Digital controlled lathe special for engine air valve continuous full-automatic machining and method thereof

A technology of engine valves and CNC lathes, applied in metal processing equipment, metal processing machinery parts, turning equipment, etc., can solve problems such as single transmission system, insufficient use of valves, failure to meet the design requirements of special machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

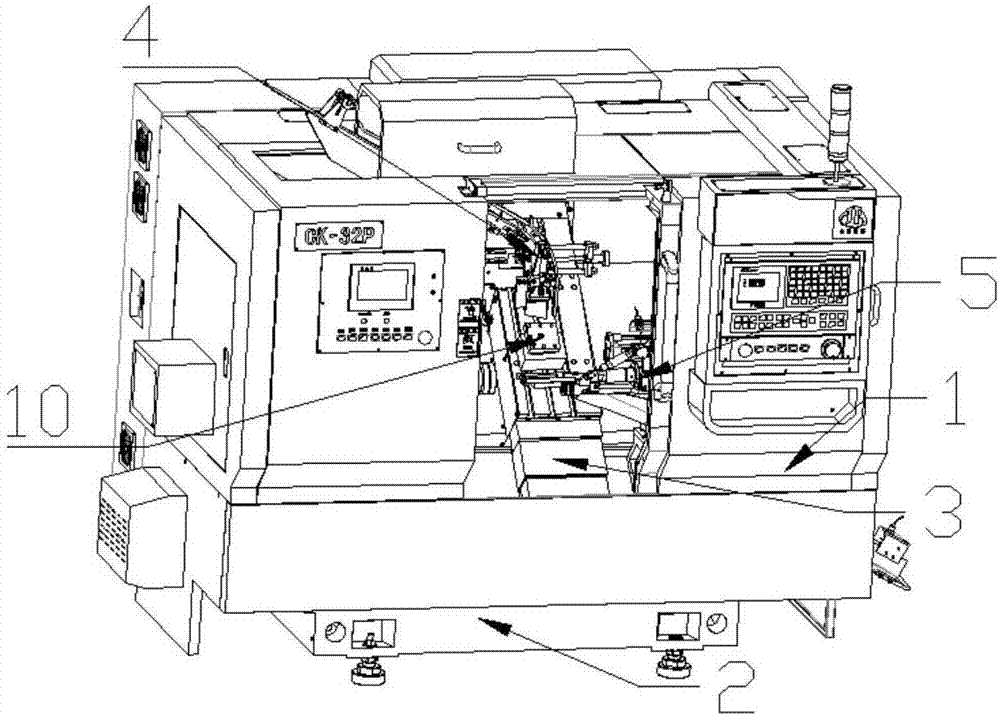

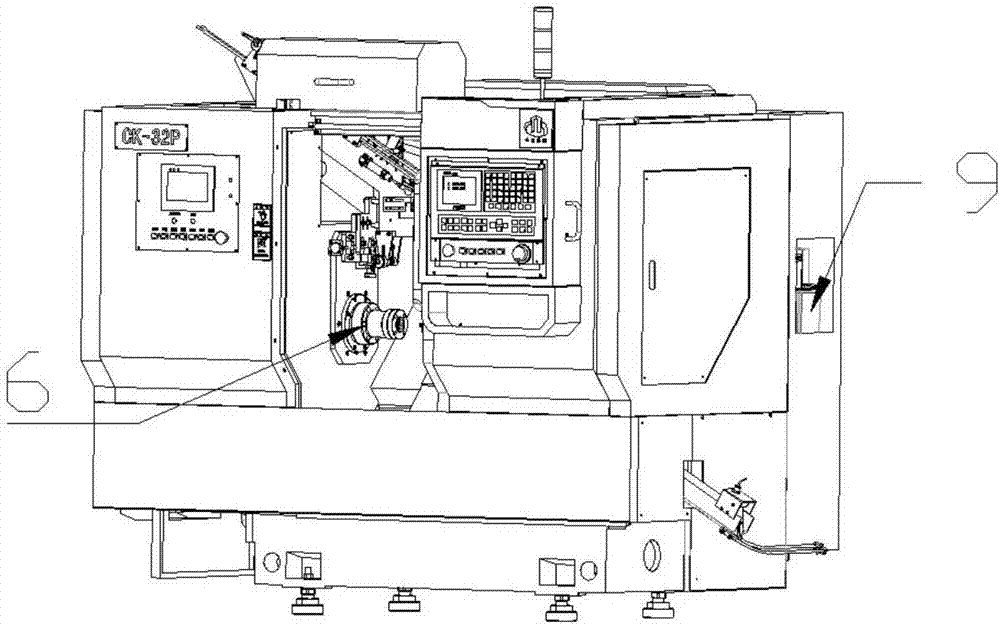

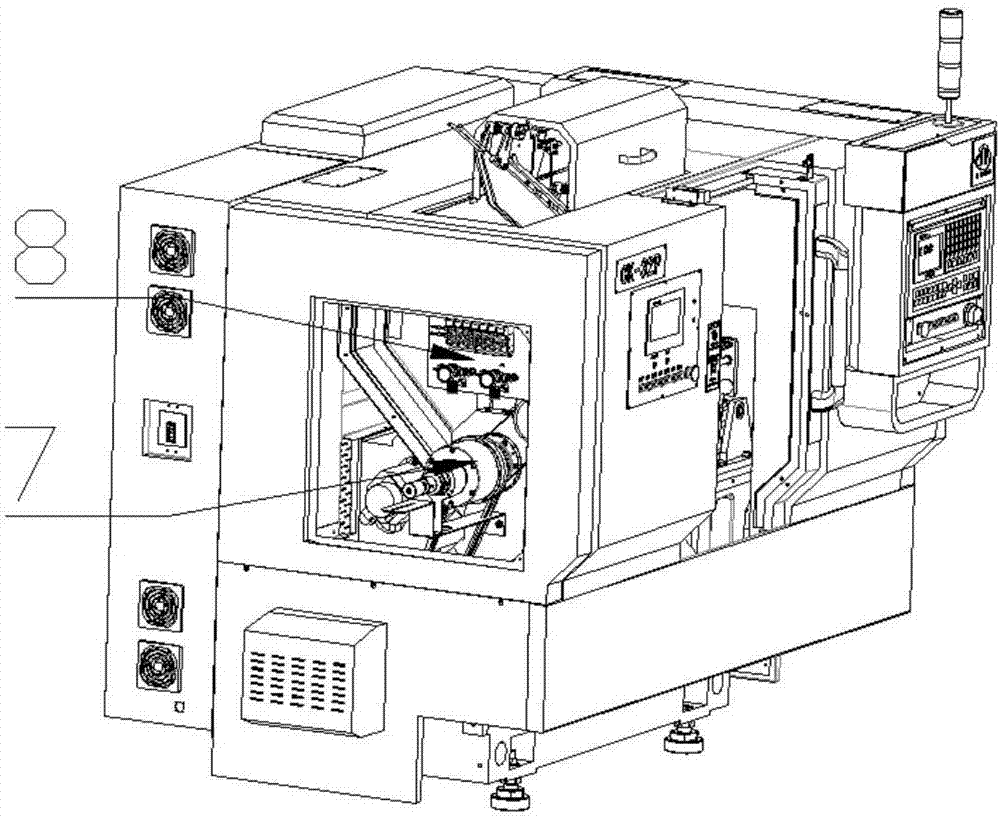

[0065] Such as figure 1 , 2 , 3, a special CNC lathe for continuous automatic processing of engine valves, including a protective assembly 1, a bed base assembly 2, a saddle assembly 3, a material distribution and discharge assembly 4, a loading and blanking assembly 5, main shaft assembly 6, clamping and pushing assembly 7, pneumatic system assembly 8, lubrication system assembly 9 and tool seat assembly 10.

[0066] The lower part of the bed base assembly 2 is fixedly connected to the ground, and the upper part is connected with the movable support of the sliding saddle assembly 3. The protective shell assembly 1 is supported by the bed base assembly 2 and installed outside the machine body. The sliding saddle assembly The upper part of Cheng 3 is detachably connected with the tool holder assembly 10, the lower part of the tool holder assembly 10 corresponds to the main shaft assembly 6 and the material clamping and pushing assembly 7, and the two are detachably connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com