Rotary tribological behavior simulation test bed for realizing vibration decoupling

A technology for simulating test benches and tribology, which is applied in the field of friction and vibration, can solve problems such as the inability to accurately study the tribological behavior of the friction pair interface, and achieve the effects of reducing motion transmission paths, response spans, and response smooth controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

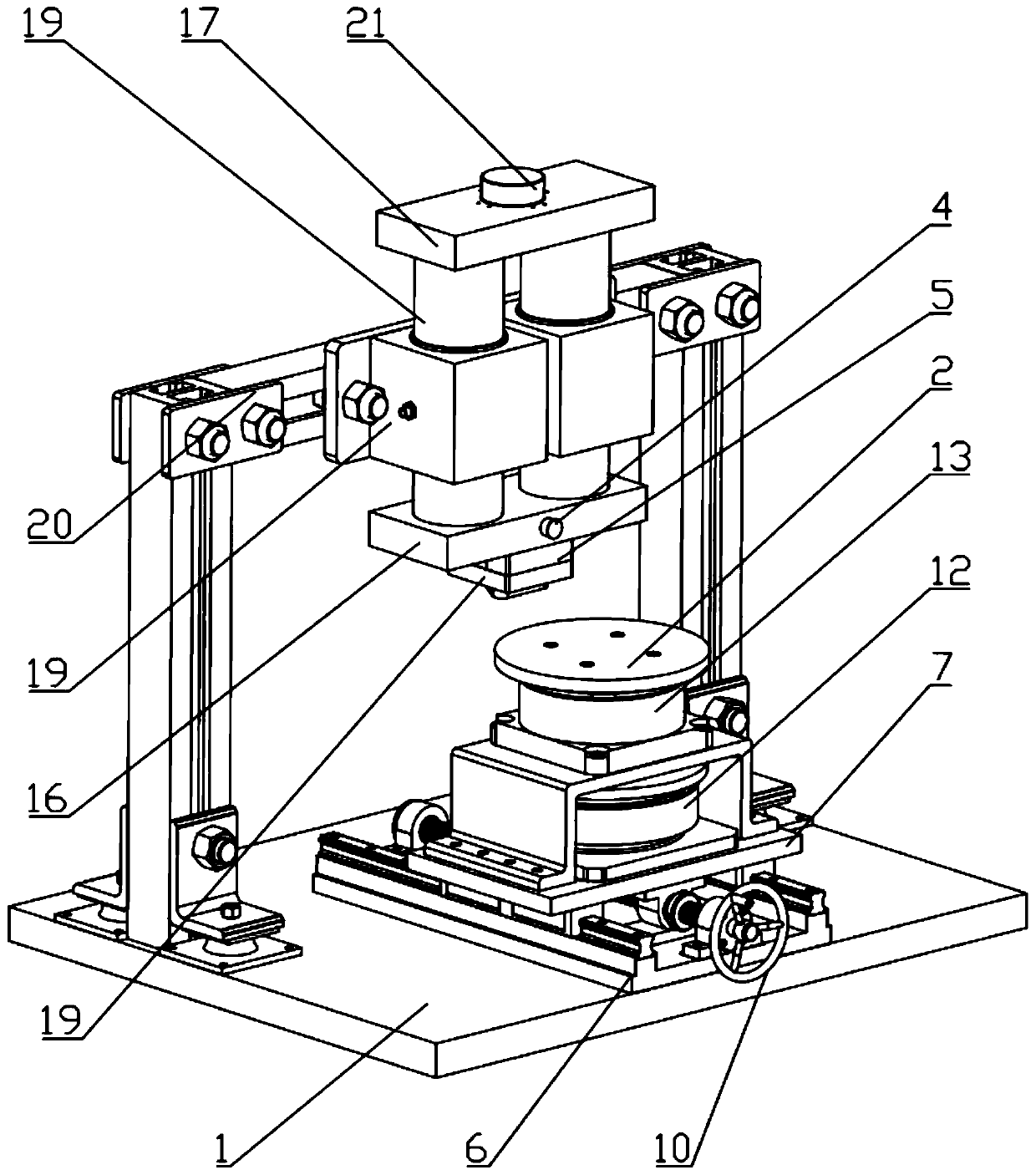

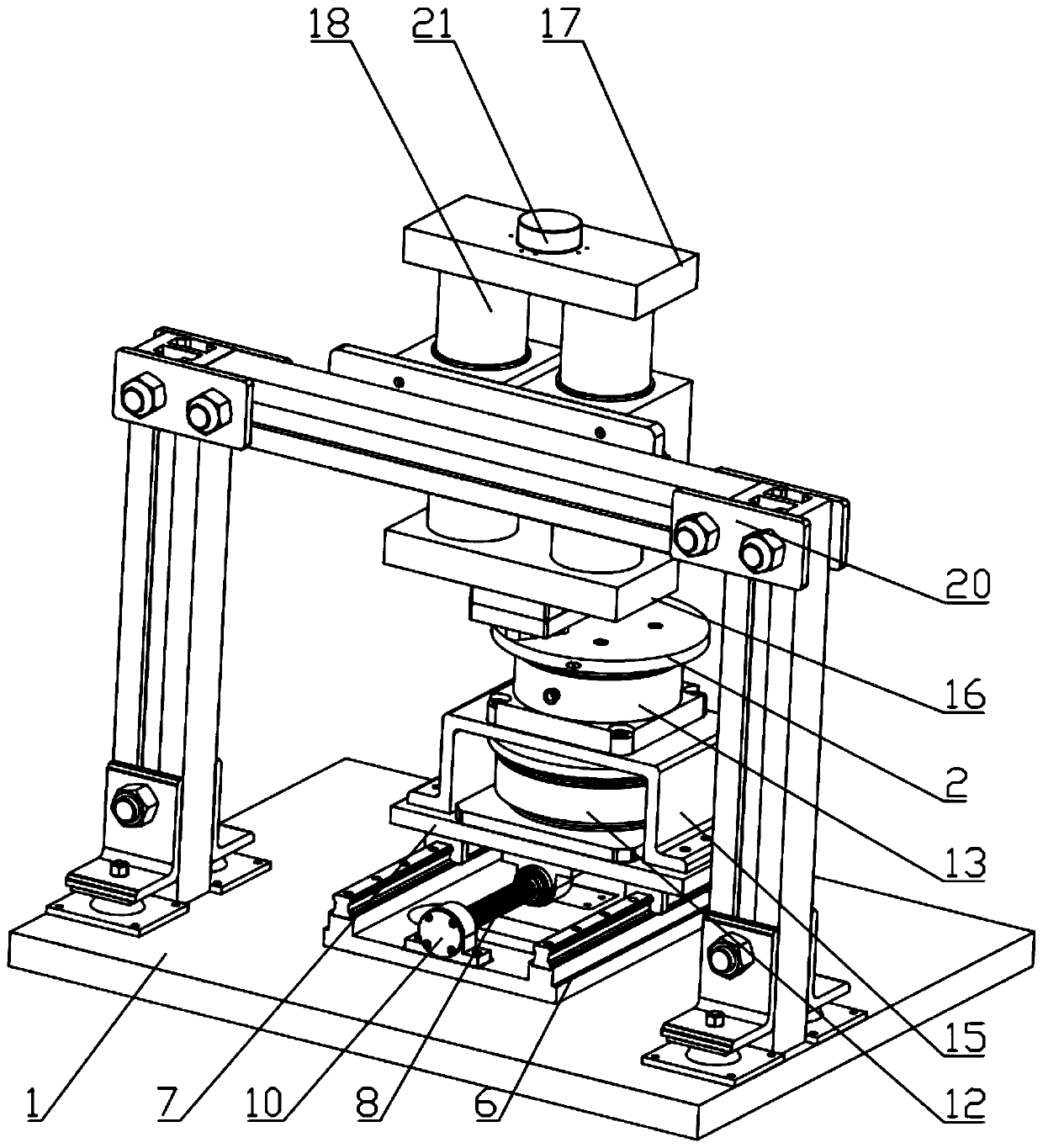

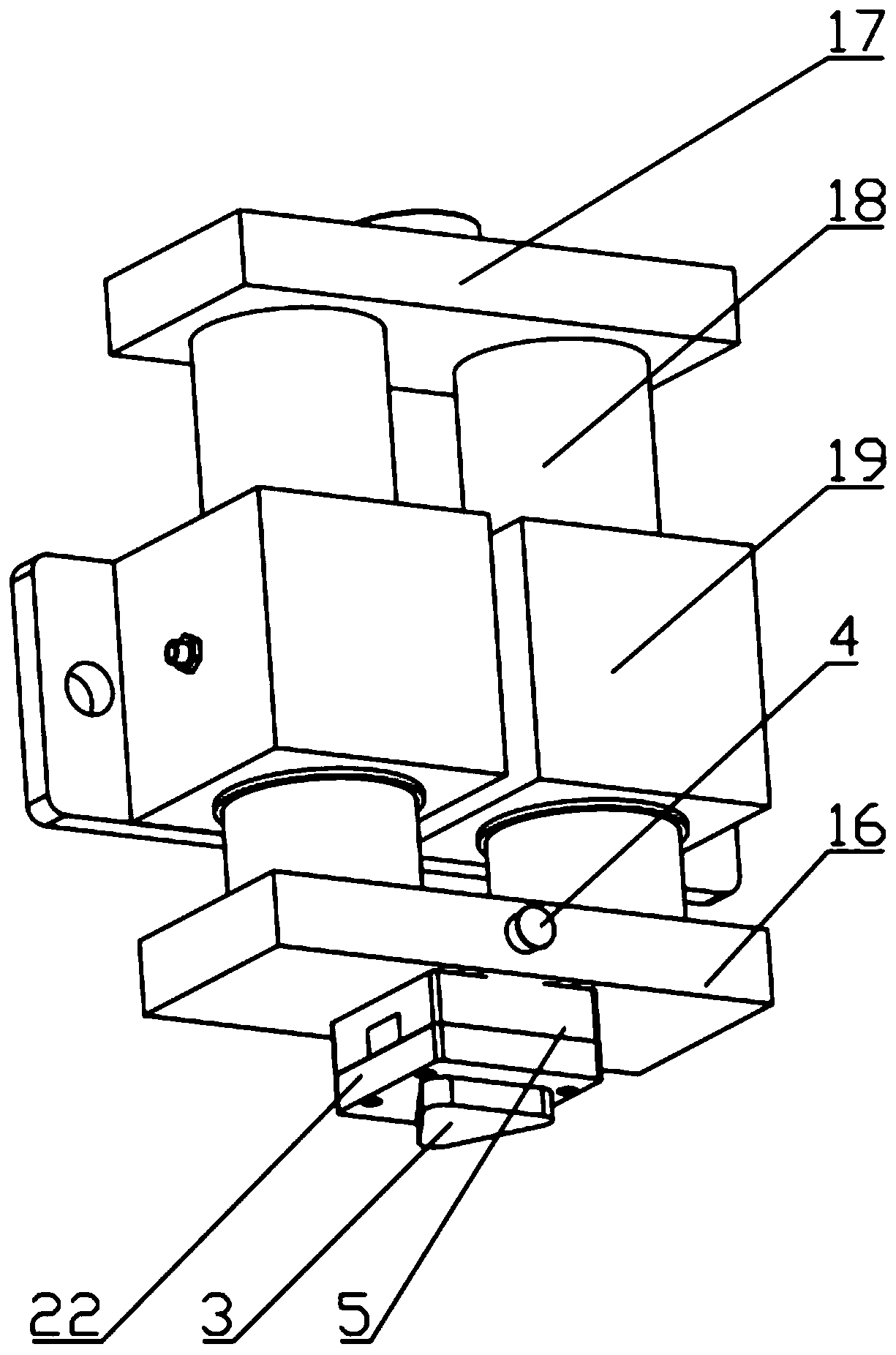

[0029] Combine below figure 1 , figure 2 The present invention will be described in detail. A rotary tribological behavior simulation test bench that realizes vibration decoupling, including a test bench base 1, a lower friction sample 2 is arranged on the test bench base 1, and an upper friction sample 2 is arranged above the lower friction sample 2. Friction sample 3, a rotation system is provided between the lower friction sample 2 and the test bench base 1, and the upper friction sample 3 is connected with a loading system, and the loading system is provided with an acceleration sensor 4 and a three-way force sensor 5.

[0030] In the above scheme, the rotating system is fixed on the base 1 of the test bench, the lower friction sample 2 is set on the rotating system, the rotating syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com