Vertical cutting device for tubular workpiece

A cutting device and workpiece technology, applied in the direction of pipe shearing device, shearing device, accessory device of shearing machine, etc., can solve the problems of low incision quality and poor workpiece cutting stability, so as to ensure the incision quality, improve the cutting efficiency, The effect of improving cutting stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

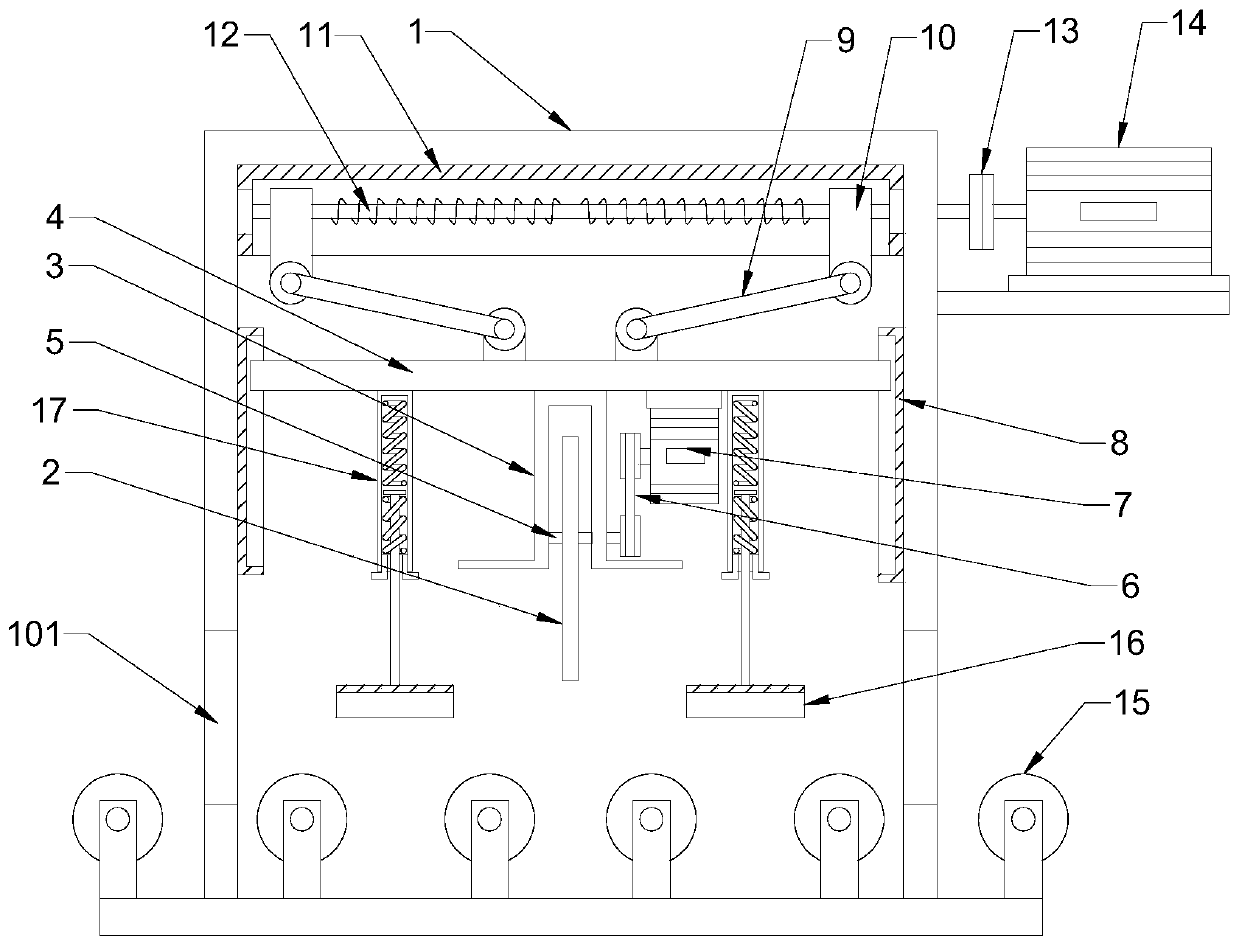

[0021] see Figure 1-3 , in an embodiment of the present invention, a vertical cutting device for a tubular workpiece includes a cutting box 1, a cutting wheel 2 and a conveying roller 15; the cutting box 1 is a hollow box with opposite through holes 101 arranged on both sides, The through hole 101 is for the steel pipe to enter the cutting box 1; the bottom plate of the cutting box 1 is provided with conveying rollers 15 distributed equidistantly, and the conveying roller 15 is connected with a driving device to realize the feeding of the steel pipe; the cutting wheel 2 is connected by rotating shaft 5 There is a protective cover 3, and the protective cover 3 avoids cutting sparks from splashing; the upper end of the protective cover 3 is fixedly connected with a lifting plate 4, and the rotating shaft 5 extends to the outside of the protective cover 3 and is connected to the output shaft of the cutting motor 7 through the transmission belt 6, and the cutting motor 7 is fixed...

