Multi-step multi-micro-blade drill bit for drilling carbon fiber reinforced plastics

A reinforced composite material and multi-step technology, applied in step drills, drilling/drilling equipment, drill repairing, etc., can solve problems such as delamination, burrs, tearing, etc., to reduce delamination and tear damage, improve Effect of Aperture Accuracy and Inlet Quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

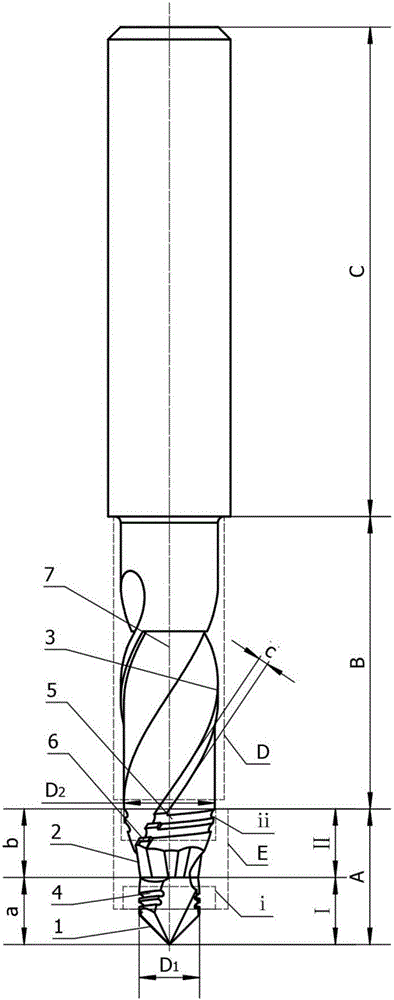

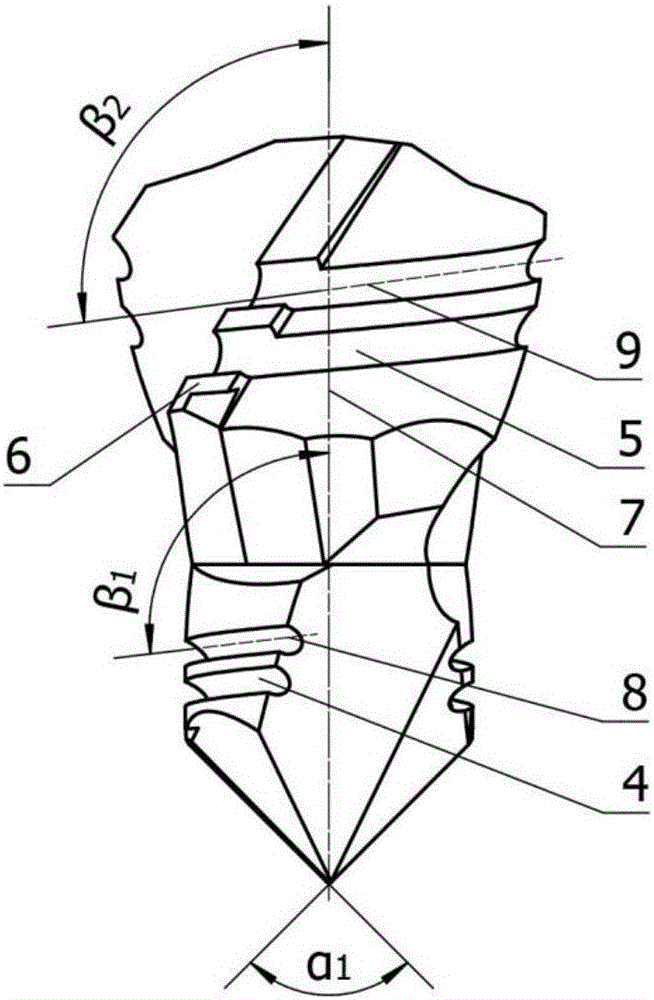

[0029] Such as figure 1 , figure 2 , a carbon fiber reinforced composite material hole-making multi-step multi-micro-edge drill shown in Figure 3 can be divided into a step cutting area A, a secondary cutting area B and a clamping area C, wherein the step cutting area A consists of two steps. Composition; from the drill tip to the clamping area, there are two ladder structures in sequence; each ladder structure is composed of a stepped main cutting area and a stepped auxiliary cutting area.

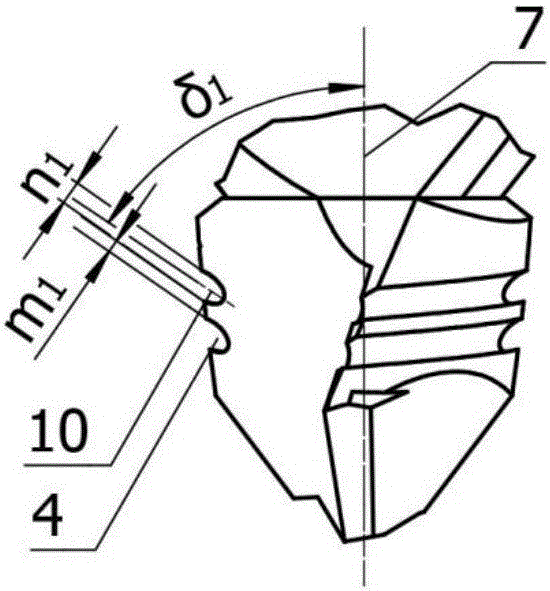

[0030] This drill bit has a micro-tooth cutting area E, which is located in the stepped cutting area A, and the micro-tooth cutting area E is composed of two-level micro-tooth structures; two-level micro-tooth structures are distributed sequentially from the drill tip to the clamping area; the second The j-level micro-too...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com