Carving machine applied to woodwork processing

A technology of engraving machines and wood products, which is applied in the field of engraving machines, can solve the problems of inconvenient replacement of engraving machine head parts, failure to satisfy customers, single engraving form, etc., and achieve the advantages of reducing labor intensity, high flexibility, and significant economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

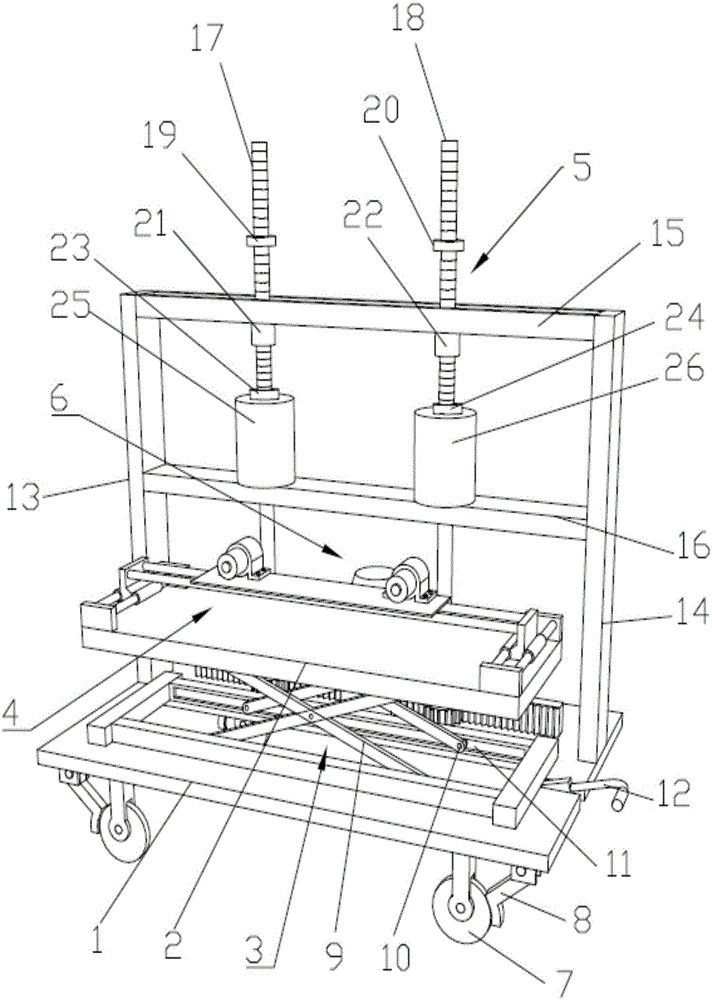

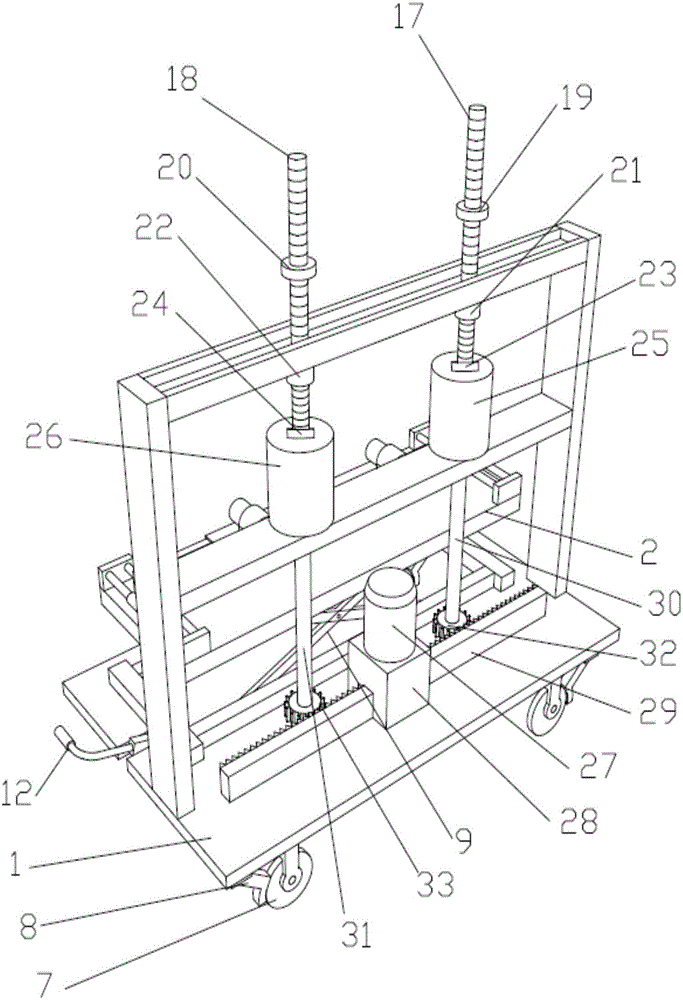

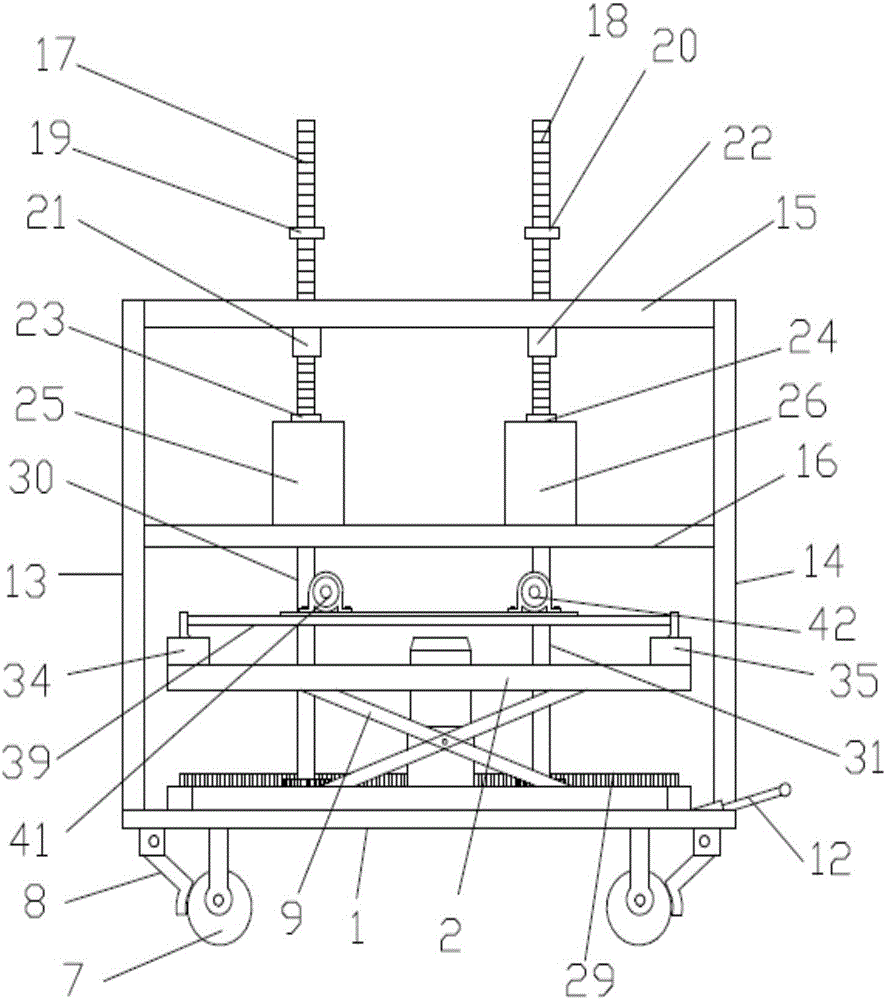

[0033] like Figure 1 to Figure 7 As shown, an engraving machine applied to woodwork processing includes a base 1, a workbench 2 and a support frame, the workbench 2 is located on the front side of the base 1, the support frame is located on the rear side of the base 1, the base 1 and the workbench 2 A cylinder lifting device 3 is provided between them, and an engraving device 4 is provided on the workbench 2. The engraving device 4 includes a slide bar assembly and a transmission assembly. The transmission assembly includes a transmission motor and a transmission plate 40. The transmission motor includes a first transmission motor 41 and a second transmission motor. Two transmission motors 42, the first transmission motor 41 is installed on the left side of the transmission plate 40, the second transmission motor 42 is installed on the right side of the transmission plate 40, the first transmission motor 41 is provided with a positioning knife 43, the second transmission motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com