Machining method for through hole in angular combination device

A combined device and processing method technology, applied in positioning devices, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of through-hole processing quality influence, general through-hole effect, low precision, etc., to avoid repeated calibration and clamping, The effect of reducing professional requirements and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

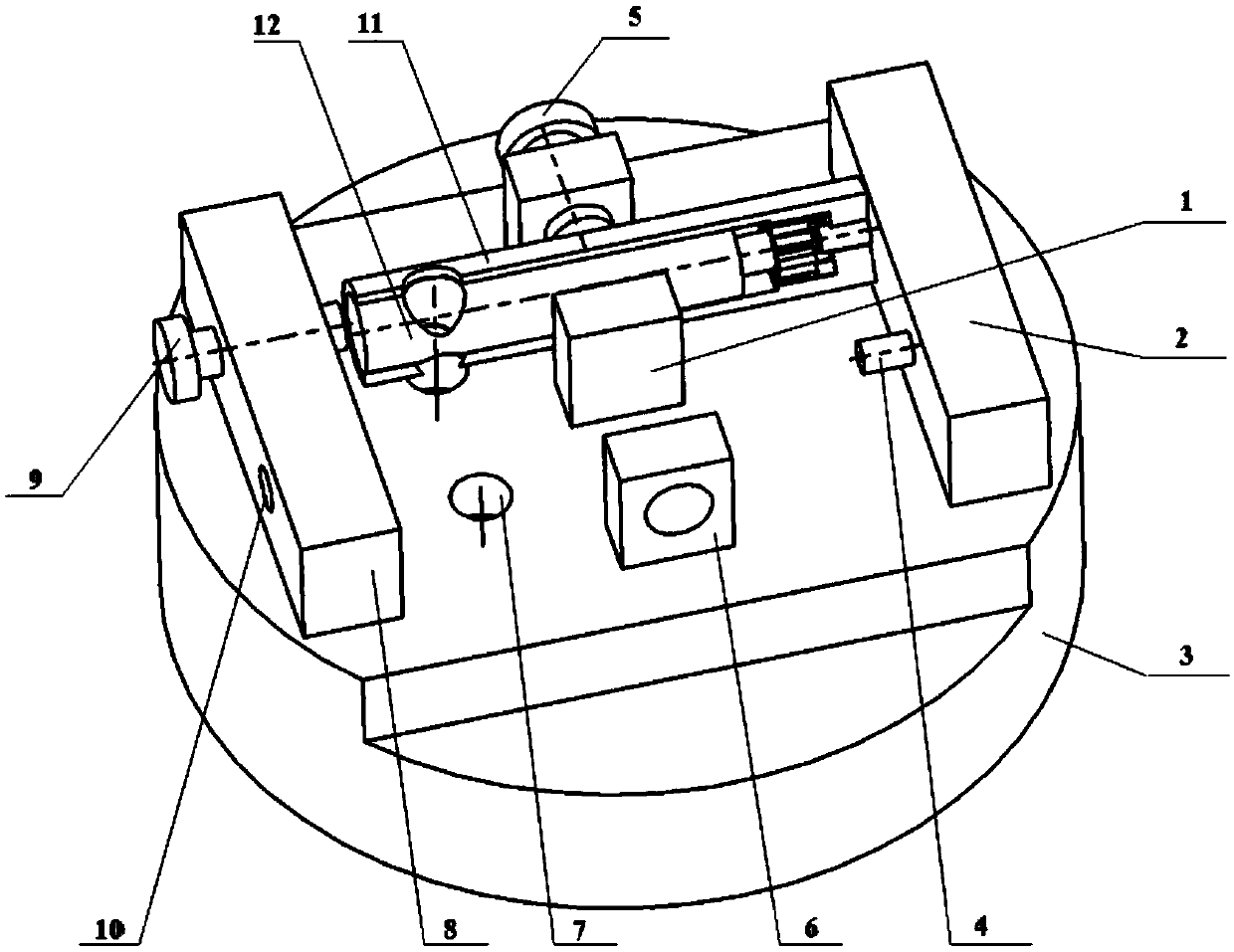

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] figure 1 As shown, put assembly one 11 on the base 3, insert the inner hole of assembly one 11 into the end face positioning pin 4, one end of assembly one 11 fits with the end face positioning block 2, and the side of assembly one 11 and the lateral positioning block 1 fit, tighten the lateral compression bolt 5 and the axial compression bolt 9, through the positioning of the end face positioning block 2 and the lateral positioning block 1, the axial compression bolt 9 and the lateral compression bolt 5 are compressed to realize the combination Fixing of piece one 11; machining the through hole of assembly one 11 with a cutter, after the cutter passes through the processing assembly one 11, inserts the avoidance hole 7, withdraws the knife, and completes the processing of the through hole of assembly one 11;