Embodiment 2

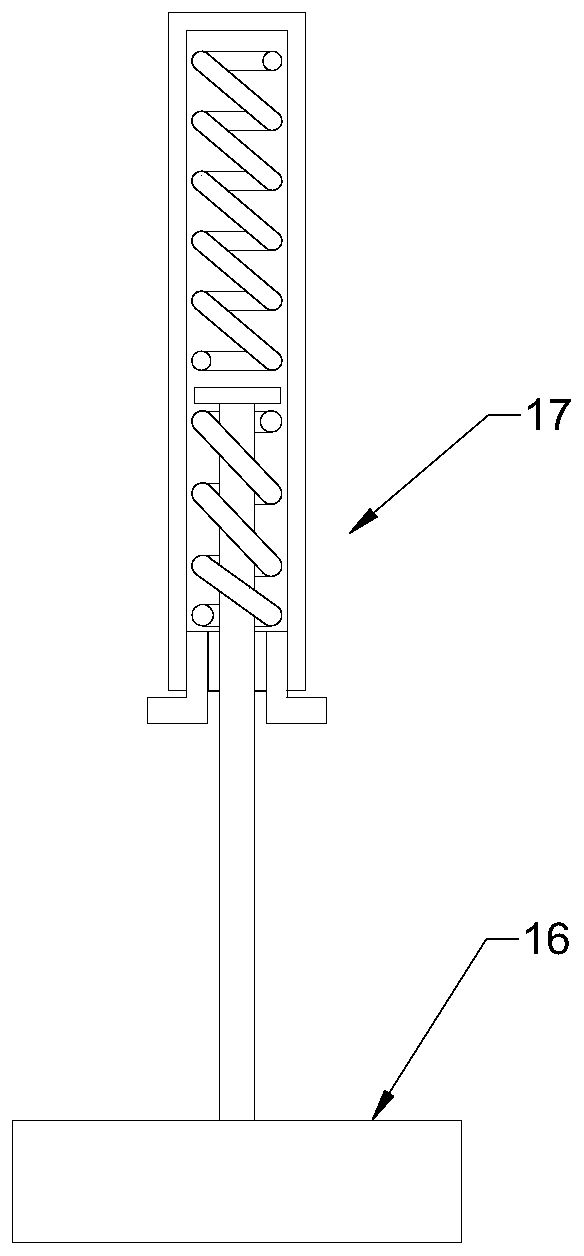

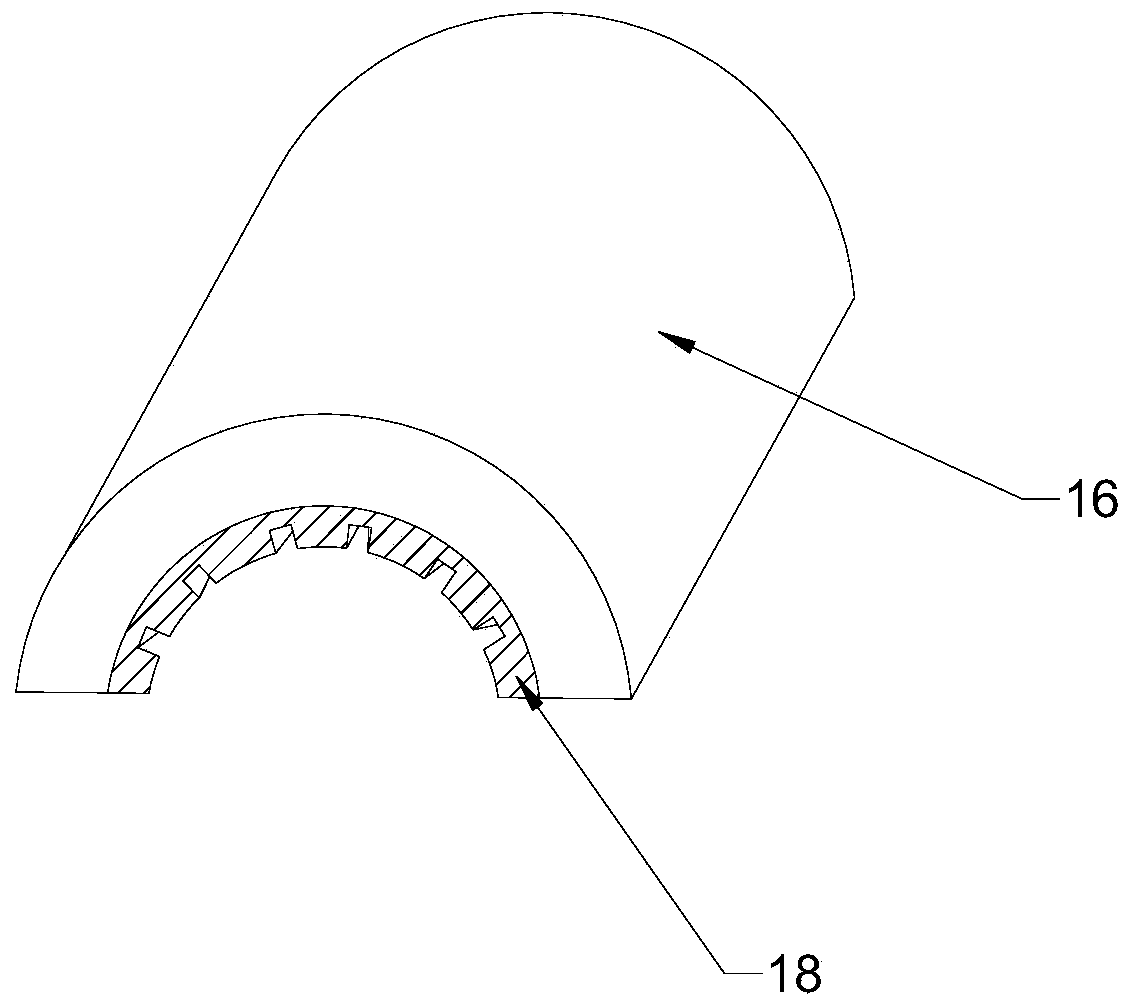

[0024] The difference between this embodiment and Embodiment 1 is that: the outer side of the cutting wheel 2 is provided with an extruding fixing mechanism, and the extruding fixing mechanism includes an extruding fixing plate 16, which is an arc-shaped plate, which can better stick To fit the tubular workpiece, the extruded fixed plate 16 is fixedly connected with the lifting plate 4 through the spring telescopic rod 17, so that the extruded fixed plate 16 moves up and down with the cutting wheel 2, and when the tubular workpiece is cut, the steel pipe is gradually extruded and fixed. Improve the stability of cutting, thereby ensuring the quality of the cut.

[0025] A rubber pad 18 is bonded to the inner side of the extruded fixing plate 16, and the rubber pad 18 is provided with strip-shaped anti-slip lines to improve friction, avoid steel pipes from slipping and rotating, and ensure cutting quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com