Patents

Literature

210results about "Stepped drills" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

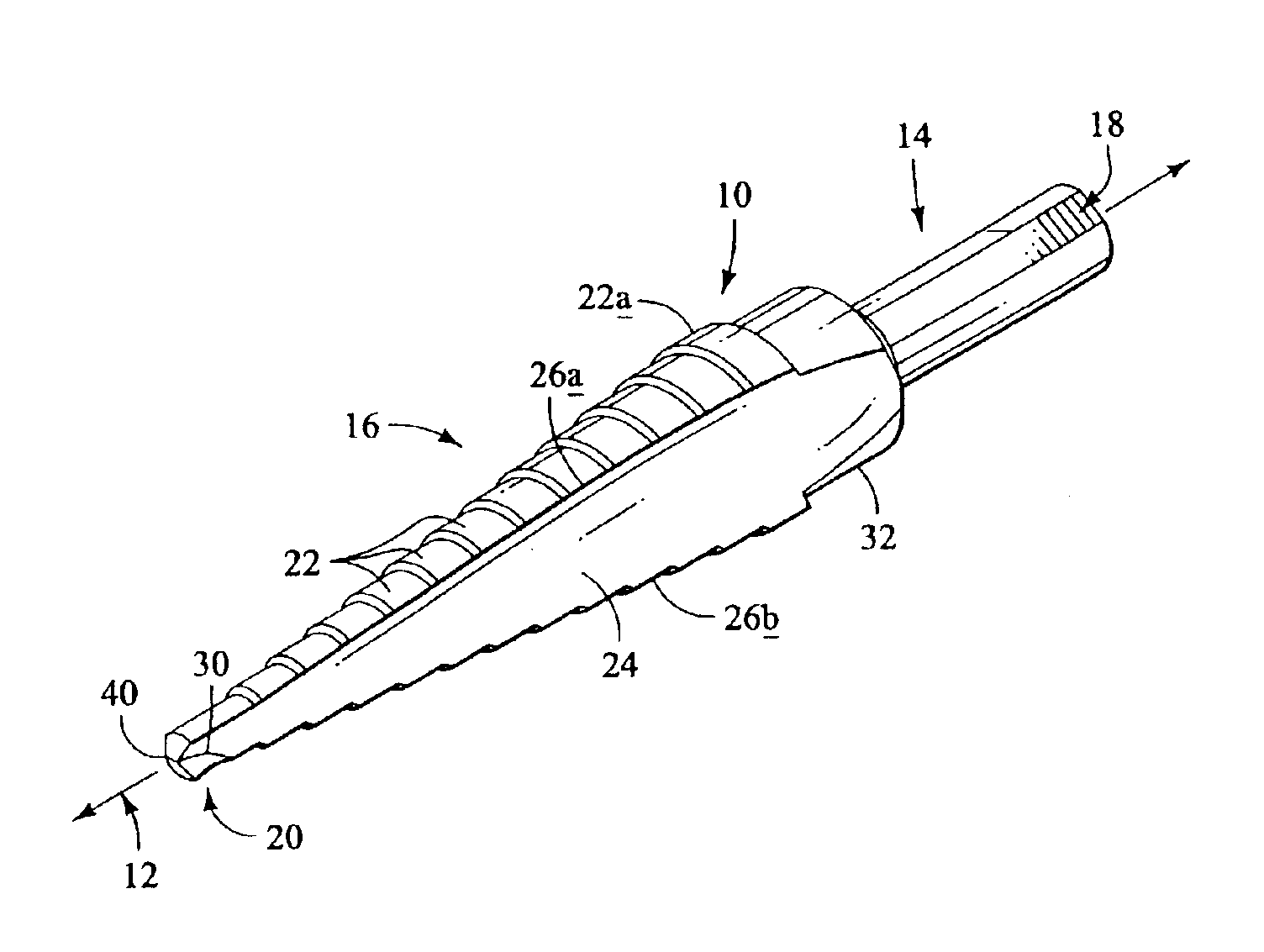

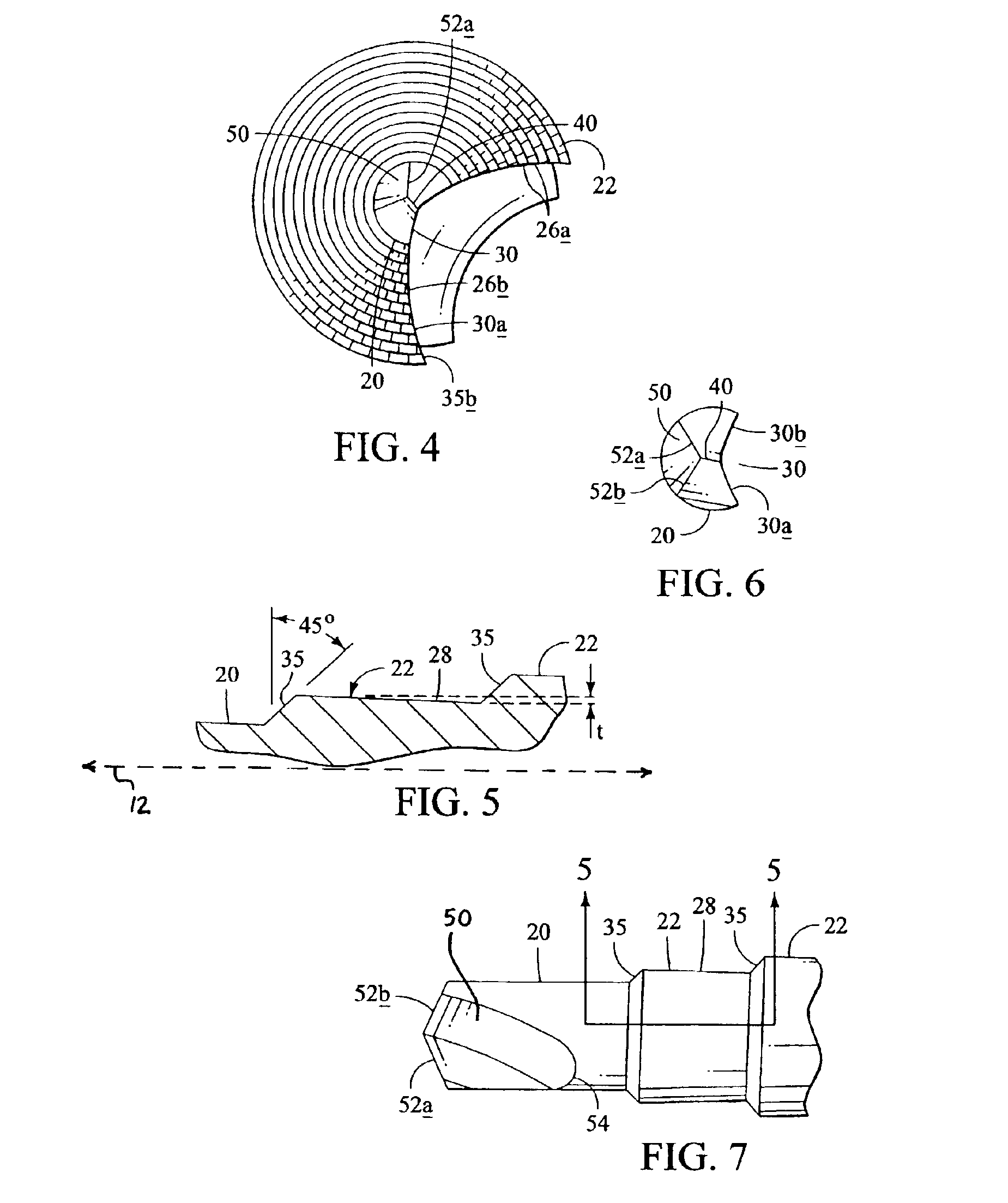

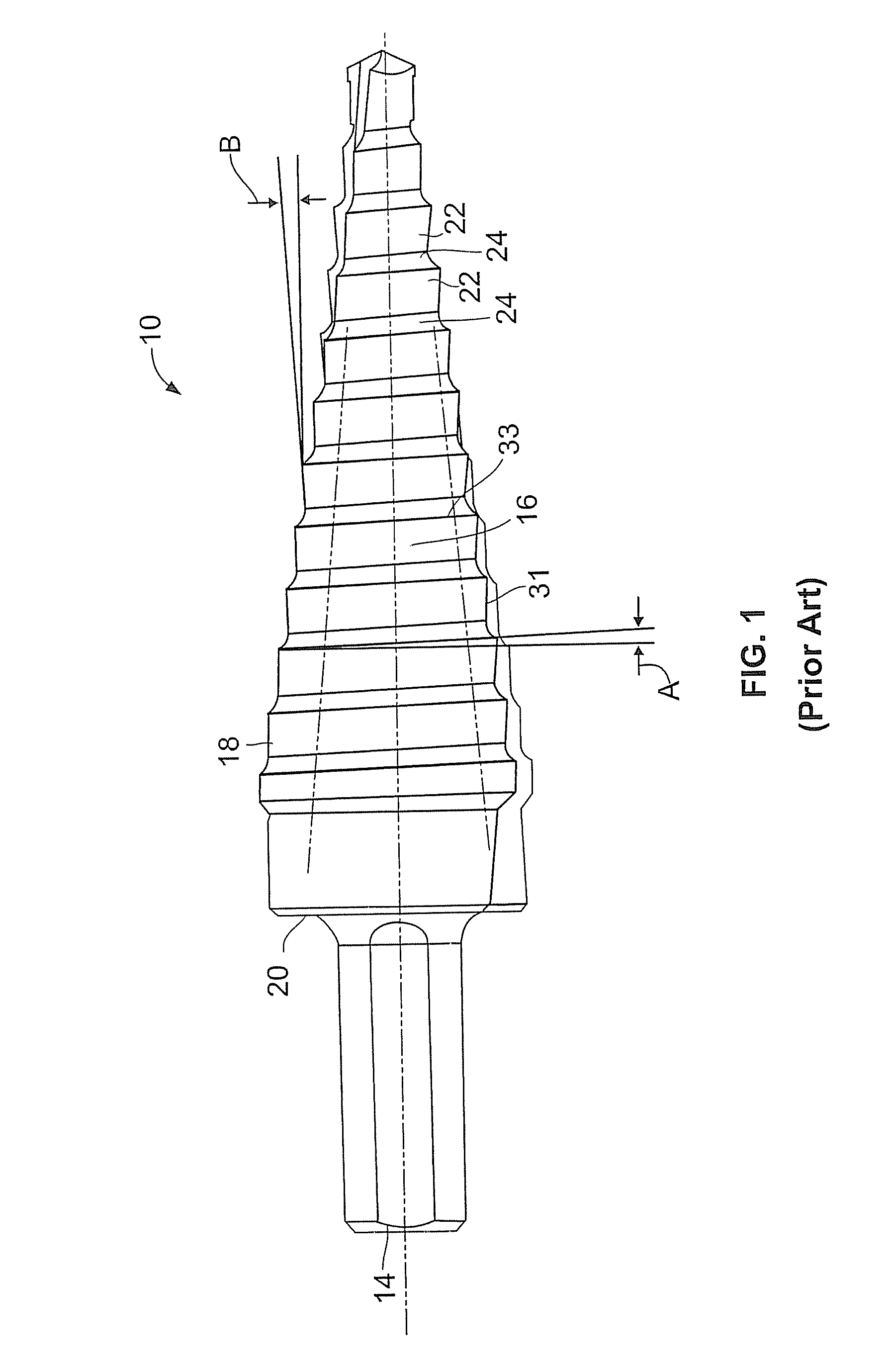

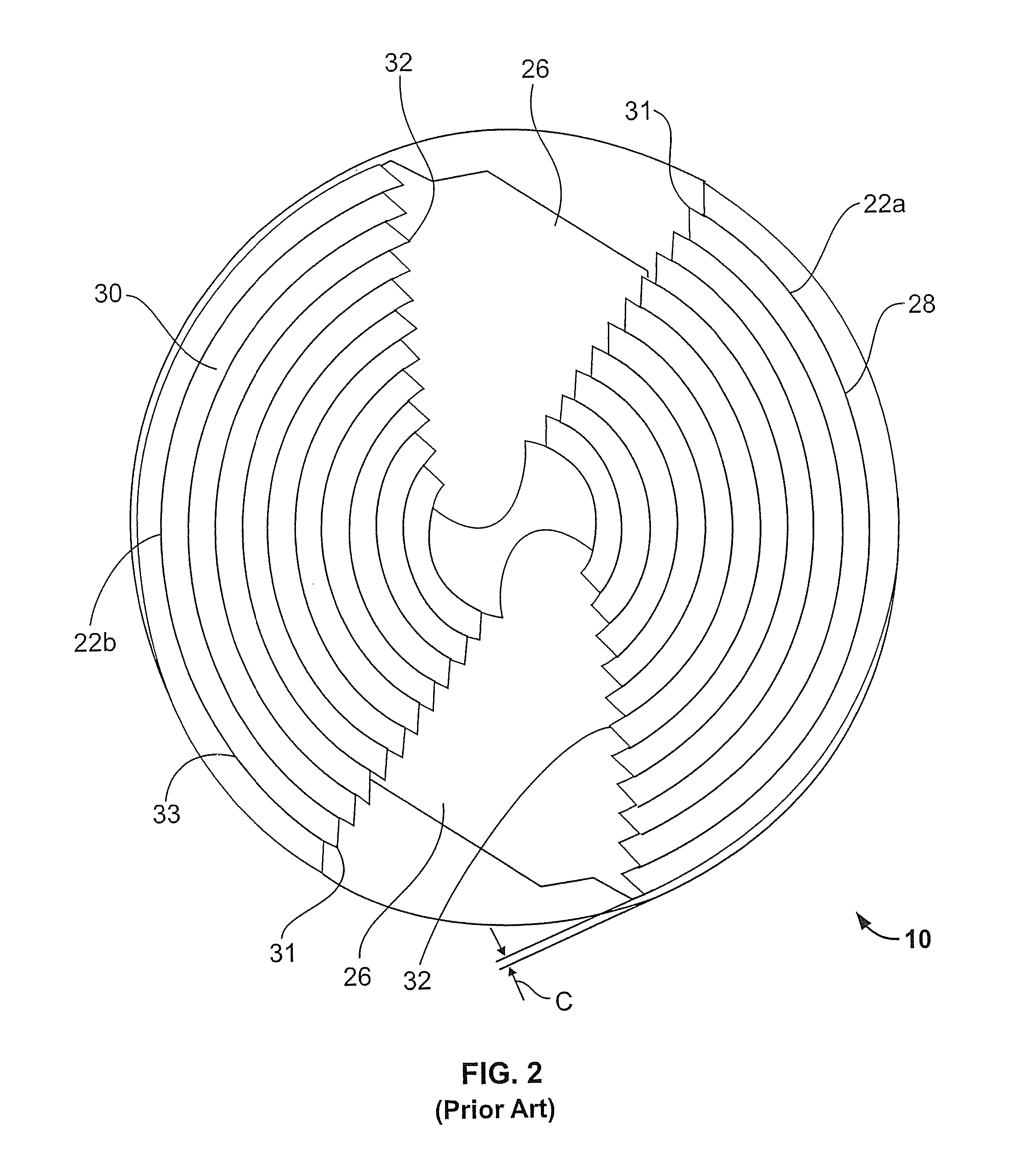

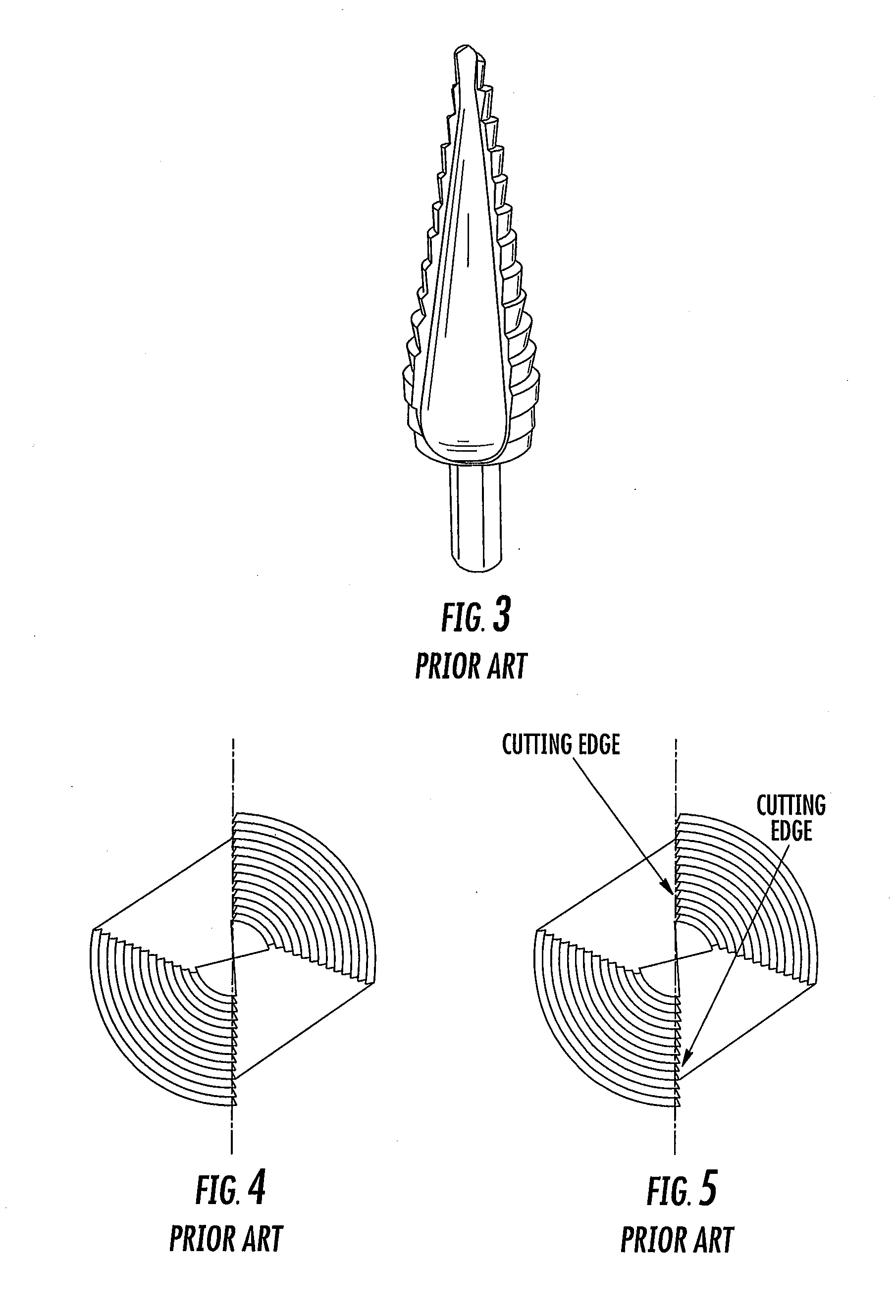

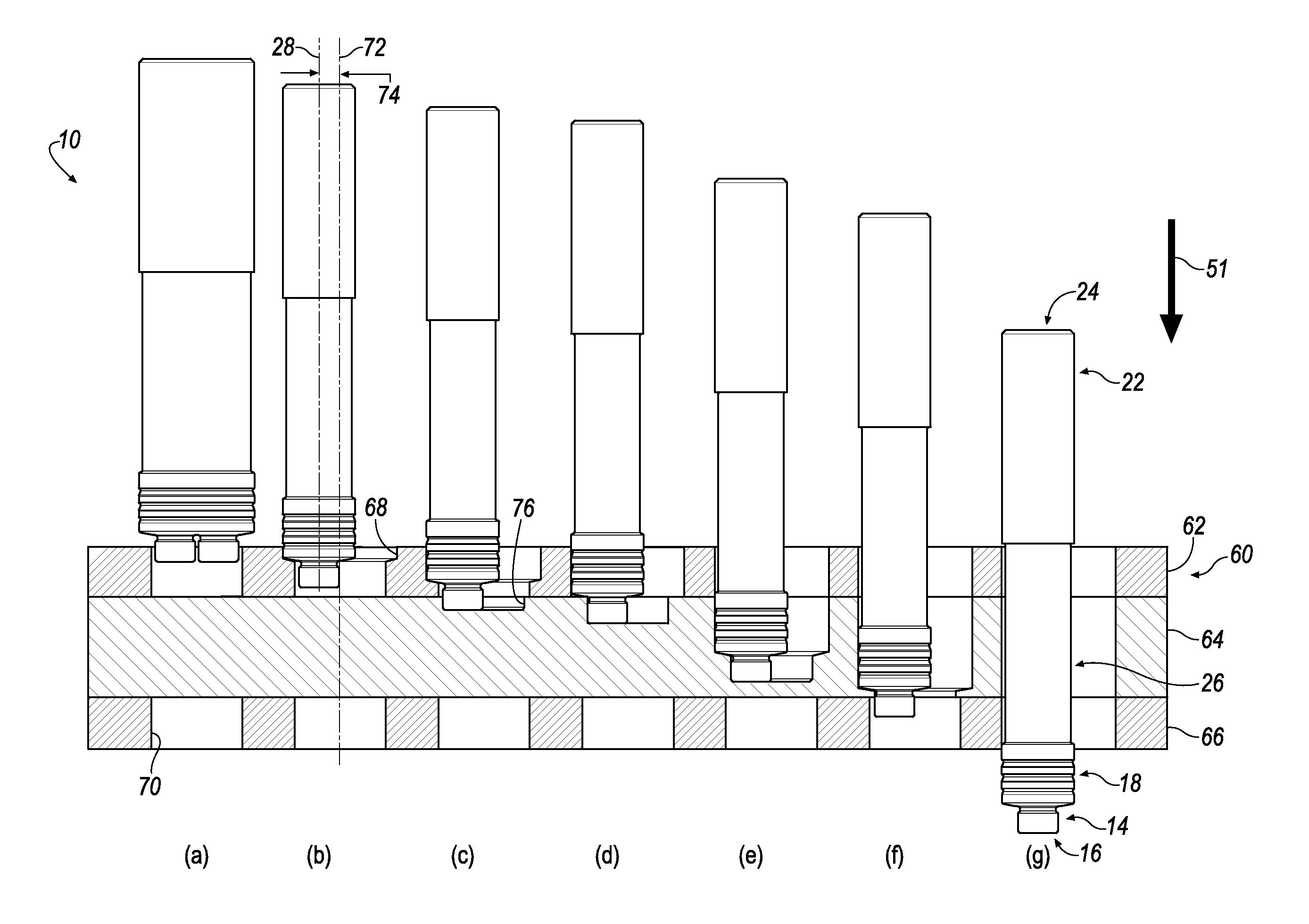

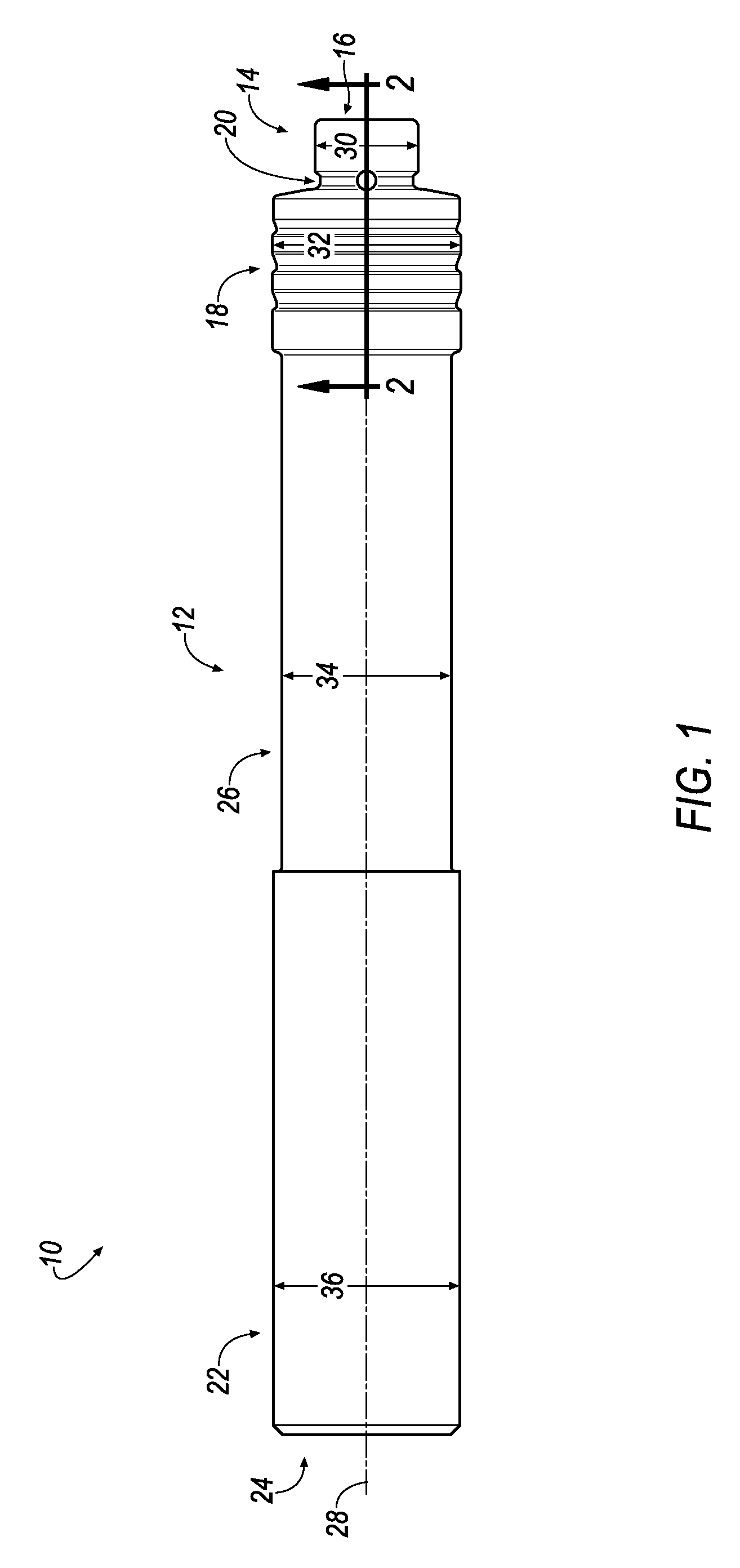

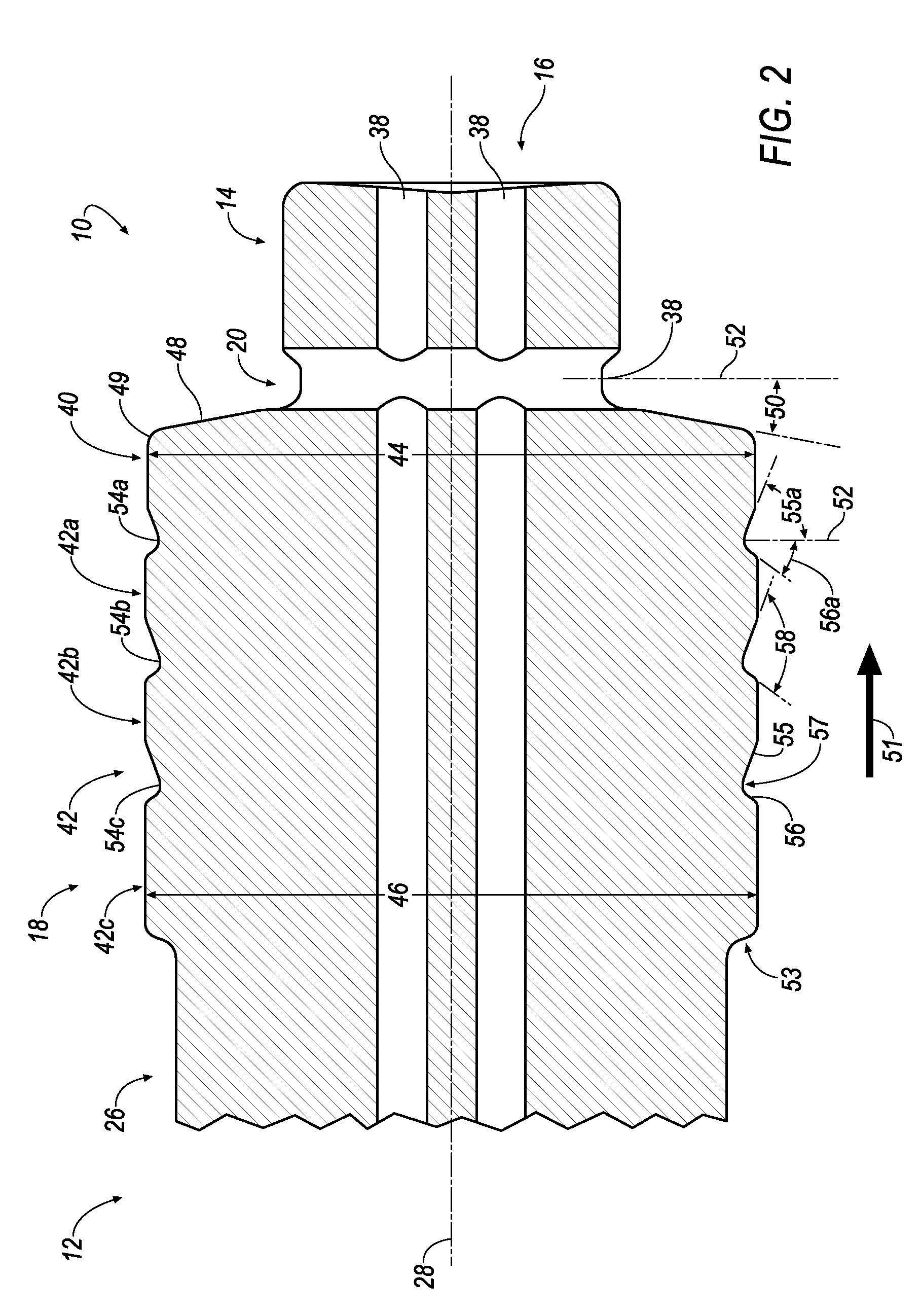

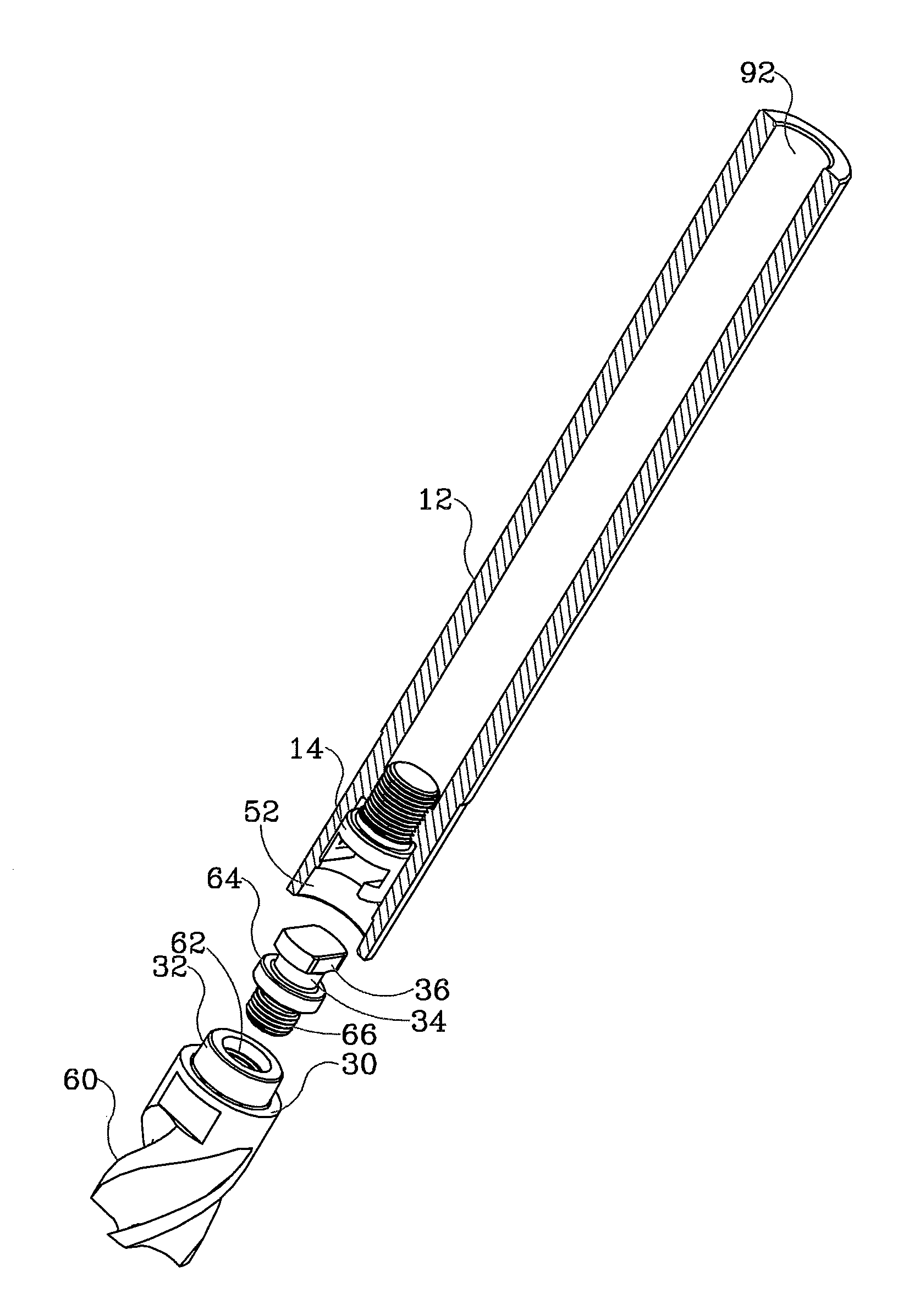

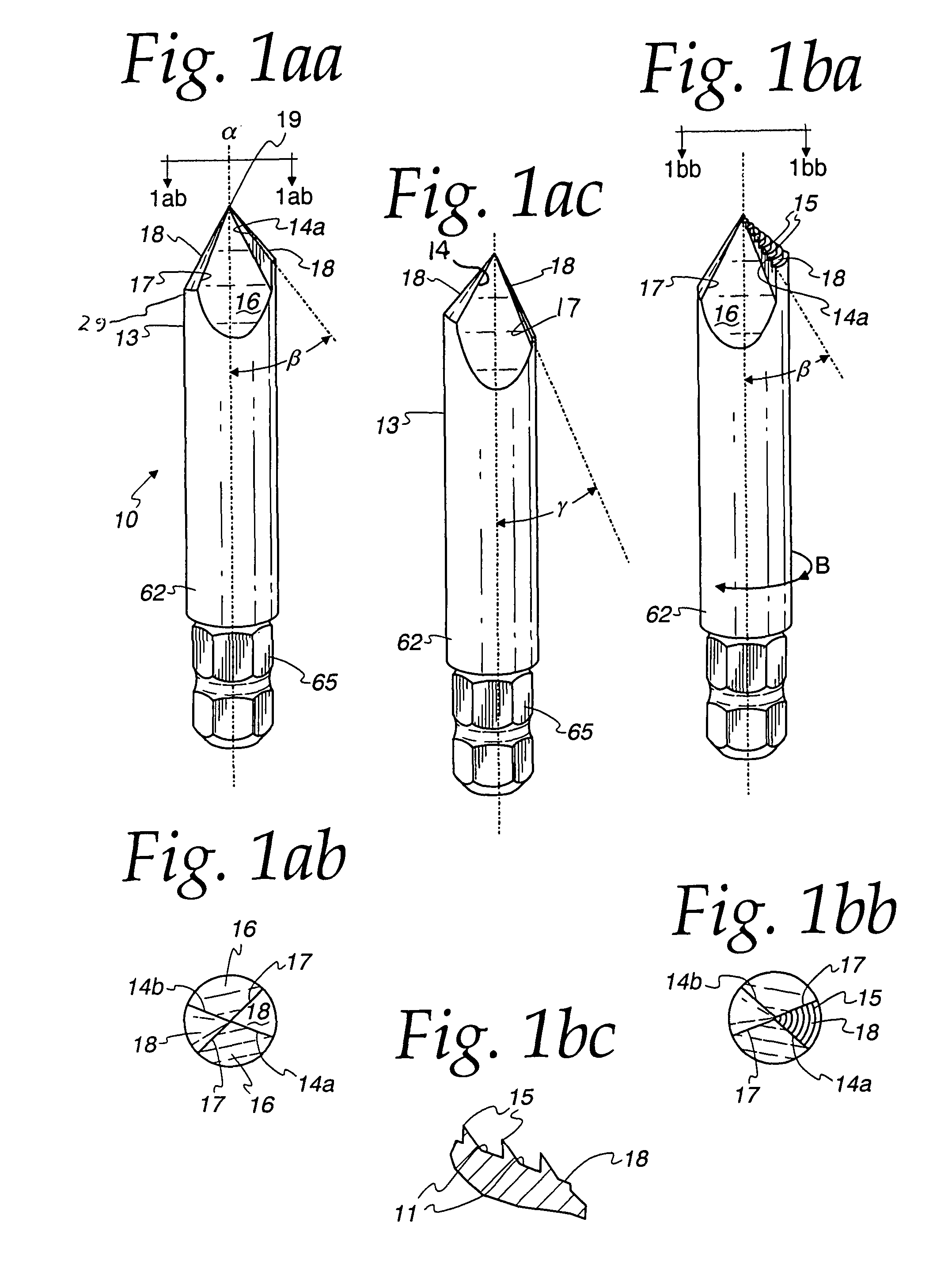

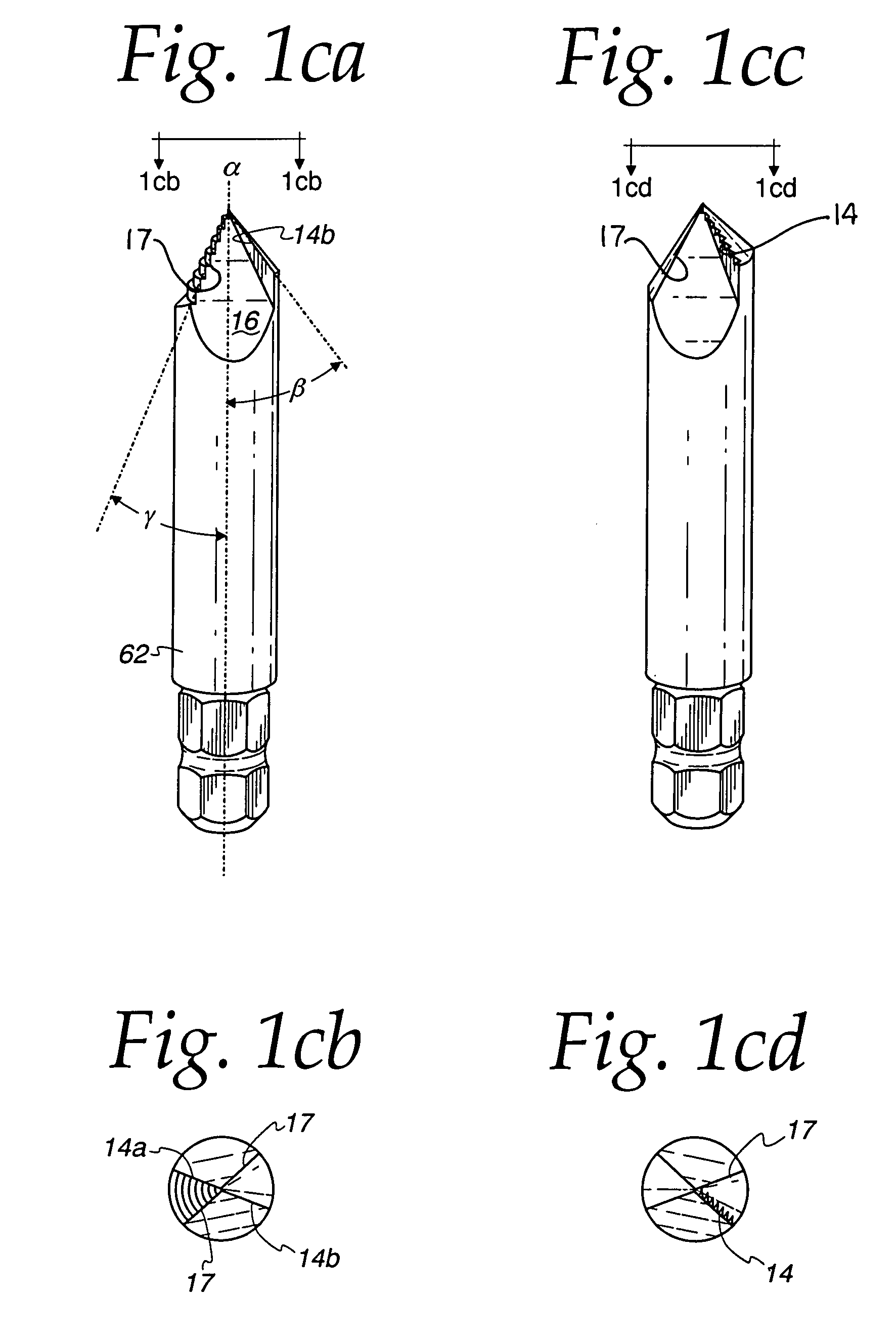

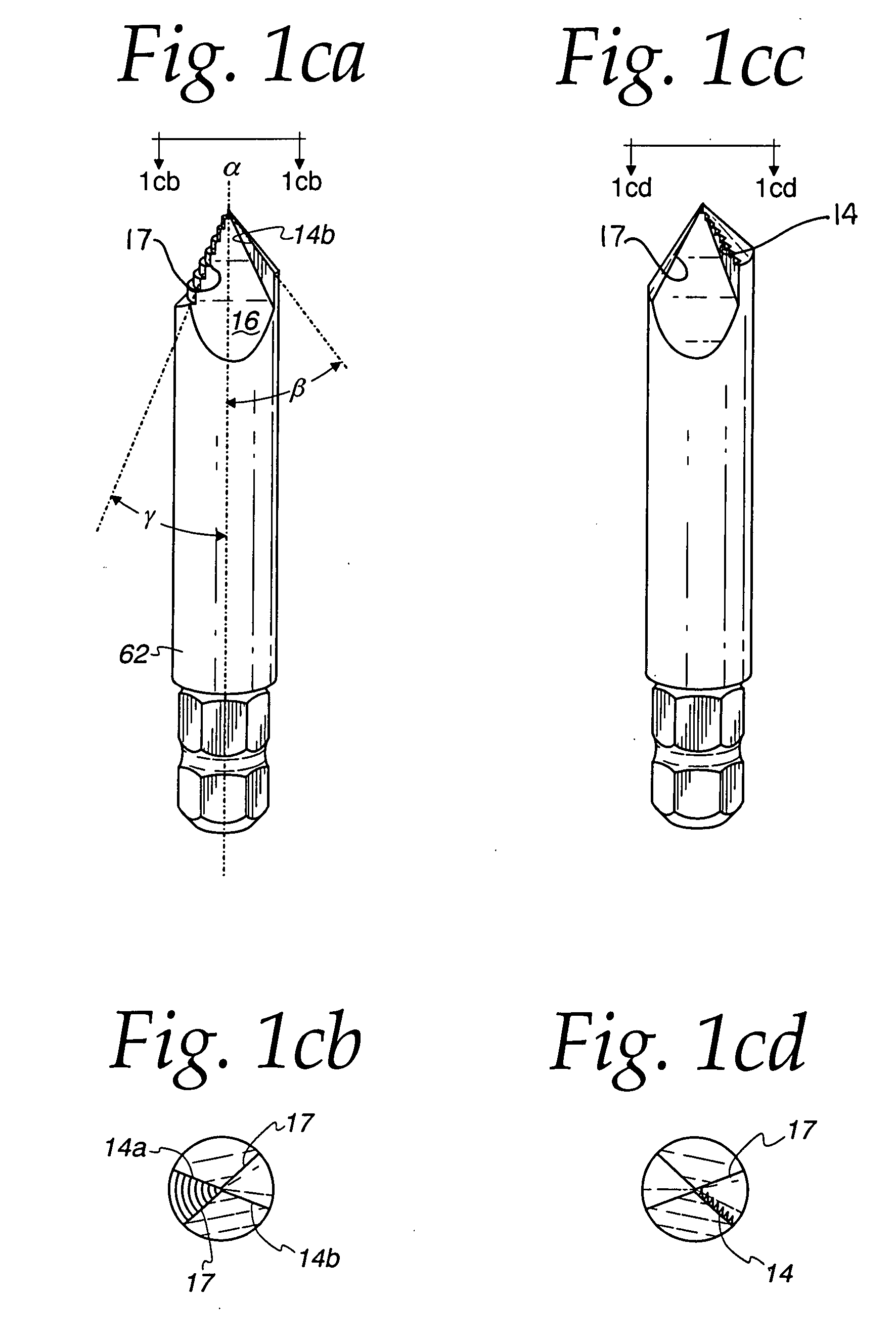

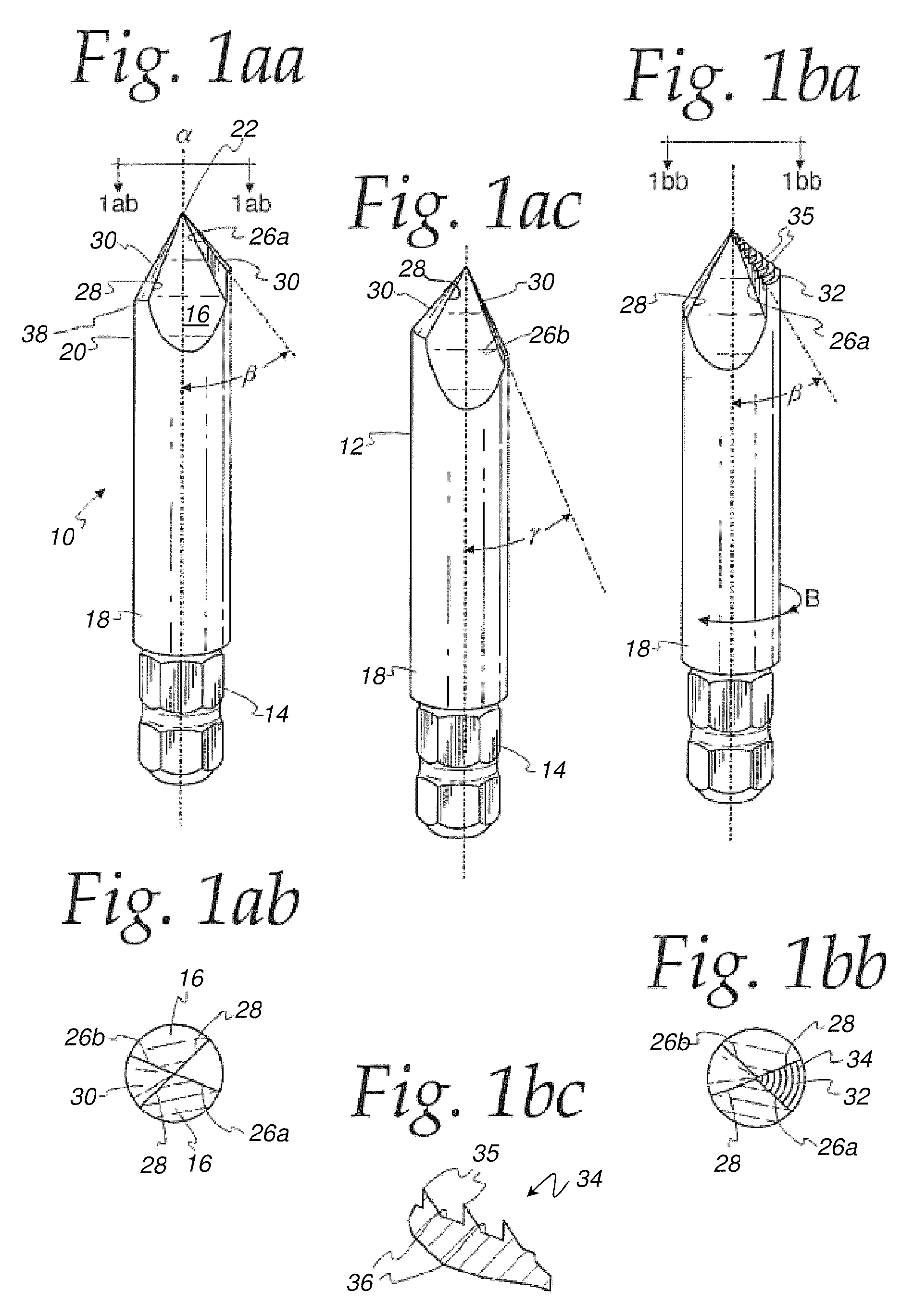

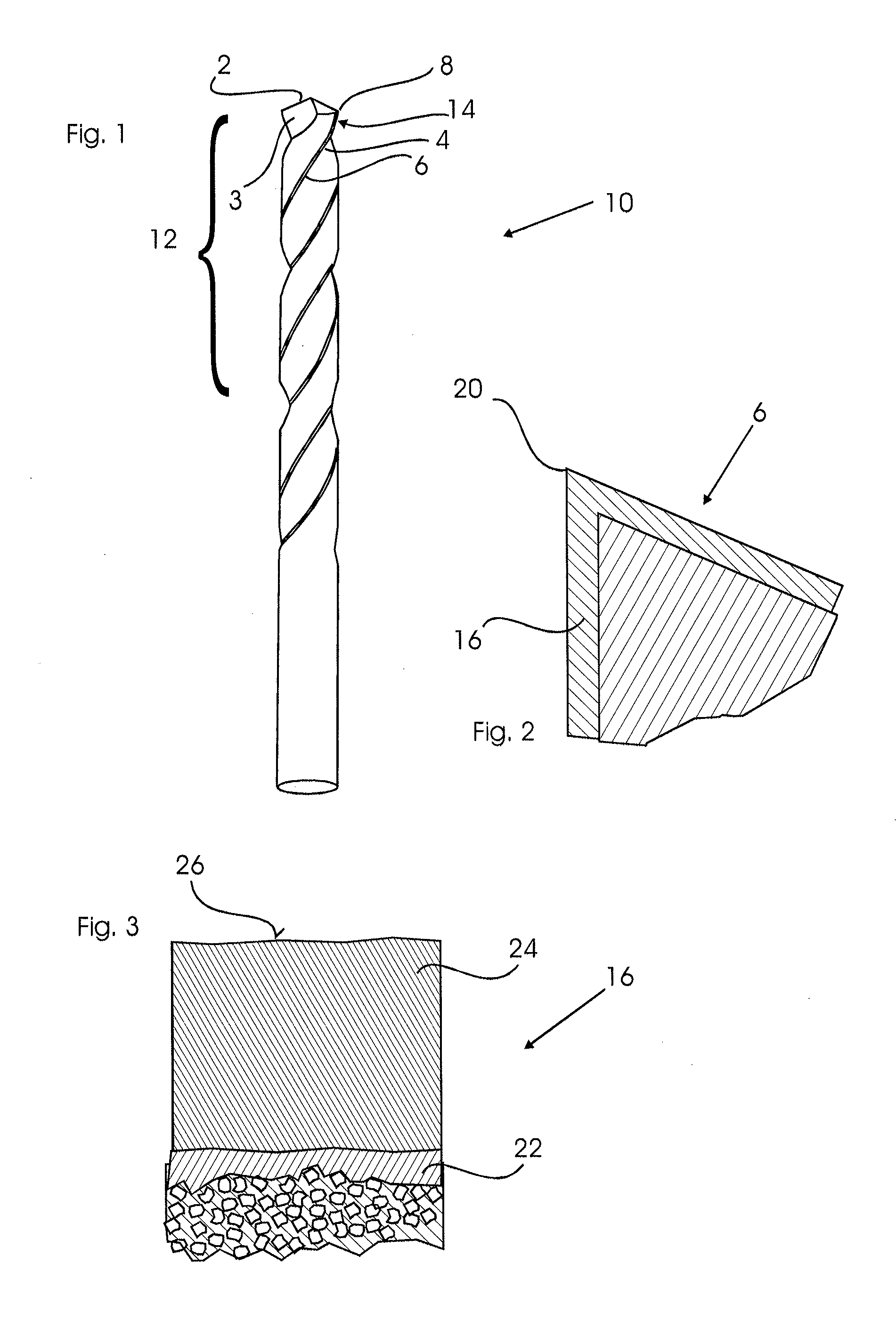

Stepped drill bit having split tip

InactiveUS6890133B2Maintain convenienceEffectively bore holeWood turning toolsTransportation and packagingEngineeringMechanical engineering

A drill bit is disclosed having a cutting portion having a plurality of axially aligned, graduated cutting members. Each of the members has cutting edges defined by a single slot extending therethrough. A tip portion at one end of the cutting portion defines at least a pair of cutouts therein, wherein one of the cutouts is aligned with the slot.

Owner:BLACK & DECKER INC

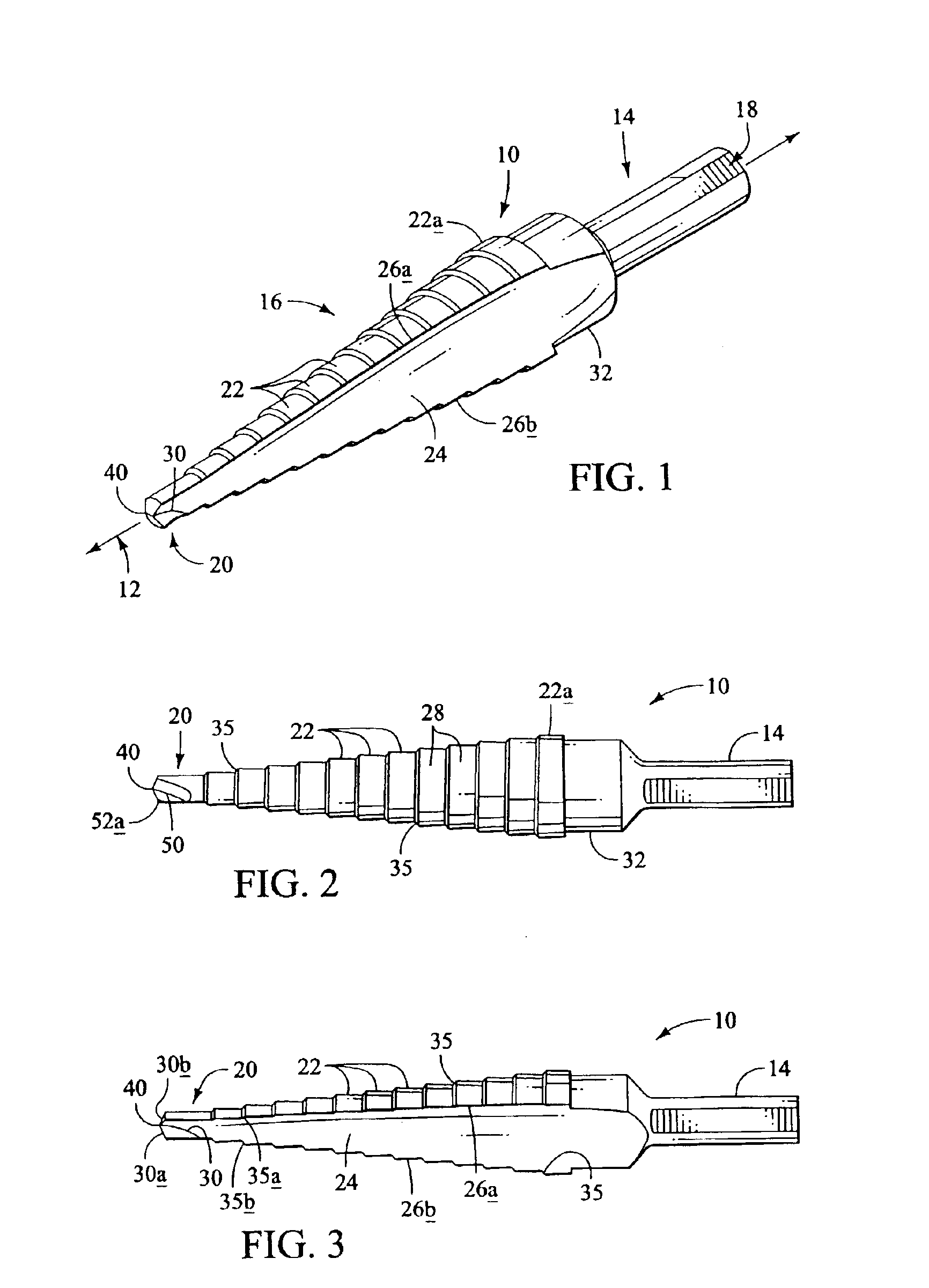

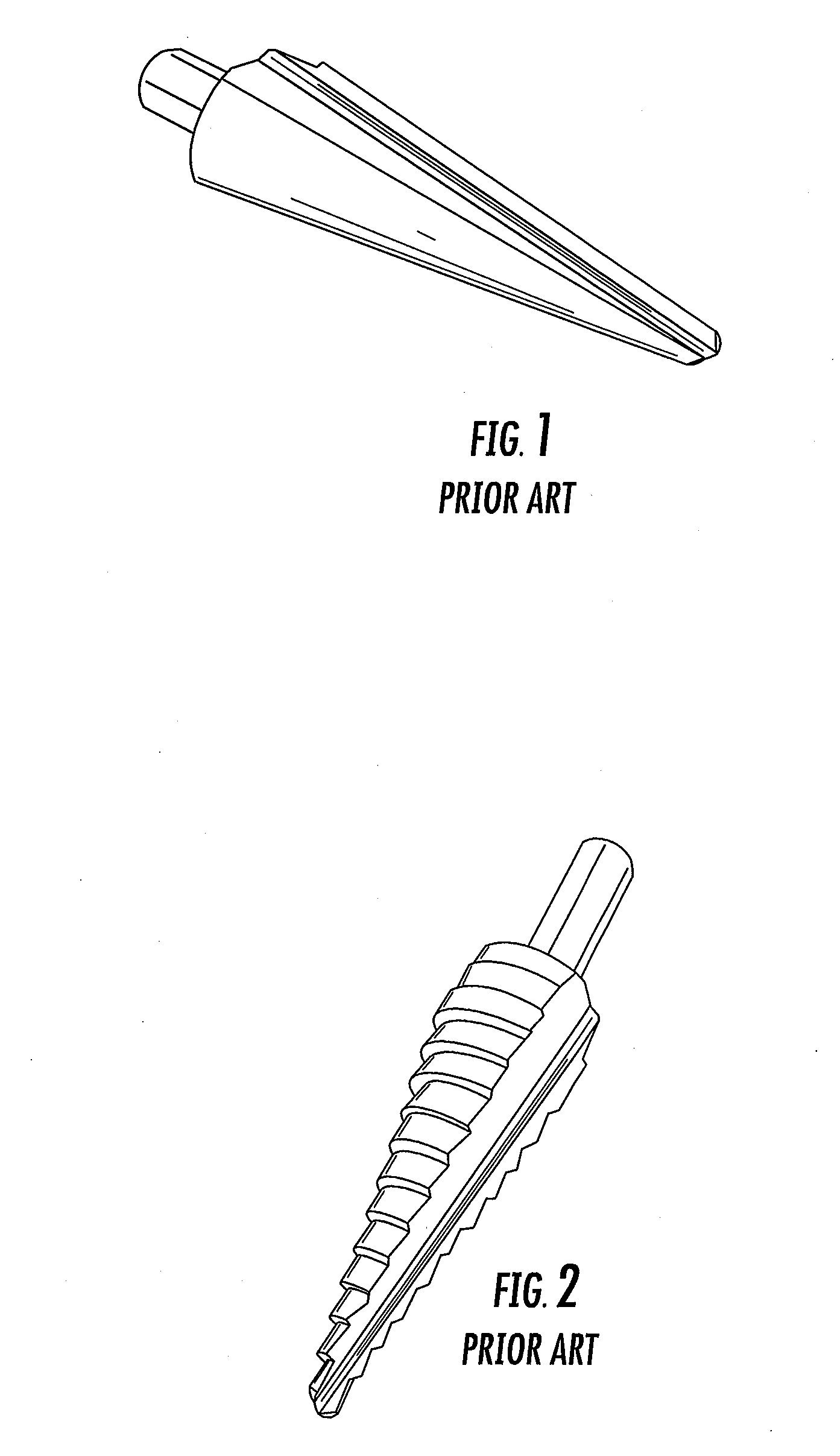

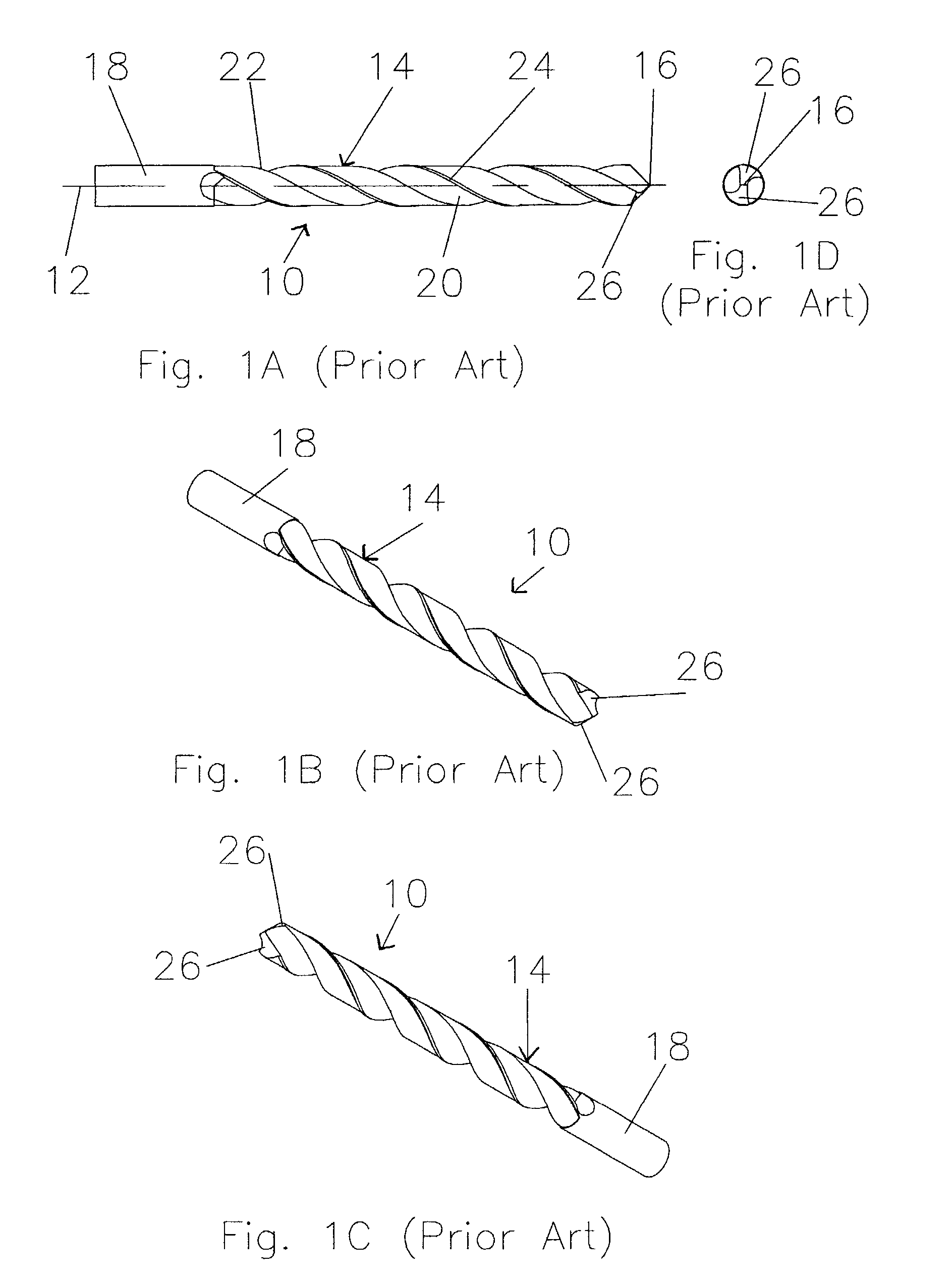

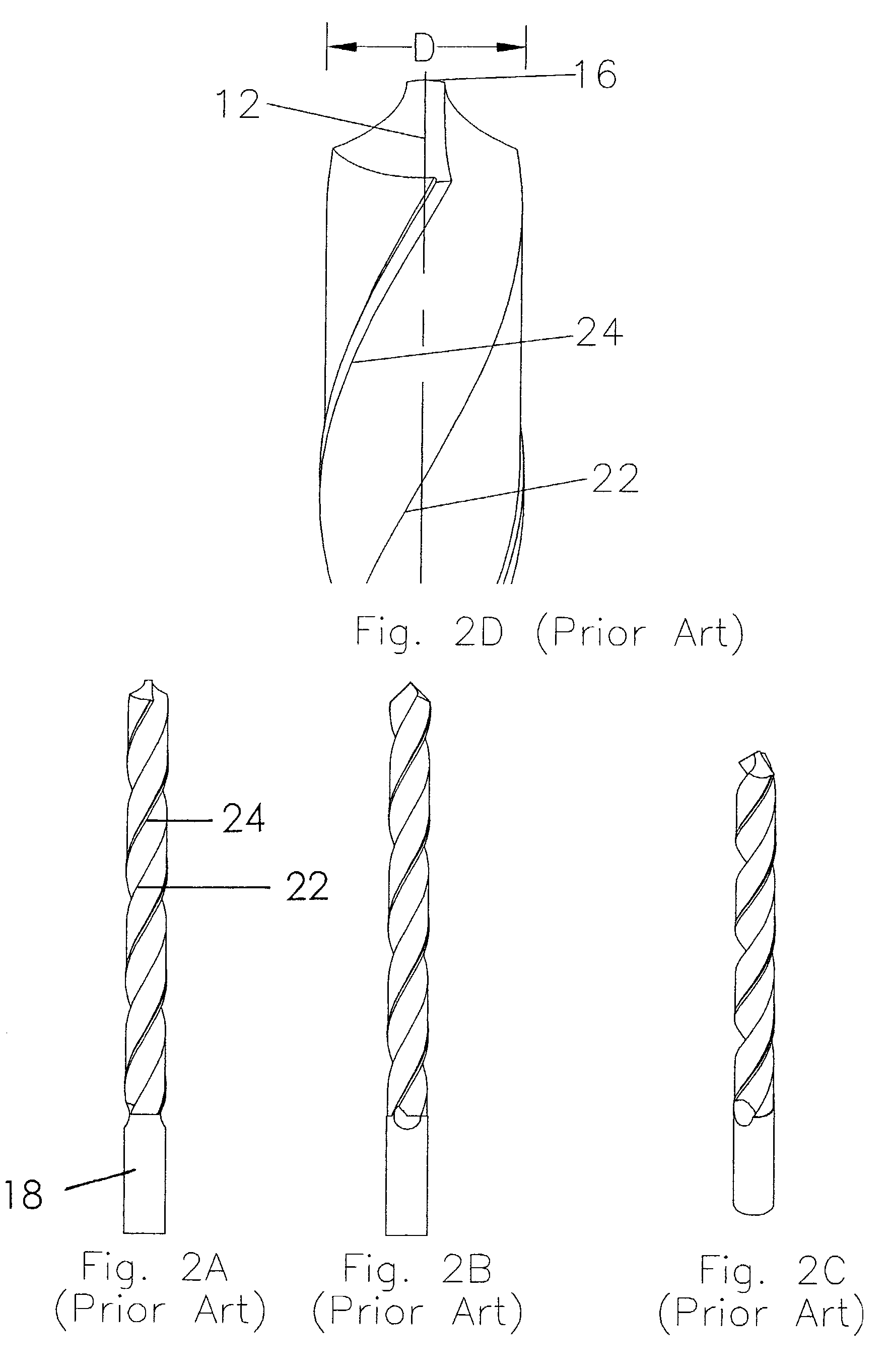

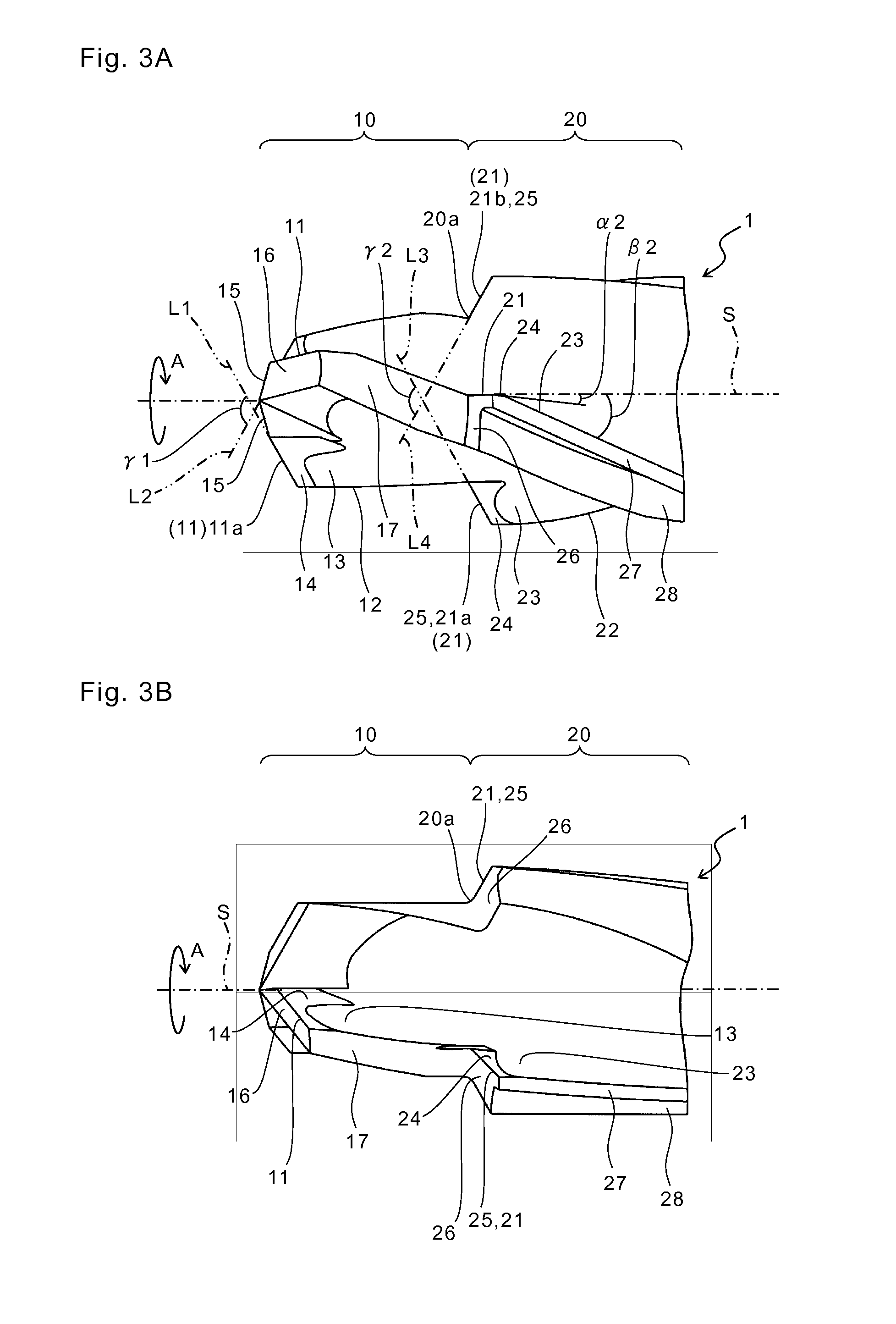

Spiral drill bit and method of forming same

