Unibit with replacement blade

a technology of unibits and blades, applied in the field of multi-hole size drill bits, can solve the problems of relatively short life, unibits are relatively more expensive than single-size twist drills, and unibits are typically not re-sharpened when

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

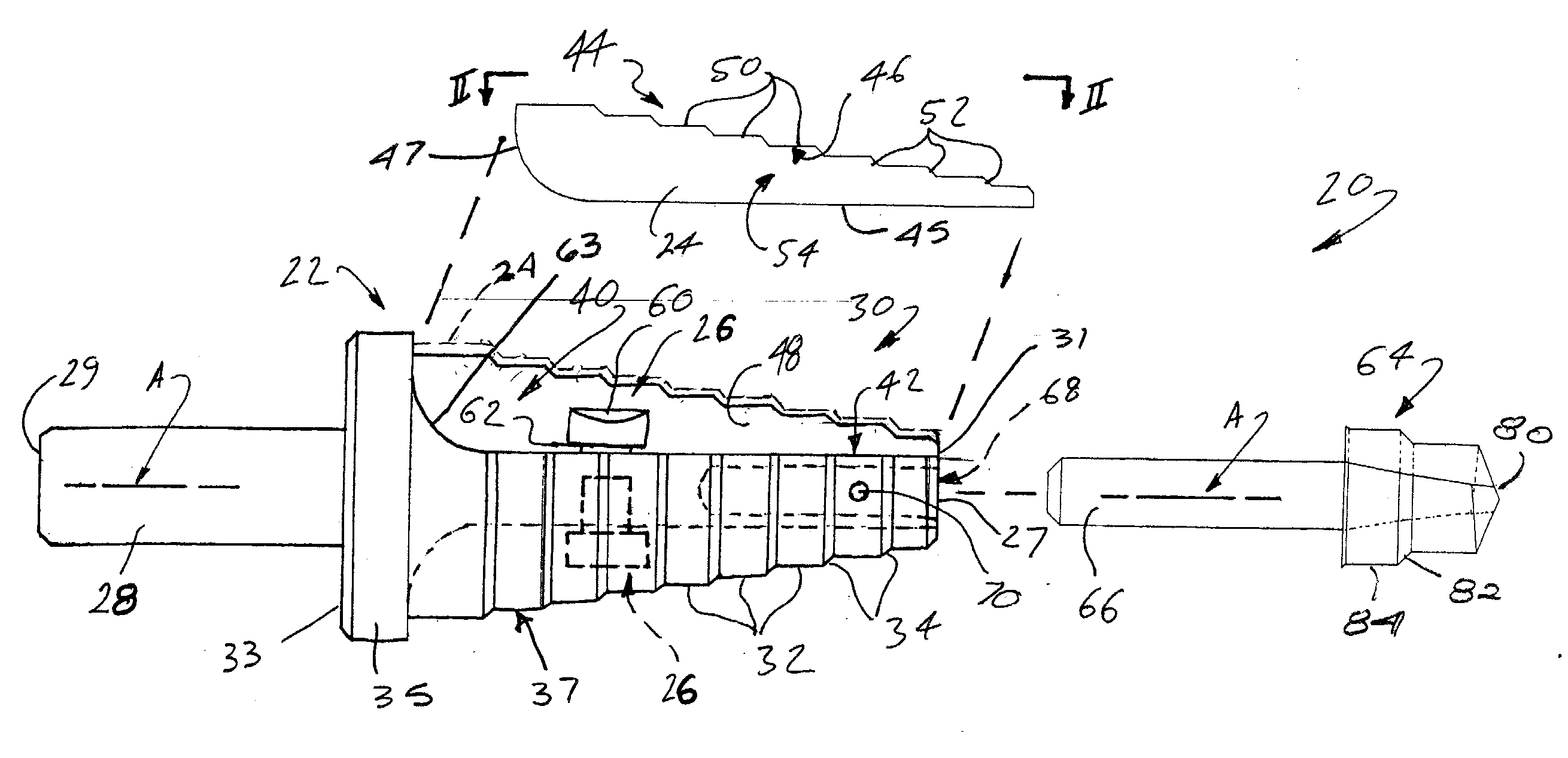

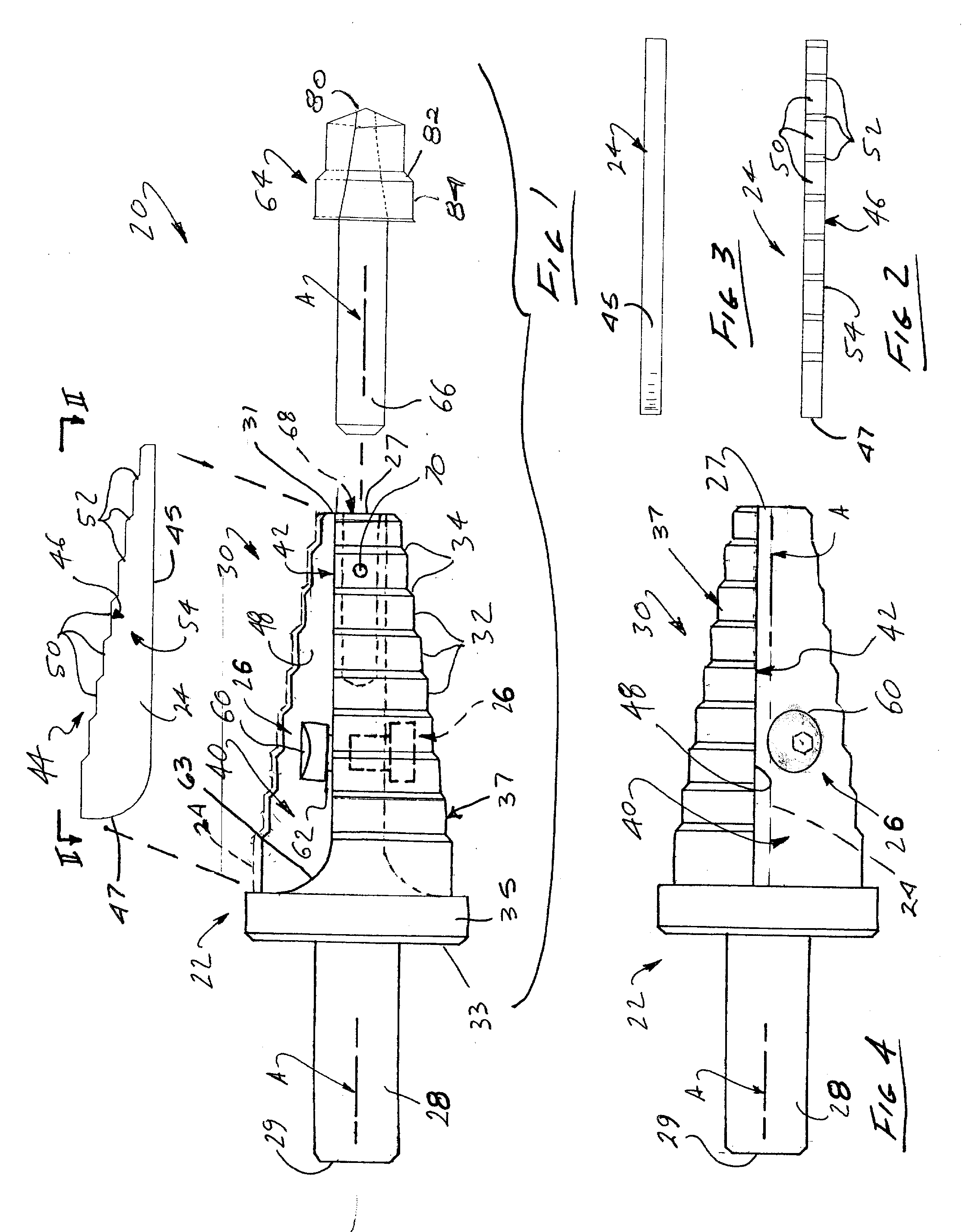

first embodiment

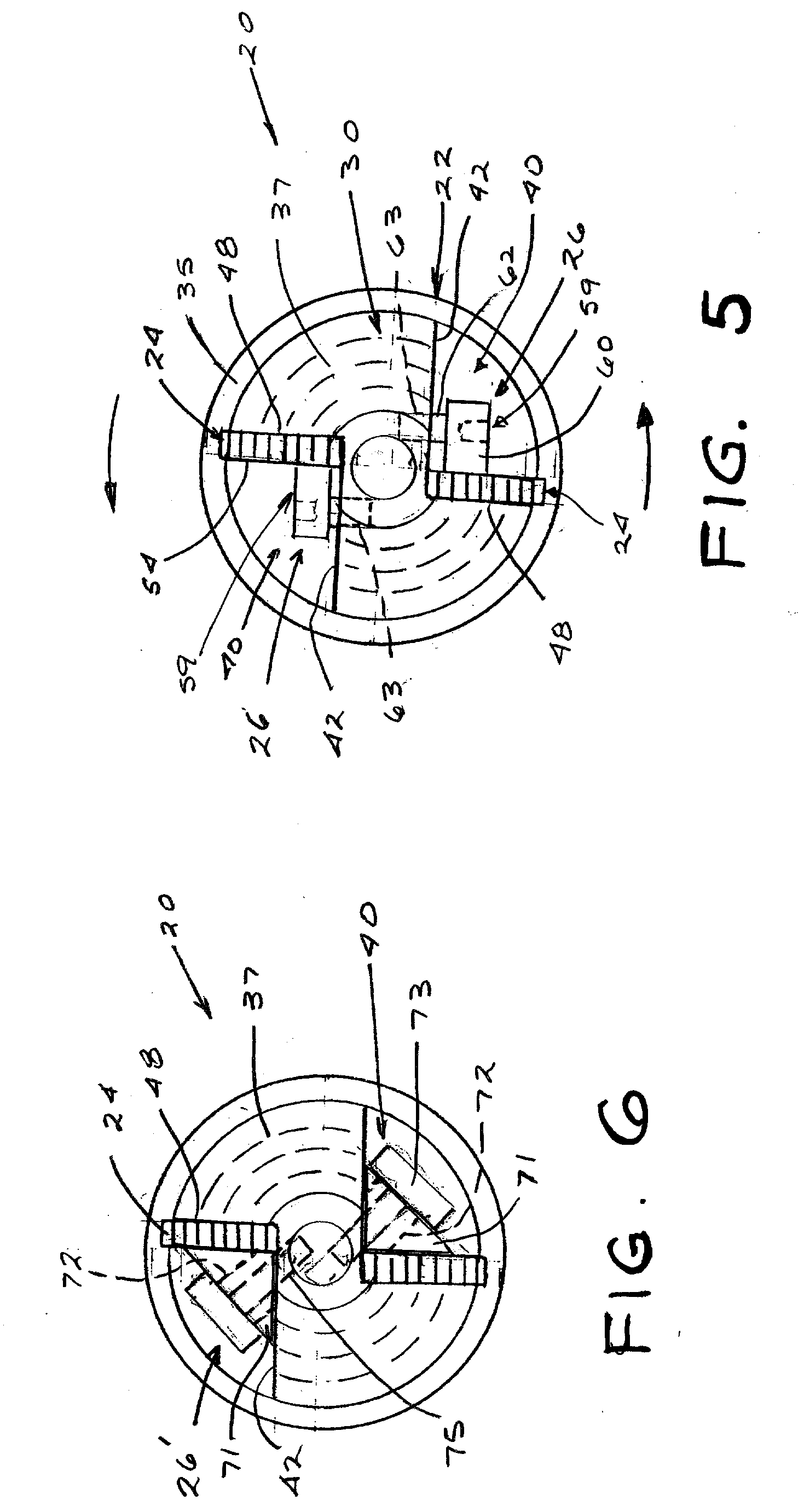

[0044] In the first embodiment, a blade receiving recess 40 is formed in each side of the head 30 and releasably receives a corresponding replacement blade 24. As shown in the drawings, the blade receiving recess is a generally V-shaped sectional void in the head 30 that resembles a quarter-section-like portion from the head. This is not a true