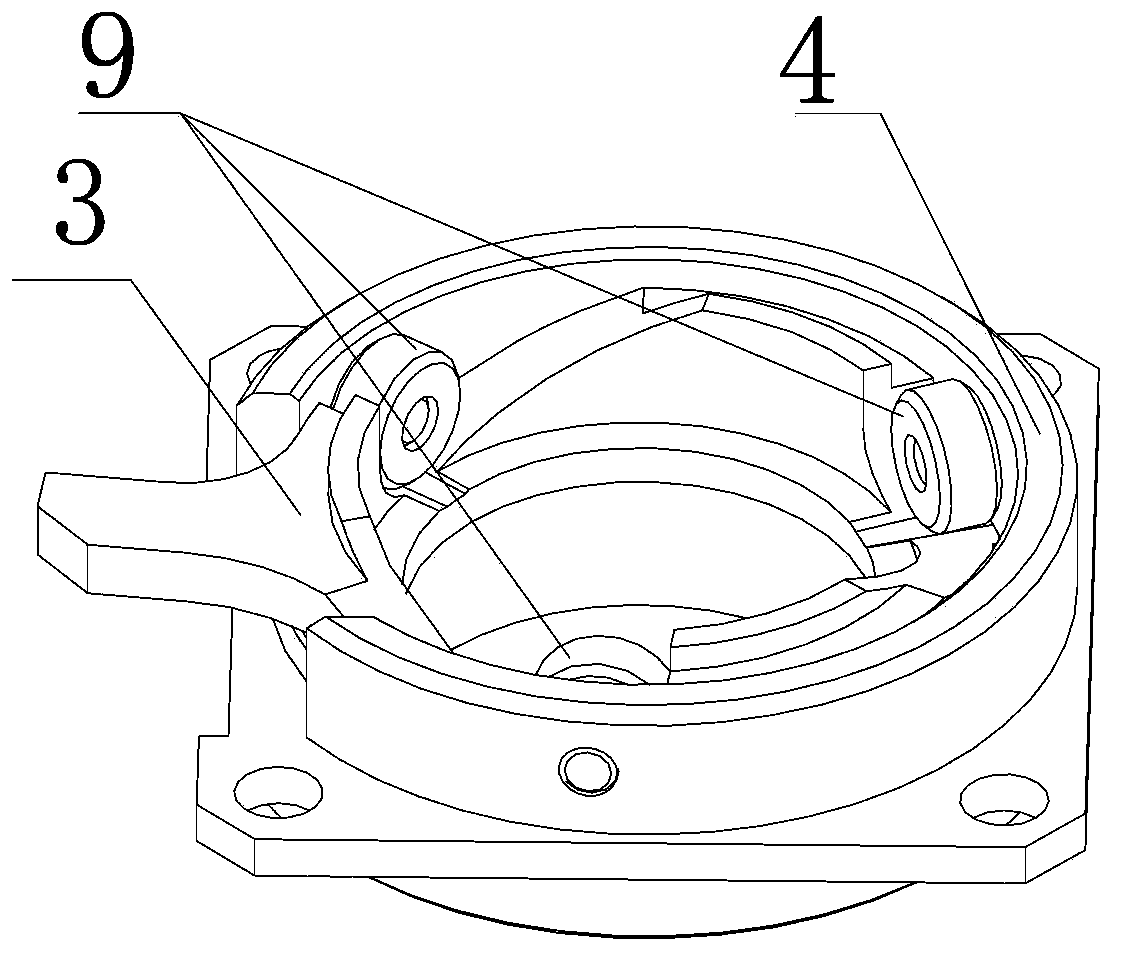

[0012] As shown in the figure, the automatic clutch device includes a bearing seat 1, a butterfly spring set 2, a spring set bearing 6, a shift fork 3, a housing 4, a friction plate set bearing 5, a friction plate set, and a transmission gear 7 , gear shaft 8, roller 9, wherein the bearing seat 1 and the housing 4 are fixed on the electric mechanism, the shift fork 3 is located in the housing 4 and is provided with a handle protruding from the housing 4, and the butterfly spring sheet group 2 is located in the dial On the inner step of the fork 3, and between the bearing housing 1, a leaf spring bearing 6 is arranged, and a roller 9 is fixedly installed inside the housing 4, and the roller 9 is in contact with the inclined surface arranged on the shift fork 3, The handle of the shift fork 3 can make the shift fork 3 rotate in the housing 4 and move axially through the action of the inclined surface in contact with the roller 9; the friction disc group bearing 5 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com