ActiveUS20080166195A1Minimizes amount of grindingShorten the timeWood turning toolsMetal-working drilling toolsFluteEngineering

A spiral drill bit for forming holes of a variety of sizes has a main body which provides first and second helical grooves. First and second flutes extend along the length of the main body to provide first and second helical groove segments. Cutting segments are provided between the helical groove segments. The method for forming the spiral drill bit includes turning the helical groove segments onto a round stock. An axial clearance and an initial diametral clearance are provided upon turning the helical grooves. A grinding process is used to form a radial clearance and a final diametral clearance. The reduction to the amount of grinding required to form the spiral drill bit results in a reduction to the cost of production and a reduction in the time necessary to produce the spiral drill bit.

Owner:GREENLEE TEXTRON

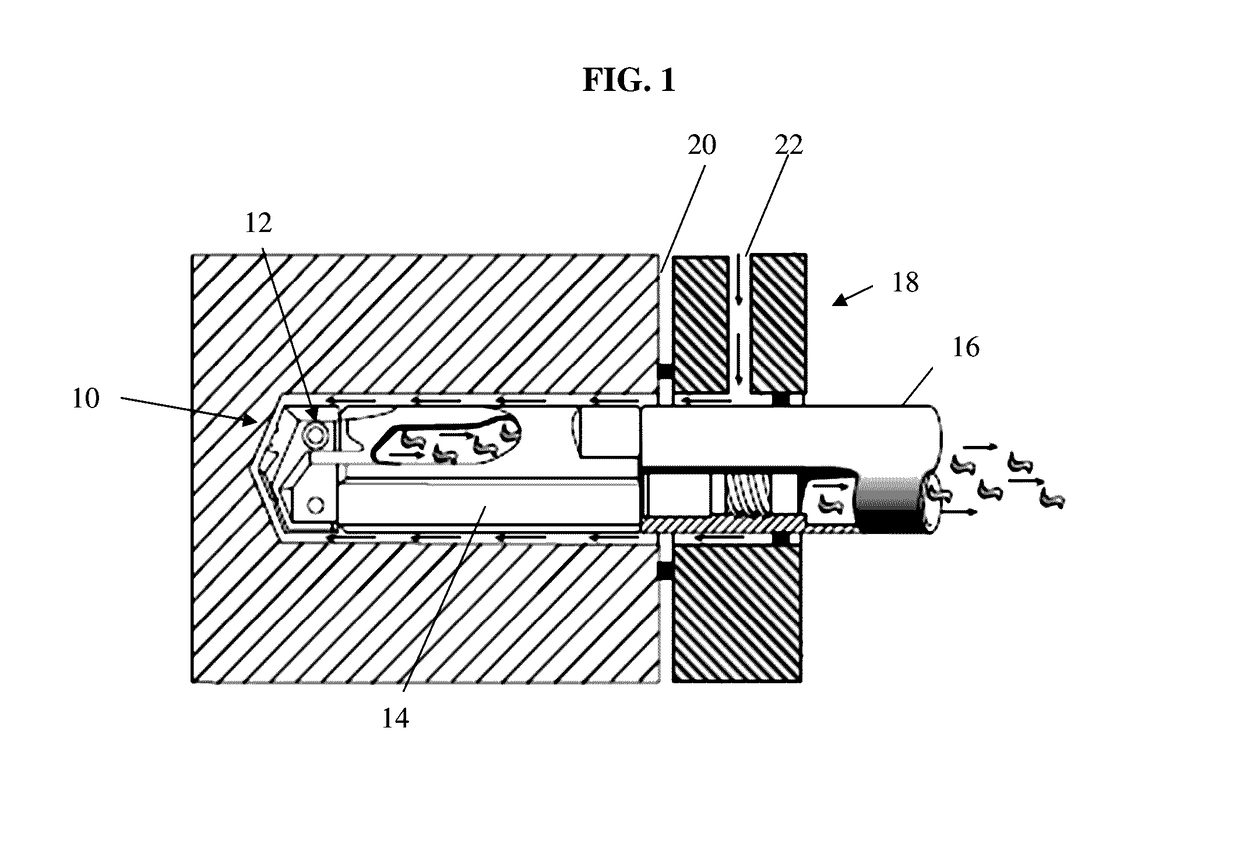

Drill bit

InactiveUS20120195704A1Addressing slow performanceGuaranteed uptimeWood turning toolsTransportation and packagingEngineeringMechanical engineering

A drill bit for cutting successively larger holes in a substrate includes a conically-shaped body having first and second cutting flutes extending along the length of the body. The first cutting flute includes a first cutting edge and the second cutting flute includes a second cutting edge. The first and second cutting edges are offset relative to each other to create a cutting angle adapted to reduce chatter.

