Waterless cutting method

A cutting method and technology without water line, which is applied in the field of aerospace servo system, can solve the problems of unformed filter element, deformation of the end face of the filter element, scrapping of the filter element, etc., and achieve the effect of increased cutting speed, extended life, and stable operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] A kind of processing method of multi-channel energy spectrum measurement proposed by the present invention is further introduced below in conjunction with accompanying drawing and embodiment:

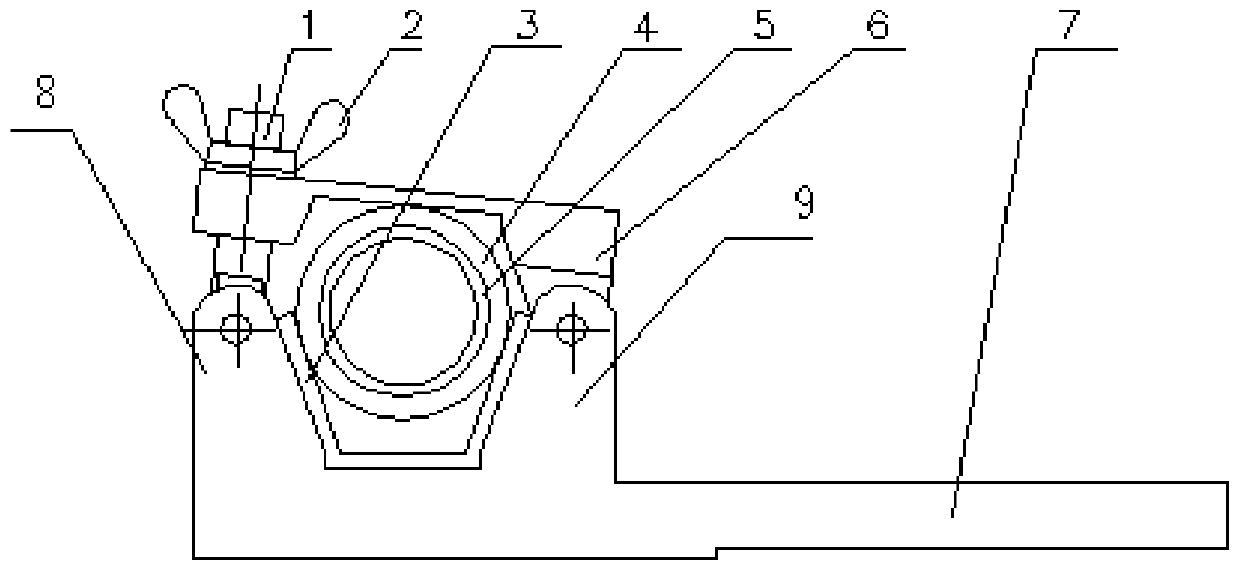

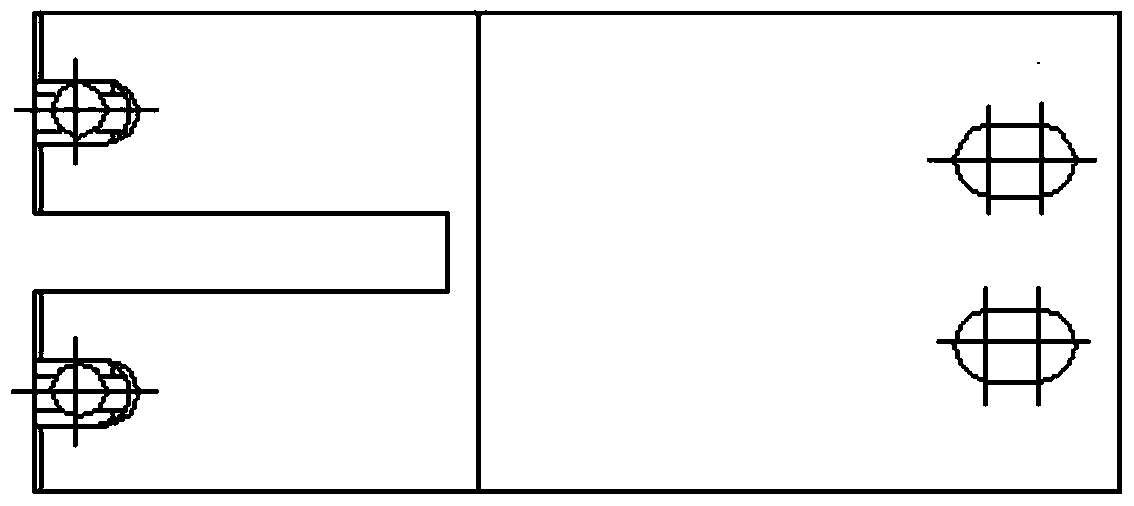

