Overall arc-edge step drill with function of controlling burr form

A stepped drill bit and arc-edge technology, applied in the field of drilling, can solve the problems of reducing drilling efficiency, affecting hole quality, and difficulty in removing work, and achieves improved drilling quality and efficiency, simple structure, and convenient manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

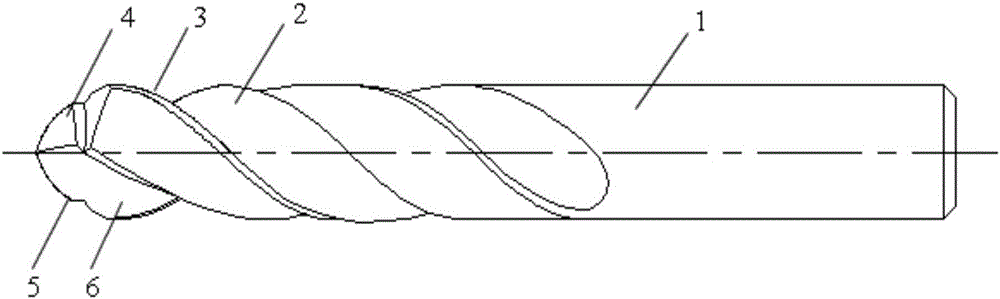

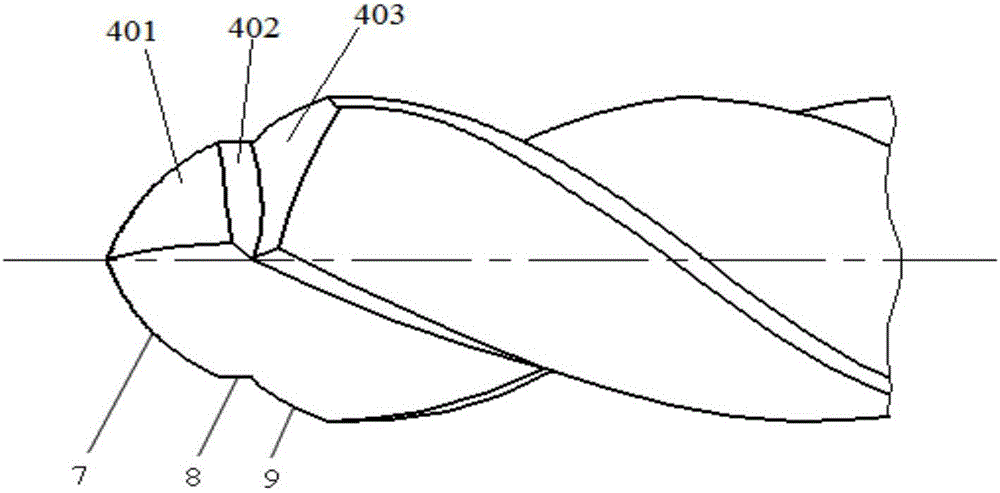

[0016] Such as figure 1 with figure 2 As shown, a stepped drill bit with an integral circular arc edge with controlled burr shape includes a drill shank 1 and a drill bit 2 . The drill bit 2 includes a rake face 6 , a main flank face 4 , a main cutting edge 5 and a minor cutting edge 3 . The main flank 5 is stepped; the main cutting edge 5 is stepped and divided into three sections: the front cutting edge 7, the transition cutting edge 8 and the rear cutting edge 9; the front cutting edge 7 and the rear cutting edge 9 It is arc-shaped, and the transitional cutting edge 8 is linear.

[0017] In the present embodiment, the apex angle of the front cutting edge 7 at the drill point is 108°, the difference between the diameter of the cylindrical surface where the rear cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com