Owner:WHITE CHRISTOPHER L

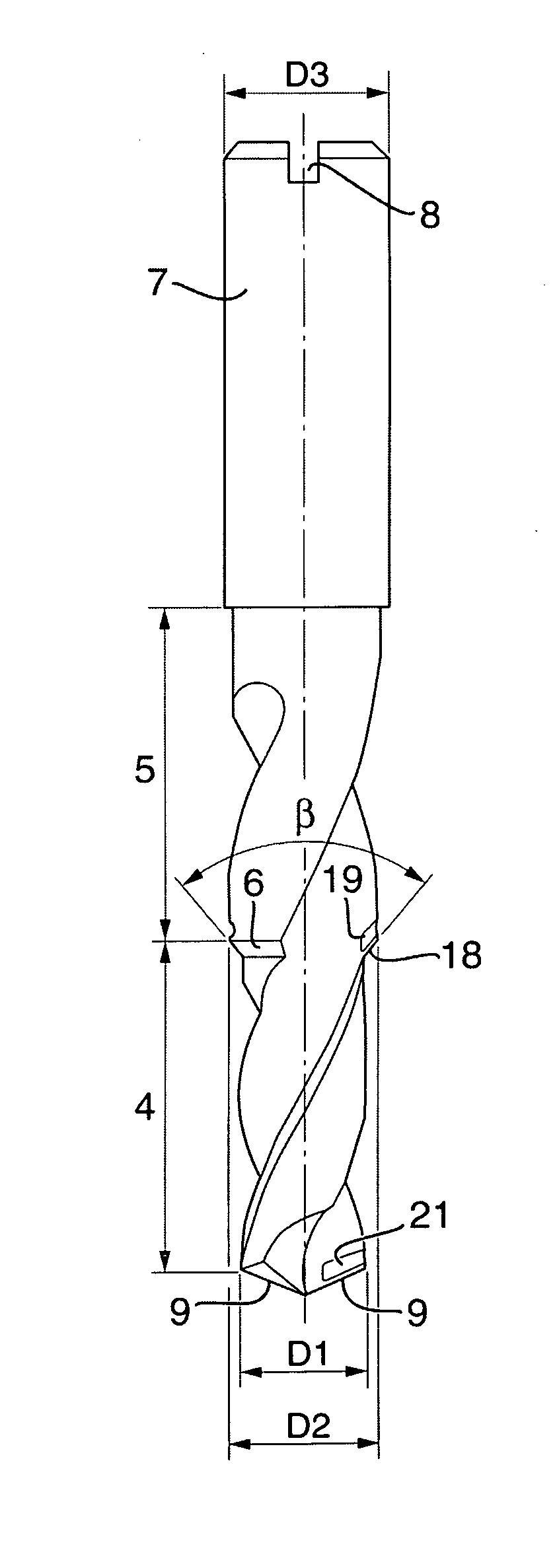

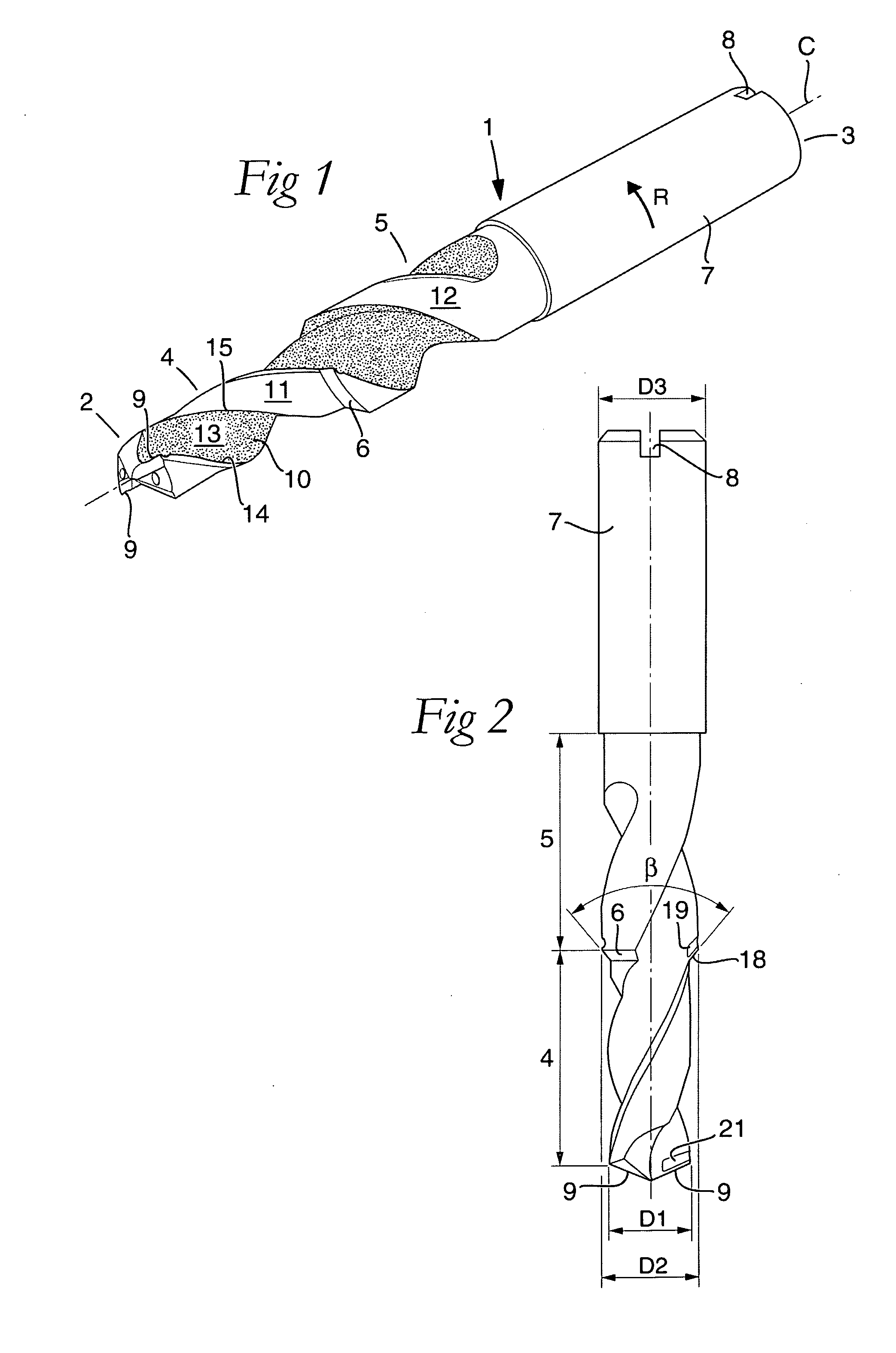

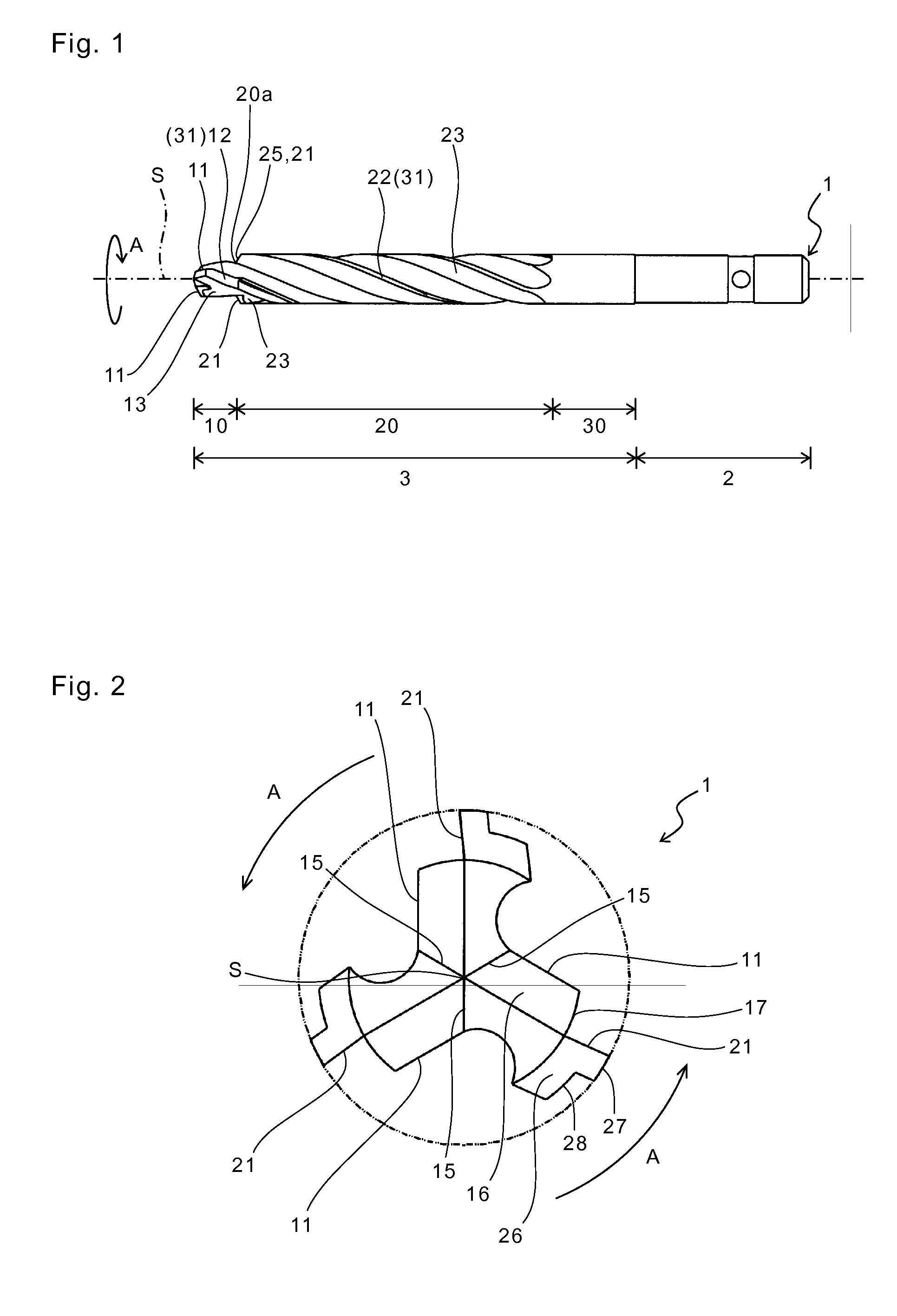

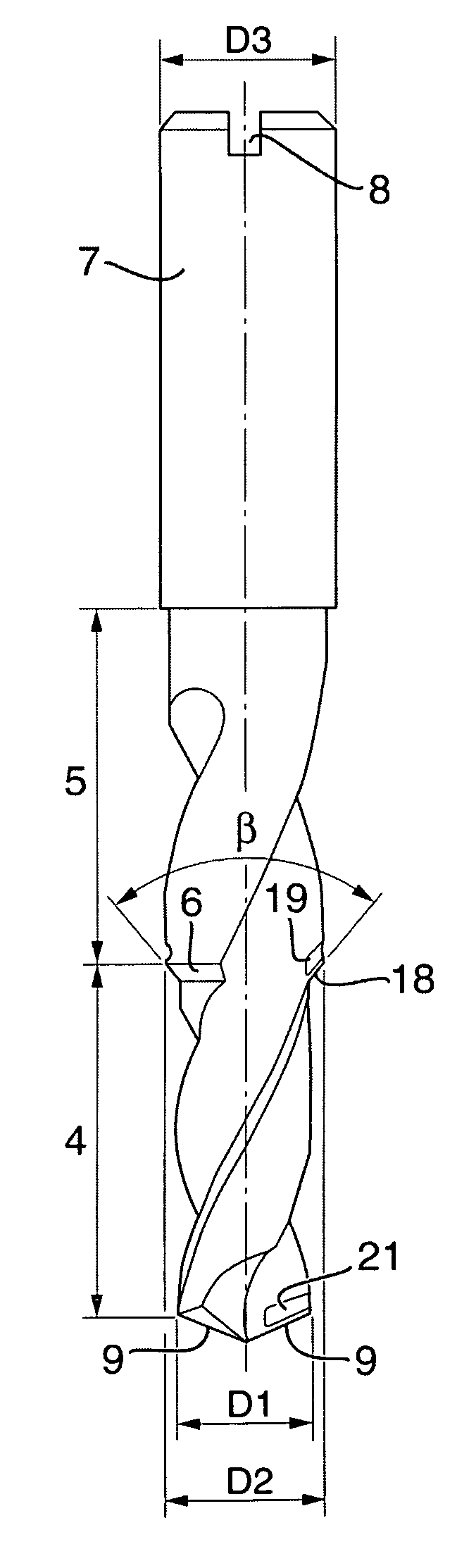

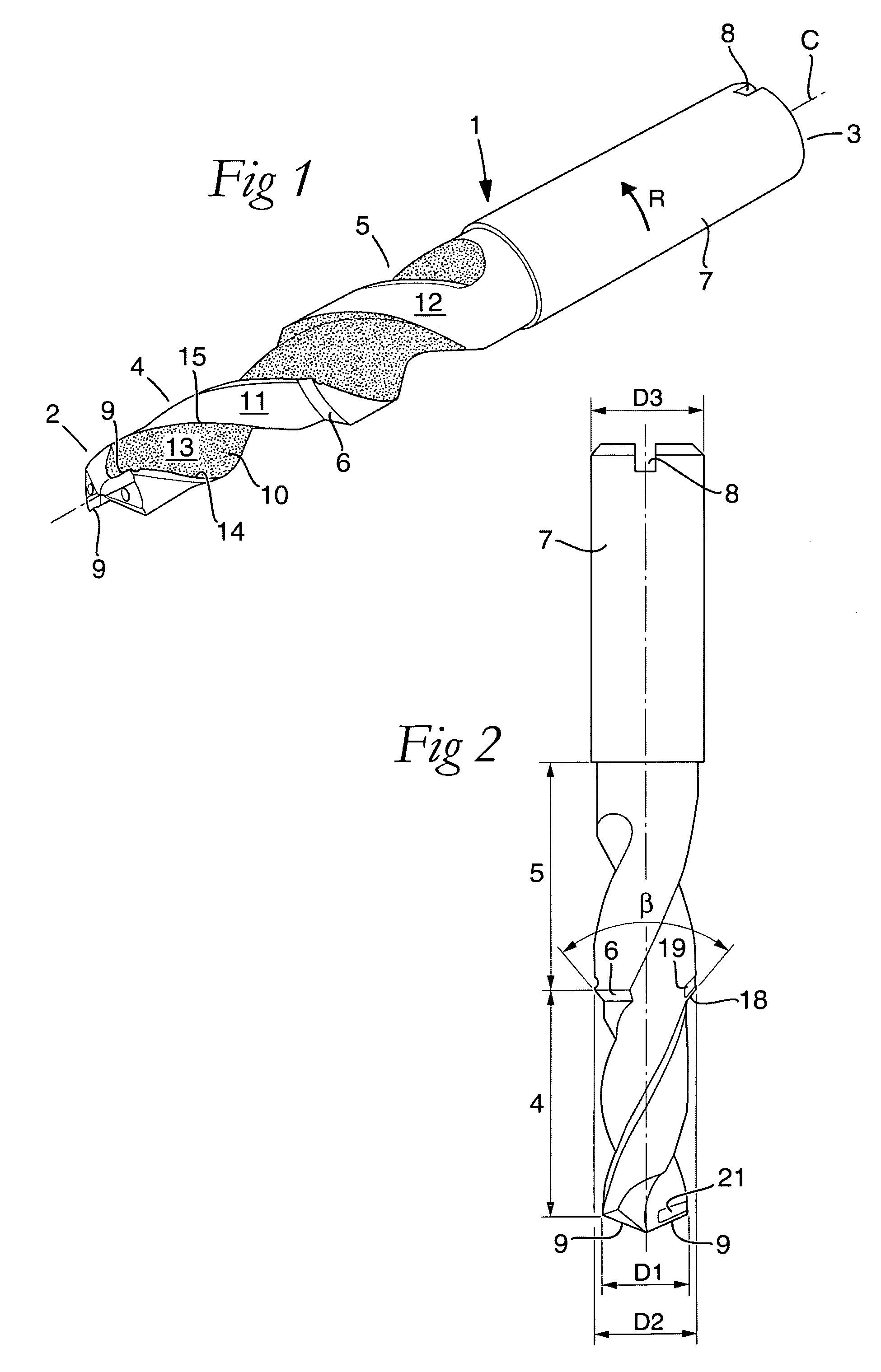

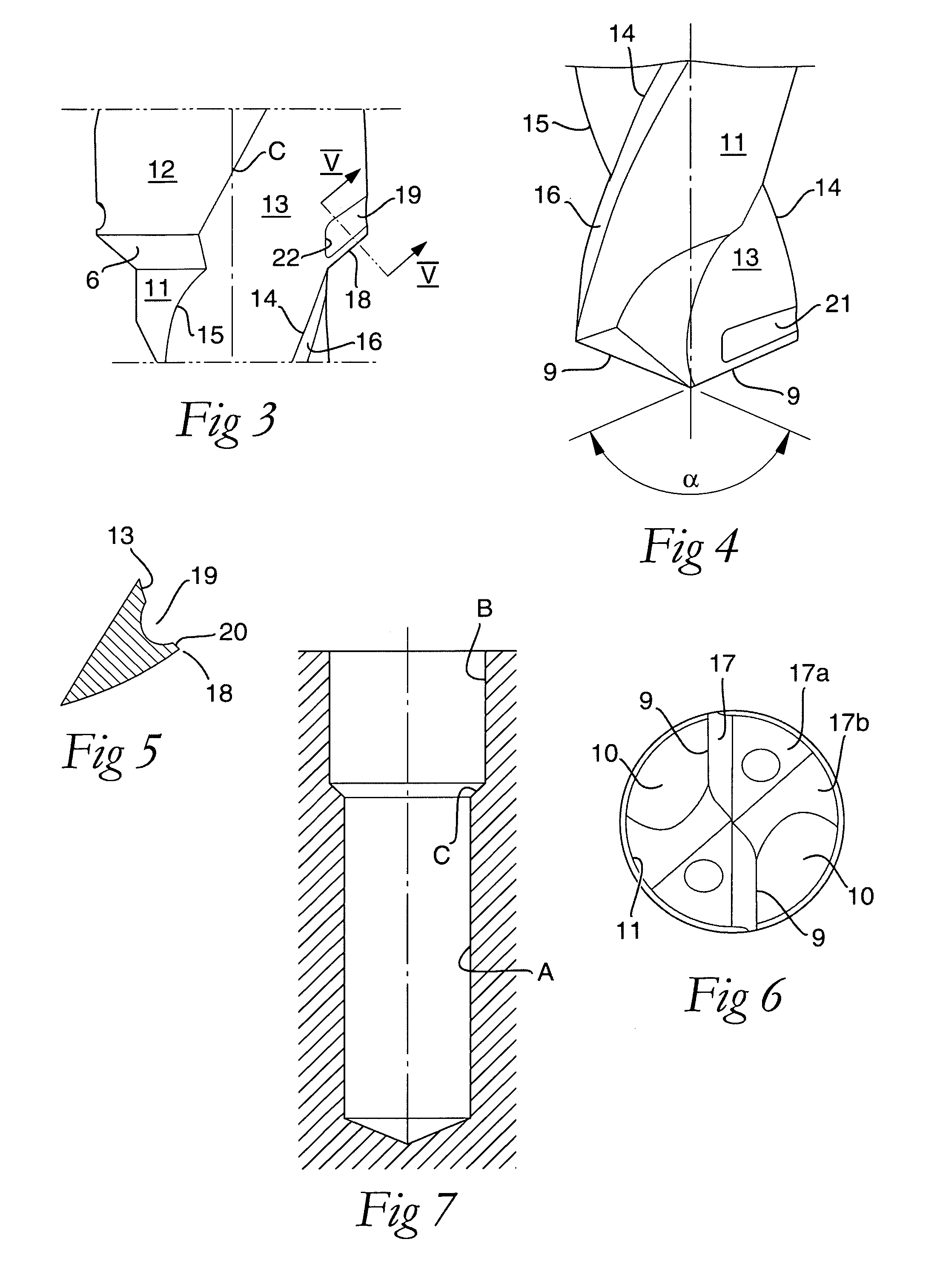

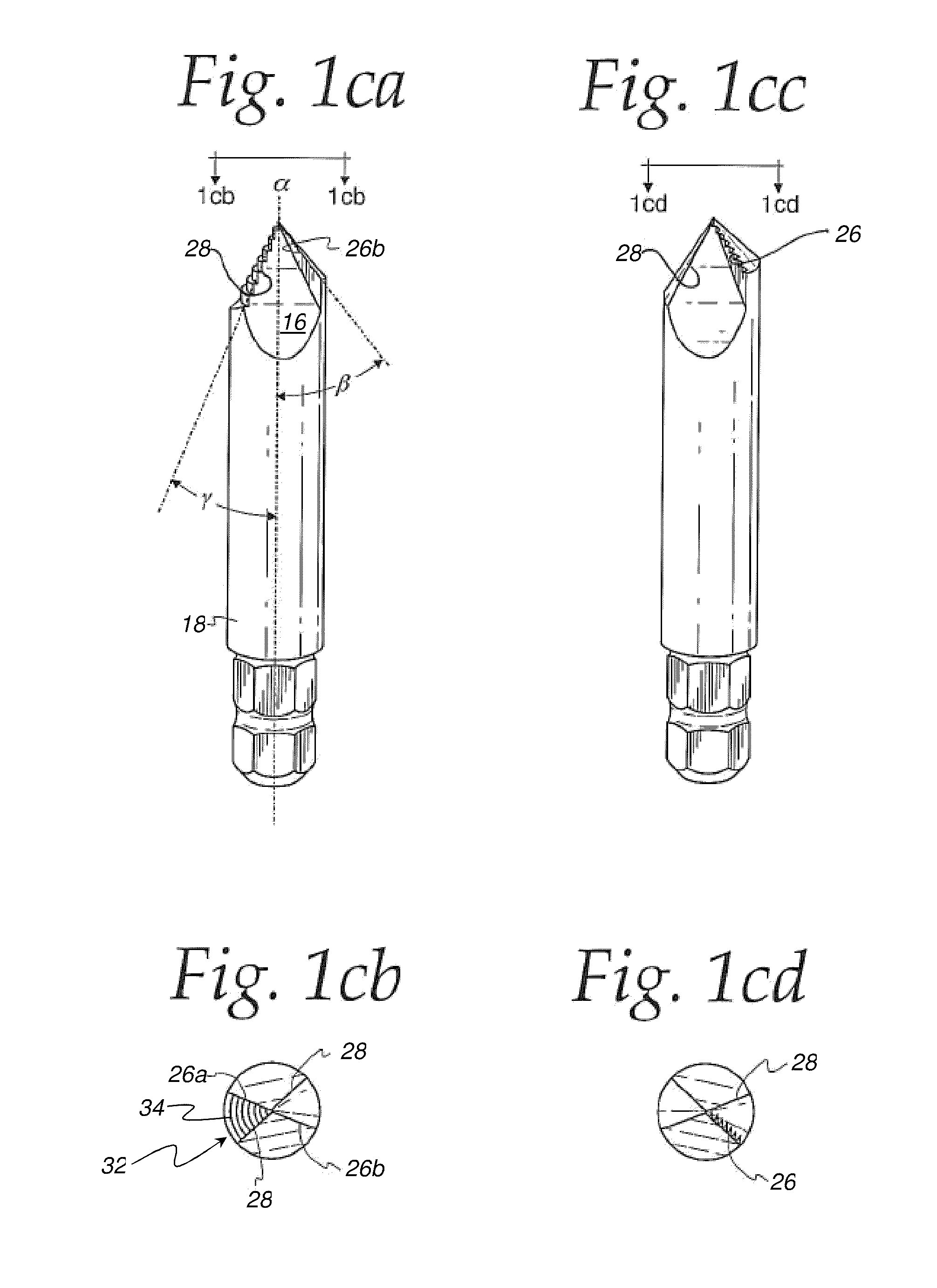

Solid step drill

A solid step drill, including a front tip and a rear end between which a center axis extends and around which the drill is rotatable in a predetermined direction. At least two cylindrical sections are concentric with the center axis, a first section extending rearward from the front tip and having a first diameter, and a second section extending behind the first section and having a second diameter that is greater than the first diameter, the first section transforming into the second section via a step. The tip includes two primary cutting edges, which individually co-operate with a respective chip flute that is delimited by a concave surface and countersunk in the first section and in the second section, the respective chip flute intersecting the step while forming a secondary cutting edge. Adjacent to the secondary cutting edge, a chip breaking recess is formed between a cutting edge line of the cutting edge and the concave surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

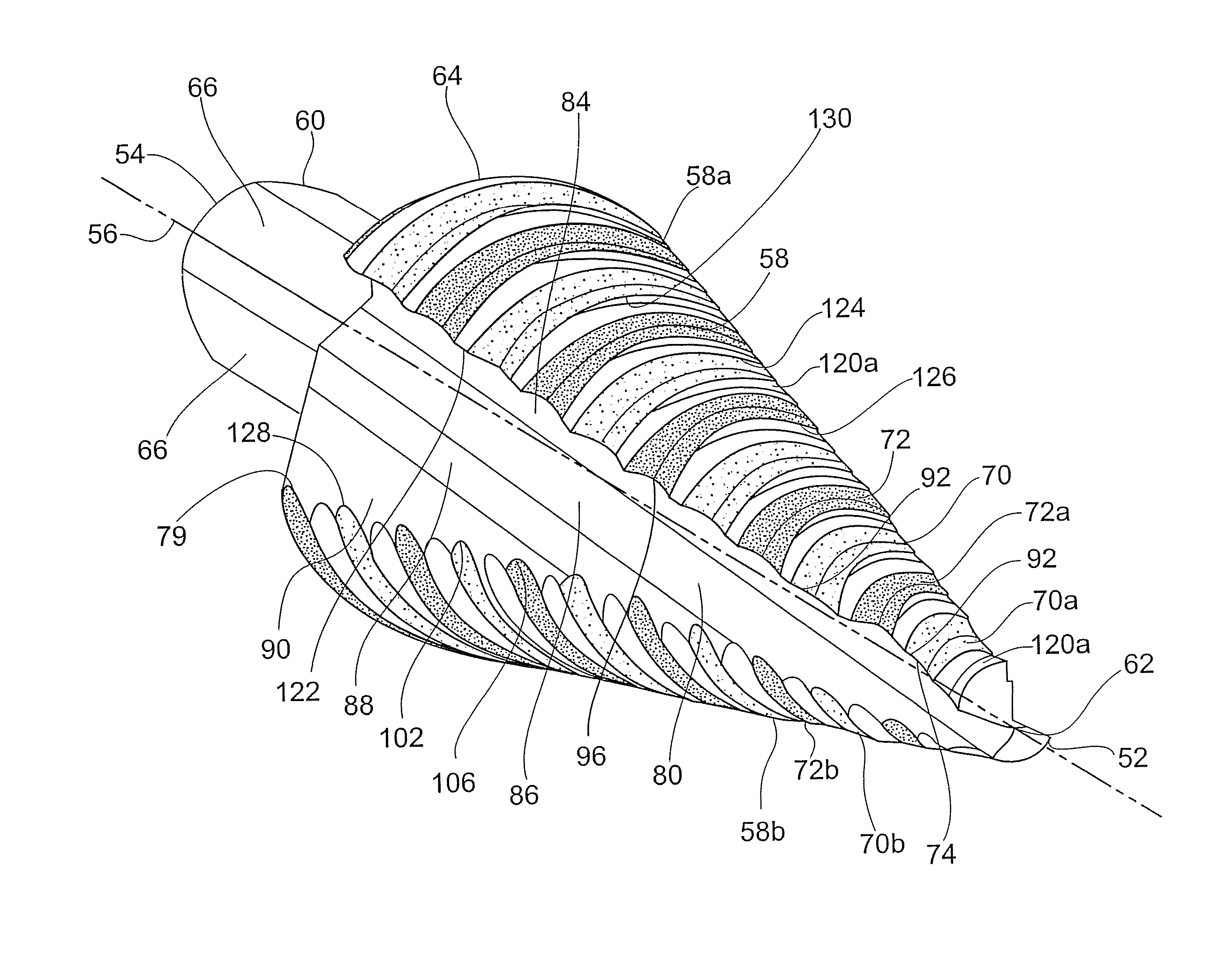

Segmented orbital drill

ActiveUS20120219371A1Improve tool lifeIncreased tool wearTransportation and packagingMilling cuttersClassical mechanicsStructural engineering

A segmented orbital drill includes a segmented portion with a semi-finishing cutting portion and a plurality of finishing cutting portions. The semi-finishing cutting portion and finishing cutting portions are separated by grooves formed by a front wall and a rear wall. The segmented portion allows for a fresh cutting edge (i.e., rear wall of the groove) to be revealed as the orbital drill wears in the axial direction. The segmented portion also causes less contact with the workpiece, which reduces power consumption and minimizes deflection of the orbital drill. The segmented orbital drill also includes an optional pilot at one end of the drill, and a clearance neck portion between a shank and the segmented portion. A method of machining a workpiece using the segmented orbital drill is also disclosed.