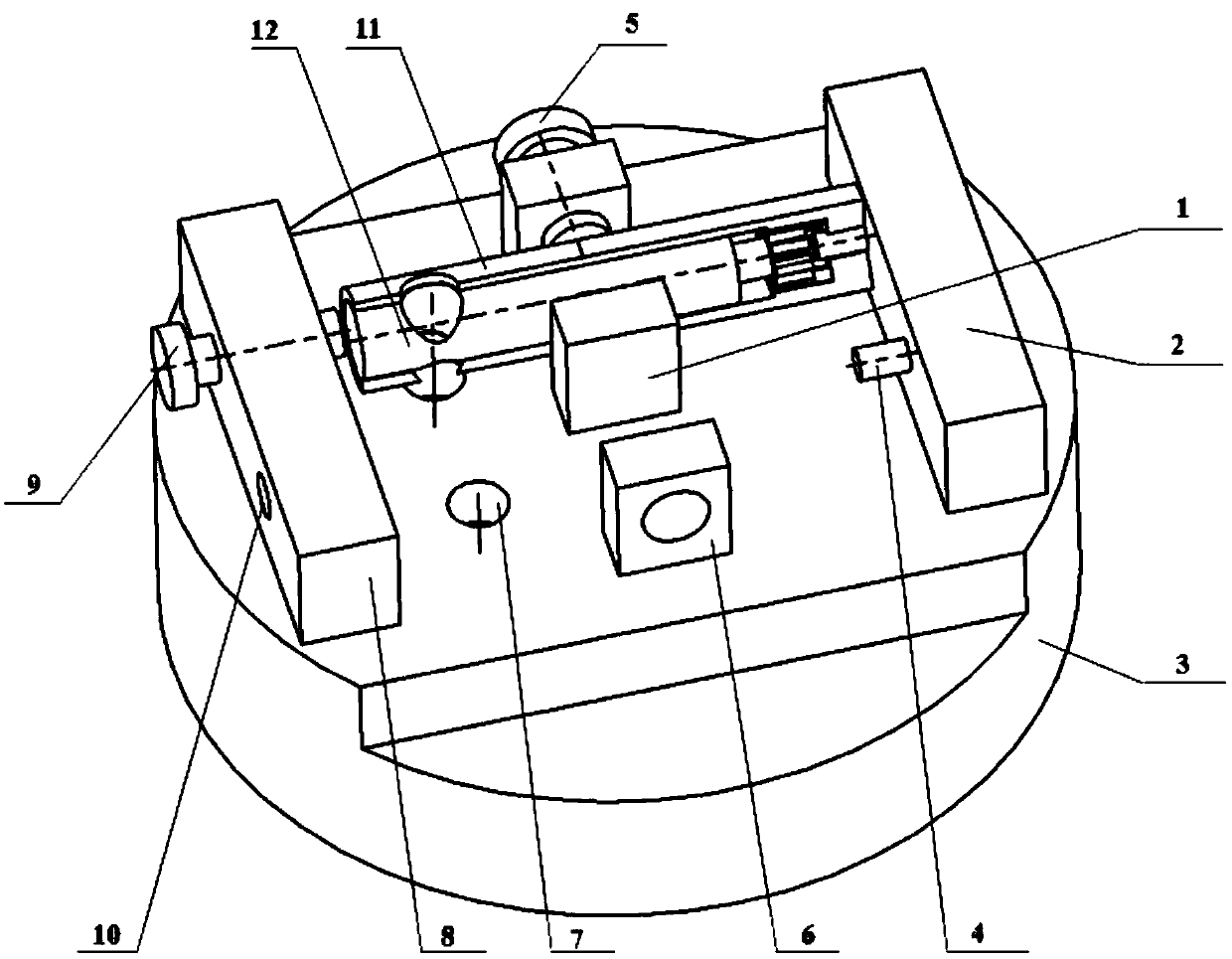

[0014] figure 2 As shown, loosen the axial compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com