Milling cutter

A technology of milling tools and cutting blades, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of the limited number of milling tool edges, large cutting force of milling tools, and large wrench movable space, so as to reduce cutting force and prolong Longevity and effect of cutting vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

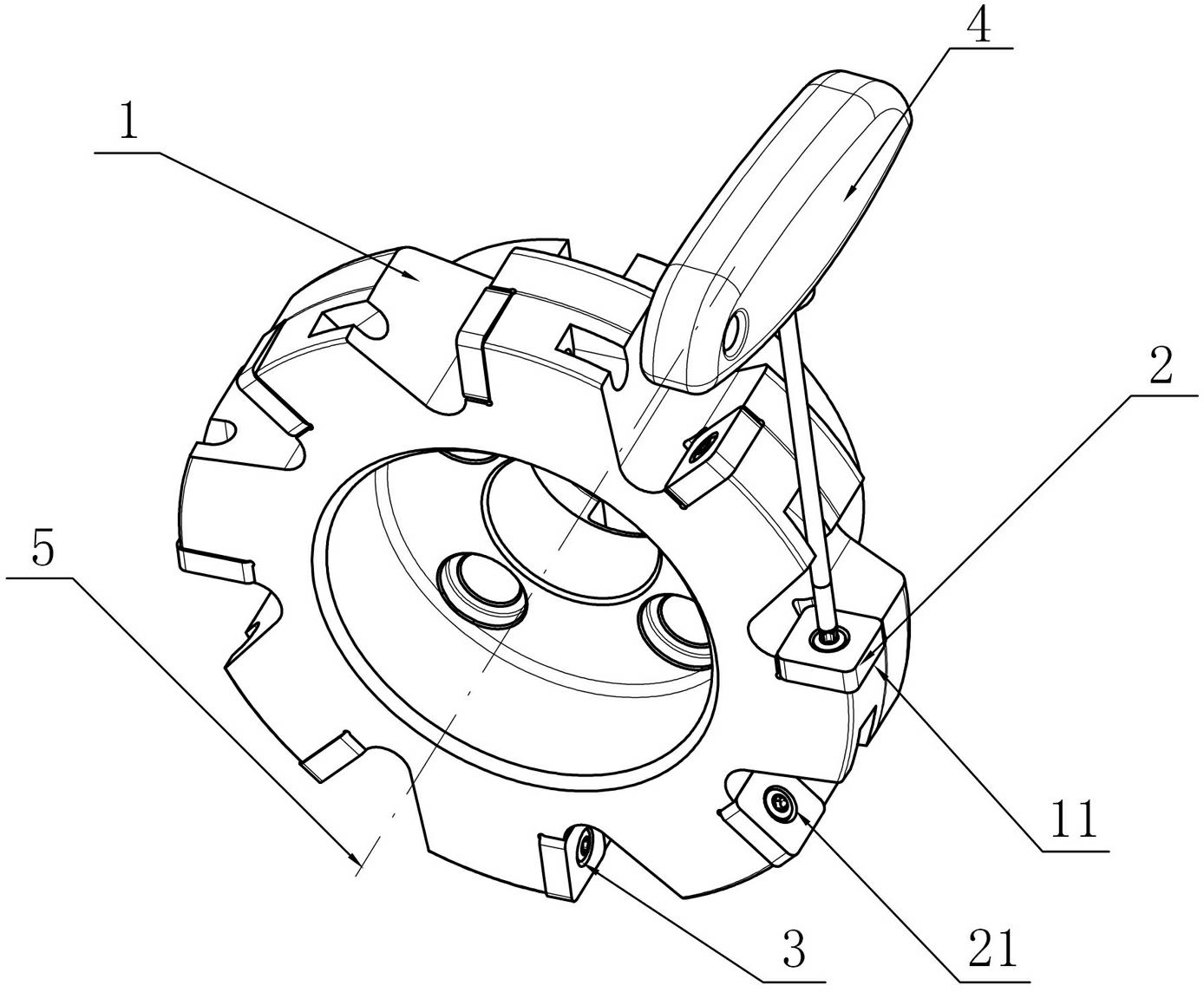

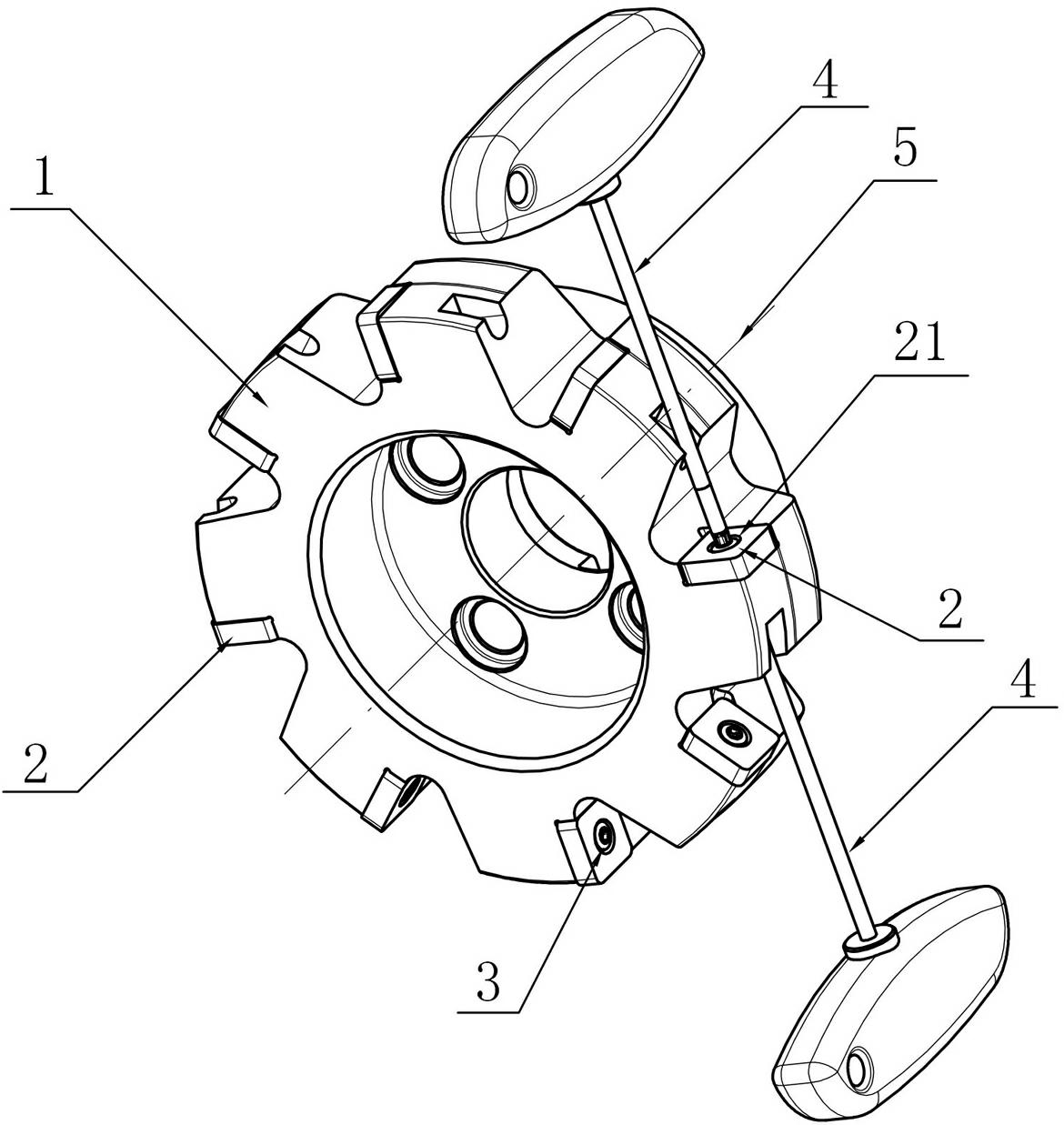

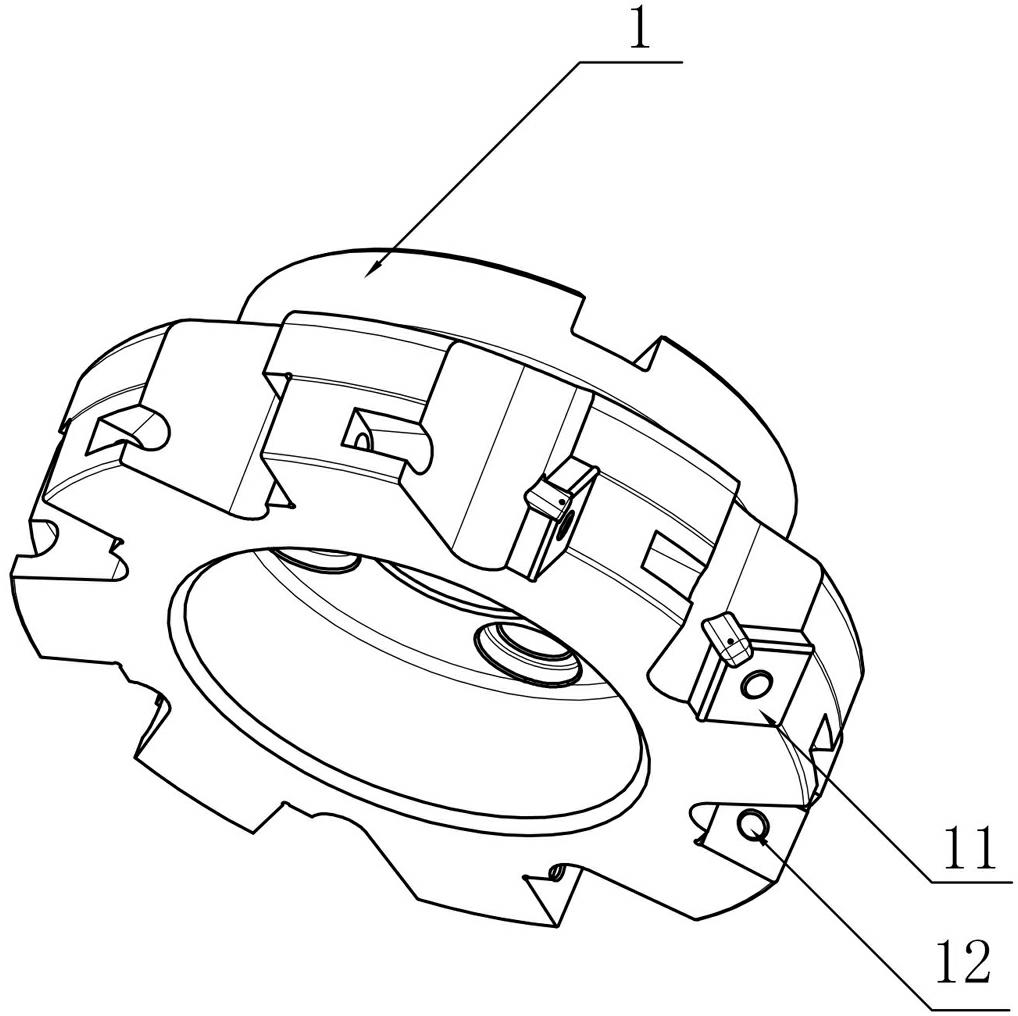

[0020] Figure 2 to Figure 5 An embodiment of a milling tool according to the present invention is shown. The milling tool rotates around an axis 5 during operation. It includes a cutter body 1, a cutting blade 2 and a fastener 3. At least one set of sipe grooves 11 is provided on the cutter body 1. A cutting blade 2 is installed in each sipe 11, the cutting blade 2 is provided with a central hole 21, the bottom surface of the sipe 11 is provided with a fastener connecting hole 12, and the head 31 of the fastener 3 is pressed in the central hole 21 Inside, the tail 32 of the fastener 3 passes through the central hole 21 and is connected to the fastener connection hole 12, and the tail end of the fastener 3 is provided with a first recessed hole 33 for plugging in with the wrench 4, and the fastener is connected The hole 12 runs through the cutter body 1, so that the wrench 4 can be inserted from the tail end of the fastener 3, and the fastener 3 is tightened so that the wrench...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com