Owner:KENNAMETAL INC

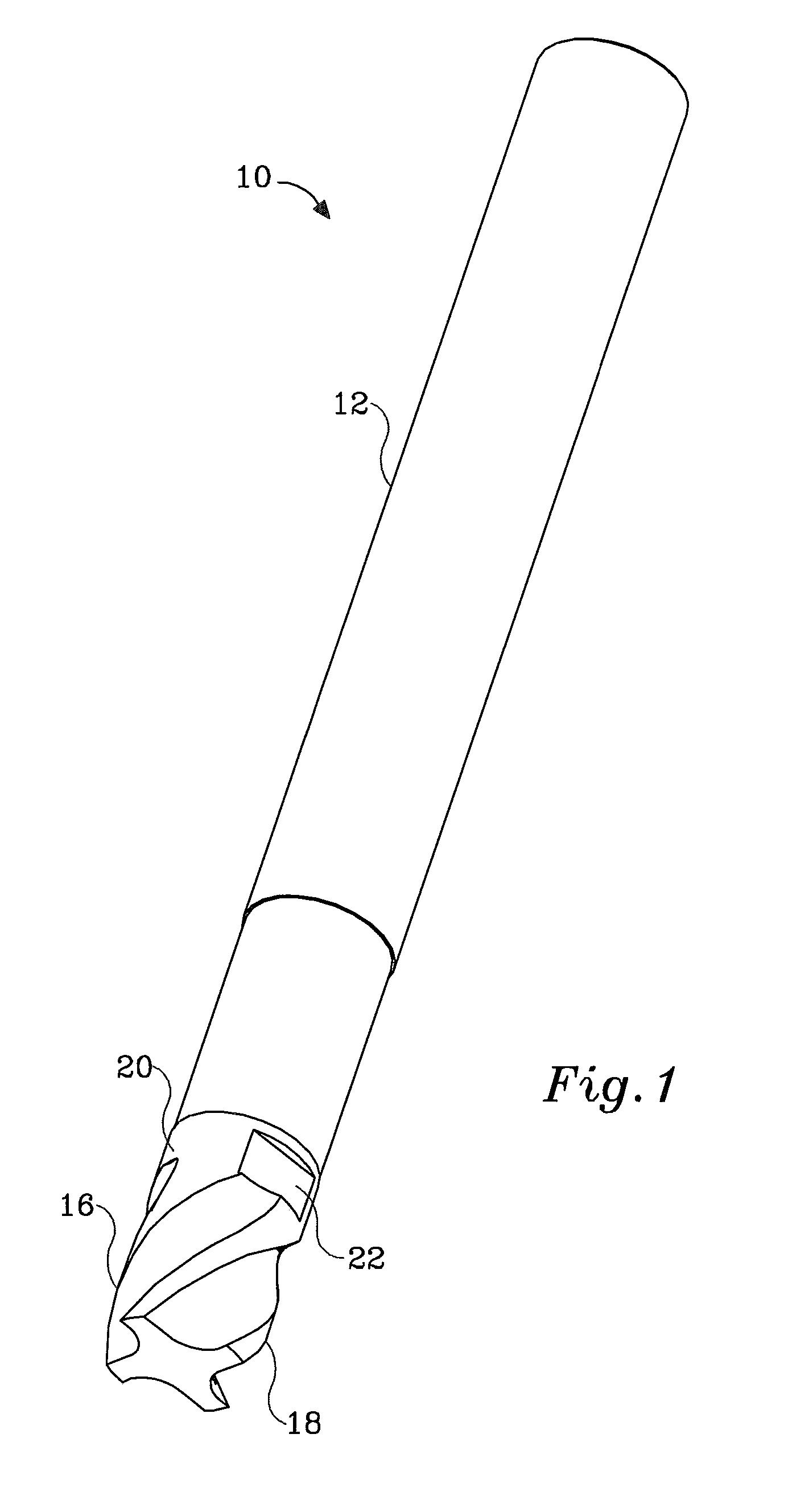

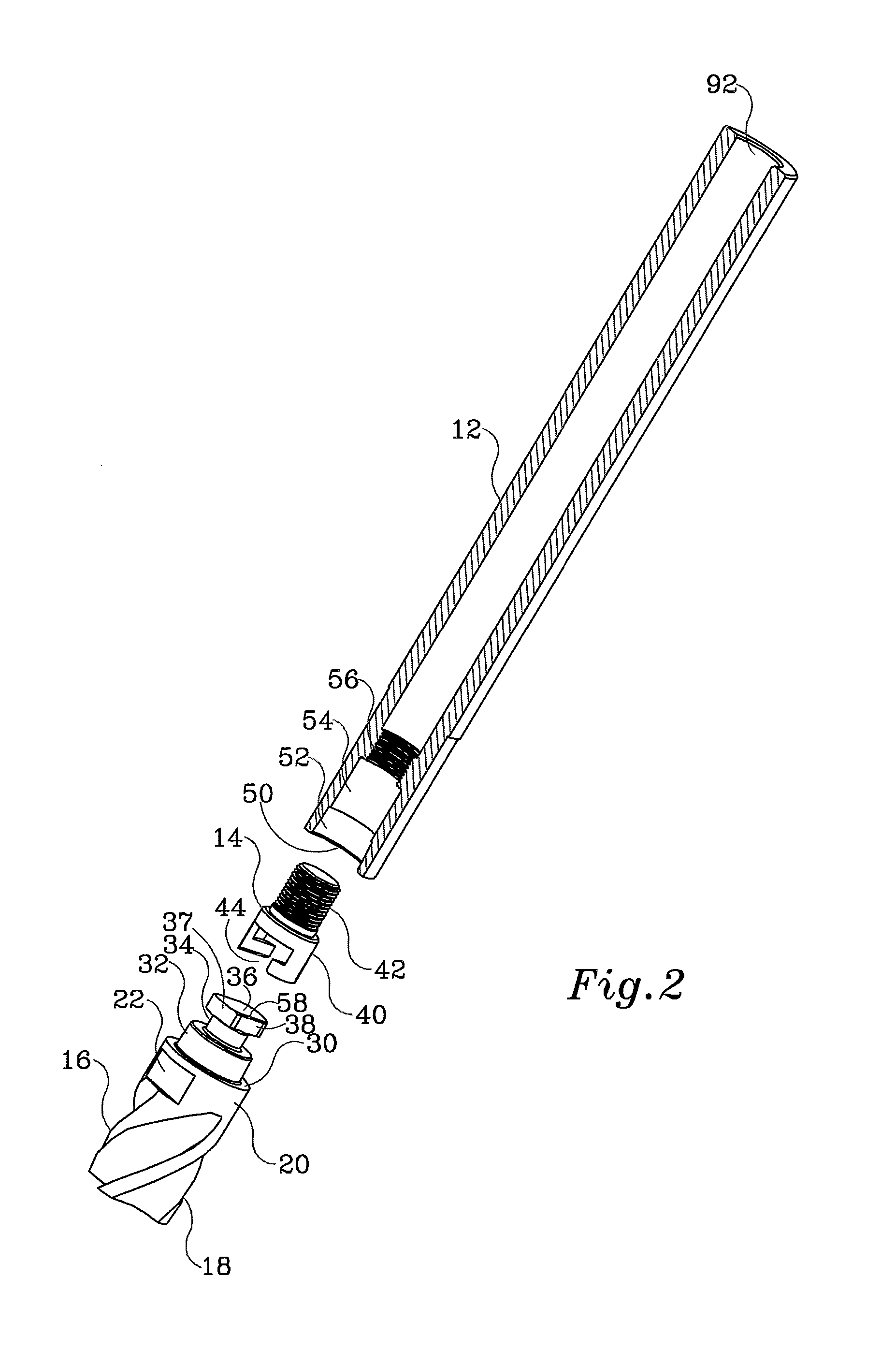

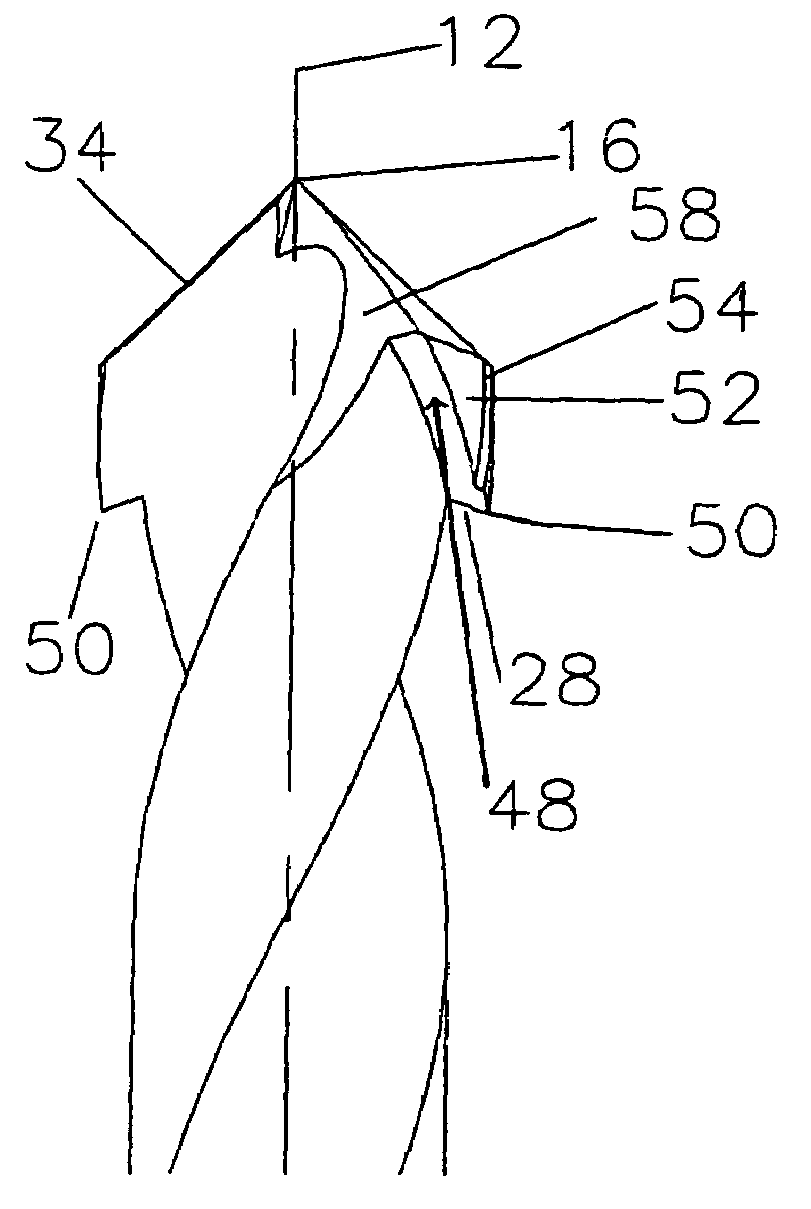

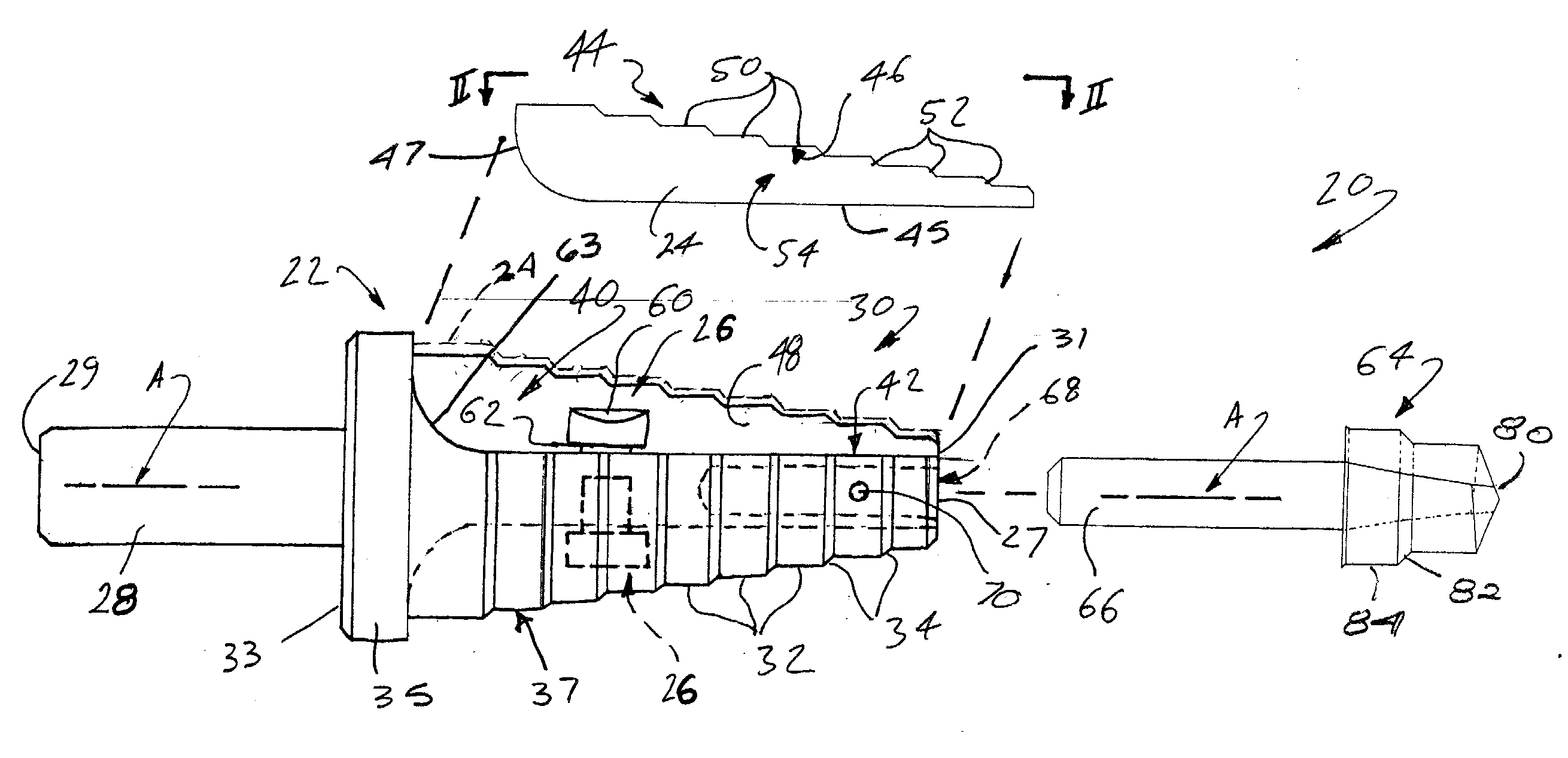

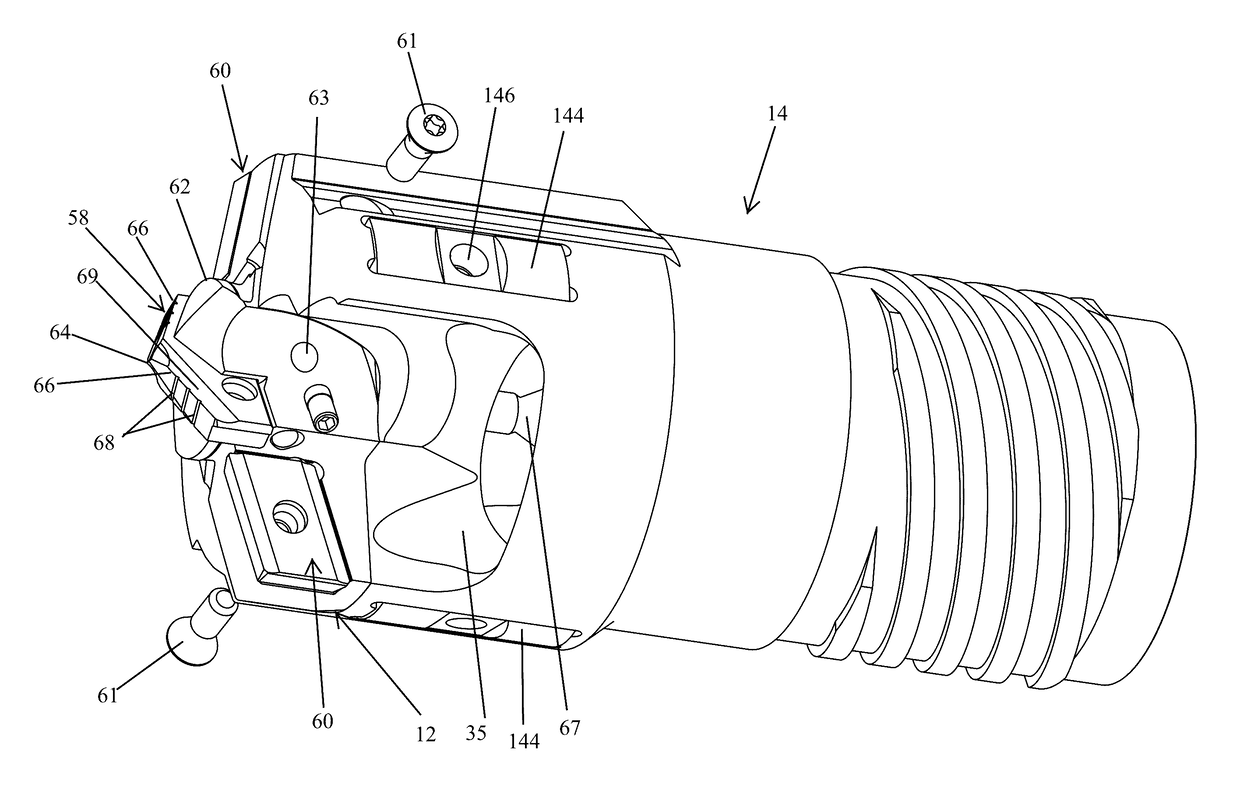

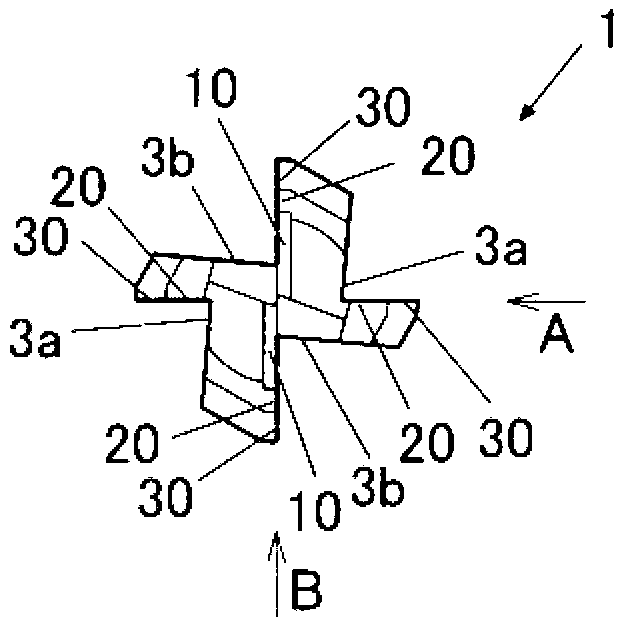

Coupler for a Quick Change Insert Rotary Cutting Tool

A coupler for a quick change rotary cutting tool assembly allowing a cutter to be quickly and releasably coupled to a shank wherein the coupler has a cylindrical portion with a threaded portion to engage the shank and a portion with a transverse groove with undercut walls to form recesses. The cutter has an anchor made as a disk with parallel flats which engage the recesses of the cylindrical portion to releasably secure the cutter to the shank.

Owner:KENNAMETAL INC

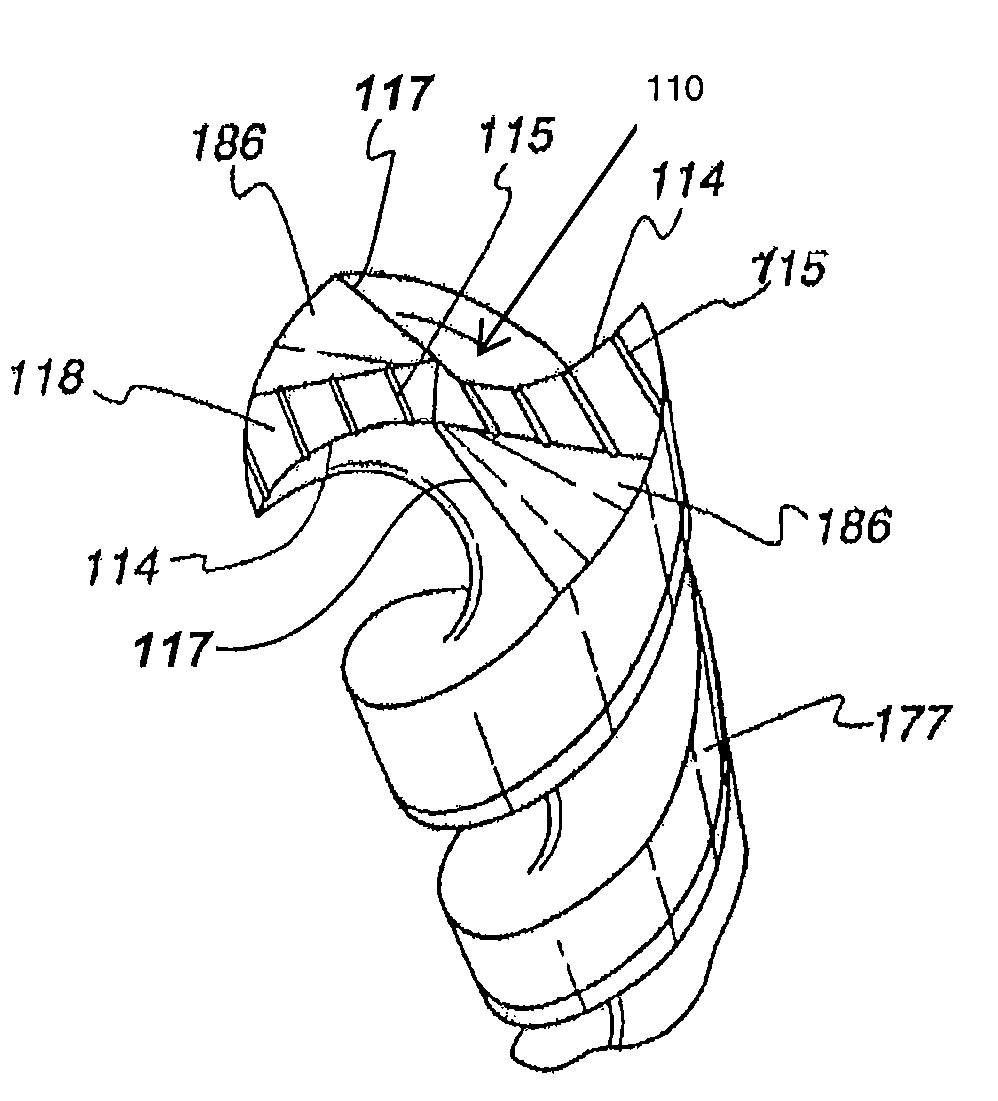

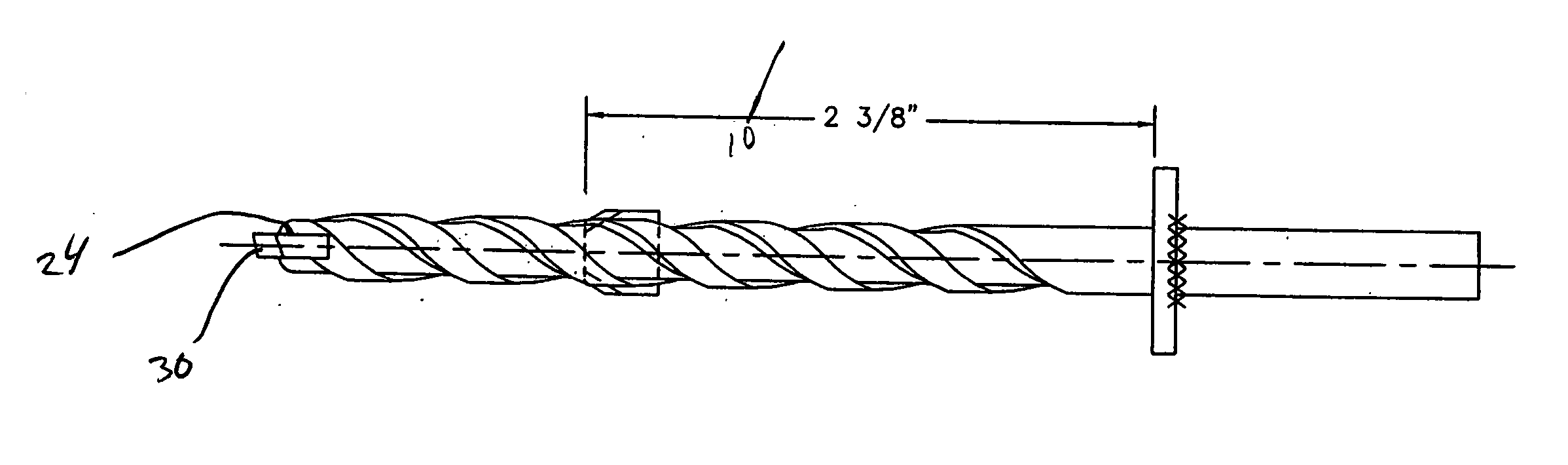

Reduced energy consuming, lateral cutting twist drill

InactiveUS7018143B2Less energyReduce frictionWood turning toolsTransportation and packagingBiomedical engineeringTwist drill

A modified prior art twist drill embodies structural features that require less energy to drill a hole during a normal plunge operation and allow for lateral cutting movement during extraction of the twist drill from a drilled work piece.