[0035] A waterless wire cutting device, comprising a stud 1, a butterfly nut 2, a dovetail support seat 3, a filter element 4, a core tube 5, an upper cover plate 6 and a base 7; the base 7 is "F" shaped, and There are two protruding supporting columns, supporting column A8 and supporting column B9, and a dovetail groove support 3 is provided between the two supporting columns; one end of the upper cover plate 6 is provided with a fixing screw hole, and the other end is passed through a pin It is fixed on the support column B9; the stud 1 is connected with the support column A8 through a pin, and the upper cover plate 6 is fixed with the stud 1 through a butterfly nut 2 .

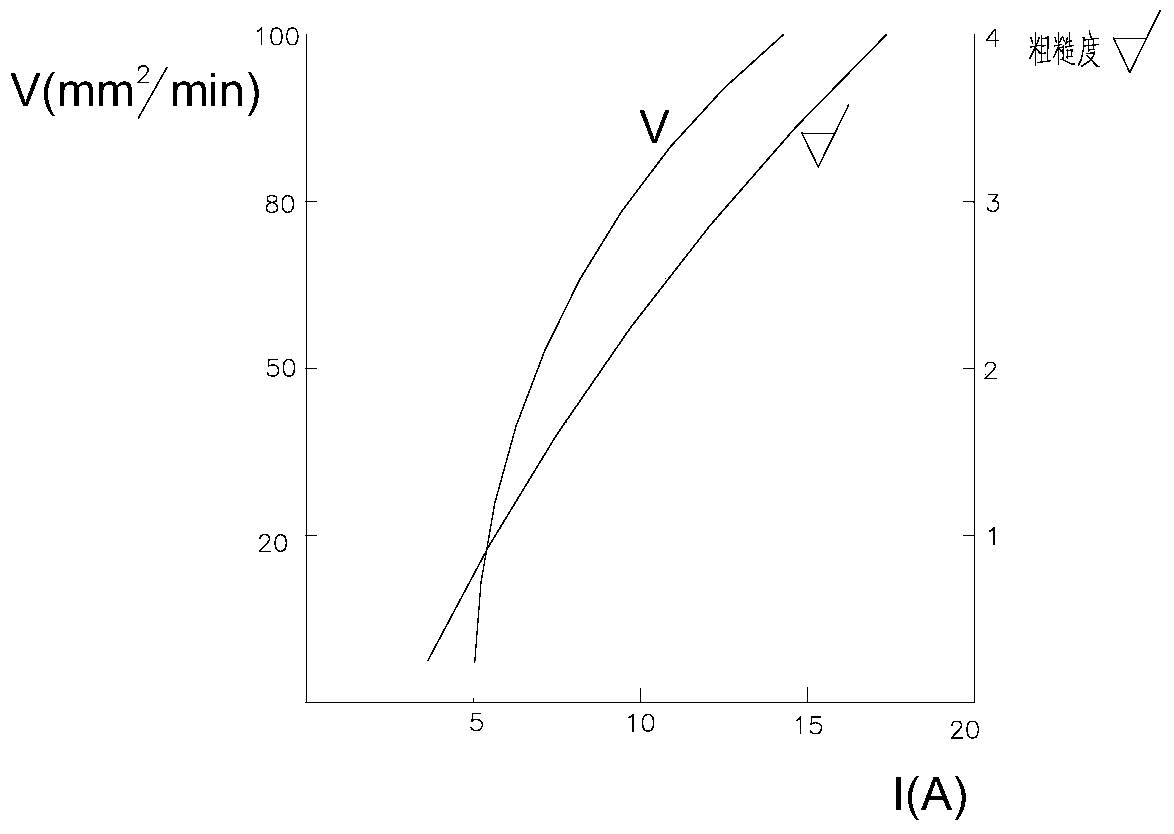

[0036] 2. A kind of waterless cutting method as claimed in claim, comprising the following steps:

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com