A finishing milling tool

A milling tool and milling technology, which is applied in the direction of milling cutters, manufacturing tools, metal processing equipment, etc., can solve the problems of lower precision requirements, difficult finishing machining, and easy vibration, so as to reduce cutting force and cutting vibration and ensure machining Surface quality, the effect of eliminating residual steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

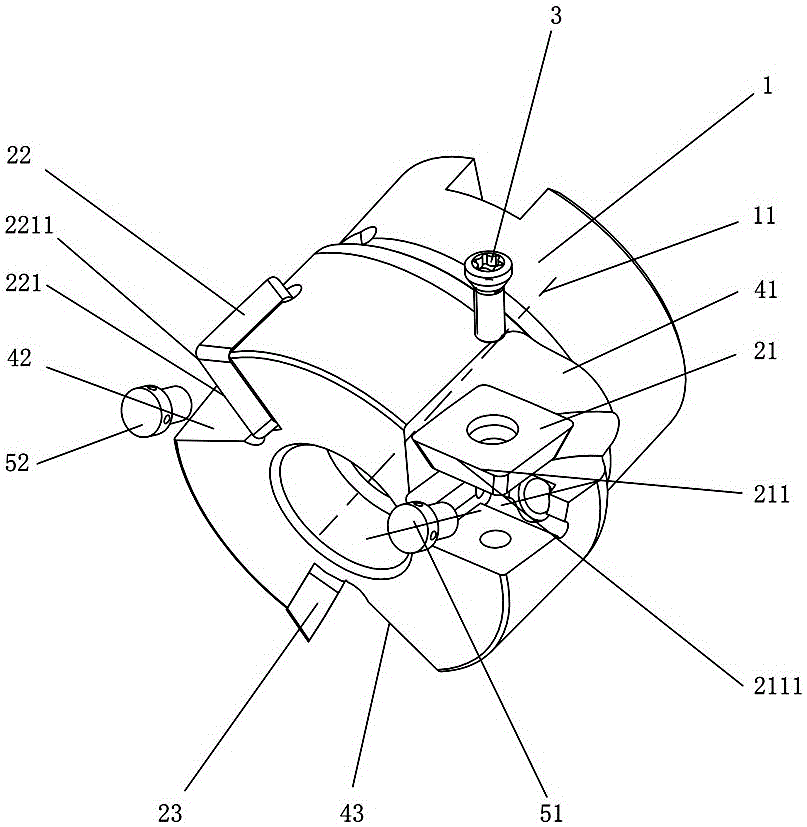

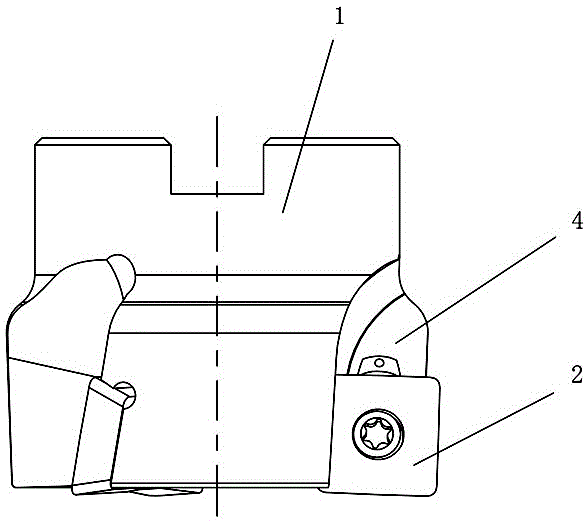

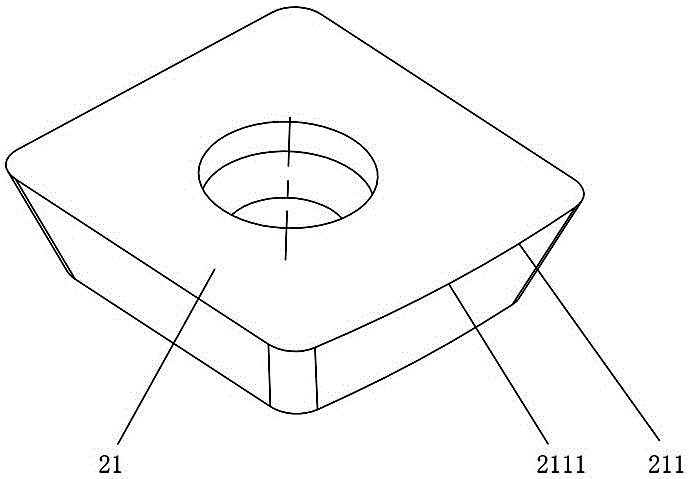

[0031] Figure 1 to Figure 8 The first embodiment of the finishing milling tool of the present invention is shown, the finishing milling tool comprises a cutter body 1, a cutting tool set 2 and a knife set fastener 3, the cutter body 1 is provided with a sipe 4, and the cutting tool The group 2 is installed in the knife groove 4 through the knife group fastener 3. The cutting tool group 2 includes a first fine cutting blade 21 and a second fine cutting blade 22. The first fine cutting blade 21 is provided with a first arched cutting blade. Edge 211, the second fine cutting blade 22 is provided with the second arched cutting edge 221 corresponding to the first arched cutting edge 211, that is, if the peripheral cutting surface of the first fine cutting blade 21 is provided with the first arched cutting edge Edge 211, the second arc cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com