Owner:BITMOORE AN OREGON GEN PARTNERSHIP

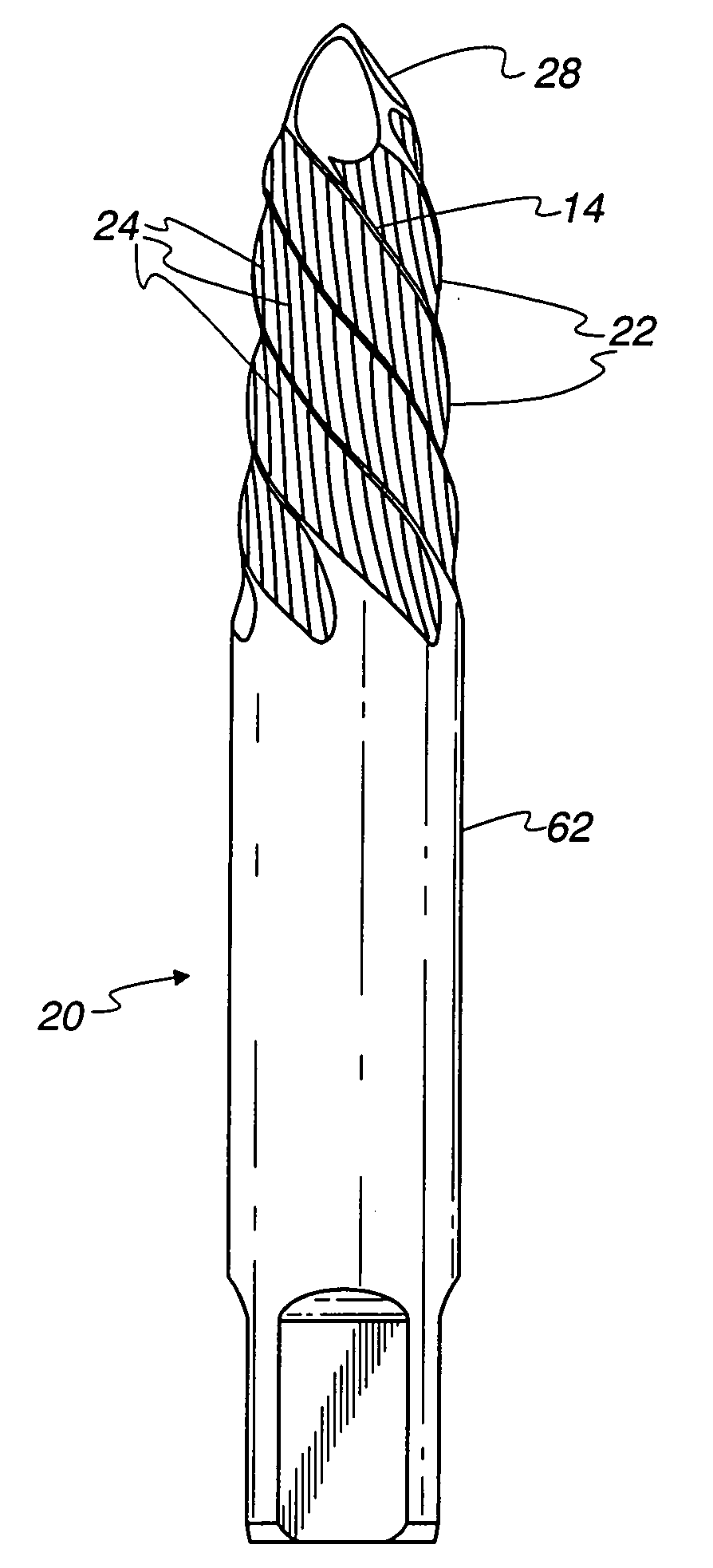

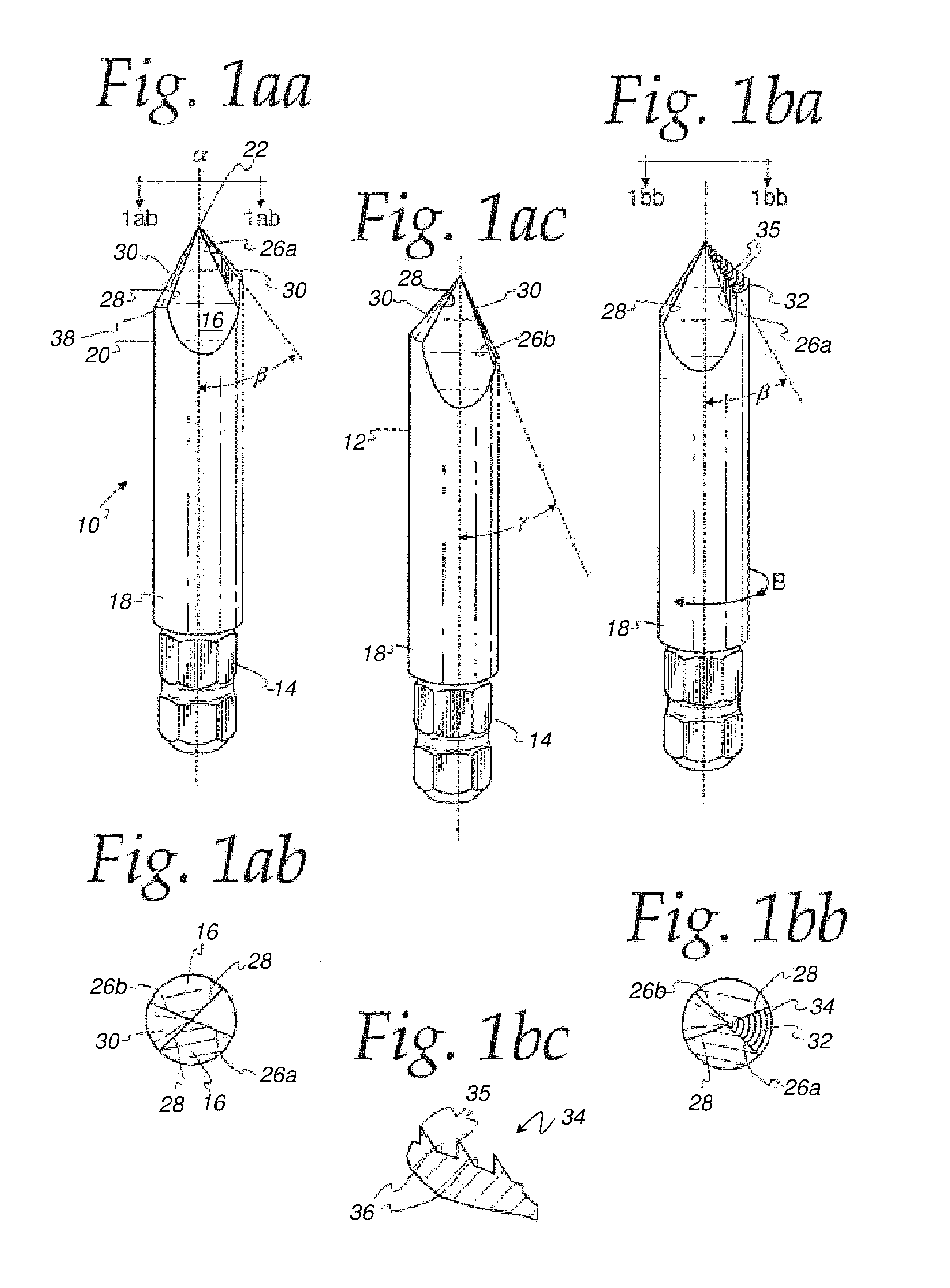

Damaged bolt and screw removing devices

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

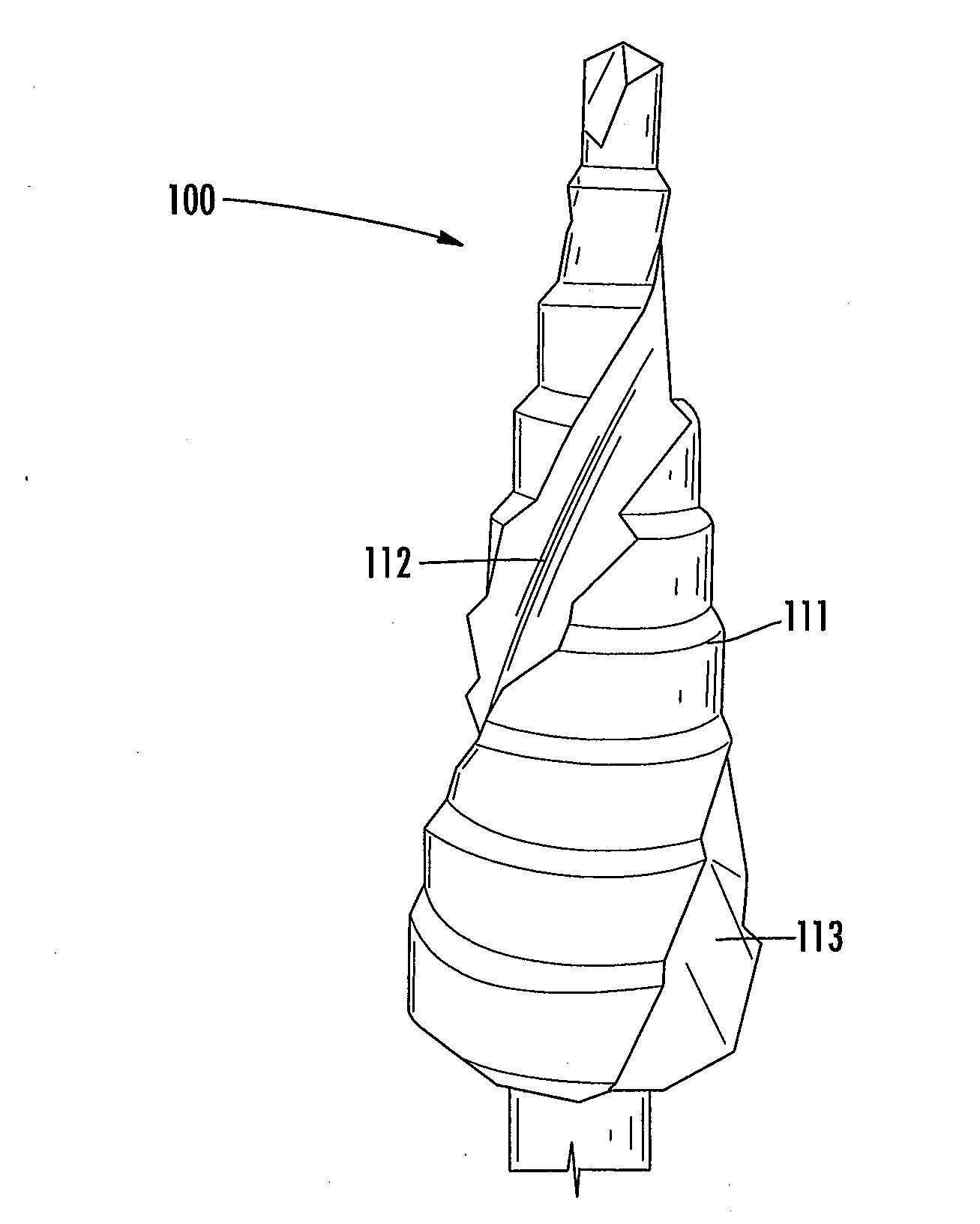

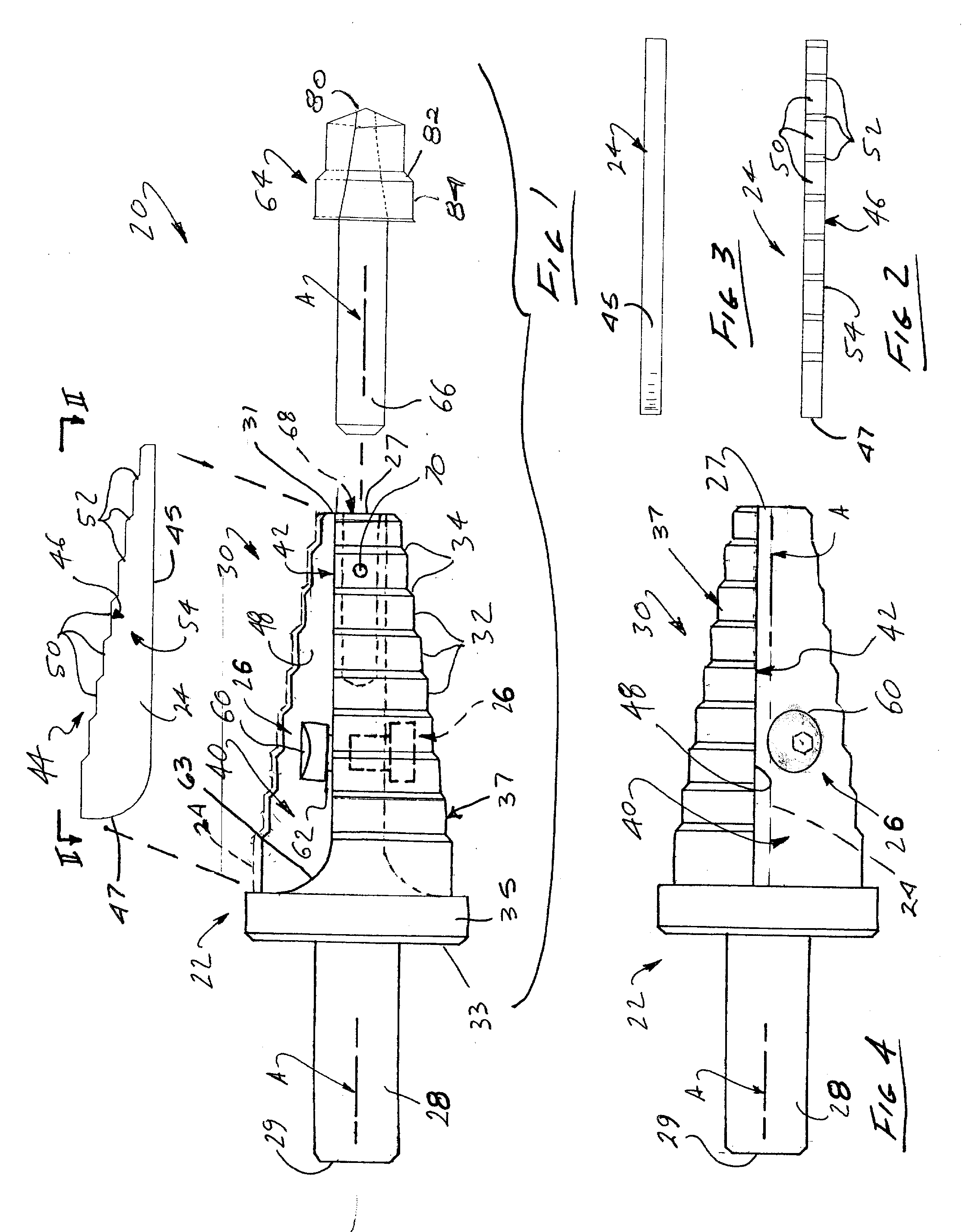

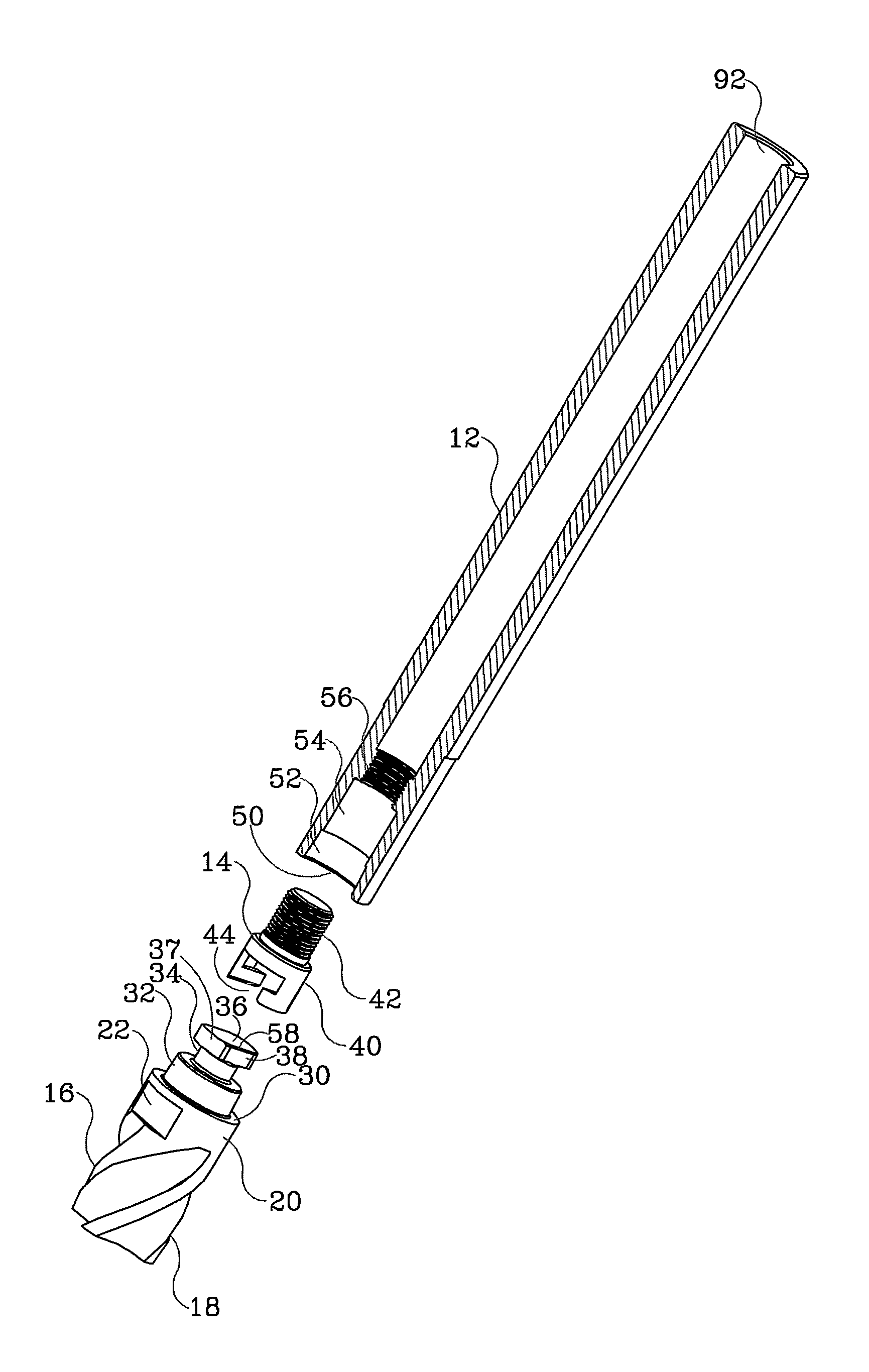

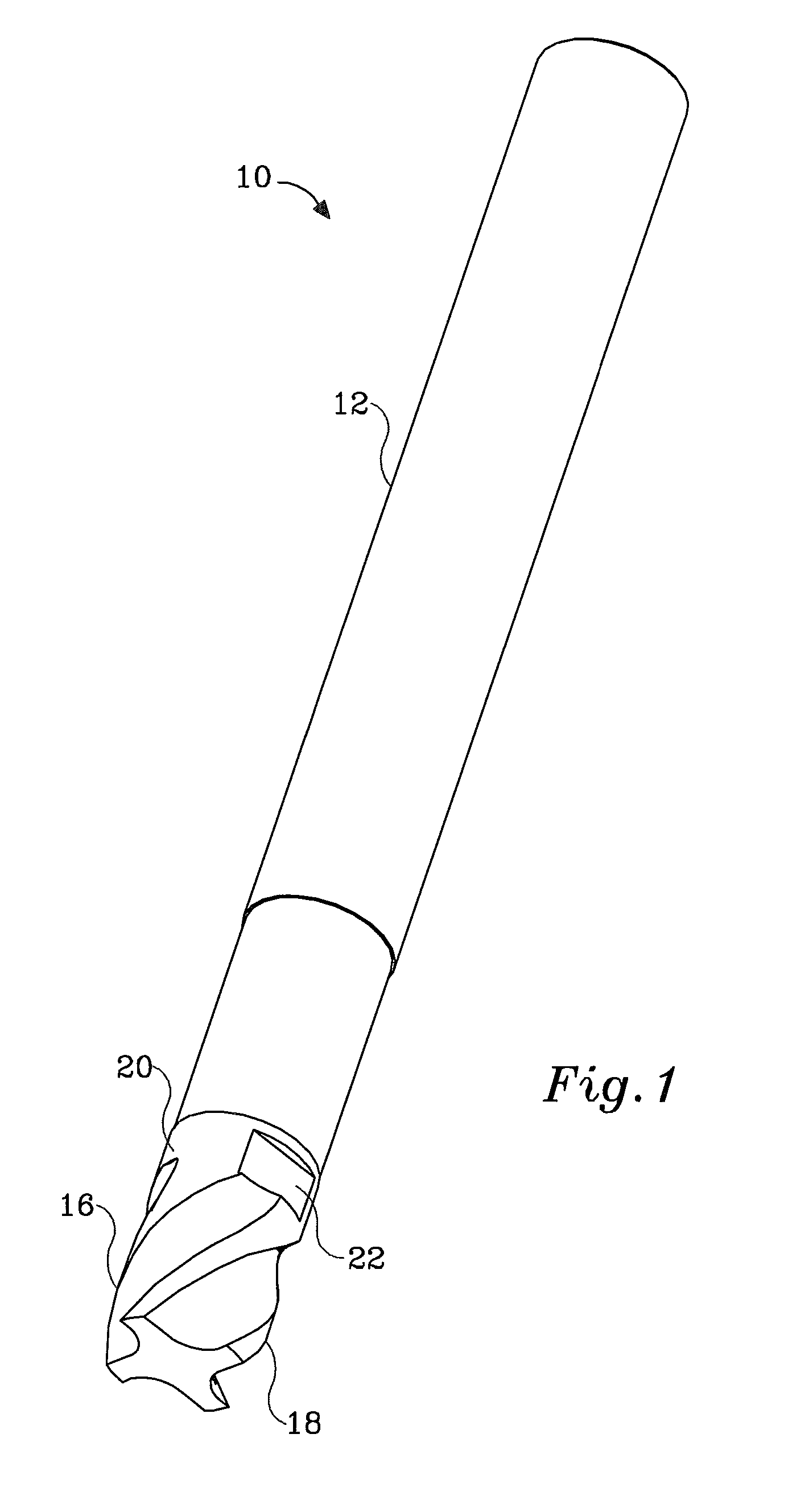

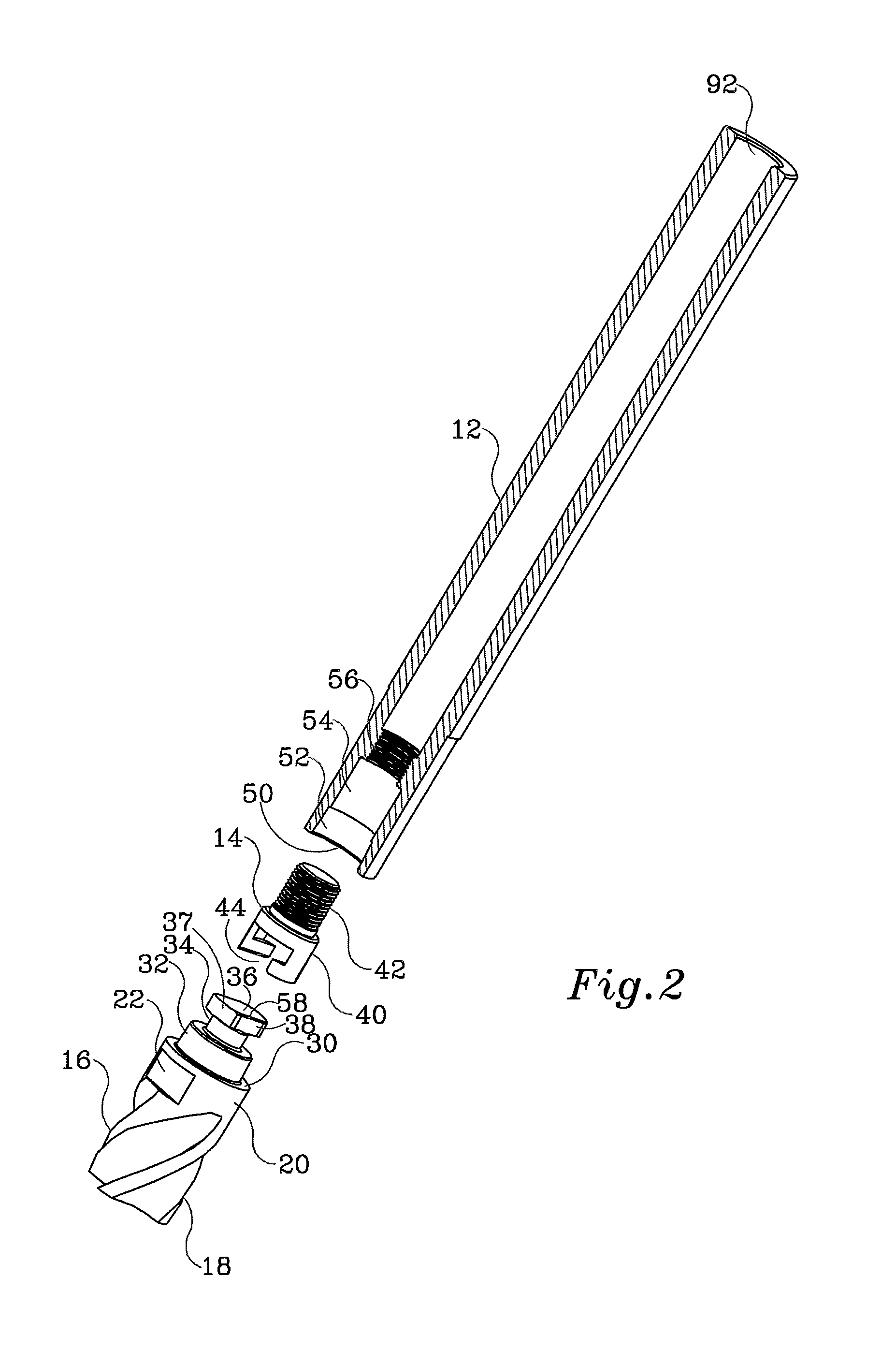

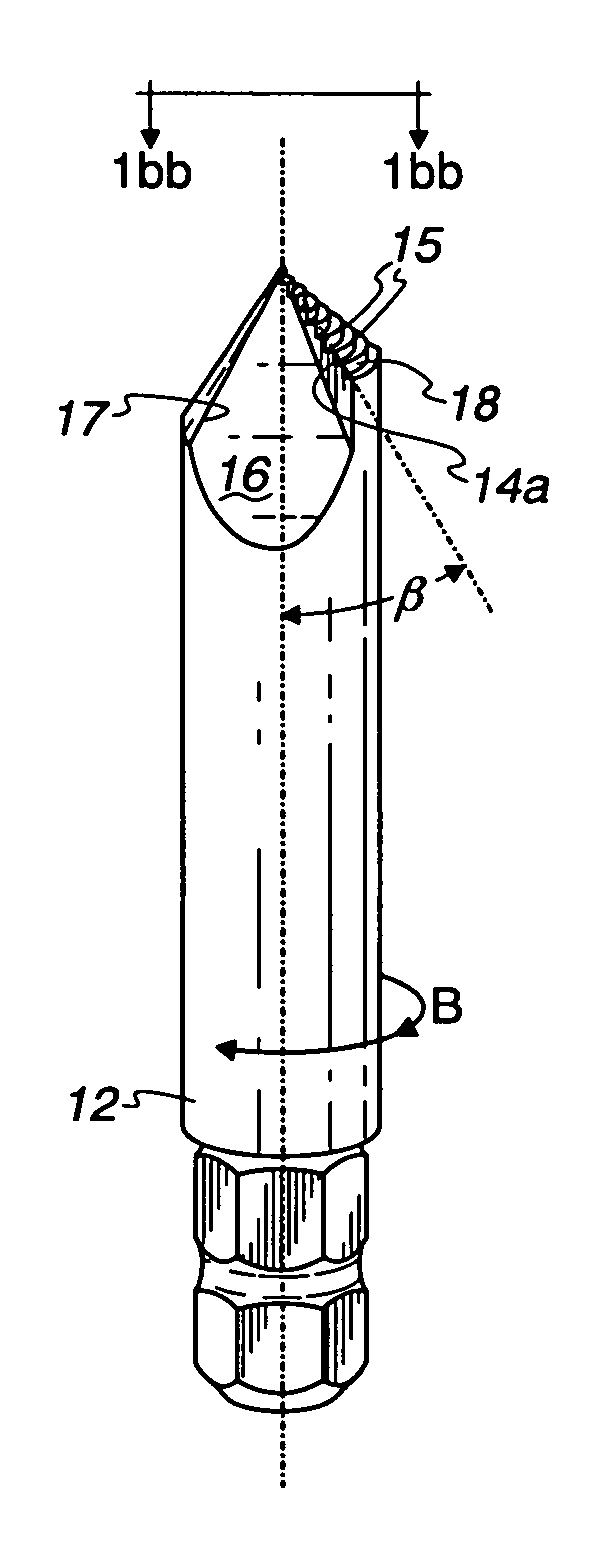

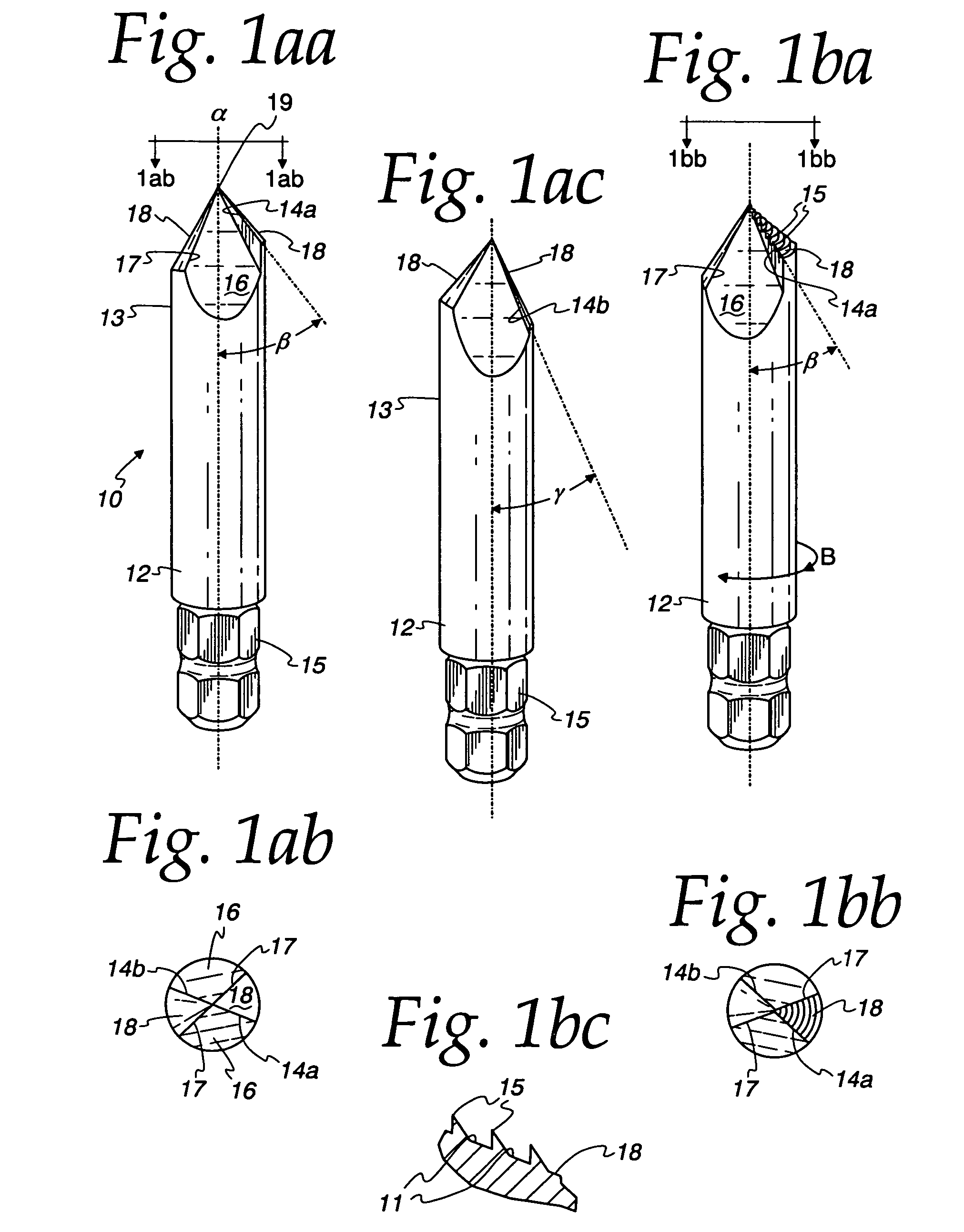

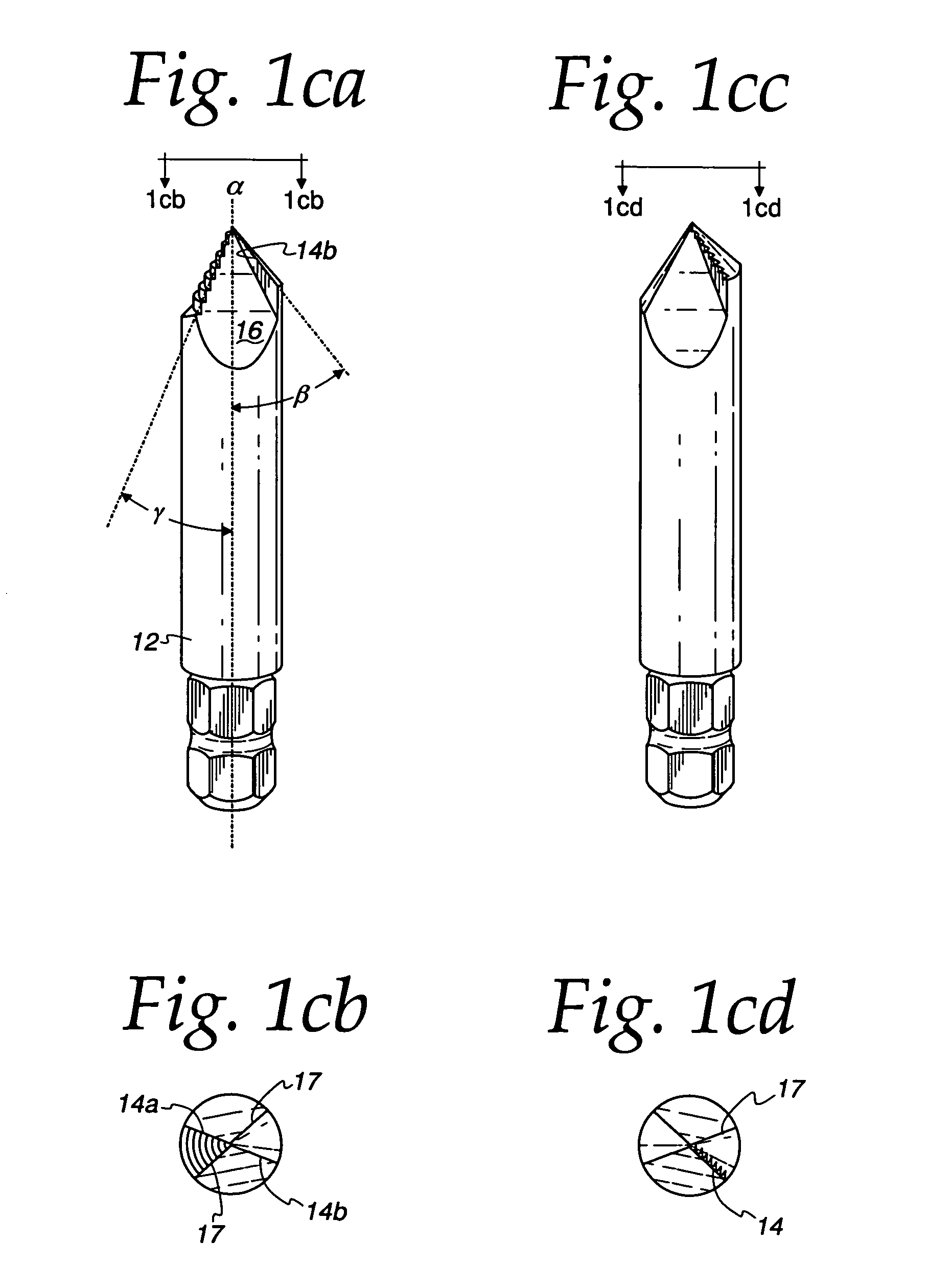

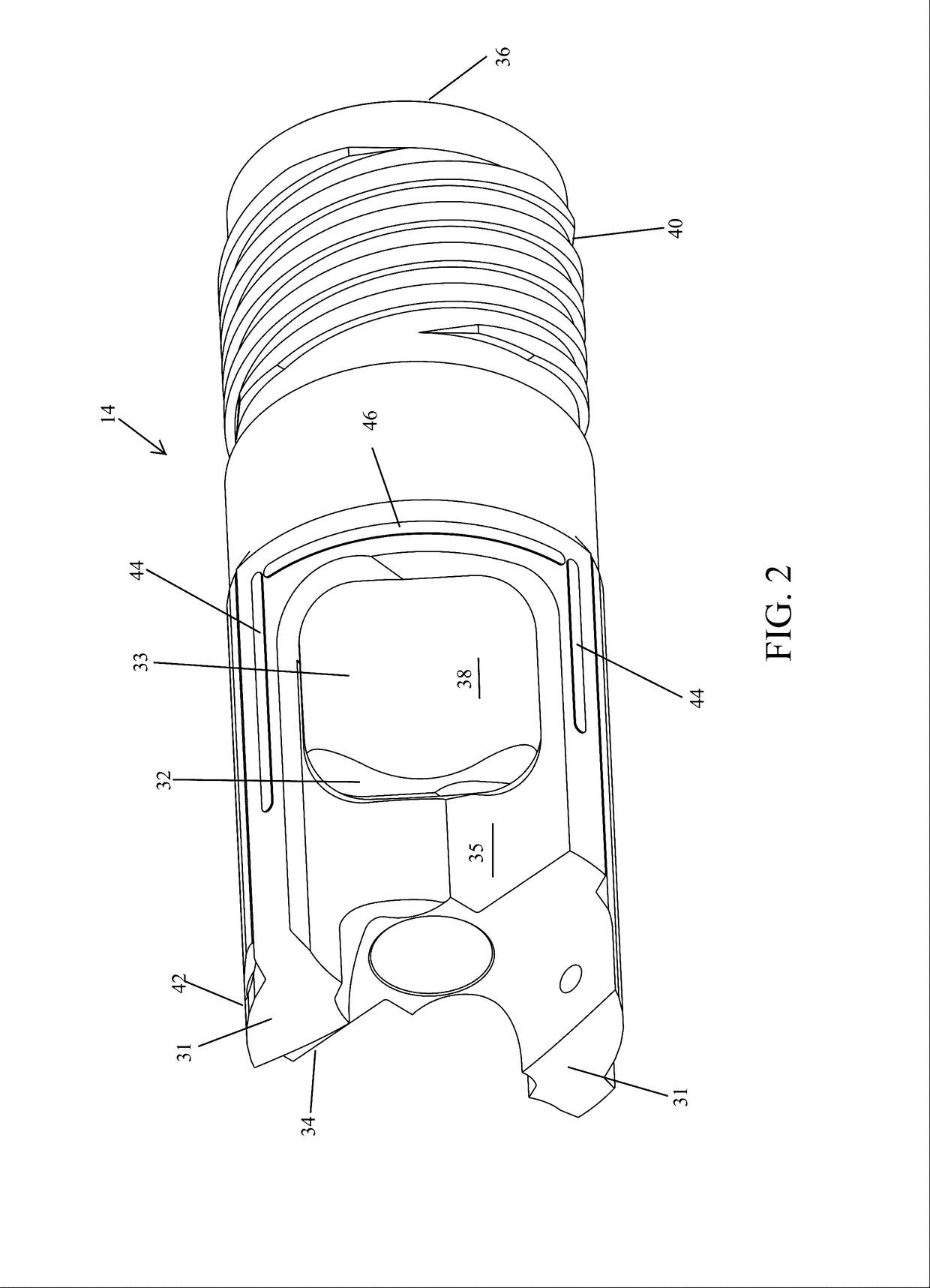

Unibit with replacement blade

A unibit with replacement blade provides economical refreshing of the many cutting facets of a unibit drill bit with a unibit replacement blade that is releasably secured in the unibit body. In one aspect of the invention, a replacement blade with cutting edges on one or both opposite side edges is releasably locked into the unibit body by a transverse locking screw. The blade can be provided with an integral tip drill when desired. In another aspect of the invention, one or more replacement blades is releasably secured in a recess in the unibit body with a simple blade lock mechanism, the blades being positioned symmetrically around the axis of the drill. In one embodiment, the blade lock is an eccentric cam member that rotates into and out of locking engagement with the blade. Other blade locks include clamping screws, screws through the blade, cam plates, tapered blades, and blade receiving grooves. Another aspect of the invention provides a replaceable tip drill.

Owner:SEELEY SCOTT C

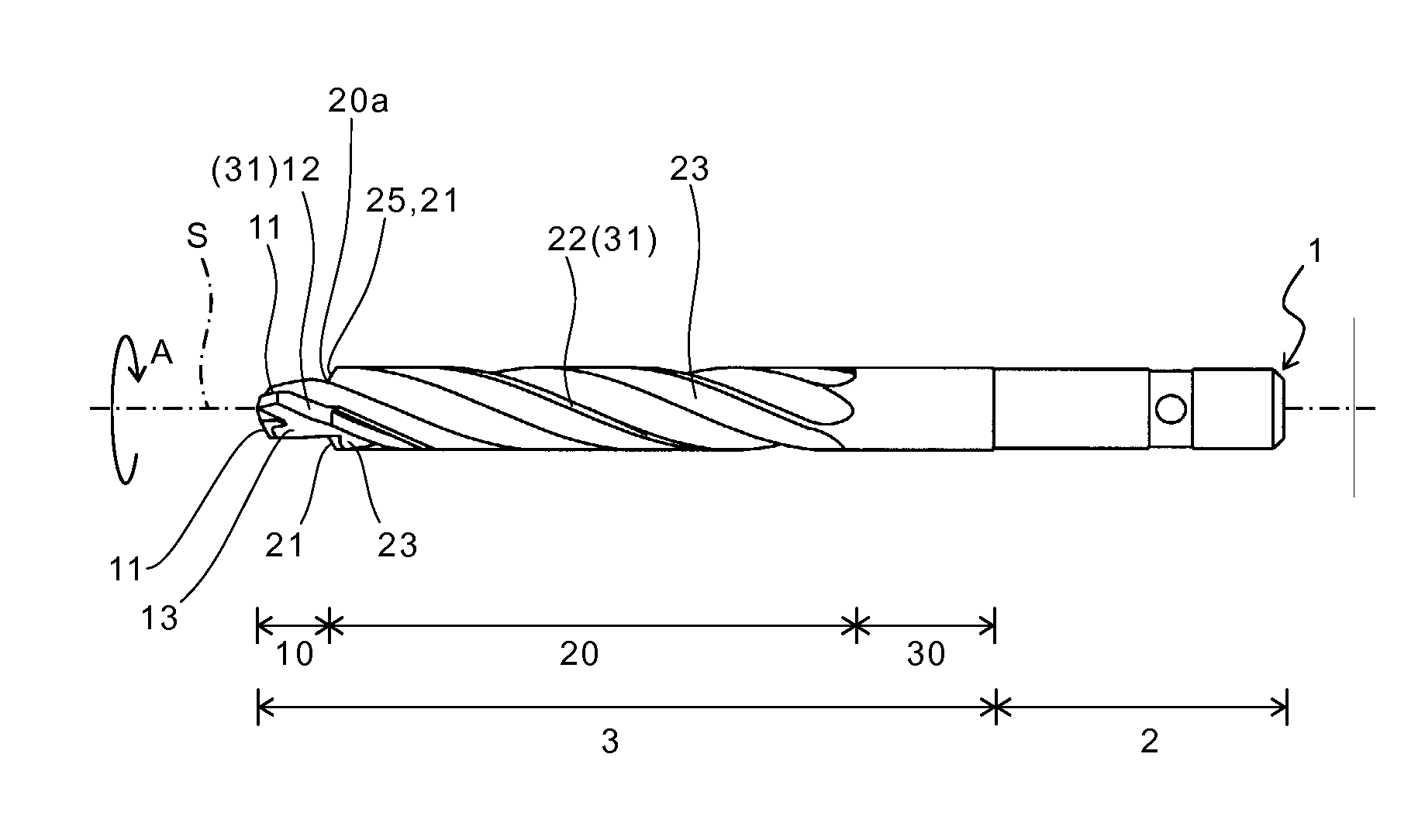

Drill and method of manufacturing machined product

ActiveUS20130136552A1Improve discharge performancePass smoothlyWood turning toolsTransportation and packagingDrill bitEngineering

A drill includes a substantially cylindrical cutting portion includes a first region located at a front end portion, and a second region which has a step whose diameter increases as going from the first region to a rear end in a sectional view perpendicular to a rotation axis, and which is continuous with the first region in an end of the second region on a side of the step, and using this drill, a method of manufacturing a machined product is provided.

Owner:SUBARU CORP +1

Damaged bolt and screw removing devices

ActiveUS20090183603A1Lower levelImprove biteTransportation and packagingSpade drillsFluteEngineering

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by traction or biting surfaces formed from two-sided frusto-conically-shaped regions. The surfaces are bounded on one side by a nonlinear cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis, where the biting surfaces comprise a plurality of serrations, and where the cutting edges are separated by flutes which spiral along a longitudinally extending periphery of the bit.

