Novel washing machine

A washing machine and a new type of technology, applied in the field of washing machines, can solve the problems of complex production and processing, complex driving components, and difficult processing, and achieve the effects of simple production and processing, simplified structure of the washing machine, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

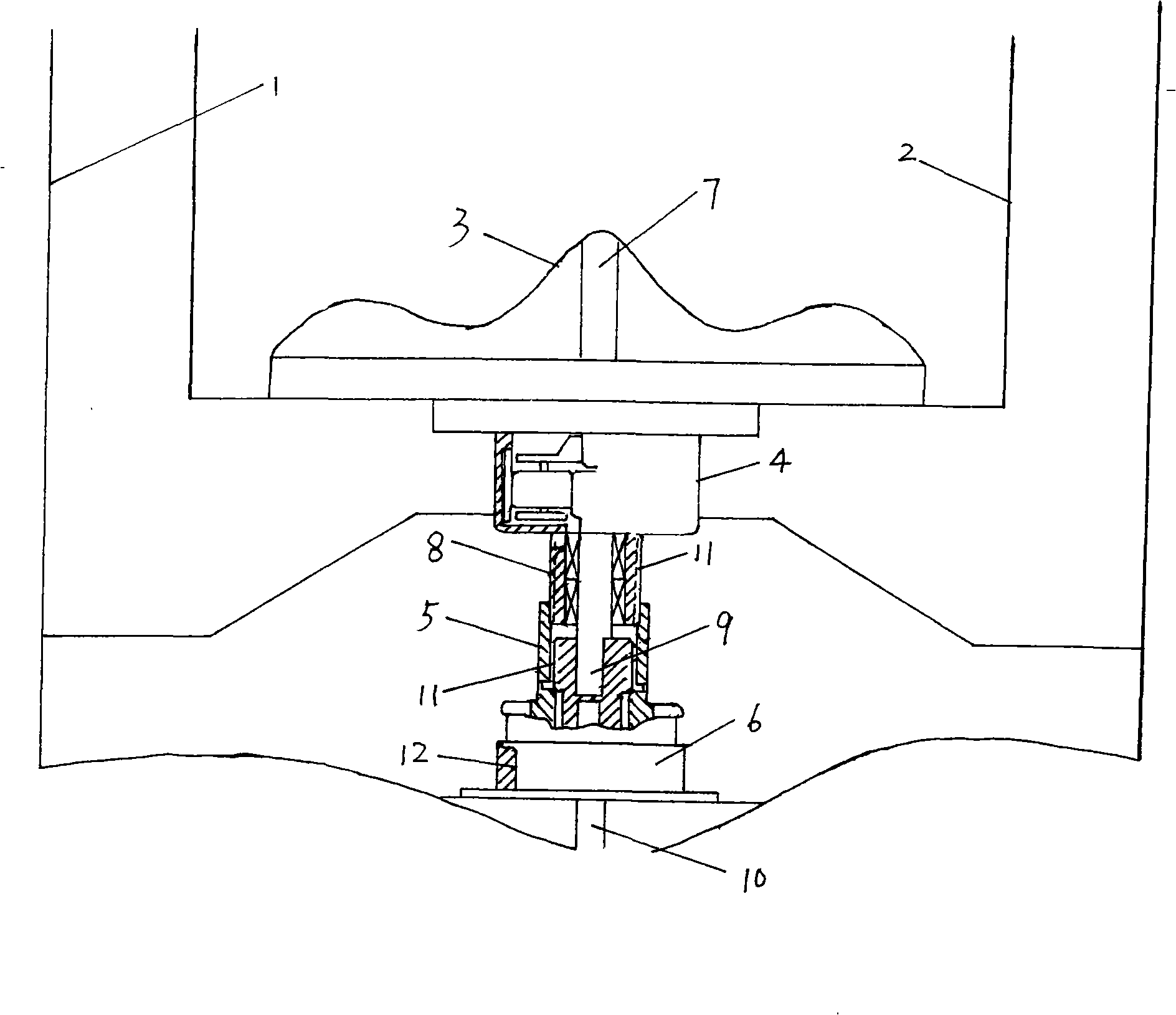

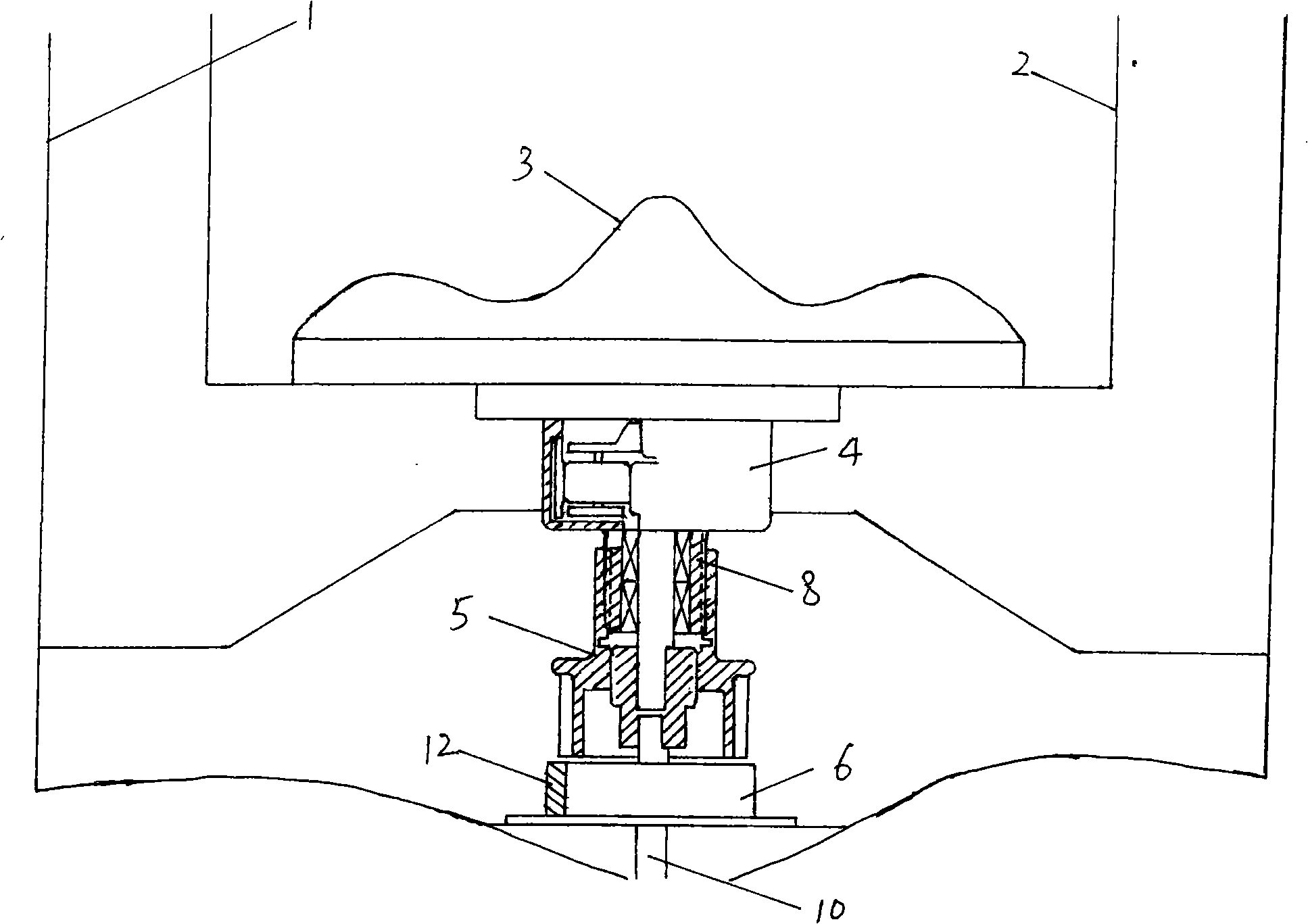

[0017] see figure 1 , figure 2 .

[0018] A new type of washing machine, including a water tank 1, a dehydration bucket 2, a washing pulsator 3, a speed reducer 4, a motor, and the speed reducer 4 has a transmission shaft 9, an output shaft 7 and an output shaft sleeve 8, and the output shaft 7 is used as The driving shaft of the wave wheel of the washing machine, the motor shaft 10 is connected with the transmission shaft 9, the output shaft sleeve 8 of the washing machine reducer is directly rigidly connected with the dehydration bucket 2 through mechanical means, and the transmission shaft 9 and the output shaft sleeve 8 are provided with Clutch, outside the transmission shaft 9, the clutch 5 can slide up and down, the clutch 5 refers to the clutch gear sleeve, the transmission shaft 9 and the output shaft sleeve 8 lower ends have external teeth 11 respectively, the brake seat 6 is installed outside the motor shaft 10, and the brake There are internal teeth 12 on the sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com