Vertical lathe for profiling internal and external circle of piston ring

A profiling lathe and piston ring technology, applied in turning equipment, turning equipment, metal processing equipment, etc., can solve problems such as loose mechanism, high production cost of the whole machine, and large floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

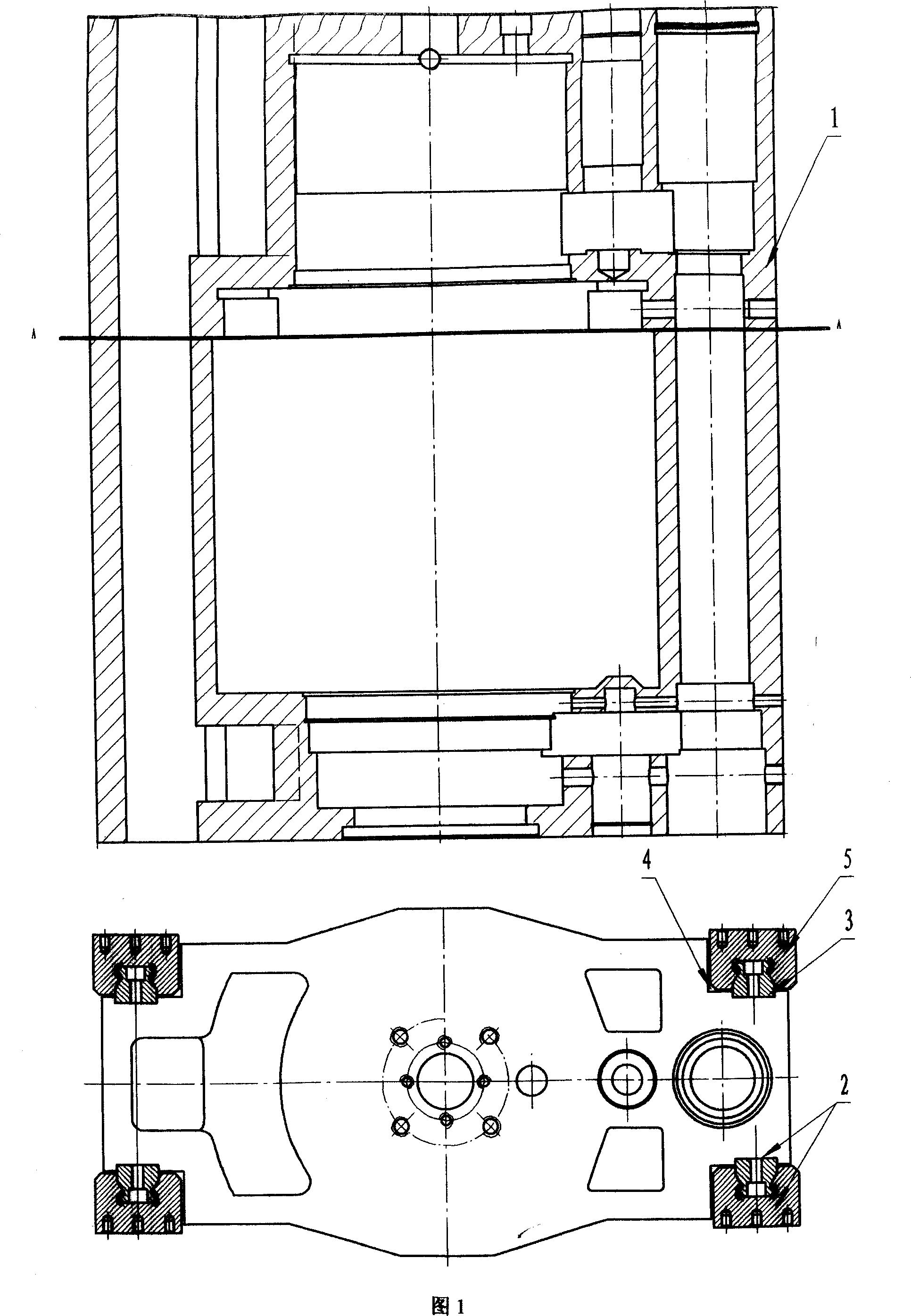

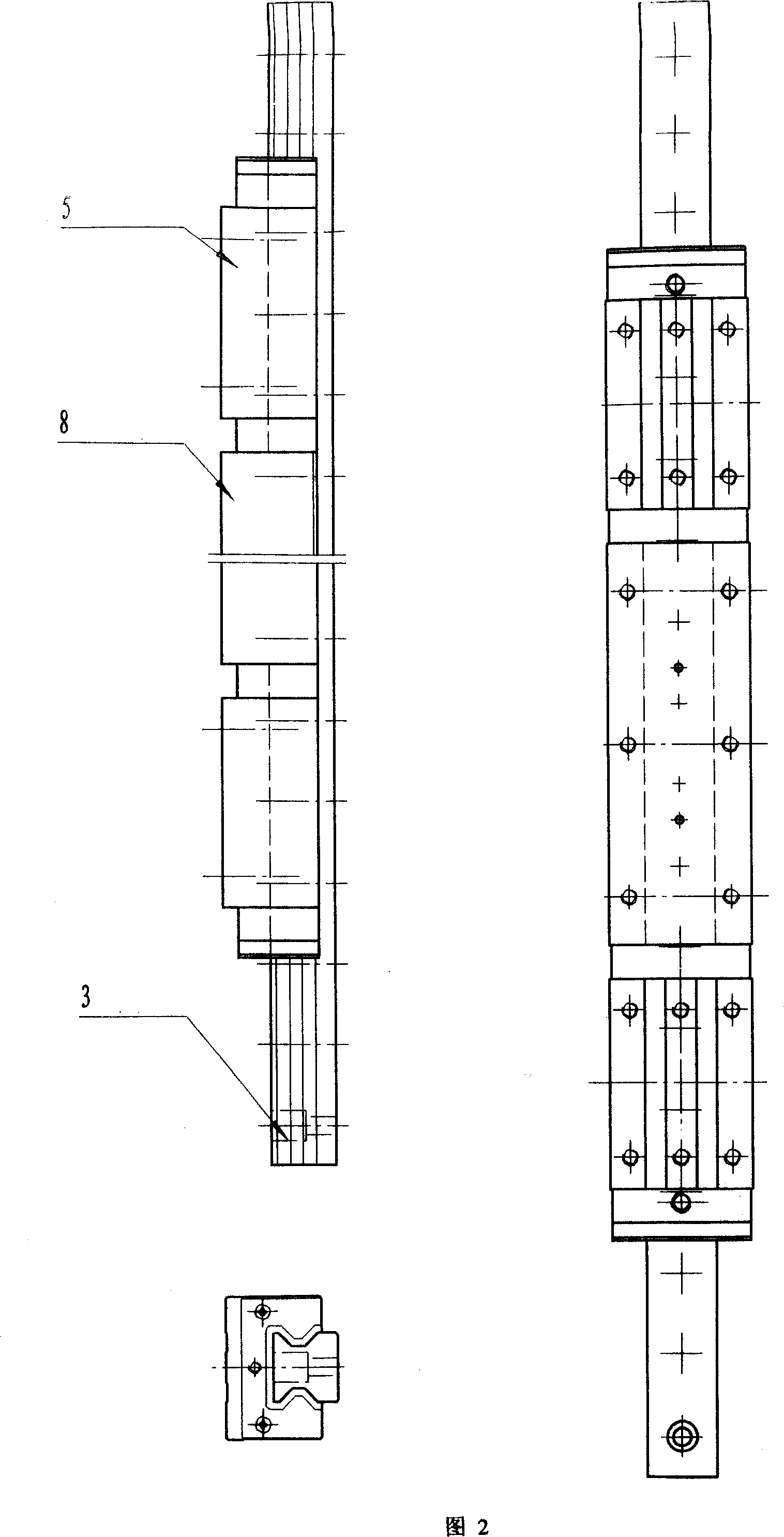

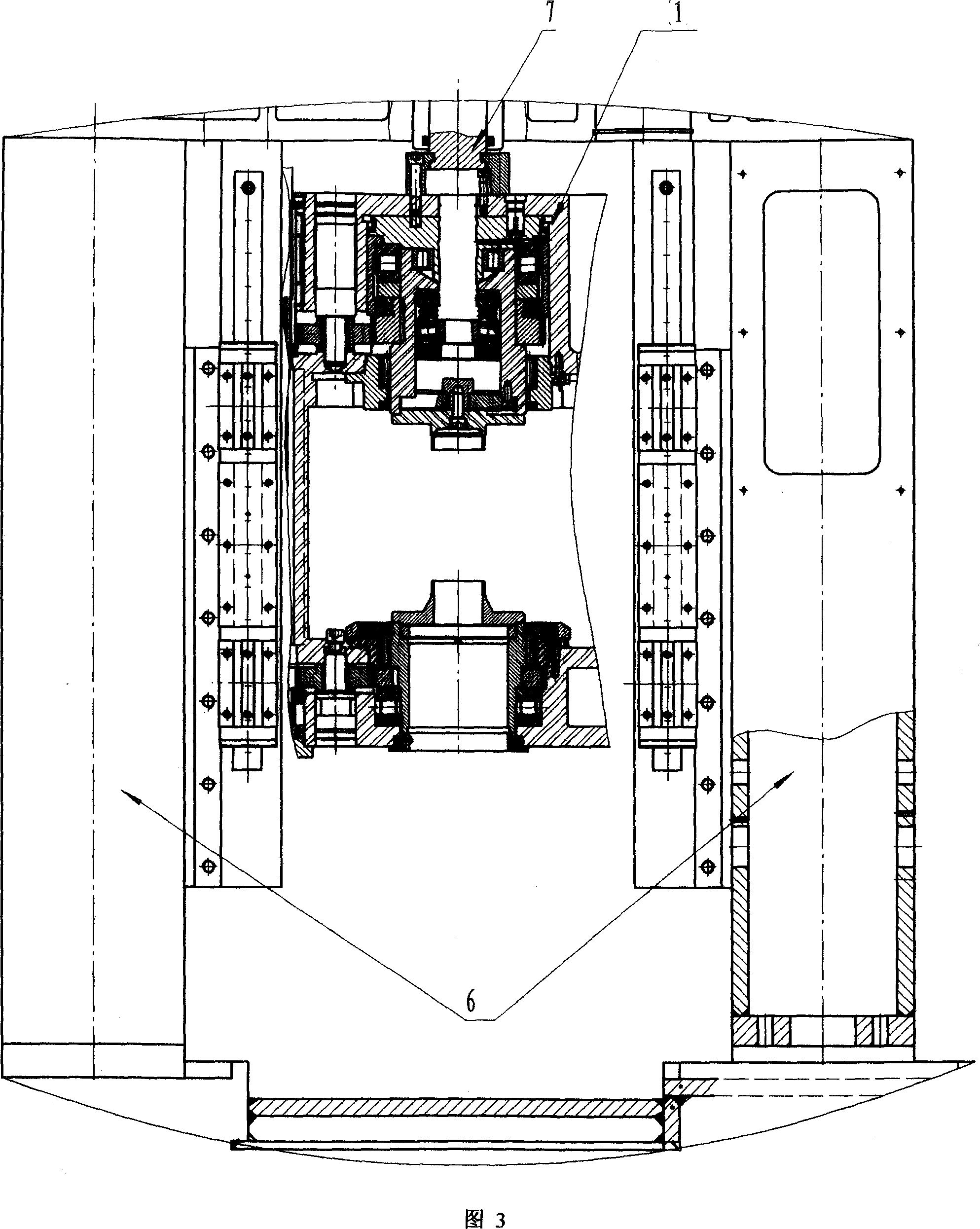

[0010] It can be seen from Fig. 1 that the main shaft frame (1) of this vertical piston ring internal and external circular profiling lathe is an integral structure, and four sets of roller linear guide pairs (2 ), the four guide rails (3) are respectively fixed in the four grooves (4) on the two shoulders of the spindle frame (1), and the eight sliders (5) are fixed on the inner side of the left and right columns (6) of the machine tool. The piston rod (7) of the cutter oil cylinder pulls the main shaft frame (1) to make a linear vertical reciprocating motion relative to the slider (5), so as to realize the cutting and reversing fast rewinding of the piston ring stack. The main shaft frame (1) of this integral structure is integrally shaped and integrally processed, which avoids defects such as misalignment and looseness that may occur in separate processing, and enhances the overall rigidity. Four sets of roller linear guide pairs (2 ) can make the spindle tooling system wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com