Four-edge end mill having cooling holes and variable spiral unequal tooth pitch

An end mill, variable helix technology, applied in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problem of chip blockage in the center groove, and achieve the effects of stable work, enhanced strength and reduced friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

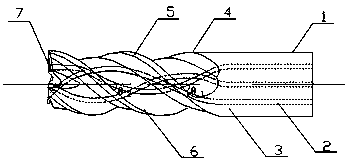

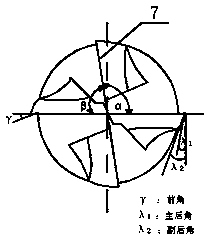

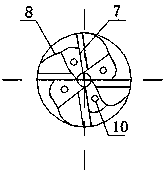

[0015] combine figure 1 As shown, a four-blade end mill with cooling holes and variable helix pitches, including the main body (1) of the end mill, the shank (3), and the milling part (4) at one end of the shank, The end mill has a rake angle, a main relief angle, and an auxiliary relief angle; among them, the rake angle is 7°-12°, the main relief angle is 4°-9°, and the auxiliary relief angle is 12°-16°. The main body of the end mill (1) There are four coolant supply holes (10) and (2) inside, and each coolant supply hole extends to the end of the bottom cutting edge according to the direction of rotation of each helix, and the tool handle (3) The milling part (4) set on the tail of the tool and one end of the tool holder includes four side cutting edges (5) set on the cylindrical surface of the milling part and four bottom cutting edges (7) on the end face. The side cutting edges of the end mill ( 5) Using the variable helix angle structure, the genetic algorithm is used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com