Owner:COMBINED PRODS

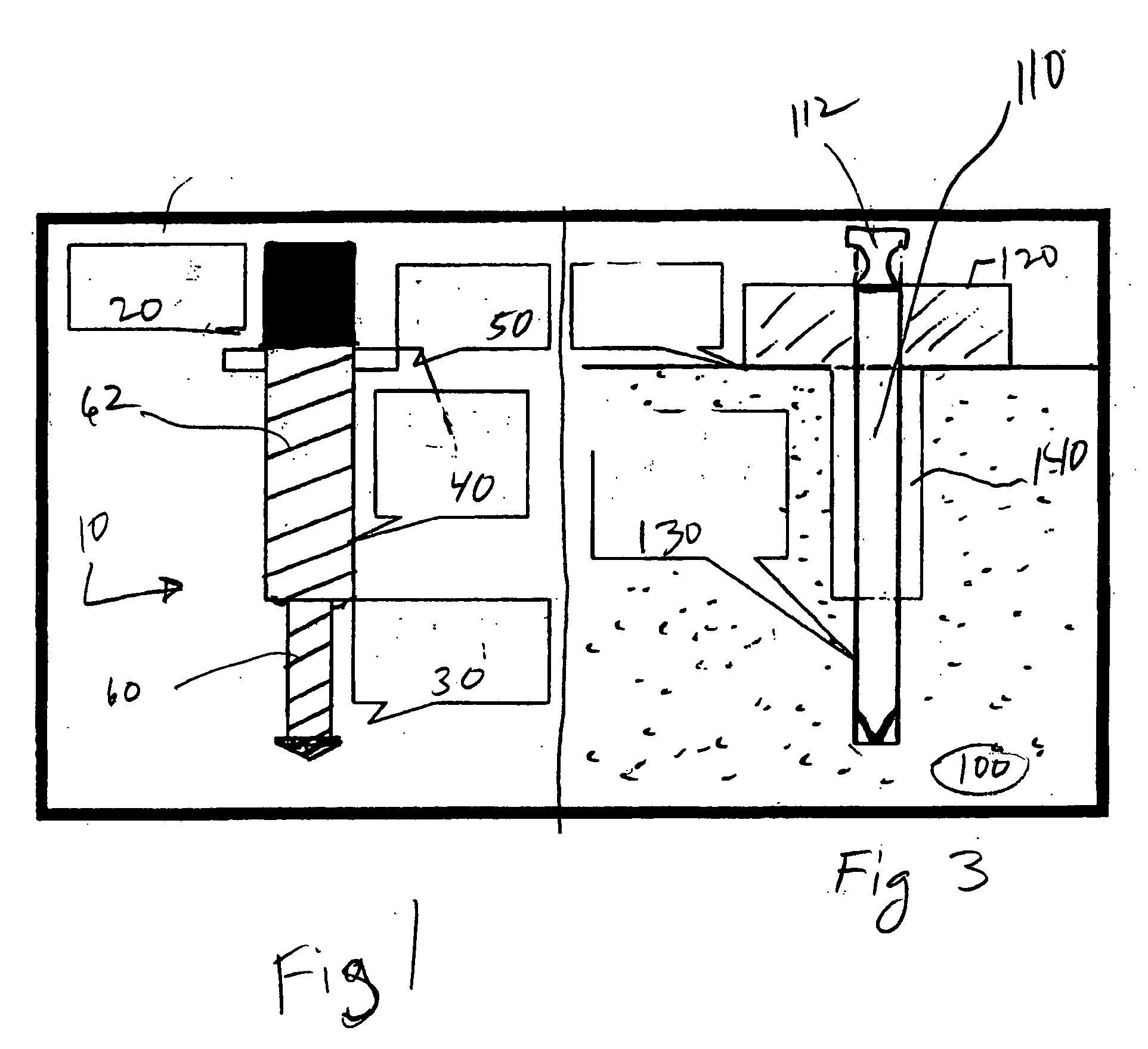

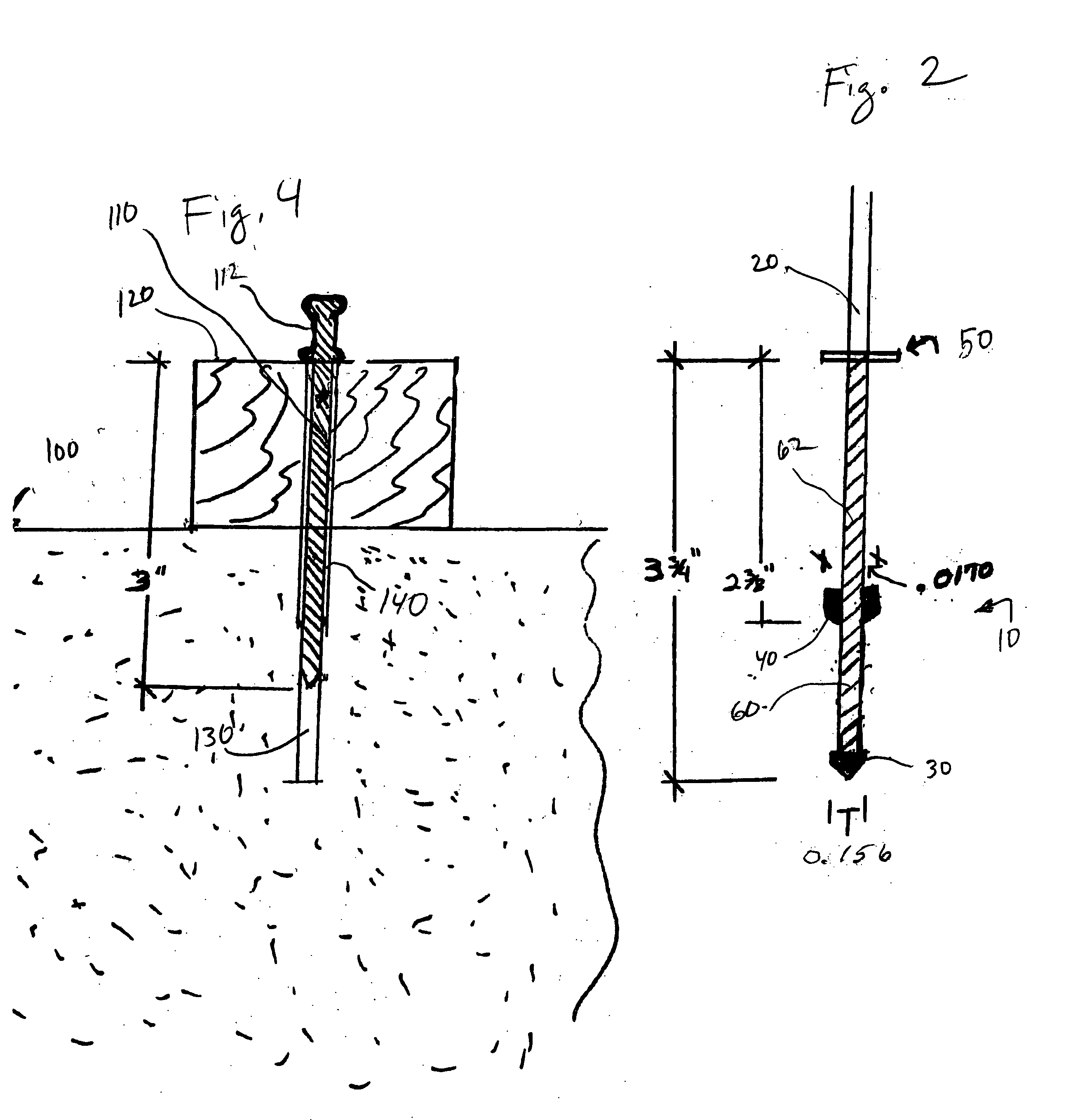

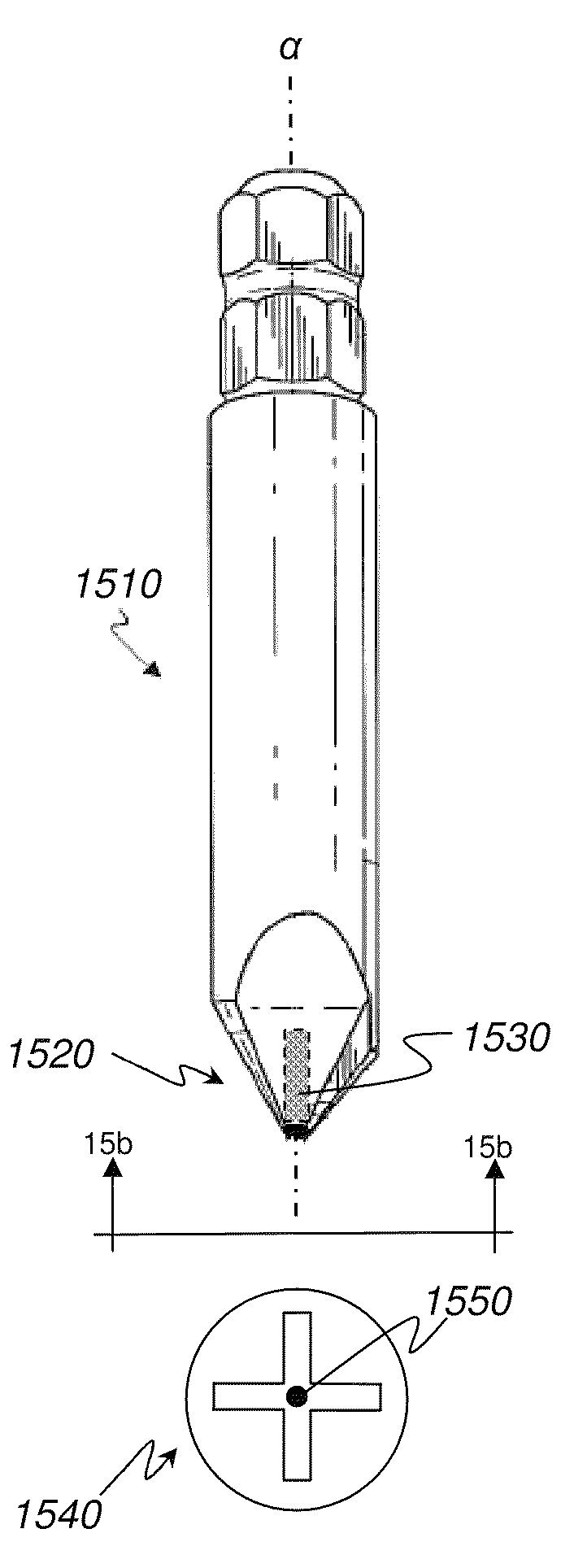

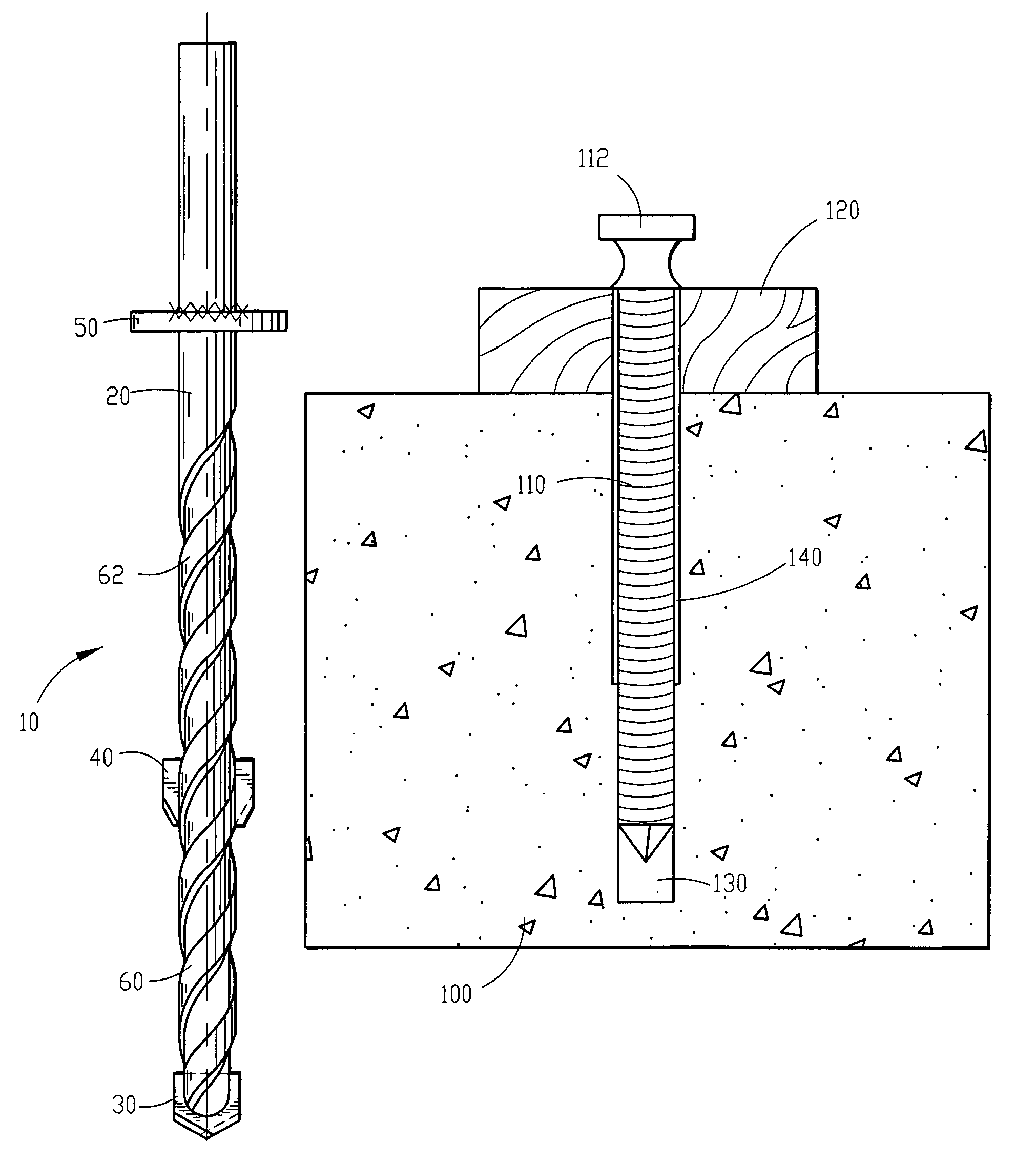

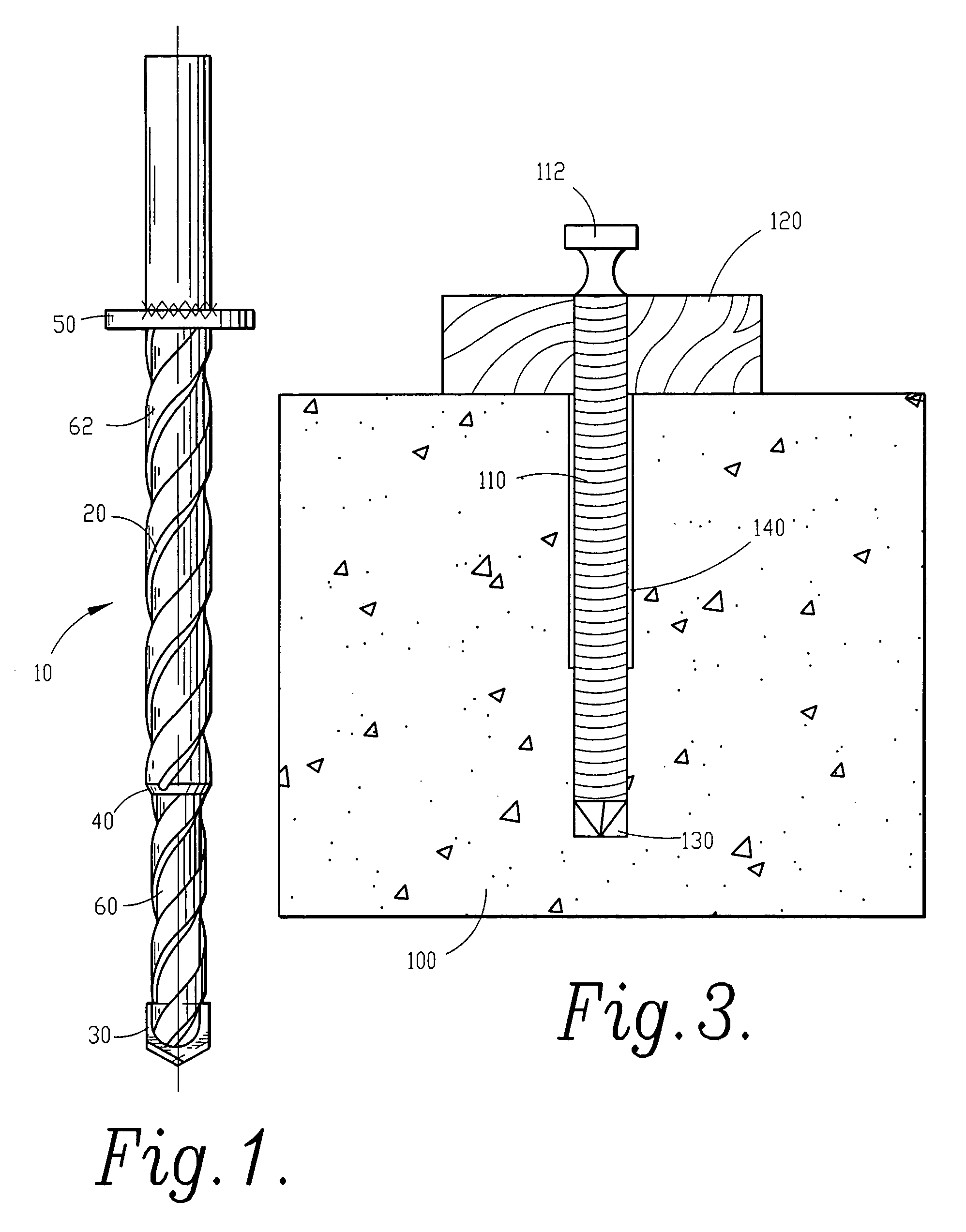

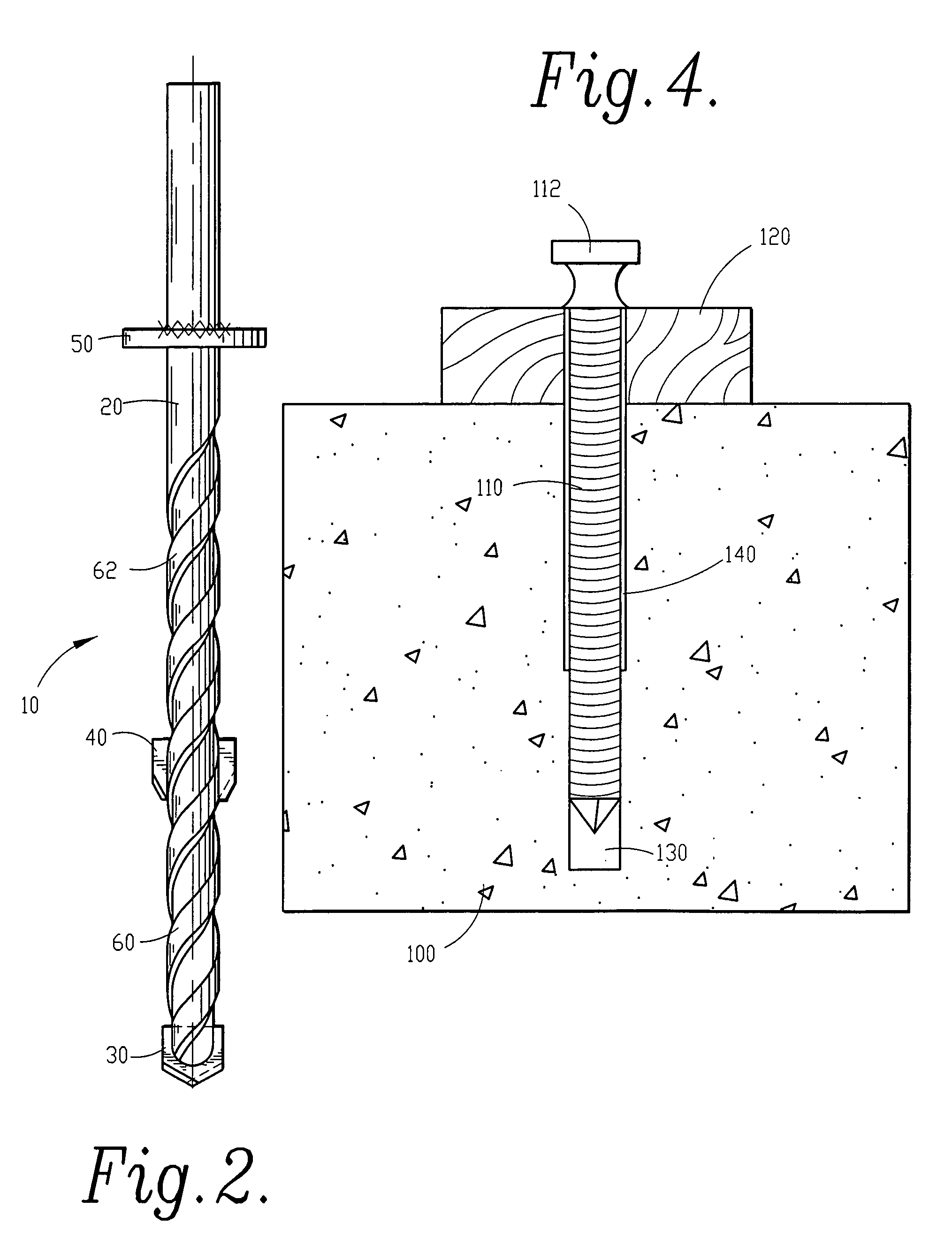

Anchoring drill bit, system and method of anchoring

InactiveUS20050098358A1Low costReduce frictionThread cutting toolsDrilling/boring measurement devicesPilot holeBiomedical engineering

A system, apparatuses and methods for anchoring are provided. The system includes two-stage drill bit and a method of anchoring into a two-stage hole drilled by the drill bit. The apparatus of the instant invention includes a two-stage drill bit for drilling a pilot hole for a common nail into a material such as concrete, stone, masonry or cementuous or other materials. The method of the instant invention includes the steps of drilling a first hole within a material to which an object is to be anchored, drilling a second hole concentric with the first hole, and placing an anchor within the holes.

Owner:NADLER DONALD S

Coupler for a quick change insert rotary cutting tool

A coupler for a quick change rotary cutting tool assembly allowing a cutter to be quickly and releasably coupled to a shank wherein the coupler has a cylindrical portion with a threaded portion to engage the shank and a portion with a transverse groove with undercut walls to form recesses. The cutter has an anchor made as a disk with parallel flats which engage the recesses of the cylindrical portion to releasably secure the cutter to the shank.

Owner:KENNAMETAL INC

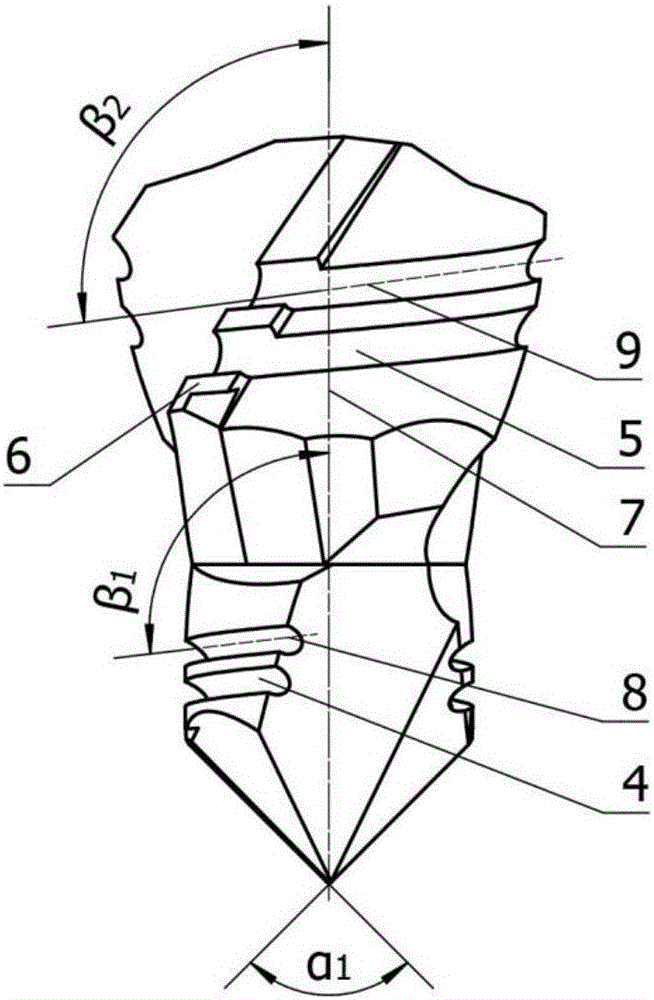

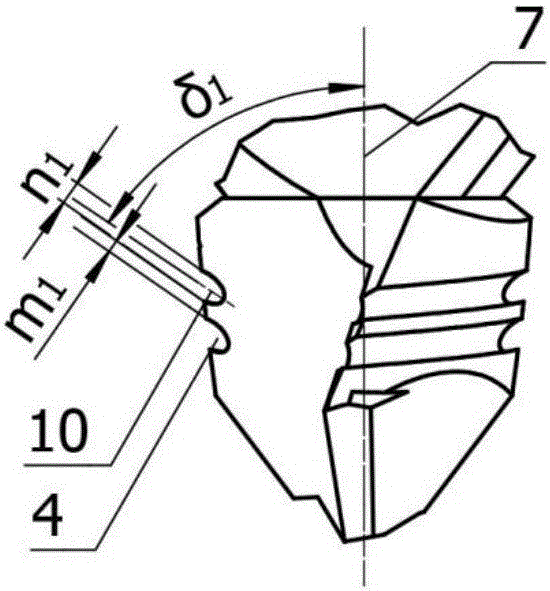

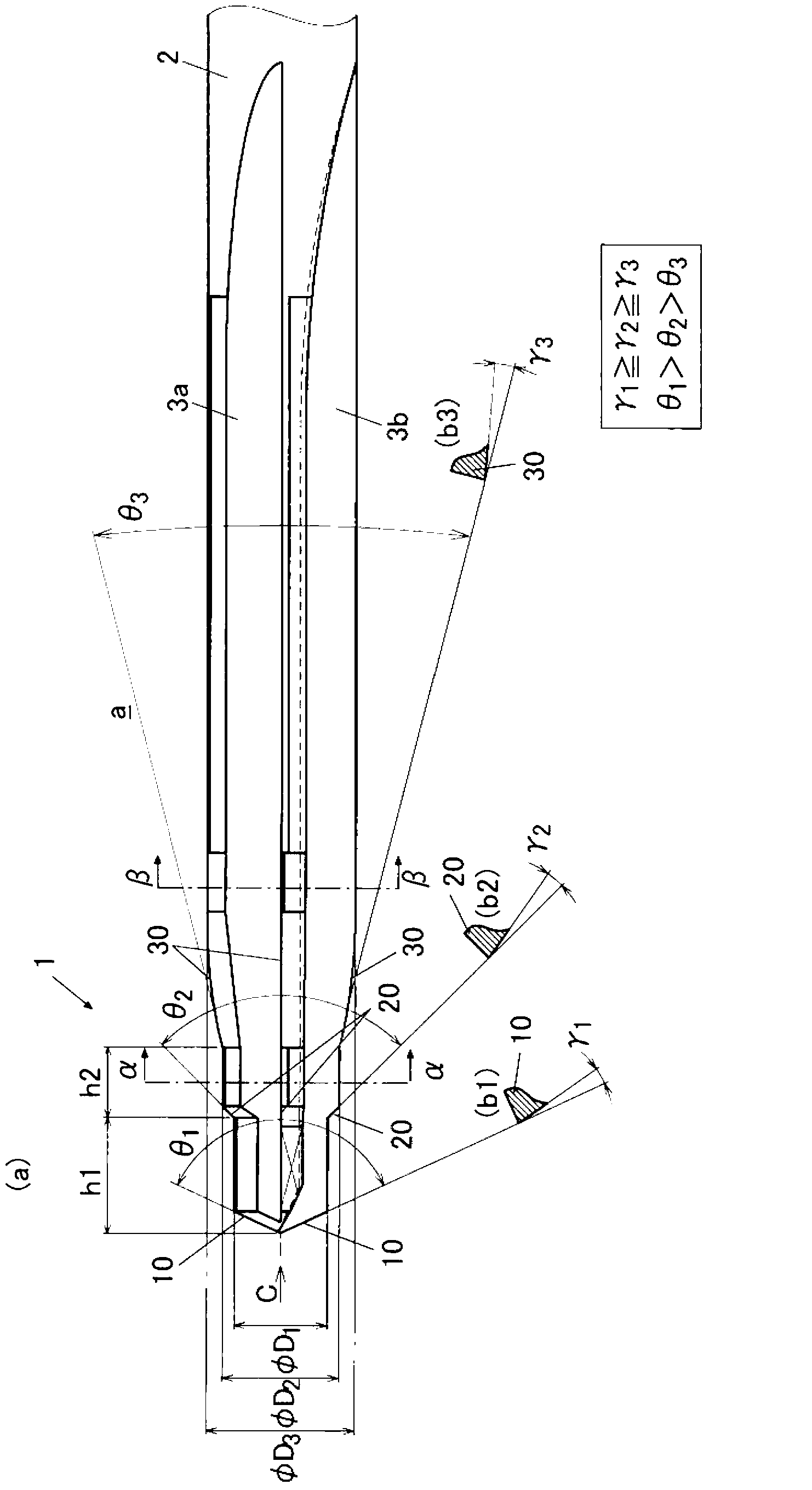

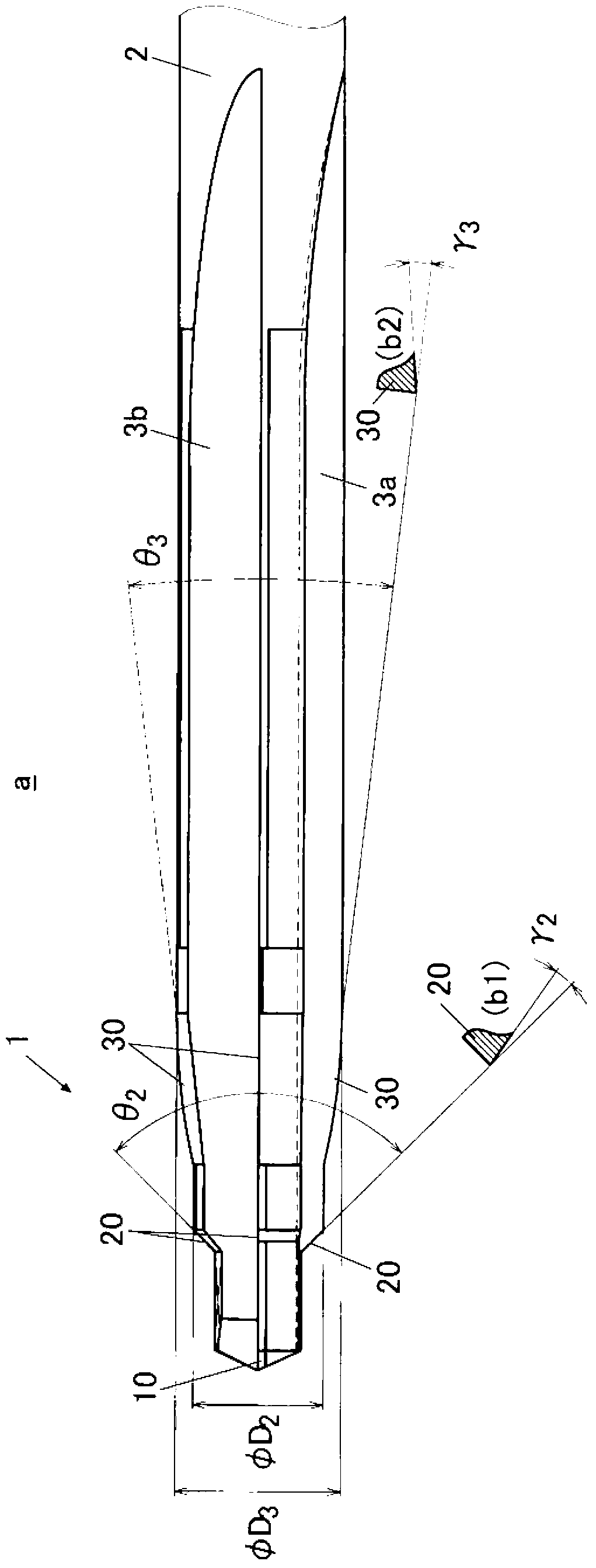

Multi-step multi-micro-blade drill bit for drilling carbon fiber reinforced plastics

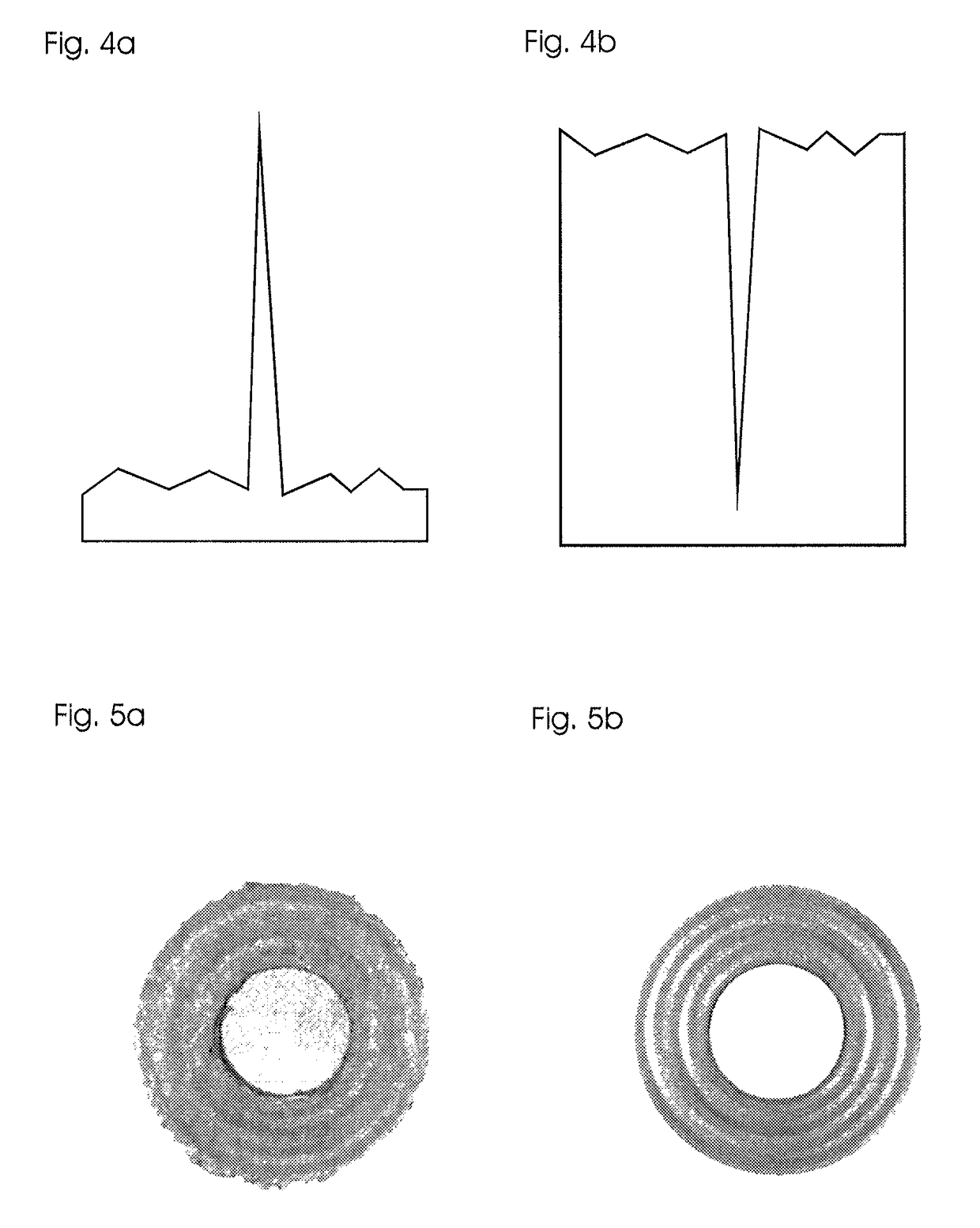

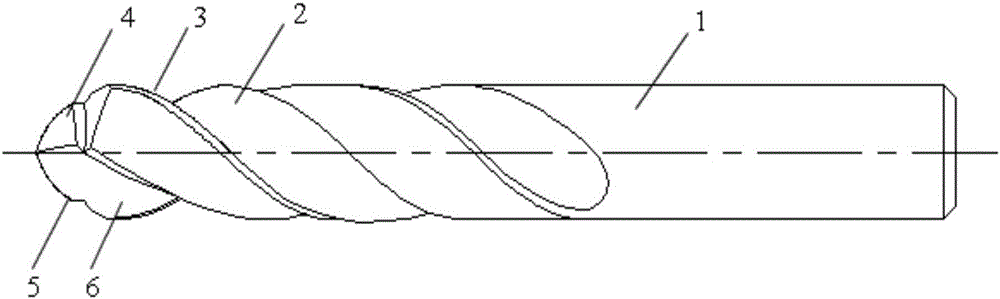

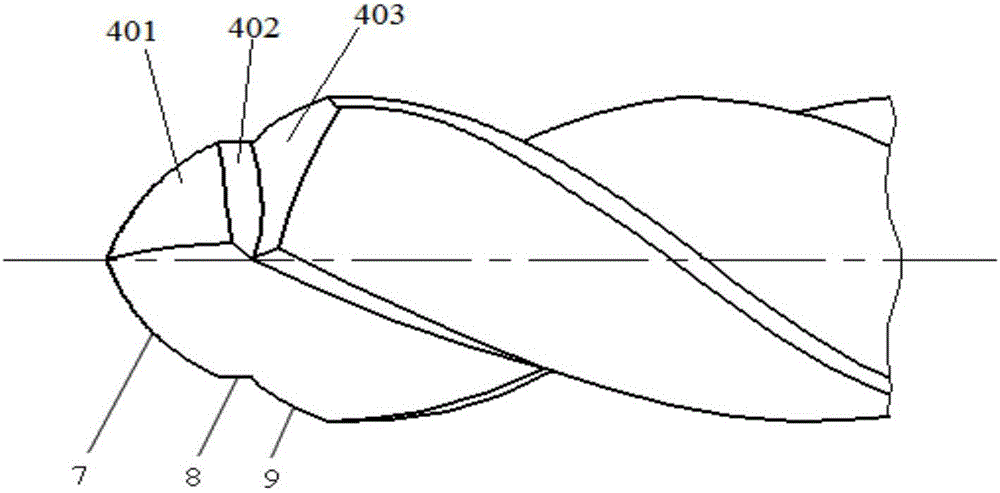

ActiveCN106077768AEfficient removalReduce vibrationTransportation and packagingStepped drillsFiberEngineering

The invention relates to a multi-step multi-micro-blade drill bit for drilling carbon fiber reinforced composite plastics. The multi-step multi-micro-blade drill bit comprises a step cutting area, a micro-tooth cutting area, an auxiliary cutting area, an inverse taper area and a clamping area. The step cutting area is formed by n stages of stepped structures; each stage of stepped structure is formed by a step main cutting area and a step auxiliary area; the micro-tooth cutting area is located in the step cutting area and formed by n stages of micro-tooth structures which are sequentially distributed in a direction from a drill point to the clamping area; and the inverse taper area is located on the auxiliary cutting area. The multi-step multi-micro-blade drill bit provided by the invention has the step structures, and the micro-tooth structures are distributed on auxiliary cutting blades of all stages of step structures, so that burrs produced in the drilling process can be rebounded into the micro-tooth structures and cut off by micro teeth, so that the burrs in an inlet and an outlet can be effectively removed, and the layering and tearing damage during final hole forming is reduced; and an inverse taper structure is adopted, so that the vibration of a hole inlet side in the final forming stage of drilling is reduced, and the hole diameter accuracy and the inlet quality are improved.

Owner:DALIAN UNIV OF TECH

Damaged bolt and screw removing devices

ActiveUS8276482B2Improve biteEfficient extractionTransportation and packagingSpannersEngineeringDrill bit

