Complicated curved face milling, grinding and measuring integrated machining machine tool and forming method

A technology for complex curved surfaces and machine tools, applied in manufacturing tools, other manufacturing equipment/tools, etc., can solve the problems of low efficiency and difficult to maintain precision of CNC milling machines, and achieve the effect of improving surface quality and reducing cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

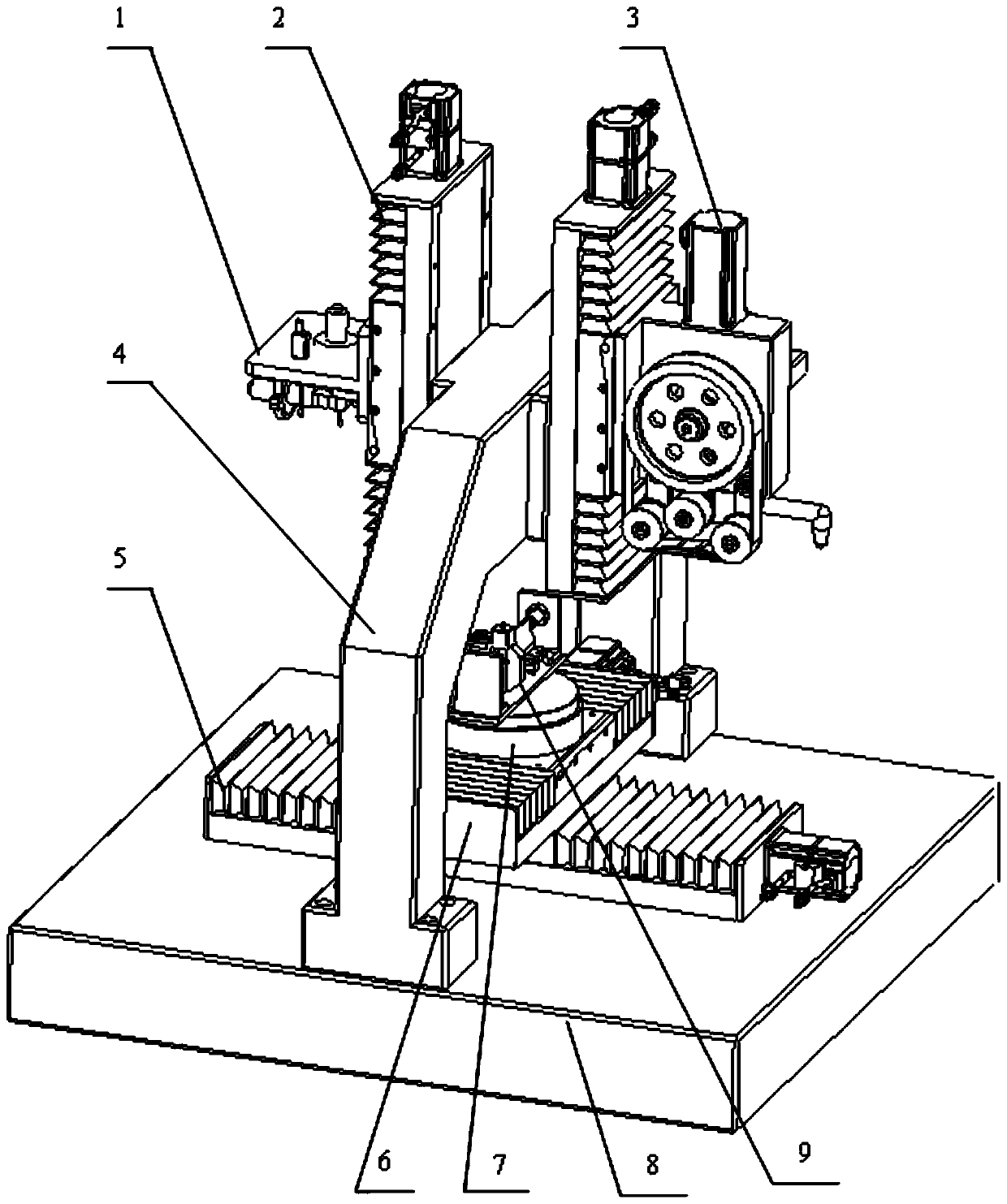

[0045] figure 1 It is a schematic diagram of the overall structure of the present invention, including ultrasonic processing system 1, Z-direction slide table 2, grinding and polishing assembly 3, gantry 4, X-direction slide table 5, Y-direction slide table 6, rotary table 7, base 8, fixture and the workpiece 9, wherein the gantry 4 is fixedly connected to the base 8, the X-direction slide table 5 is fixedly connected to the base 8, the Y guide rail 6 is fixedly connected to the slide table of the X guide rail 5, and the rotary table 7 is fixedly connected to the Y guide rail 5. On the sliding table of the guide rail 6, the fixture and the workpiece 9 are fixedly connected to the rotary table 7. There are two Z-direction sliding tables 2, which are respectively fixedly connected to the left and right sides of the middle of the gantry 4. The ultrasonic processing system 1 is fixedly connected to the left On the slide table of the Z-direction slide table 2 on the side, the grind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com