Customizing method of drum-taper-shaped ball-end milling cutter

A ball-end milling cutter and conical technology, which is used in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of complex modeling, low cutting efficiency of ball-end cutters, and difficulty in calculation, so as to avoid tool marks and improve processing efficiency. Improve and avoid the effect of tool change error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

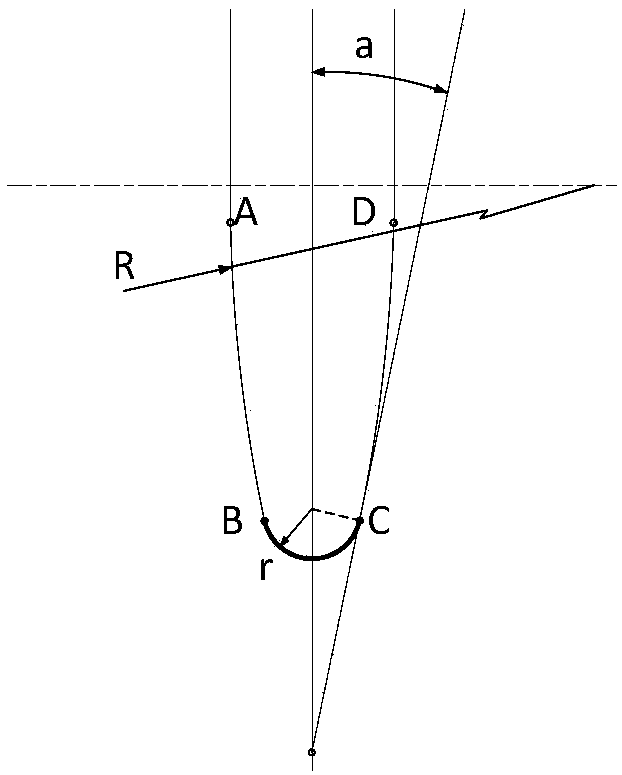

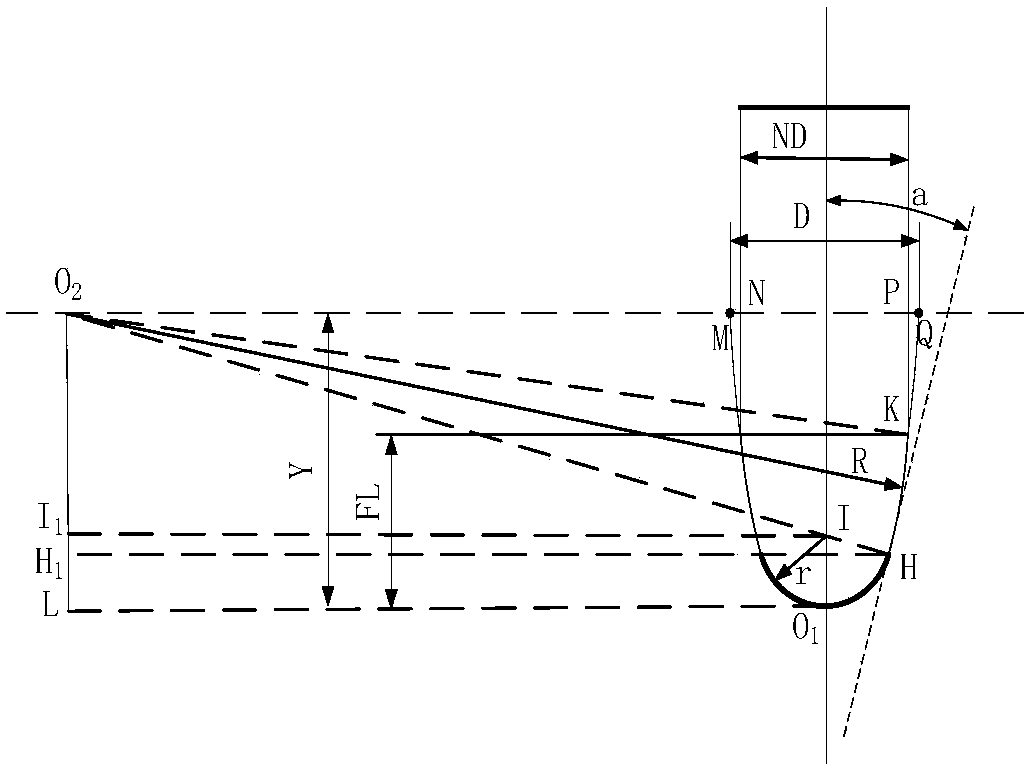

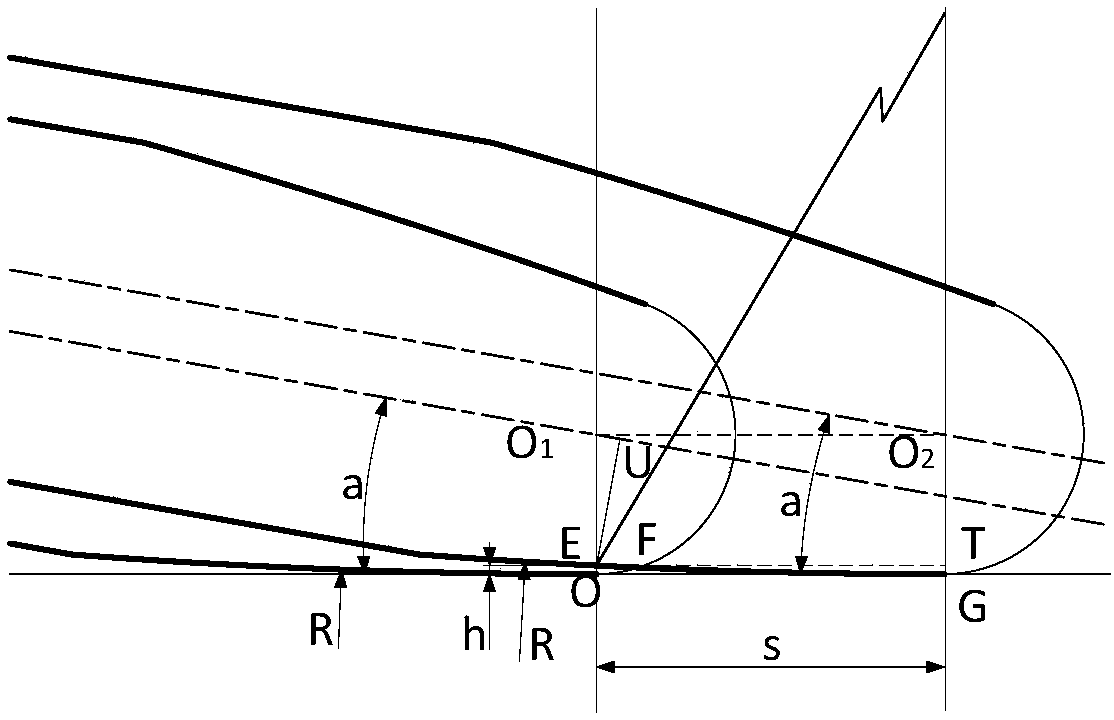

[0056] The radius of the ball head is 4mm when machining the root of a certain blisk; the maximum cutting inclination angle limited by geometry to prevent the interference of adjacent blades is 8 degrees; the cutting residue height to ensure the surface quality is 0.02, and the ideal cutting line spacing to ensure the processing efficiency 2mm, all the parameters used in CNC programming of custom drum cone ball end milling cutter.

[0057] According to formula (6)

[0058]

[0059] The above parameters are set during programming, and the shape of the tool is obtained through modeling, such as Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com