quarter-section, however, in that the sides or walls 42 and 48 of the section are not aligned (coplanar) with the axis of rotation “A.” Rather, as shown in the end view of the FIG. 5, the plane of side 48 is overextended beyond the axis. The extent of overextension is preferably about the thickness of the replacement blade 24, such that a cutting edge 46 of the replacement blade at a face surface 54 of the blade lies in a plane that extends generally through the axis “A.”

[0045] The replacement blade 24 is a generally triangular shaped plate member that is constructed of a suitably hard material, such as 6264 tool steel, for example. In the fi...

second embodiment

[0049] In the invention, shown in FIG. 6, rather than locking the blade in place with the eccentric cam 60 of FIG. 1, the blade can be locked in place by a blade lock 26′ that includes a cam plate in the form of angle plate 71 that bears against the outside of the blade. A bolt 73 extends through a slot 72 in the angle plate and screws into a threaded, inclined opening 75 in the body of the unibit. Tightening the bolt urges the bolt against an inclined outer surface of the angle plate and causes the angle plate to clamp the blade in position.

third embodiment

[0050] In the invention, shown in FIG. 7, blade lock 26″ includes a screw or bolt 77 that extends into a threaded opening 79 that is parallel with the side of the blade. A cam plate 81 with an inclined side is positioned between the blade and a screw head 83, so that the head of the screw urges the plate against the blade as the screw is screwed into the opening.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com