Laser Heating Assisted Micro-turning Device

A technology of laser heating and micro-turning, which is applied in the direction of auxiliary devices, turning equipment, turning equipment, etc. It can solve the problems of precision micro-cutting of difficult-to-machine materials, burrs on the machined surface, and tool fracture failure, so as to reduce mechanical properties and improve wear. Severe, reducing cutting force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

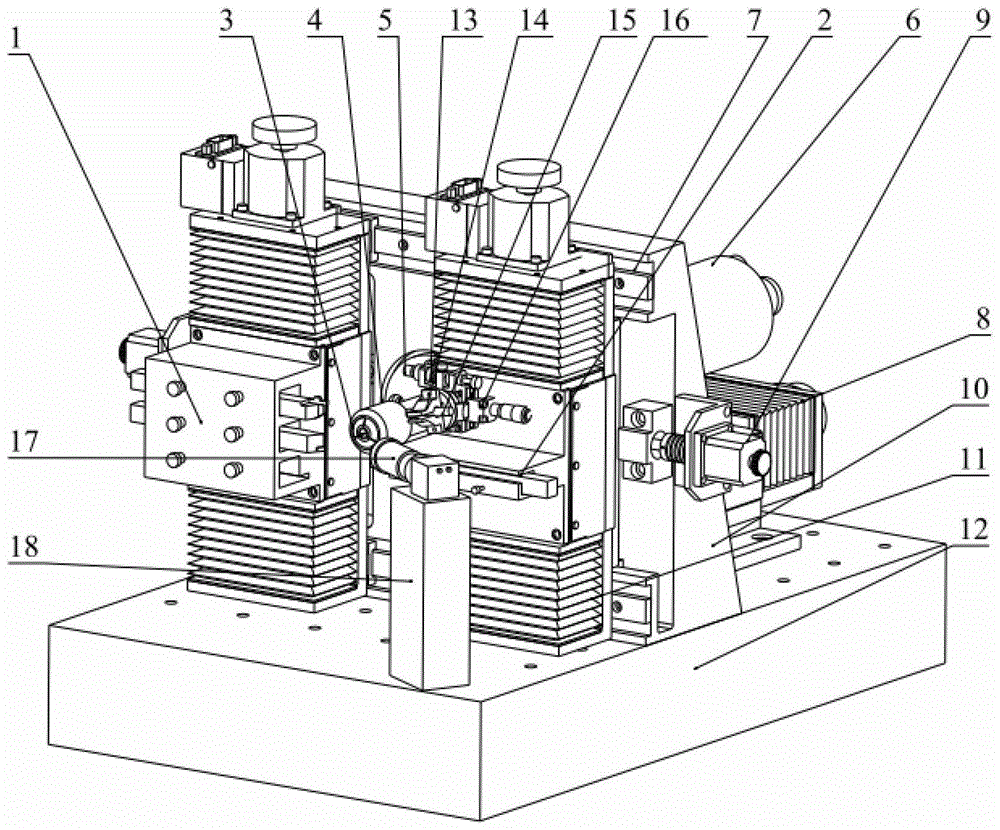

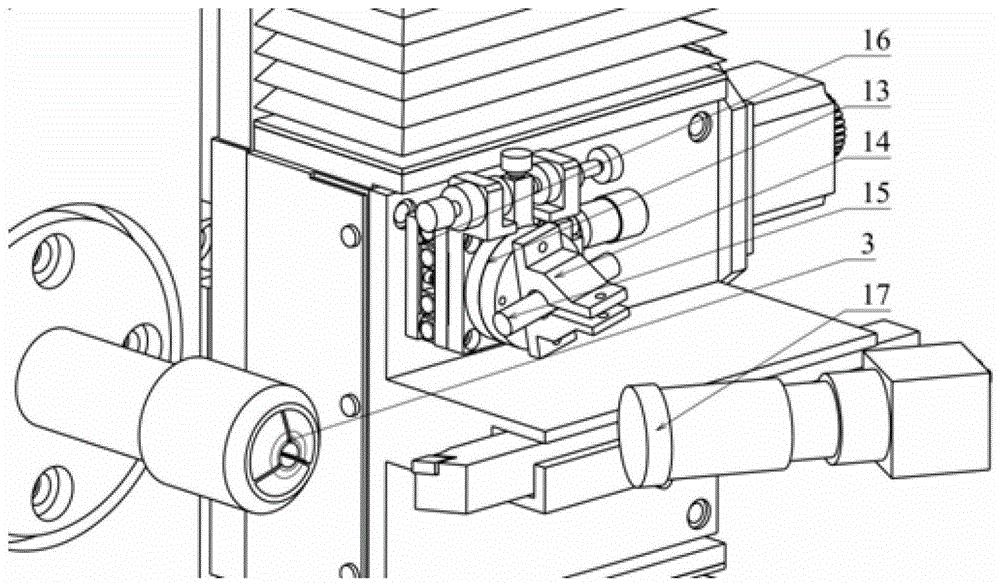

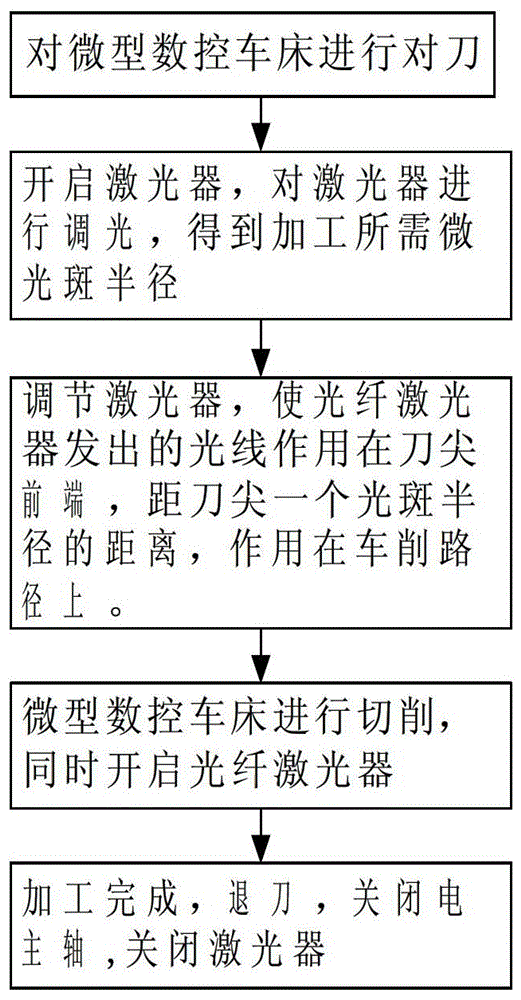

[0014] The miniature slitting double-knife row turning machine tool includes a shock absorbing platform 12, a support unit, a spindle unit, a turning unit and a computer control system; the support unit is fixed on the shock absorbing platform 12, and the spindle unit is fixed on the shock absorbing platform 12. on the vibration platform 12, and pass through the support unit, the turning unit includes two subunits with the same structure, and the two subunits with the same structure are respectively located on both sides of the main shaft and fixed on the support unit, The two sub-units are respectively placed with a symmetrical tool 2 relative to the main shaft in the main shaft unit; the main shaft unit can realize feeding along the main shaft direction, and the turning unit can realize the movement in the left and right and up and down directions; the computer contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com