Drill bit

一种钻头、切削刃的技术,应用在修钻、阶梯钻、麻花钻等方向,达到稳定切削的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Hereinafter, an embodiment of the present invention will be described with reference to the drawings. The following is an embodiment of the present invention, but does not limit the present invention.

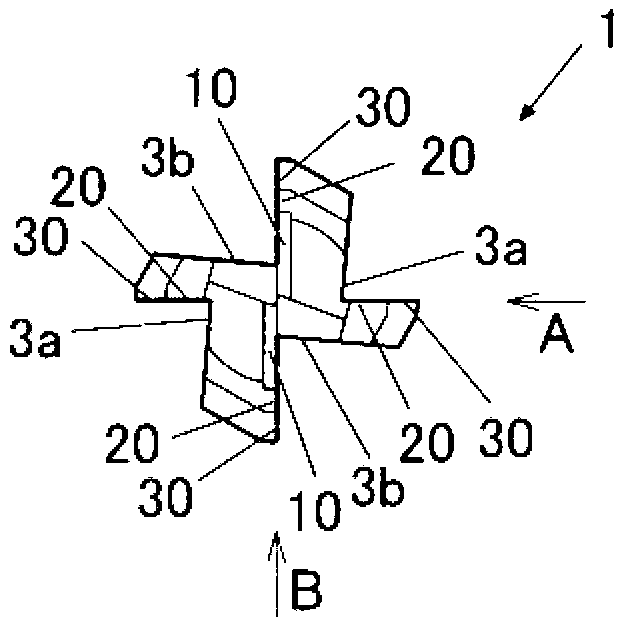

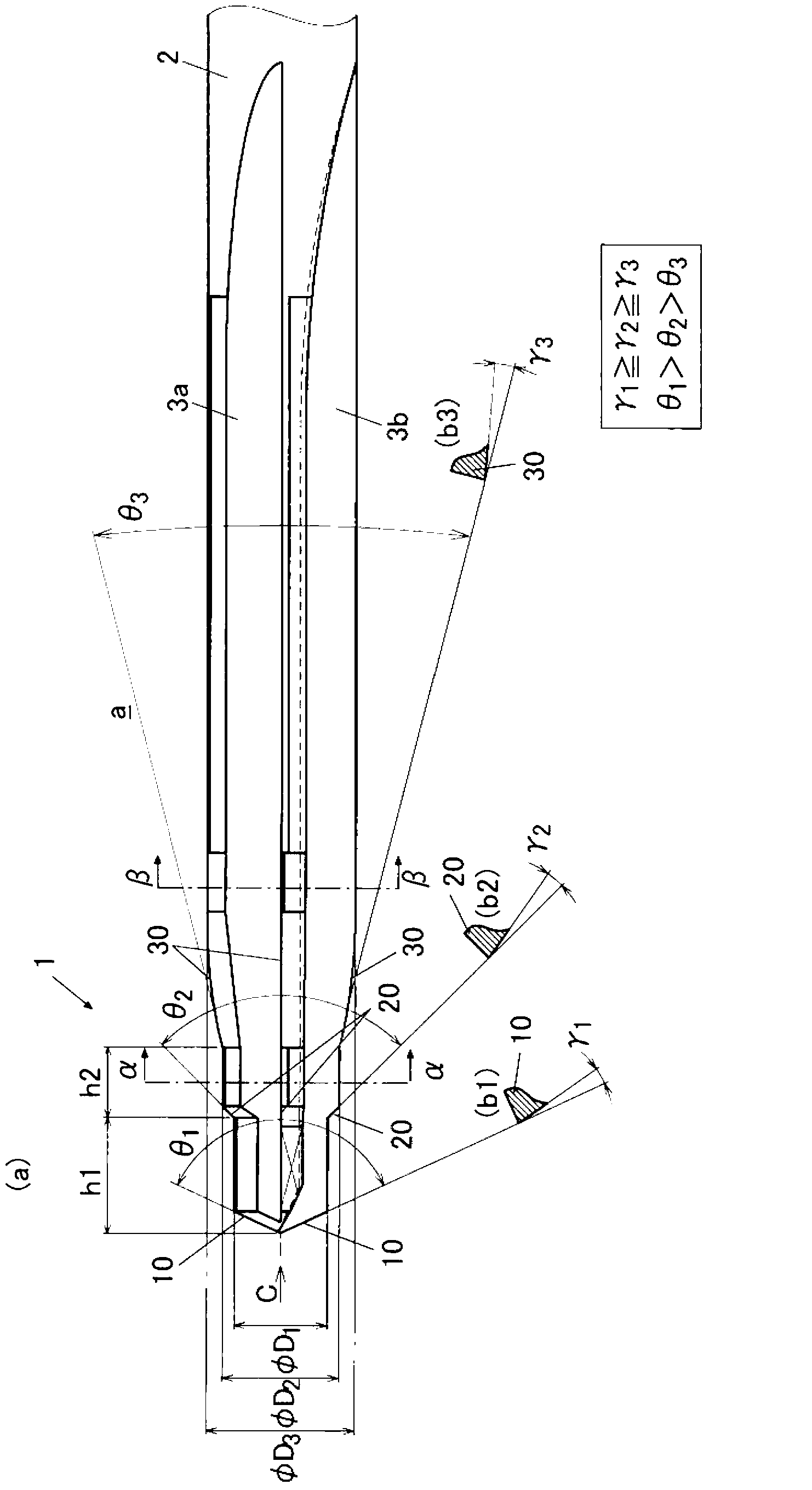

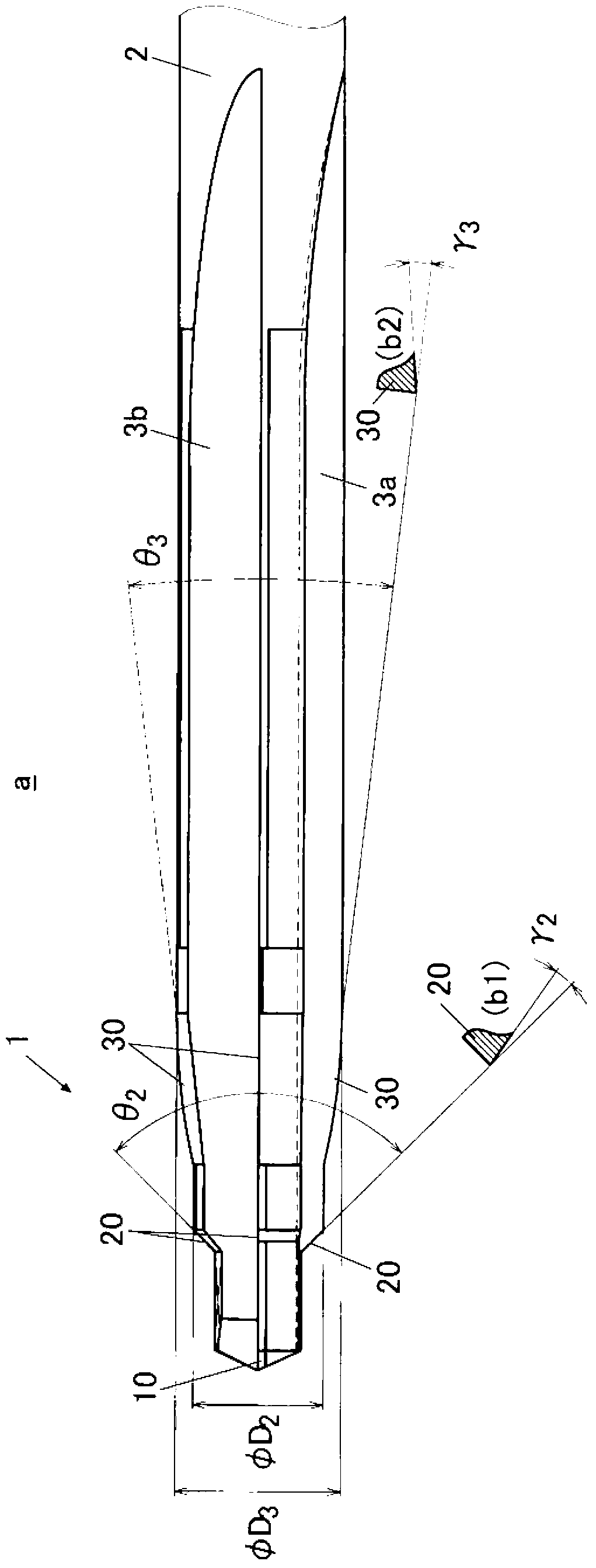

[0072] Such as figure 1 , figure 2 and image 3 As shown, the drill a of this embodiment has a chisel portion 1 and a shank portion 2 . Four straight V grooves 3 a , 3 b , 3 a , 3 b are formed from the chisel blade 1 to the shank 2 .

[0073] The drill a of the present embodiment has three stages of cutting edges 10 , 20 , and 30 divided in the axial direction.

[0074] The first-stage cutting edge 10 is two cutting edges arranged at a distance of 180 degrees from each other around the drill axis, formed from the front end of the drill, and has a maximum diameter φD 1 .

[0075] The second segment cutting edge 20 is 4 cutting edges arranged at different positions every 90 degrees around the drill bit axis, separated by a distance h1 from the drill bit front end t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com