Owner:COMBINED PRODS

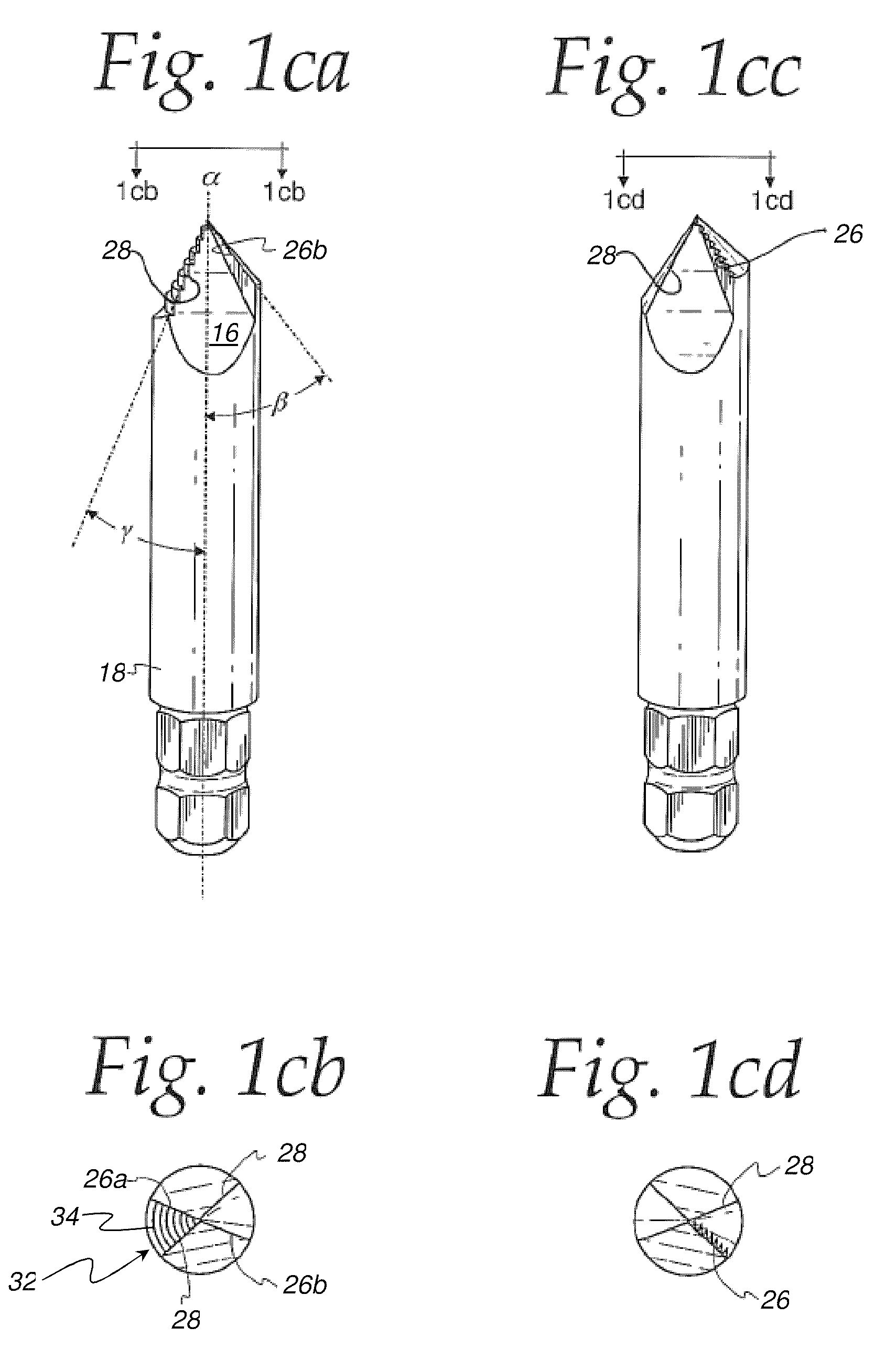

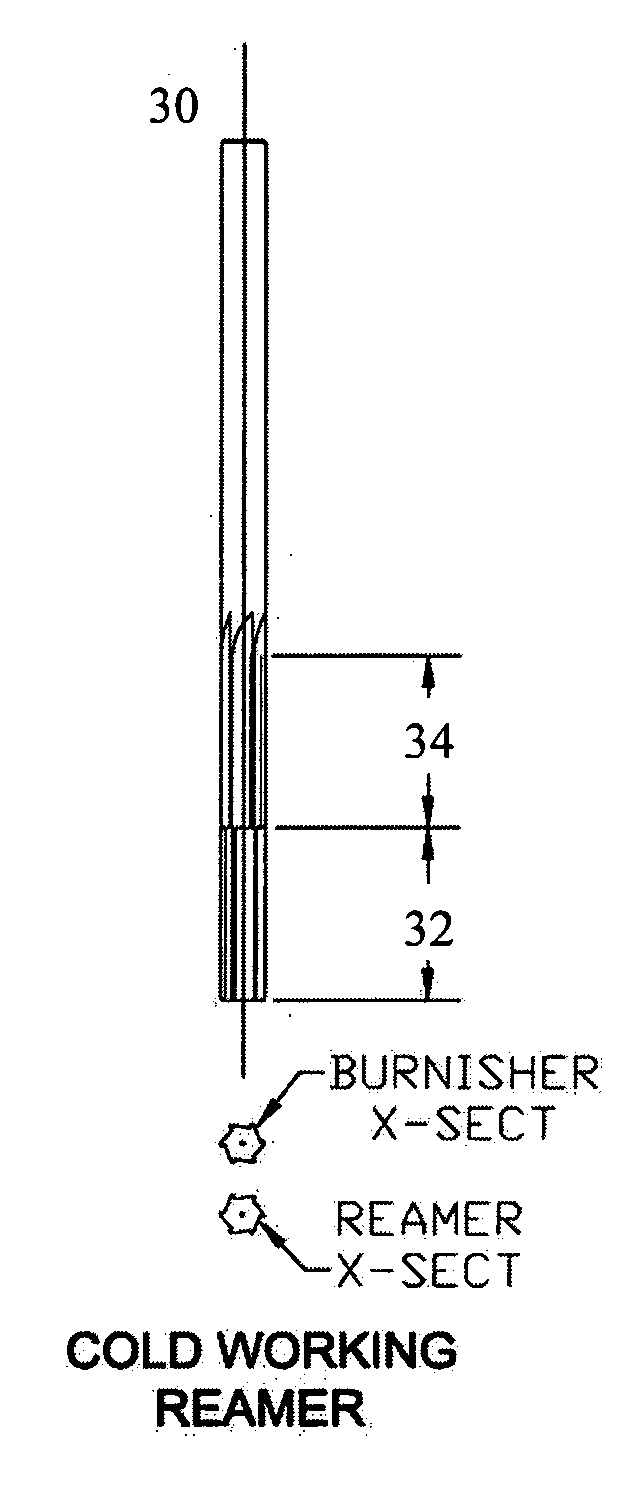

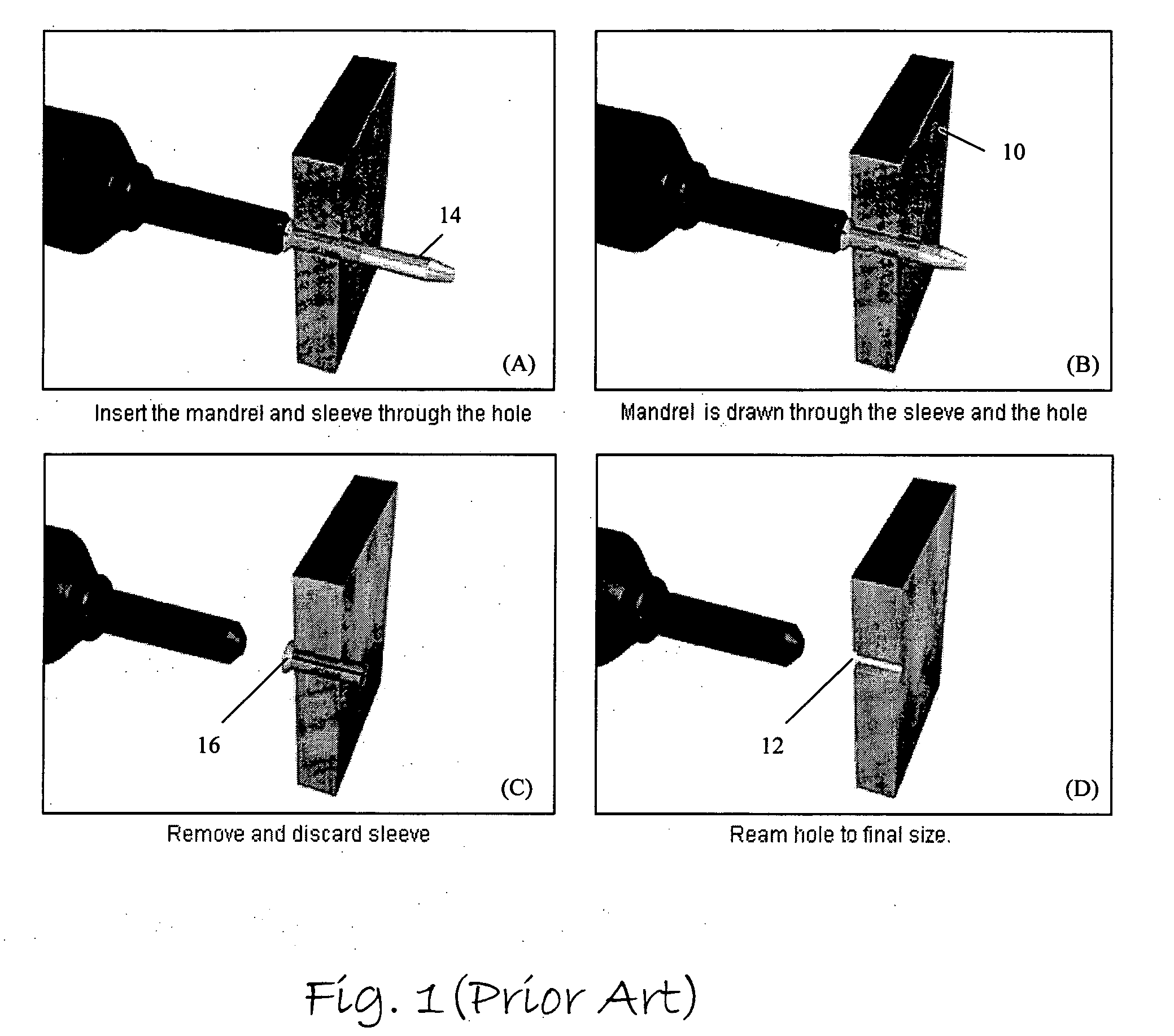

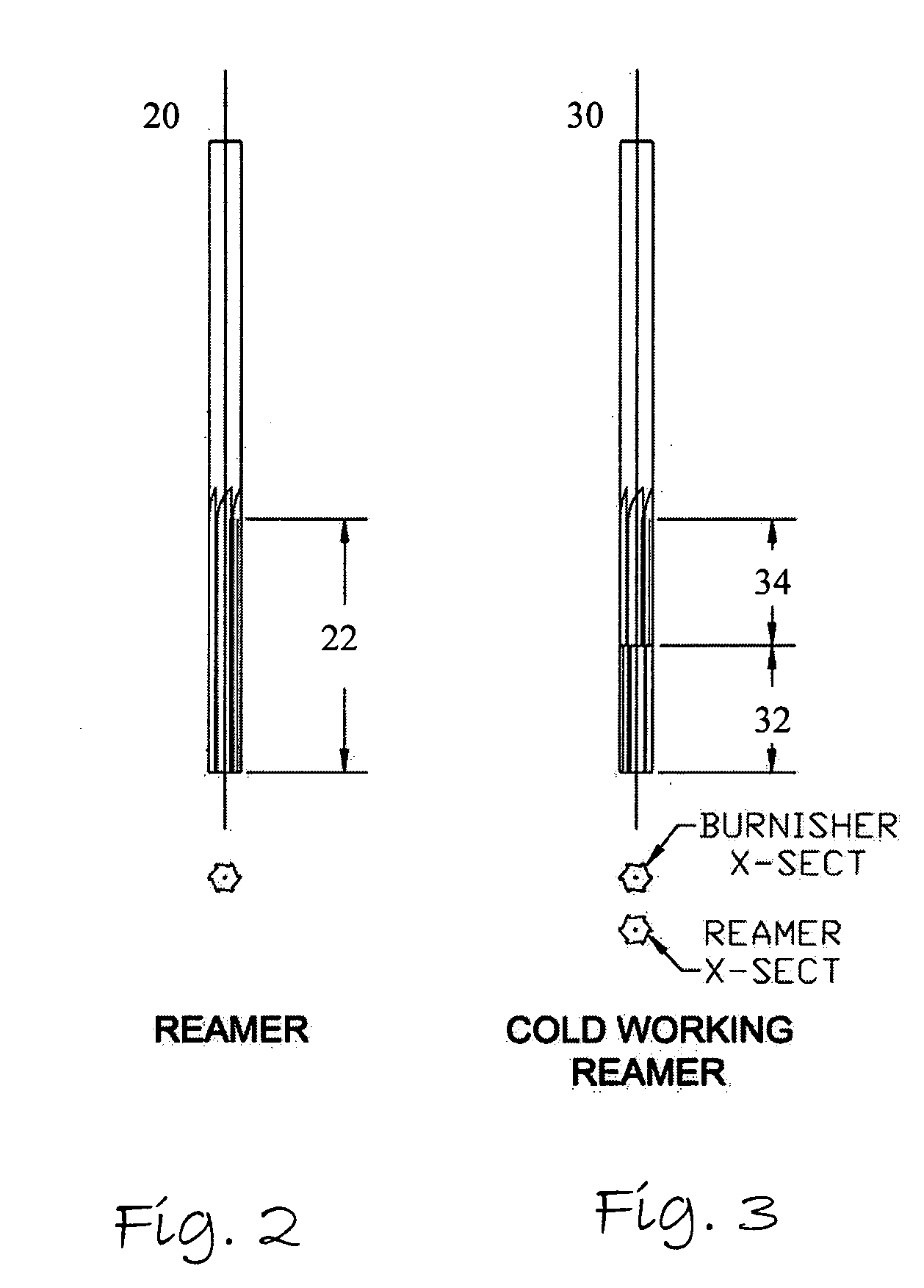

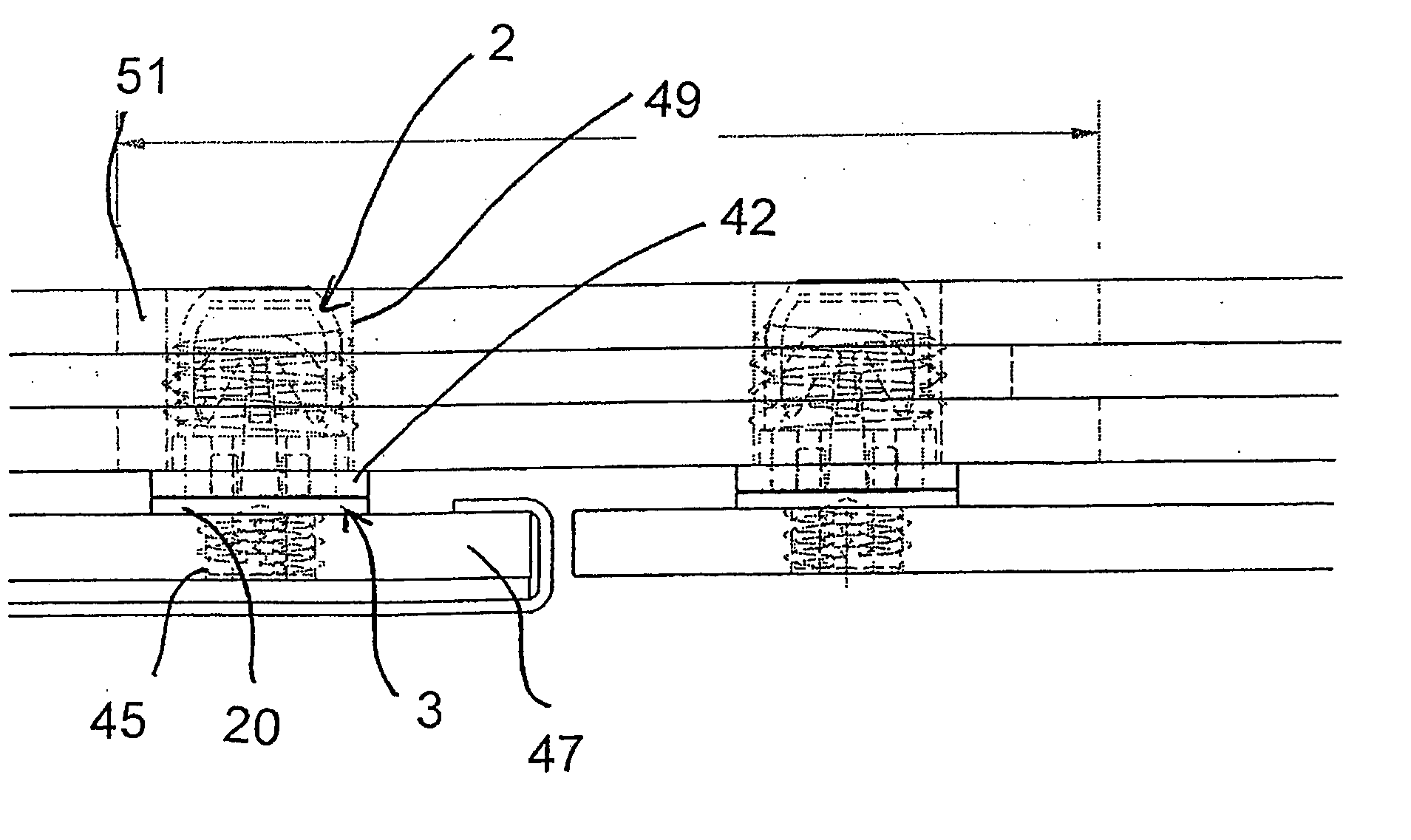

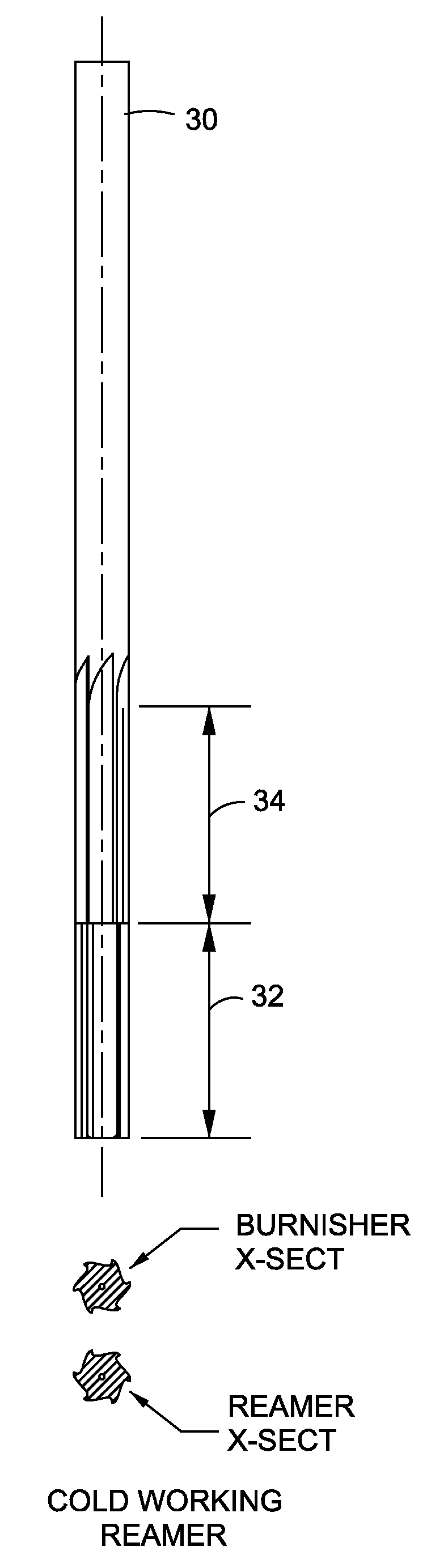

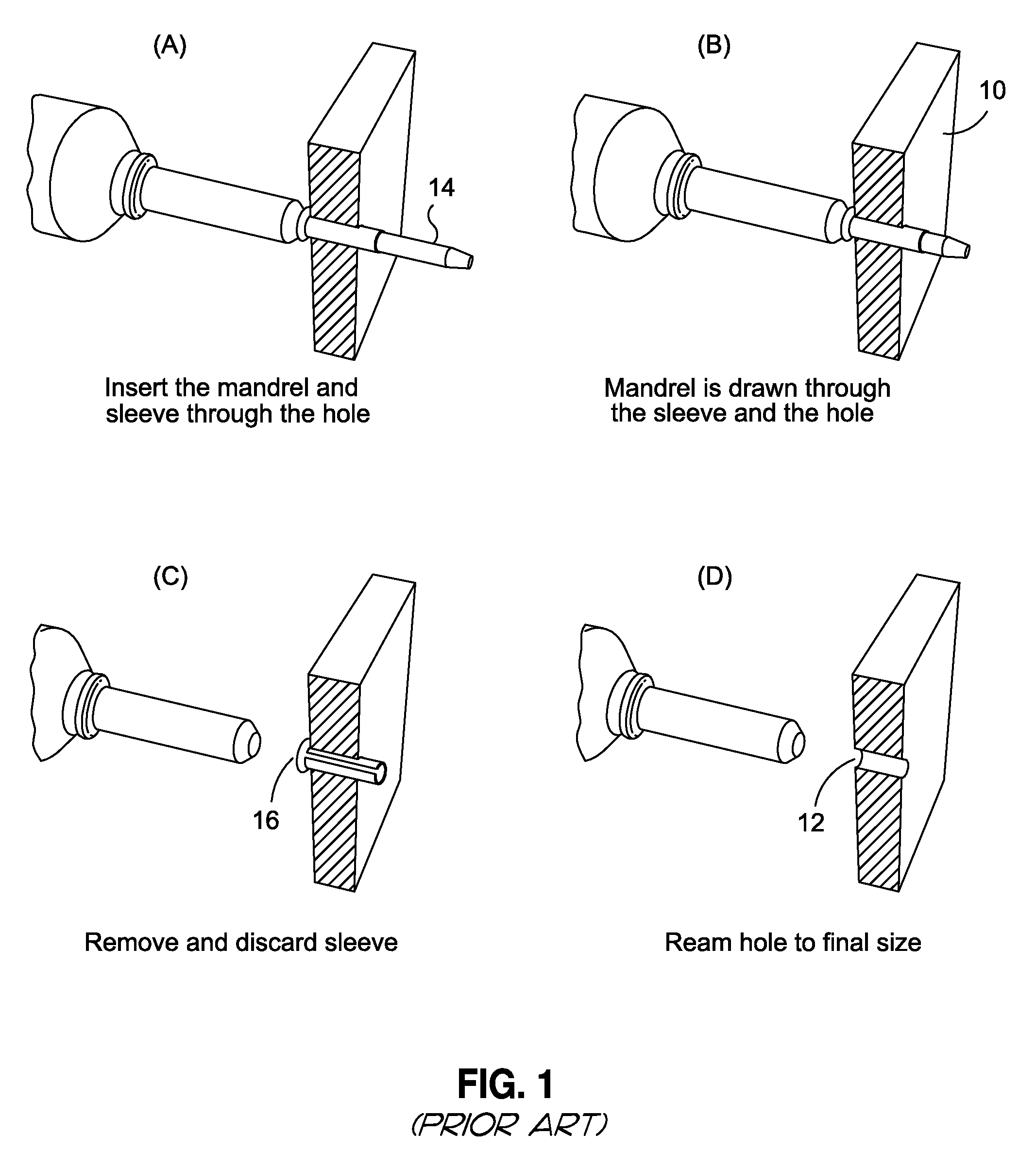

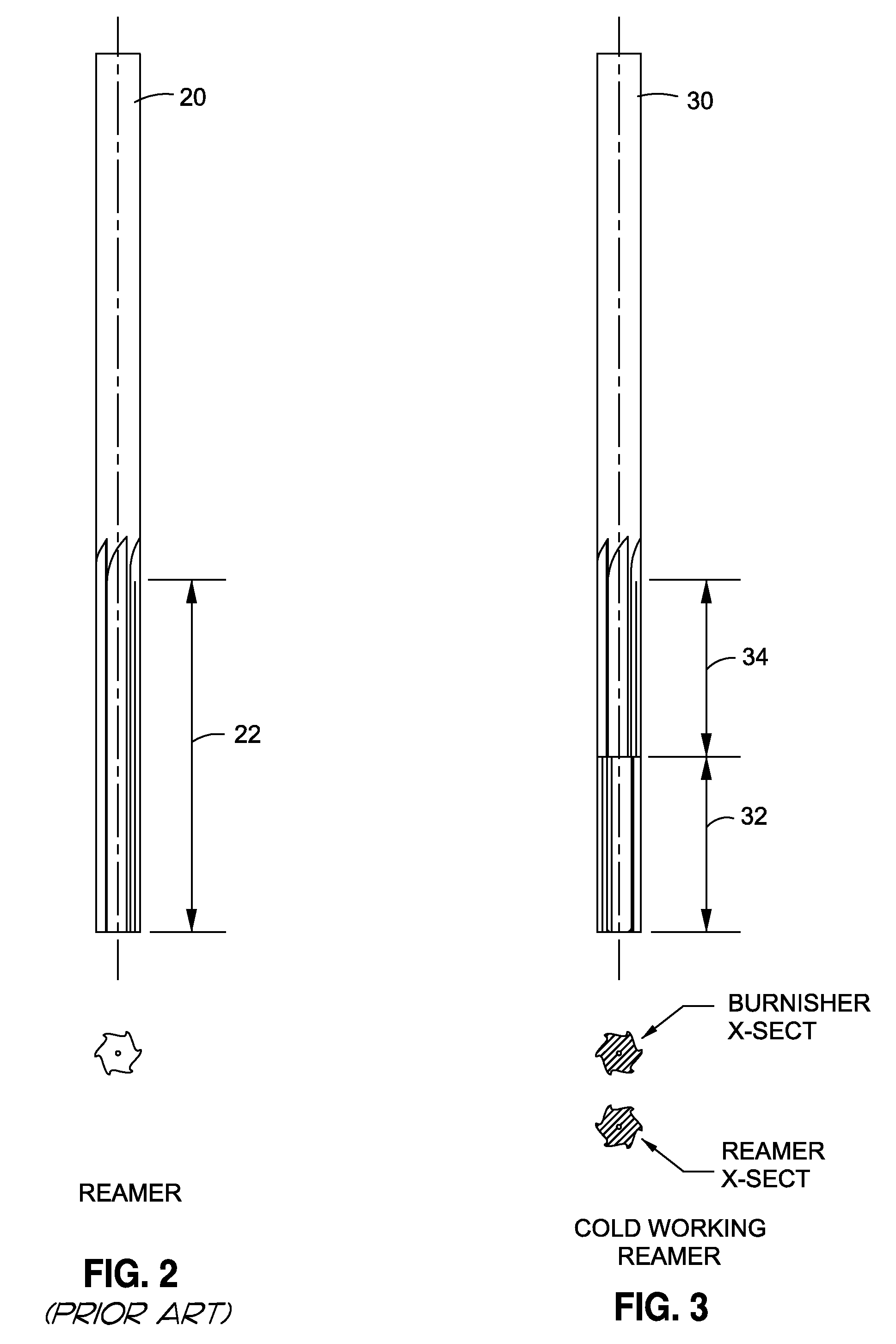

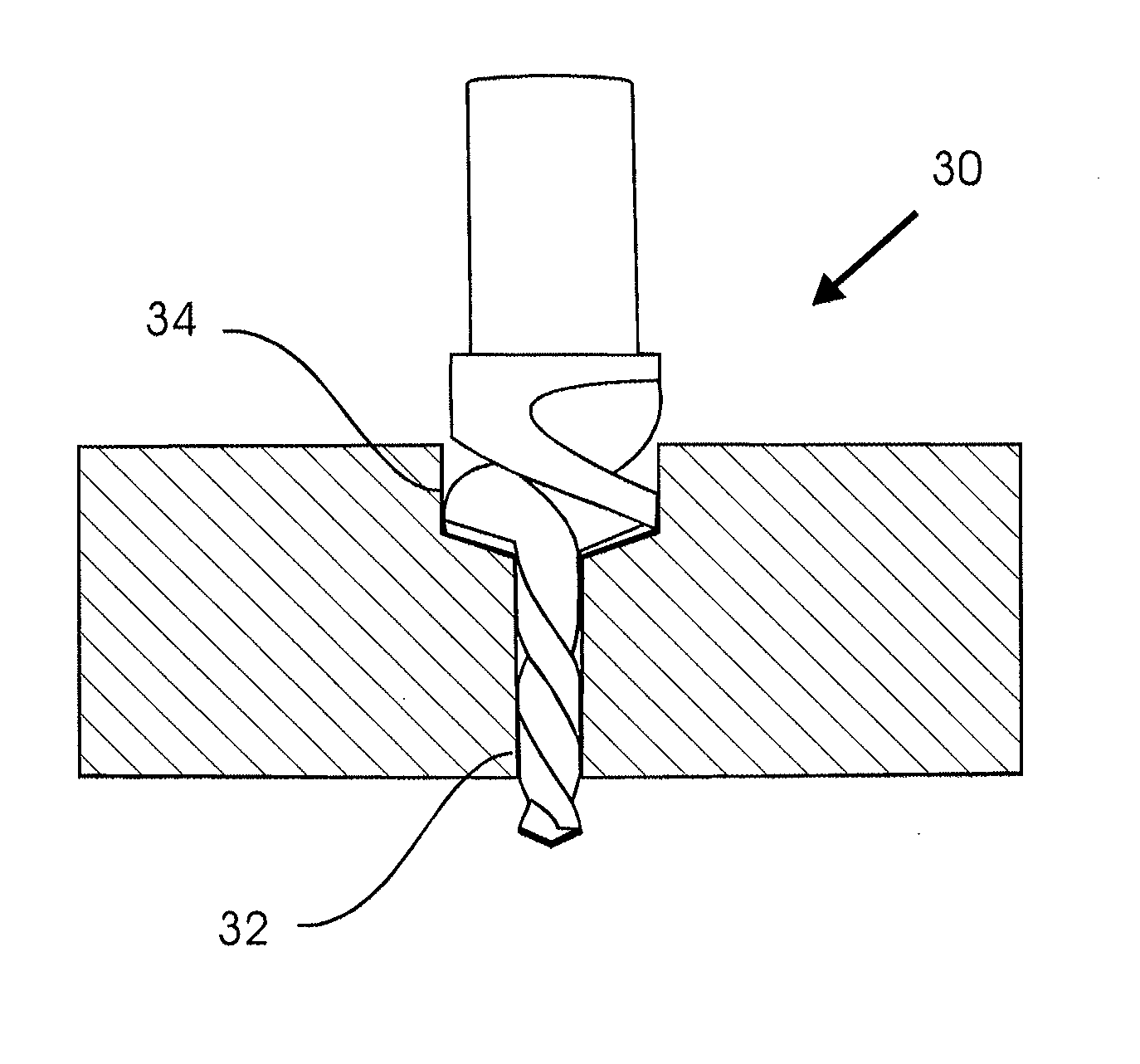

Device and method for sequentially cold working and reaming a hole

A device and a method are provided to allow a user to ream a hole to an accurate final diameter as desired, and at the same time, to cold work the hole to induce a beneficial residual stress that will enhance the life of the component by retarding the onset and growth of fatigue cracks in the hole. The basic design of the device has an elongated body having a forward end portion to extend through a hole to be reamed and cold worked, a reamer section formed on the circumference of the forward end portion to enlarge the hole, and a burnishing section formed on the circumference of the elongated body adjacent to the reamer. The burnishing section is operative to upset the material around the hole, so as to result in a residual stress beneficial to the hole. The reamer section is in the form of a plurality of cutting edges extending from a tip of the elongated body, while the burnishing section is also in the form of a plurality of cutting edges adjacent to the reamer section along the elongate body. The cutting edges of the reamer sections are parallel straight cutting edges or helical cutting edges. The cutting edges of the burnishing section are configured with an orientation opposite to that of the cutting edges of the reaming section. Therefore, when the cutting edges of the burnishing section are configured with the same profile as the cutting edges of the reamer section, the burnishing section is in the form of a backward reamer section.

Owner:NORTHROP GRUMMAN SYST CORP

Damaged bolt and screw removing devices

A bit for removing a broken fastener comprises a tip from which extend two or more notches separated by scraping surfaces formed from two-sided frusto-conically-shaped regions. The scraping surfaces are bounded on one side by a cutting edge and on the other side by a non-cutting edge and are configured to cut into the fastener when the bit is rotated in a direction opposite to the fastener's direction of engagement. Specific embodiments include configurations where the cutting edges extend at different angles with respect to the bit axis and where the scraping surfaces comprise a plurality of serrations.

Owner:COMBINED PRODS

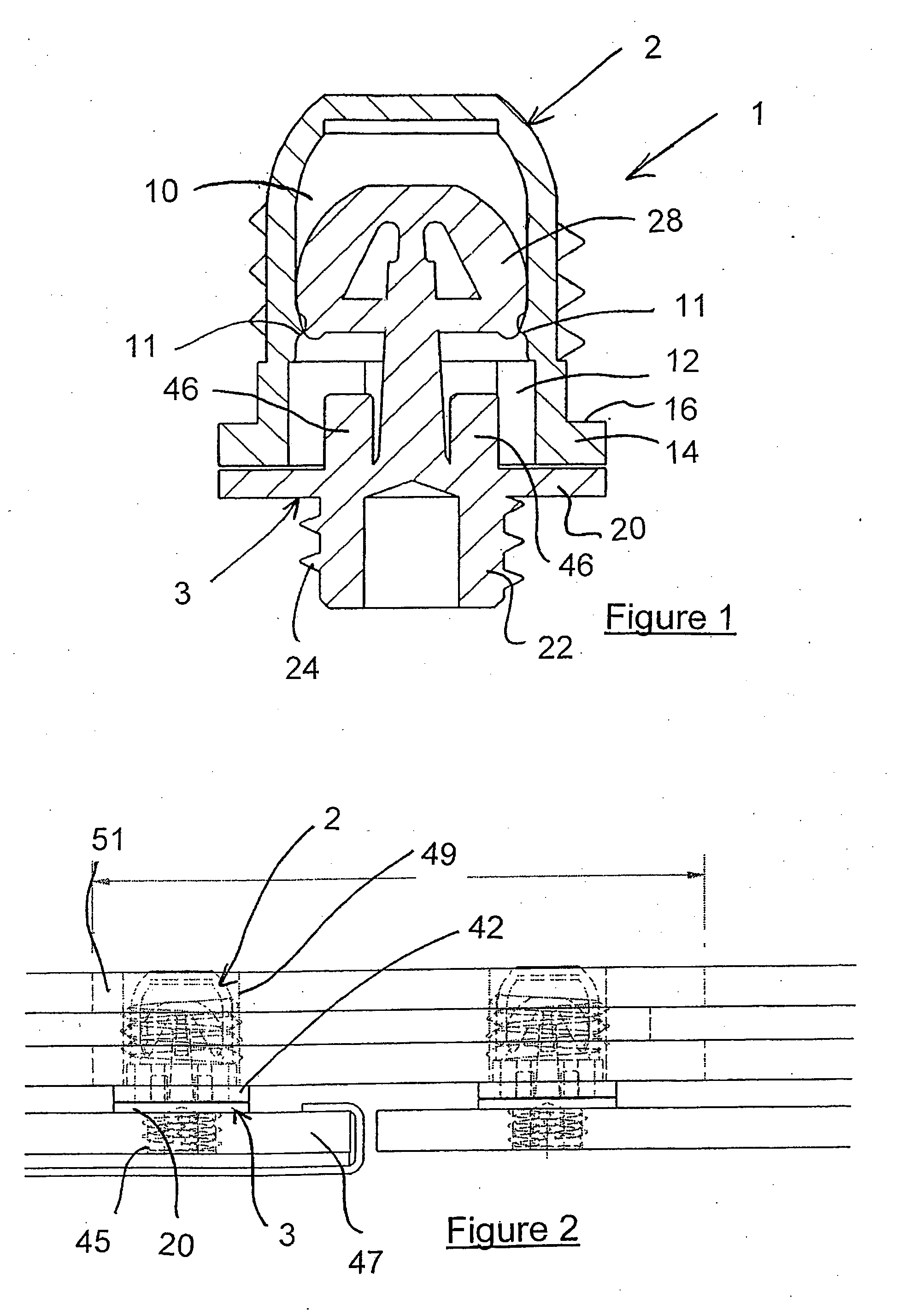

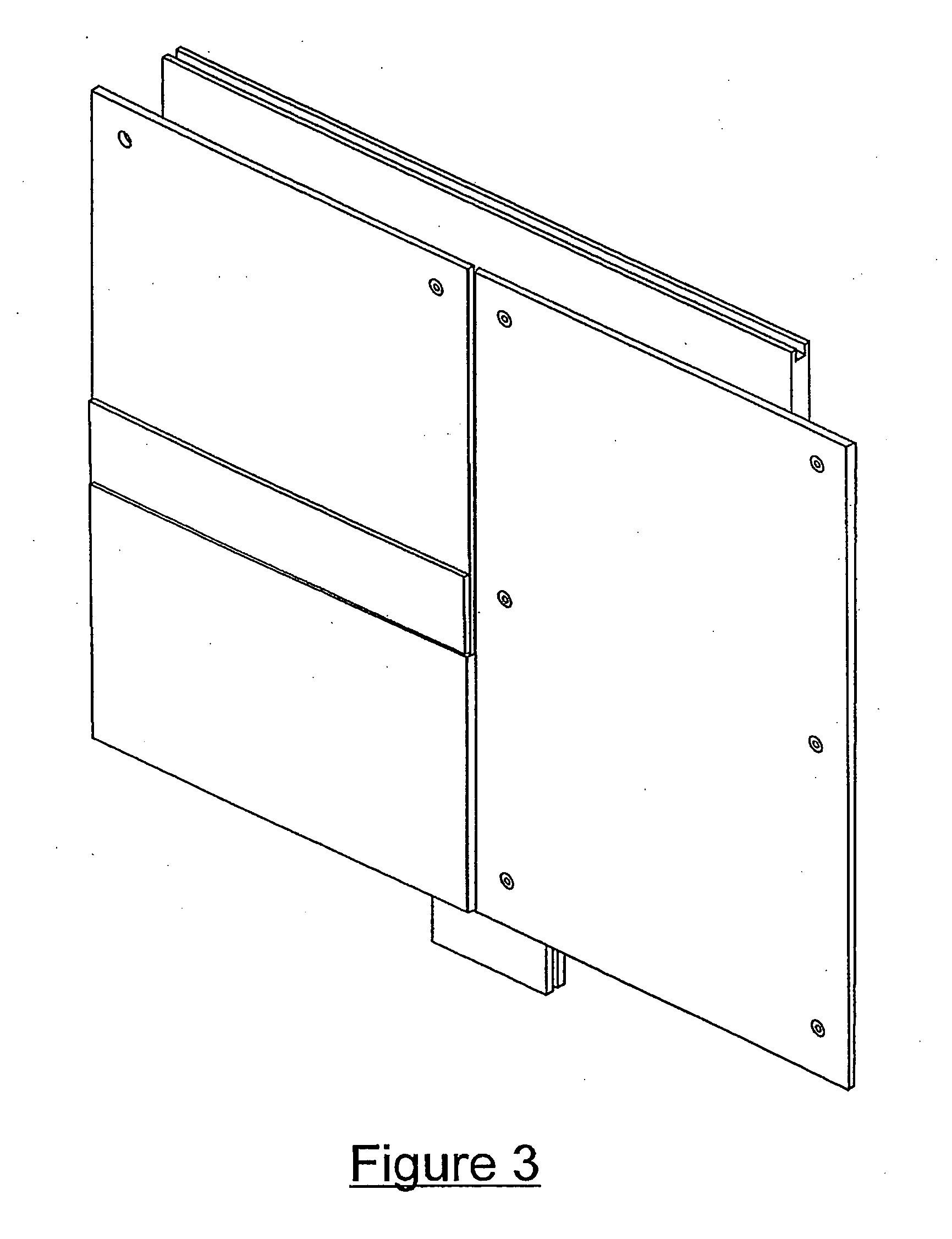

Panel mounting clip

A method of installing panels includes temporarily securing un-upholstered panels in place on an underlying support and marking the underlying support at each of a plurality of panel clip locations on the panel. The panel is removed from the support structure for upholstering. The support structure is drilled at the marks to provide a hole to receive a socket component, and a socket component is driven into each of the receiving holes in the support structure. The socket component includes a cup open to at least one end, an external thread for engaging the support structure, and a constriction in the cup spaced away from the bottom of the cup. A plug component is secured at each of the panel clip locations on the panel, the plug component having a protruding portion to engage in the socket. The upholstered panel is lifted into position and the periphery is pressed into place to engage the protruding portions of the plug components within the cups of the sockets.

Owner:FASTMOUNT

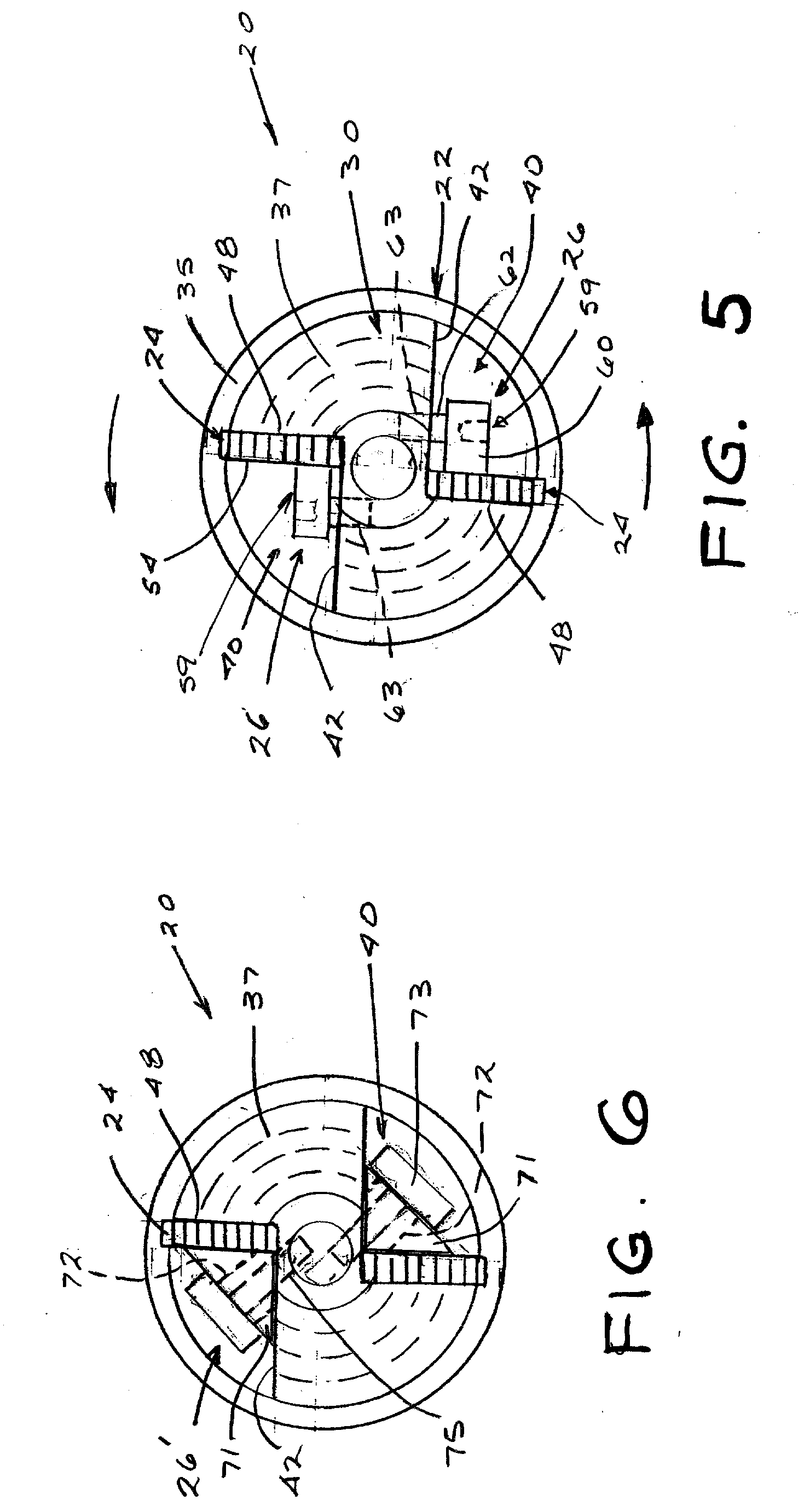

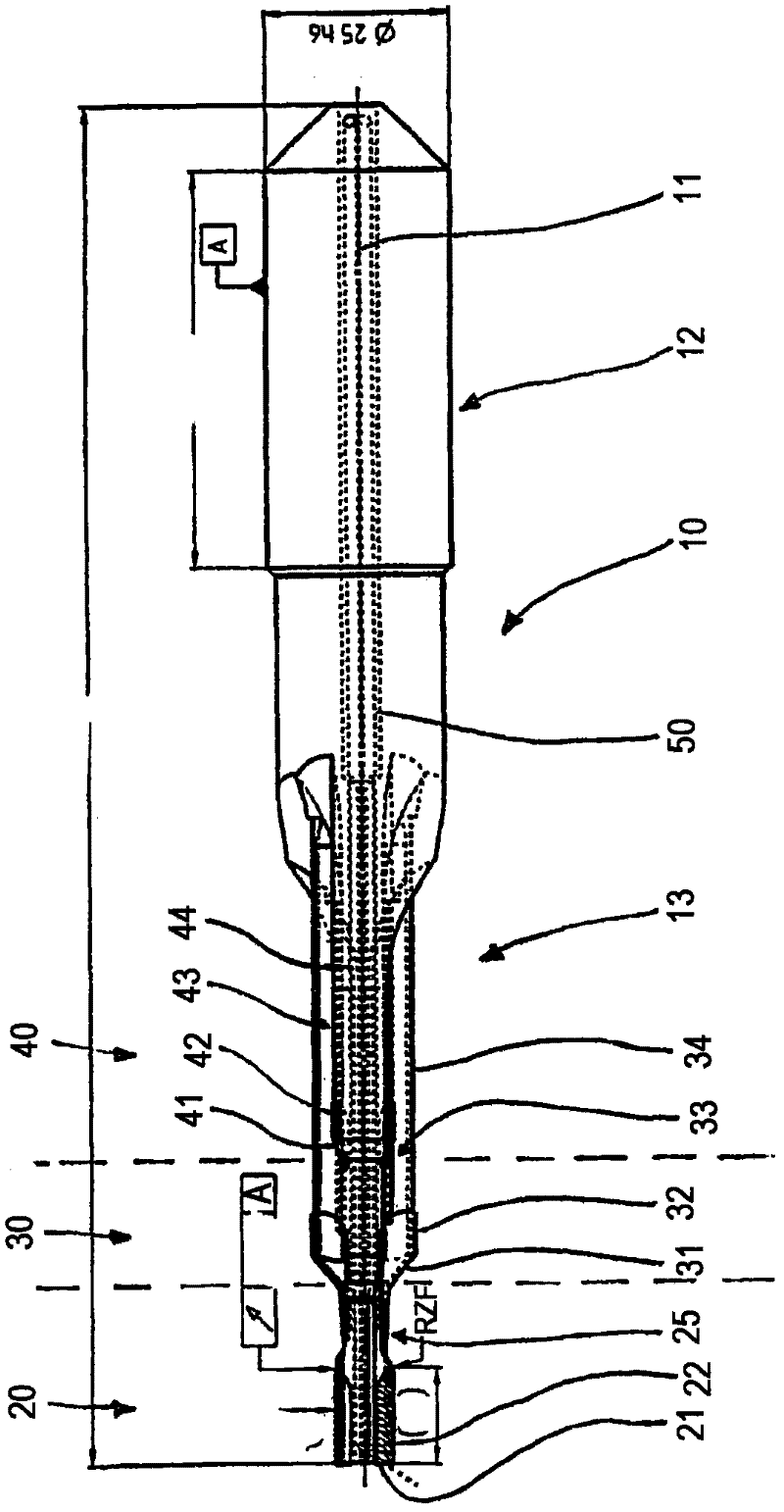

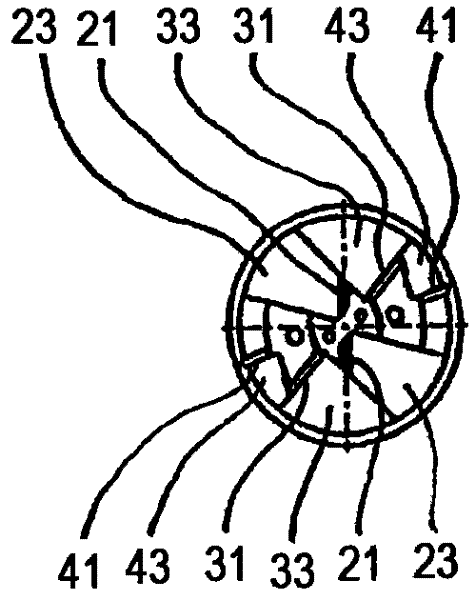

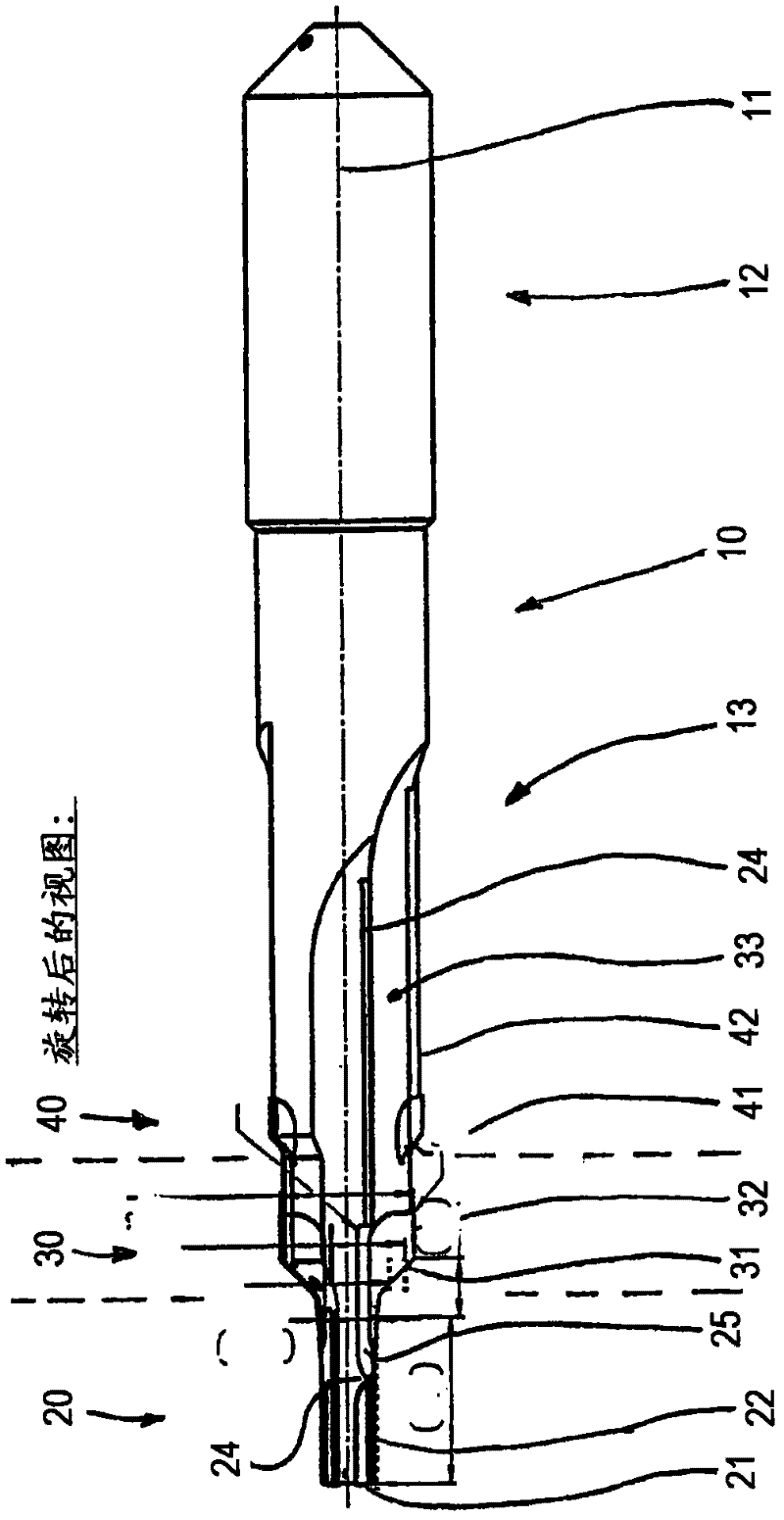

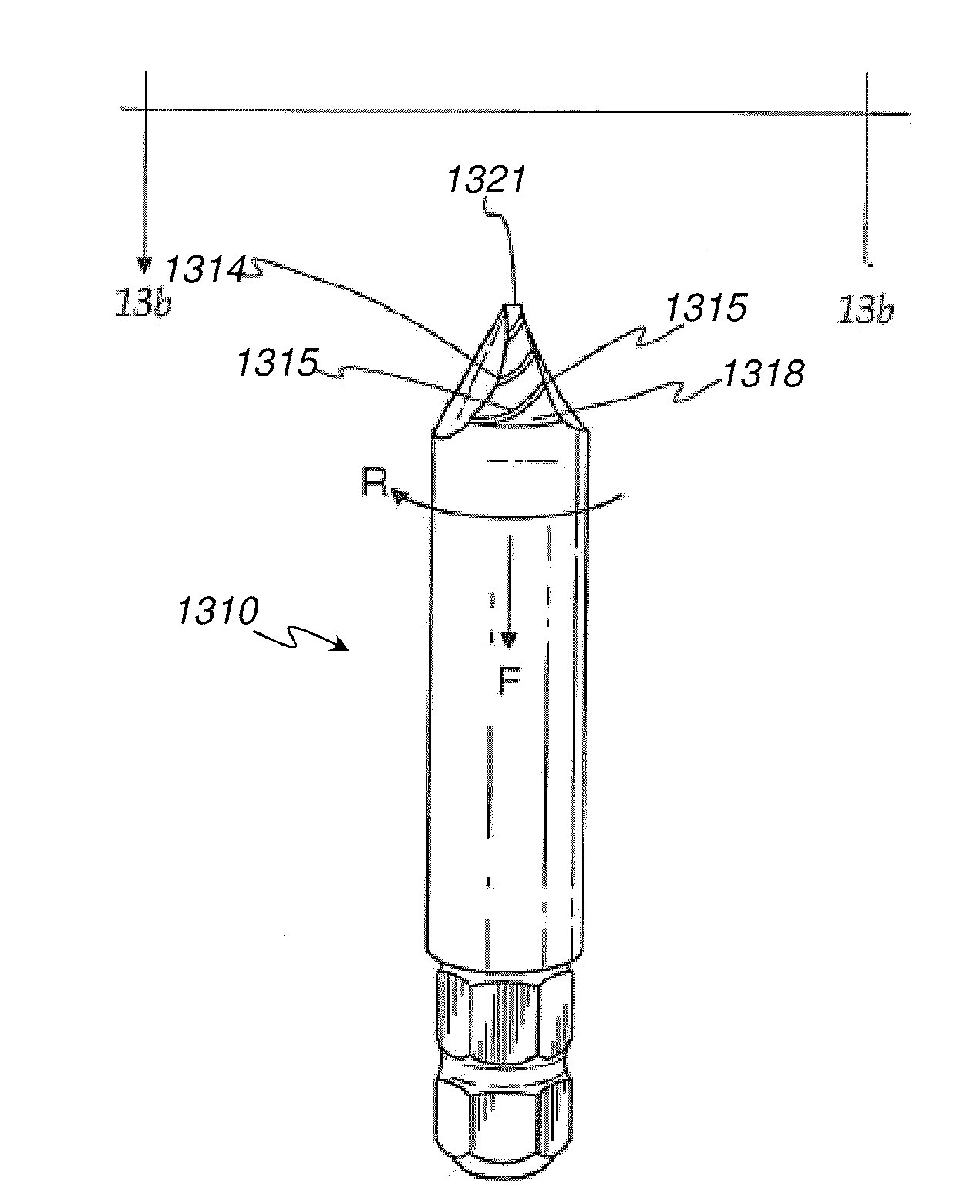

Rotationally driven multi-bevel step tool

InactiveCN102448646AIncrease the lengthIncreased usable chip removal volumeTransportation and packagingWorkpiecesFluteEngineering

The invention relates to a rotationally driven multi-bevel step tool, particularly a step drill for drilling into solid material, comprising a plurality of one-edged or multi-edged cutting steps which are arranged in a staggered manner in the cutting and advancing directions and each have a number of flutes that corresponds to the number of edges. Flutes (23, 33) adjoining each other in the circumferential direction are separated from each other by a web (24). According to the invention, the flues (23, 33) adjoining each other in the circumferential direction of two consecutive cutting steps (20, 30) in the cutting and advancing directions are connected to each other by a metal-cutting window (25) that is open on the circumferential side and interrupts the interposed web (24).

Owner:GUEHRING OHG

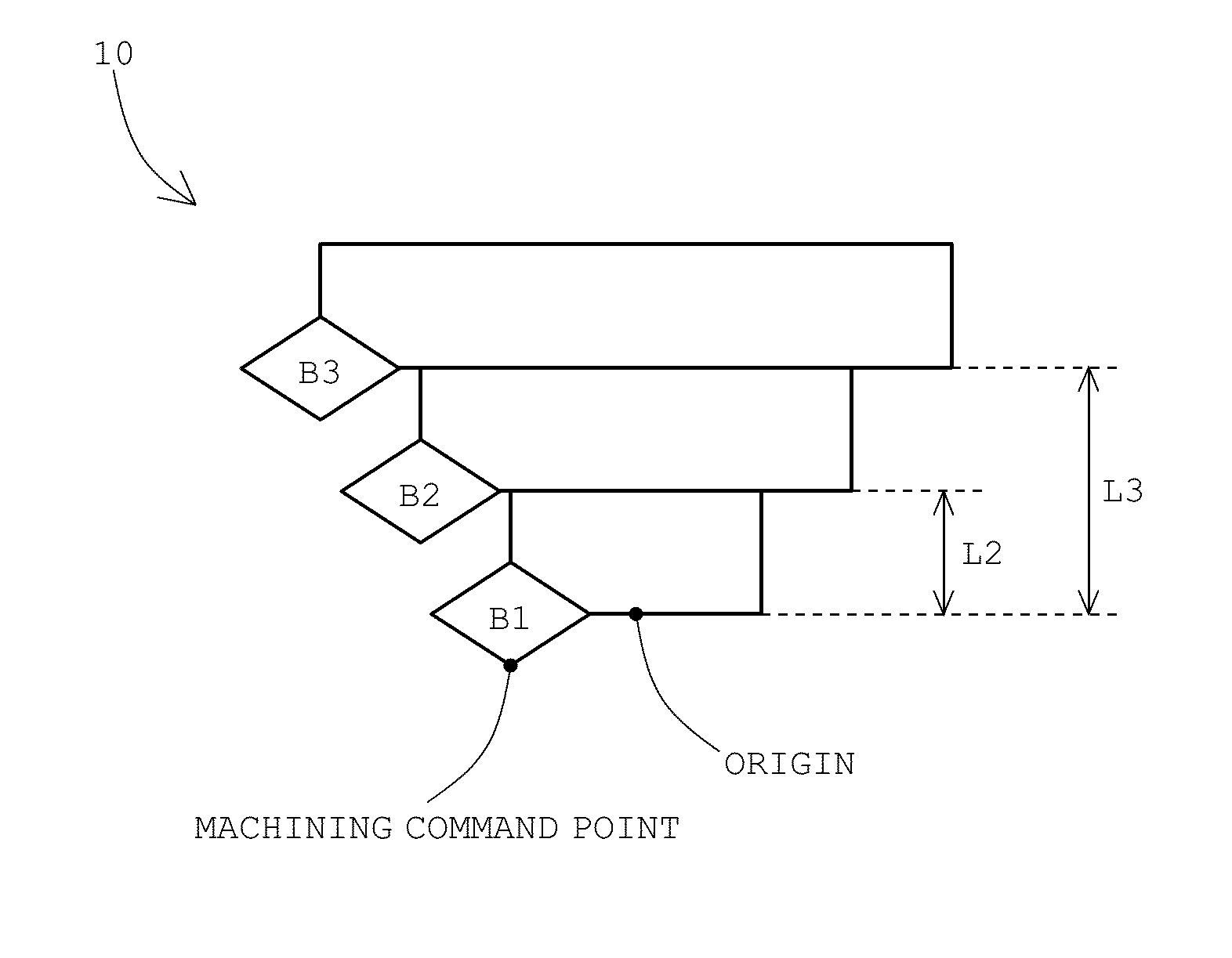

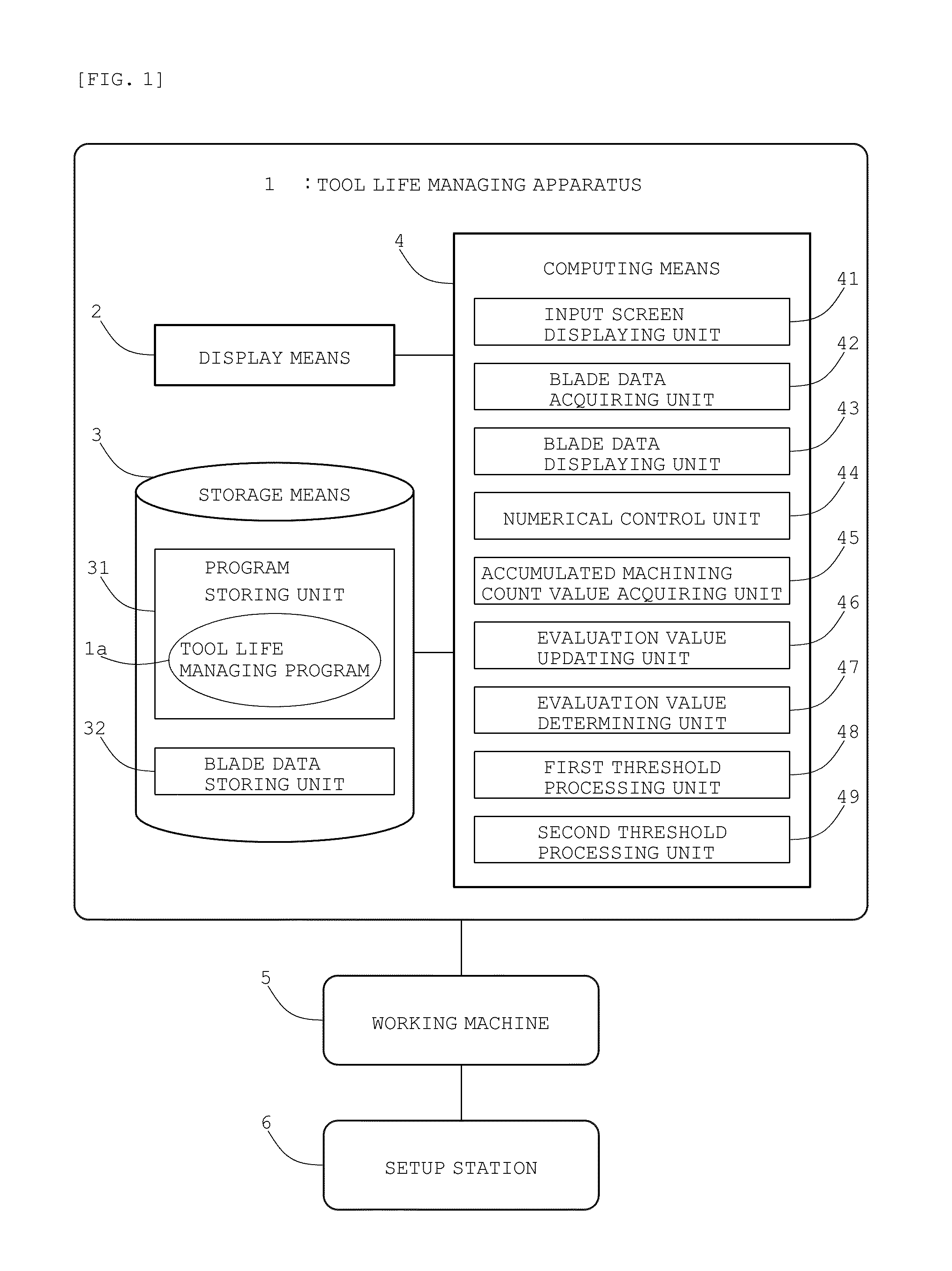

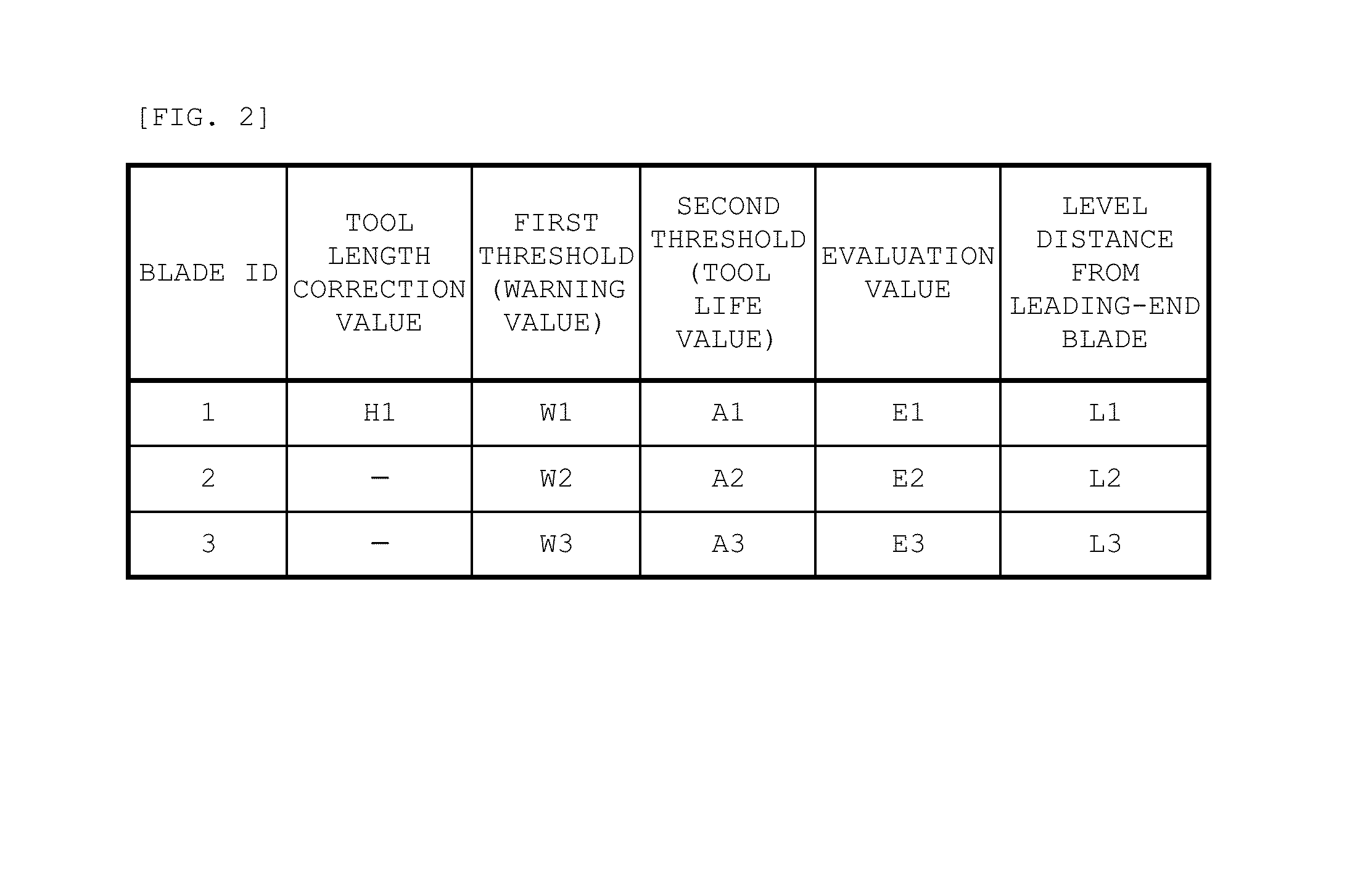

Tool life managing apparatus for stepped tool

InactiveUS20160170404A1Low costWork lessProgramme controlComputer controlData storingSystems engineering

Provided is a tool life managing apparatus for a stepped tool capable of appropriately managing the tool life of each blade provided to the stepped tool and reducing cost and work for blade replacement. A tool life managing apparatus 1 manages the tool life of a stepped tool 10 provided with a plurality of replaceable blades in a multi-stage manner, and includes: a blade data storing unit 32 that stores, for each of the plurality of blades, a threshold concerning the tool life of the blade, an evaluation value indicating the degree of use at present of the blade, and a level distance from a leading-end blade; an accumulated machining count value acquiring unit 45 that acquires accumulated machining count values of a working machine 5 before and after machining by the stepped tool 10; an evaluation value updating unit 46 that updates the evaluation value of each blade on the basis of the accumulated machining count values, the evaluation value, and the level distance; and an evaluation value determining unit 47 that determines whether or not the updated evaluation value reaches the threshold.

Owner:DMG MORI SEIKI CO LTD

Device and method for sequentially cold working and reaming a hole

A device and a method are provided to allow a user to ream a hole to an accurate final diameter as desired, and at the same time, to cold work the hole to induce a beneficial residual stress that will enhance the life of the component by retarding the onset and growth of fatigue cracks in the hole. The basic design of the device has an elongated body having a forward end portion to extend through a hole to be reamed and cold worked, a reamer section formed on the circumference of the forward end portion to enlarge the hole, and a burnishing section formed on the circumference of the elongated body adjacent to the reamer. The burnishing section is operative to upset the material around the hole, so as to result in a residual stress beneficial to the hole. The reamer section is in the form of a plurality of cutting edges extending from a tip of the elongated body, while the burnishing section is also in the form of a plurality of cutting edges adjacent to the reamer section along the elongate body. The cutting edges of the reamer sections are parallel straight cutting edges or helical cutting edges. The cutting edges of the burnishing section are configured with an orientation opposite to that of the cutting edges of the reaming section. Therefore, when the cutting edges of the burnishing section are configured with the same profile as the cutting edges of the reamer section, the burnishing section is in the form of a backward reamer section.

Owner:NORTHROP GRUMMAN SYST CORP

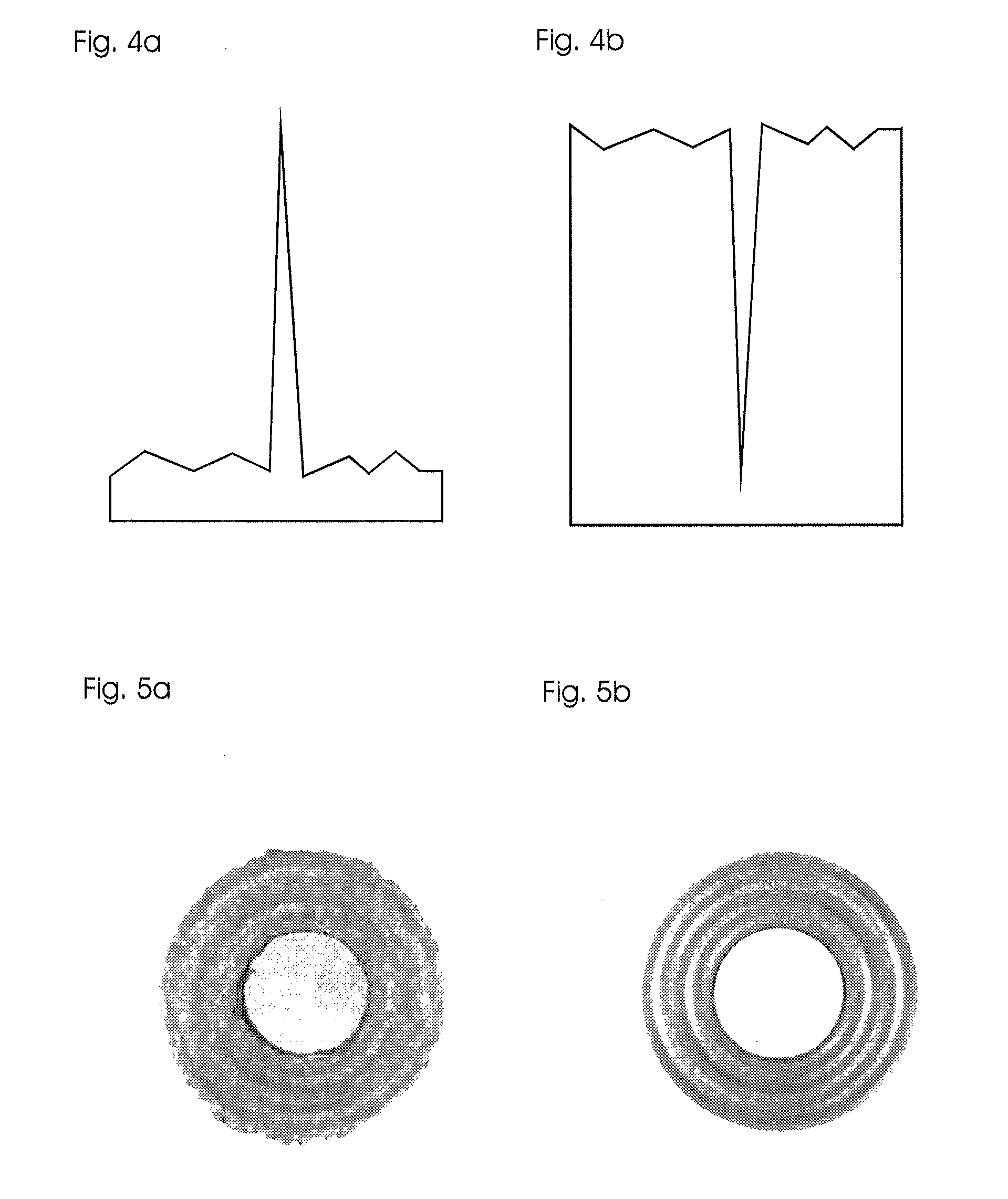

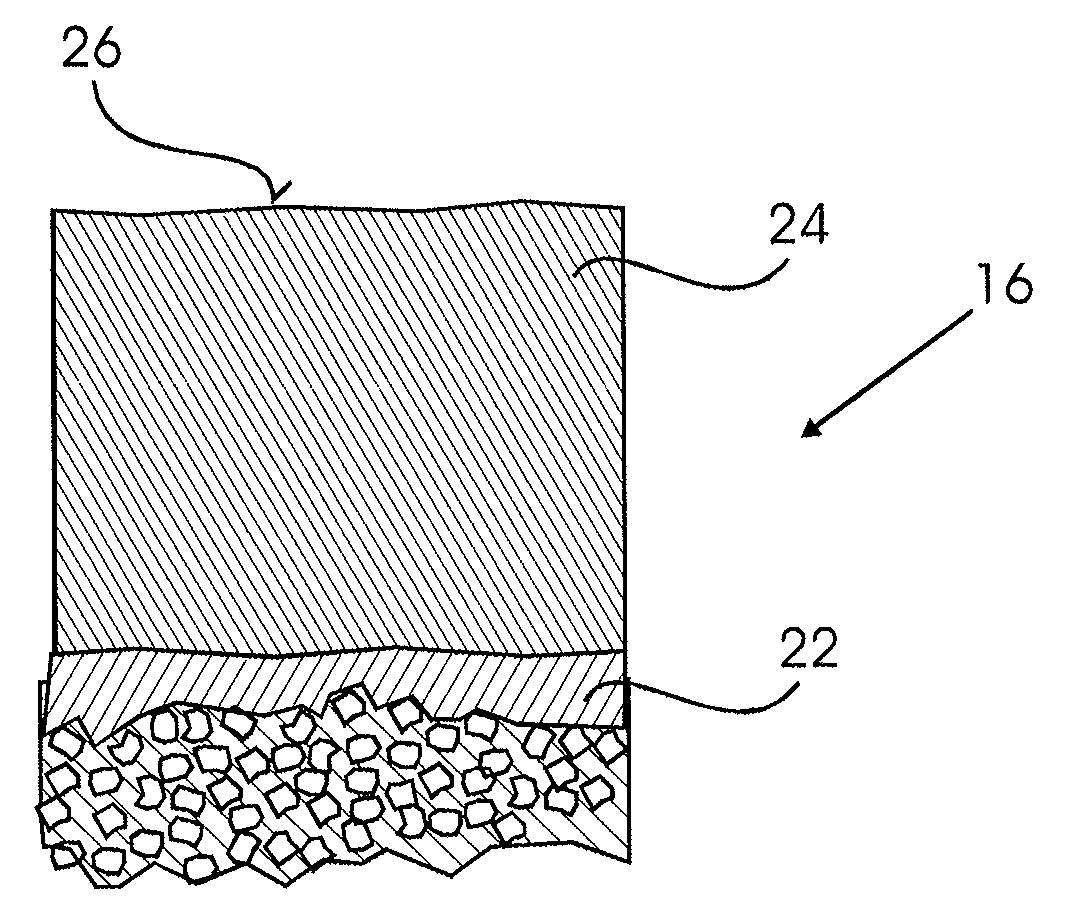

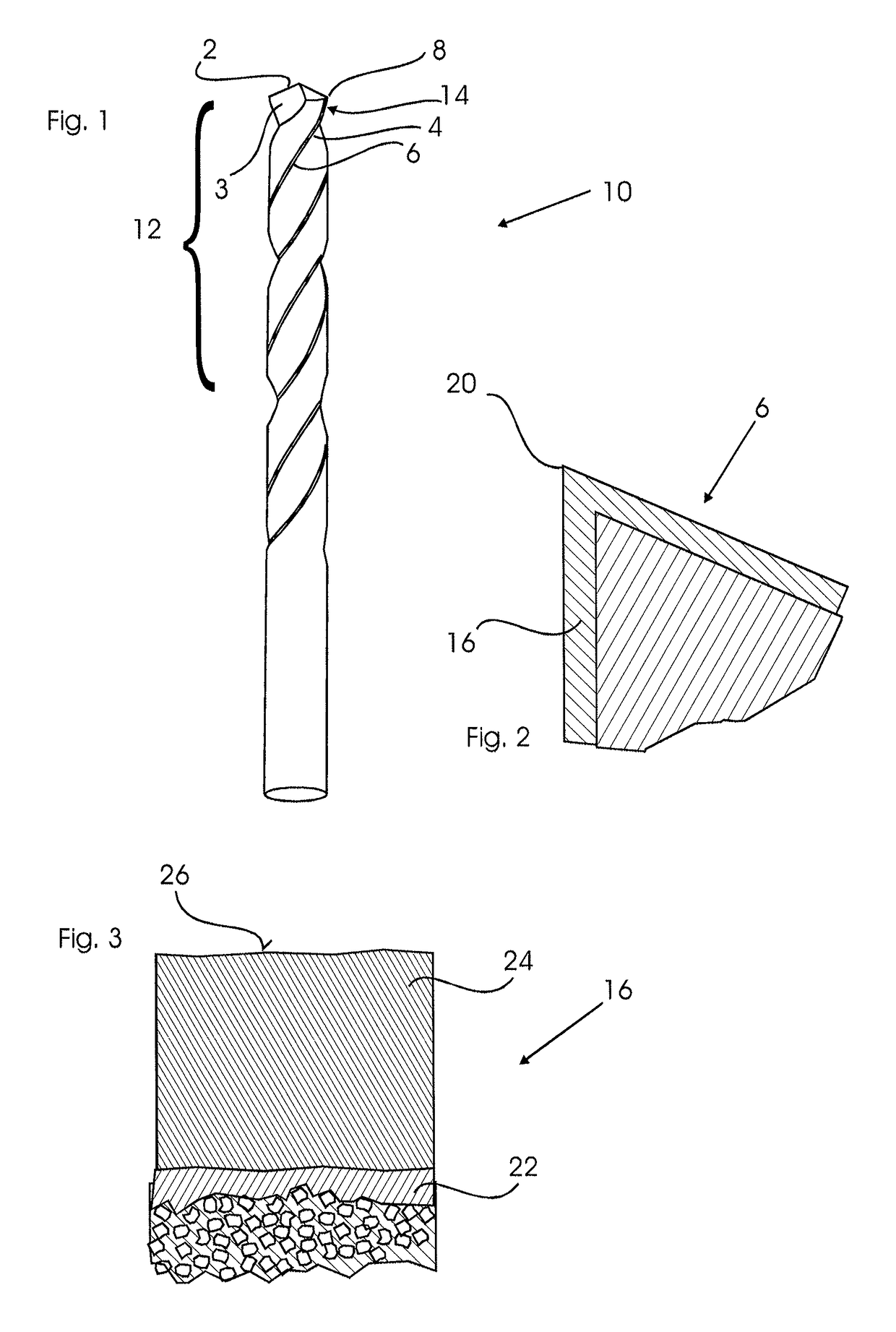

Tool and Method for Machining Fiber-Reinforced Materials

ActiveUS20160228954A1Extended service lifeCleaner drilled holesTransportation and packagingMilling cuttersMetallurgyMaterials science

A tool for machining fiber-reinforced materials, said tool having a tool body having a particular cutting edge that has at least a main function surface and has a diamond coating applied at least to said main function surface. In order to provide a tool and a method which are especially suitable for machining fiber-reinforced materials, the surface of the diamond coating has a reduced peak height Spk of less than 0.25 μm.

Owner:CEMECON

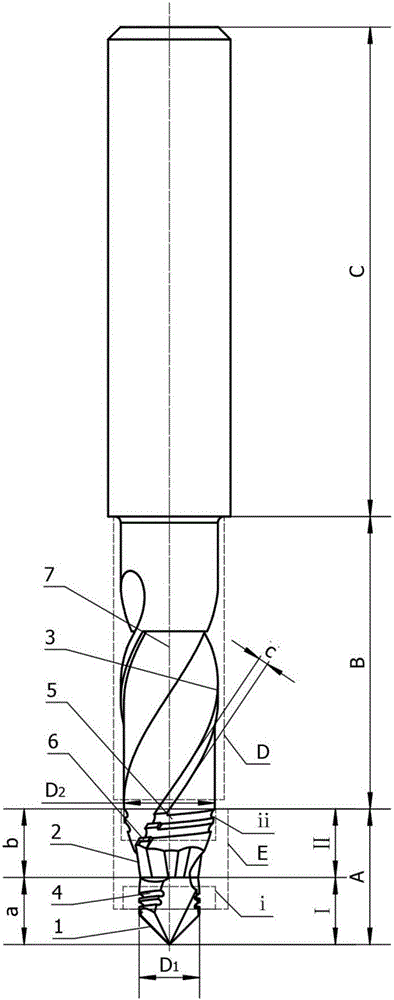

Solid step drill

A solid step drill, including a front tip and a rear end between which a center axis extends and around which the drill is rotatable in a predetermined direction. At least two cylindrical sections are concentric with the center axis, a first section extending rearward from the front tip and having a first diameter, and a second section extending behind the first section and having a second diameter that is greater than the first diameter, the first section transforming into the second section via a step. The tip includes two primary cutting edges, which individually co-operate with a respective chip flute that is delimited by a concave surface and countersunk in the first section and in the second section, the respective chip flute intersecting the step while forming a secondary cutting edge. Adjacent to the secondary cutting edge, a chip breaking recess is formed between a cutting edge line of the cutting edge and the concave surface.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Drilling system and methods for deep hole drilling

A deep hole drilling system and methods provide stability and cutting performance to produce deep holes having desired straightness. The system may include a replaceable cutting head provided with a center cutting member and first and second side cutting inserts. The tool provides a major diameter with the OD cutting margins on the replaceable side inserts, as well as possibly cutting margins on the center cutting member. Adjustment mechanisms are provided to adjust the center cutting member and / side cutting inserts.

Owner:ALLIED MASCH & ENG CORP

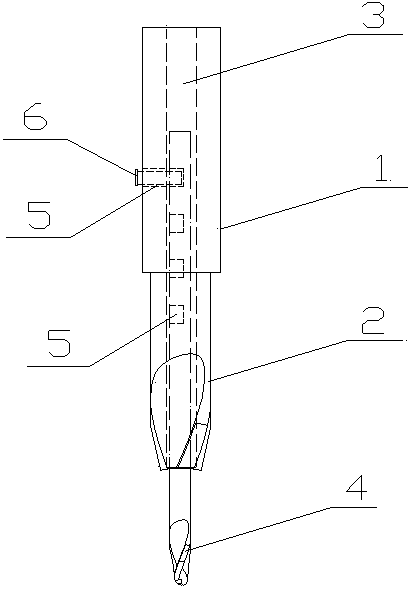

Stepped drill capable of adjusting depth of stepped hole

InactiveCN104107936AAdjustable lengthAdjust depthTransportation and packagingStepped drillsPetroleum engineeringDrill hole

The invention aims to provide a stepped drill capable of adjusting depth of a stepped hole. The stepped drill comprises a drill handle and a first drill blade mounted at the end of the drill handle. The stepped drill is characterized in that the stepped drill is provided with an accommodation hole extending from the head end of the first drill blade into the drill handle or the tail end of the drill handle, a second drill blade is mounted in the accommodation hole and exposed outside the accommodation hole, and the diameter of the second drill blade is small than that of the first drill blade. The stepped drill is provided with a fixing structure used for fixing the first drill blade and the second drill blade relatively. The stepped drill is capable of adjusting the exposure length of the second drill hole blade since the first drill blade is of hollow structure, thus, depth of the stepped hole drilled is adjustable, and the stepped drill is more convenient to use and highly practical.

Owner:SUZHOU WENDING MOLD

Anchoring drill bit, system and method of anchoring

InactiveUS7384223B2Low costReduce frictionThread cutting toolsDrilling/boring measurement devicesPilot holeBiomedical engineering

A system, apparatuses and methods for anchoring are provided. The system includes two-stage drill bit and a method of anchoring into a two-stage hole drilled by the drill bit. The apparatus of the instant invention includes a two-stage drill bit for drilling a pilot hole for a common nail into a material such as concrete, stone, masonry or cementuous or other materials. The method of the instant invention includes the steps of drilling a first hole within a material to which an object is to be anchored, drilling a second hole concentric with the first hole, and placing an anchor within the holes.

Owner:NADLER DONALD S

Damaged bolt and screw removing devices

ActiveUS20100037734A1Improve biteEfficient extractionTransportation and packagingSpannersEngineeringDrill bit

A bit for removing a broken security fastener having an elongated shaft with a longitudinal axis. The shaft has a first end and a second end. The first end terminates in a tip region having a recess for receipt of the post of the security fastener, the recess being disposed substantially along the longitudinal axis. The second end of the shaft is configured to be received by the chuck of a tool which provides rotational torque.

Owner:COMBINED PRODS

Drill bit

ActiveCN102825304AReduce axial resistanceFew cutting edgesTransportation and packagingWorkpiecesPunchingEngineering

Provided is a drill bit which can perform punching long-term and stably in a process of performing punching on a to-be-cut material which is stacked by a metal component and a fiber reinforced resin composite layer.The drill bit includes at least two stepped cutting edges a which are axially split. A cutting edge of a first step from a tip is formed so as to satisfy at least one of the following conditions. That is, a number of blades is smaller, a point angle of the cutting edge is larger, or a clearance angle of the cutting edge is larger than that of cutting edges of a second and subsequent step(s). As a result, a thrust resistance during a perforation can be reduced compared with a case in which the first step cutting edge is formed such that the number of blades, the point angle of the cutting edge and the clearance angle of the cutting edge are the same as those of the second and subsequent step(s). For example, under a condition of using two blades of the first step cutting edge, four blades of the second step cutting edge, four blades of a third step cutting edge, and the point angles [theta]1)[theta]2)[theta]3, and the clearance angles [gamma]1>=[gamma]2>=[gamma]3, each point angle of the first step cutting edge and the second step cutting edge is constant, and the point angle of the third step cutting edge gradually reduces as moving towards a rear end of the drill bit, so that ridge of the cutting edges forms a smooth curve shape.

Owner:SUBARU CORP

Tool and method for machining fiber-reinforced materials

ActiveUS10099297B2Extended service lifeCleaner drilled holesTransportation and packagingMilling cuttersMaterials scienceFibre reinforcement

A tool for machining fiber-reinforced materials, said tool having a tool body having a particular cutting edge that has at least a main function surface and has a diamond coating applied at least to said main function surface. In order to provide a tool and a method which are especially suitable for machining fiber-reinforced materials, the surface of the diamond coating has a reduced peak height Spk of less than 0.25 μm.

Owner:CEMECON

Overall arc-edge step drill with function of controlling burr form

ActiveCN105965071AGeneration of controlQuality improvementTwist drillsStepped drillsMachiningDrill bit

The invention provides an overall arc-edge step drill with a function of controlling the burr form. The overall arc-edge step drill with the function of controlling the burr form comprises a drill handle and a drill bit; and the drill bit comprises a front tool face, a main rear tool face, a main cutting edge and an auxiliary cutting edge. The main rear tool face and the main cutting edge are in a step shape; and the main cutting edge is divided into three segments, namely, a front cutting edge, a transition cutting edge and a rear cutting edge. The front cutting edge and the rear cutting edge are each in an arc shape; and the transition cutting edge is in a straight line shape and is arranged between the front cutting edge and the rear cutting edge. The vertex angle of the front cutting edge at the position of a drill point is not larger than 118 degrees; the difference between the diameter of the cylindrical face where the rear cutting edge is located and the diameter of the cylindrical face where the front cutting edge is located is smaller than 5 mm; and the helical angle of the auxiliary cutting edge ranges from 35 degrees to 40 degrees. The overall arc-edge step drill with the function of controlling the burr form can effectively control production of burrs in drilling machining, the drilling quality and the drilling efficiency are both improved, and the overall arc-edge step drill with the function of controlling the burr form is simple in structure and convenient to manufacture and can be widely used in the machining field.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com