Patents

Literature

55results about How to "Avoid recalibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

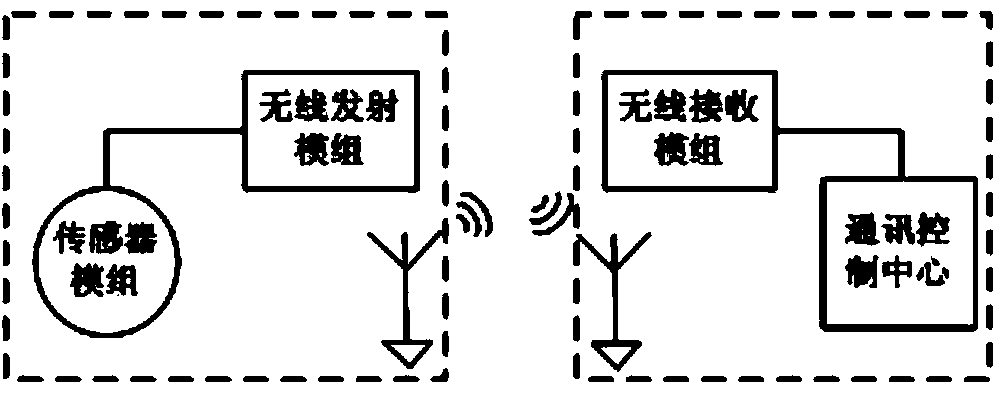

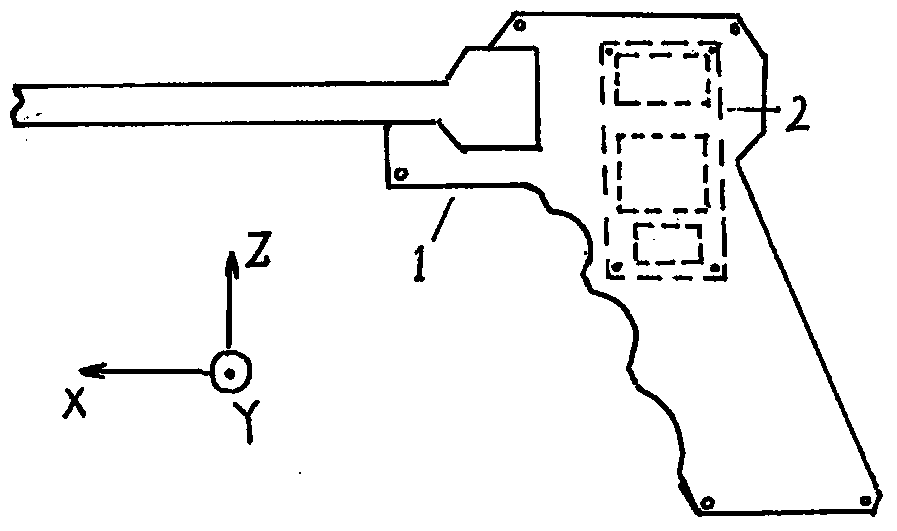

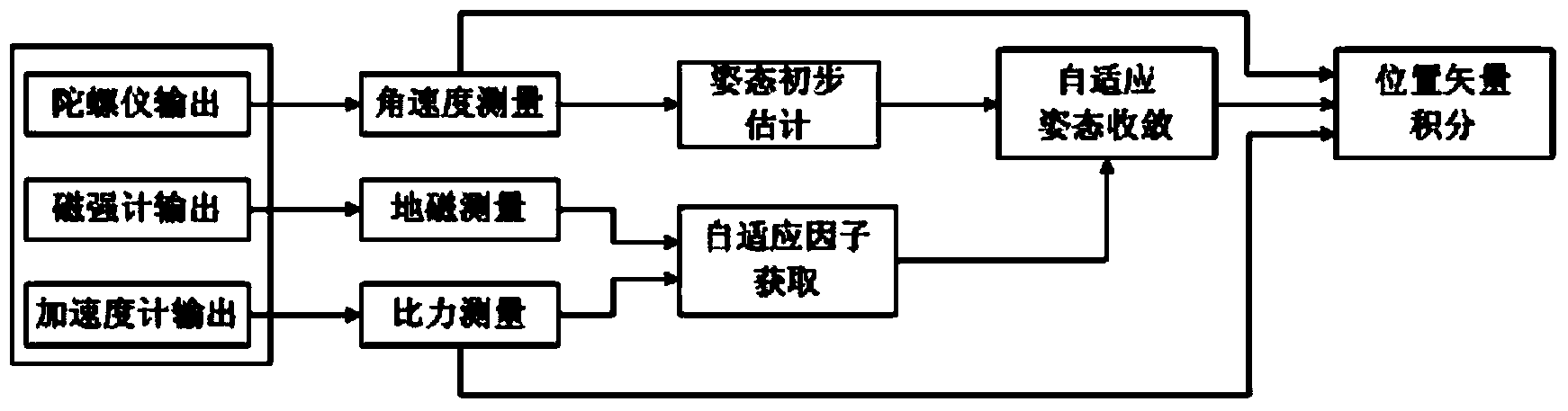

Endoscope system with anti-interference capacity and surgical navigation function

ActiveCN104224089AAvoid influenceReduce space pressureDiagnosticsSurgeryTriaxial accelerometerGyroscope

The invention provides an endoscope system with an anti-interference capacity and a surgical navigation function. A surgical navigation subsystem is realized by an inertial navigation module, and the inertial navigation module comprises three sensors, i.e., a triaxial accelerometer, a triaxial gyroscope and a triaxial magnetometer. Depending on a micro-electro-mechanical system technique, the navigation subsystem can be integrated in a handle of an endoscope, so that the endoscope has a positioning function. In a positioning algorithm, through proper anti-interference treatment, positioning errors caused by external magnetic fields and movement of the endoscope are reduced, and the positioning stability and accuracy are improved.

Owner:TIANJIN UNIV

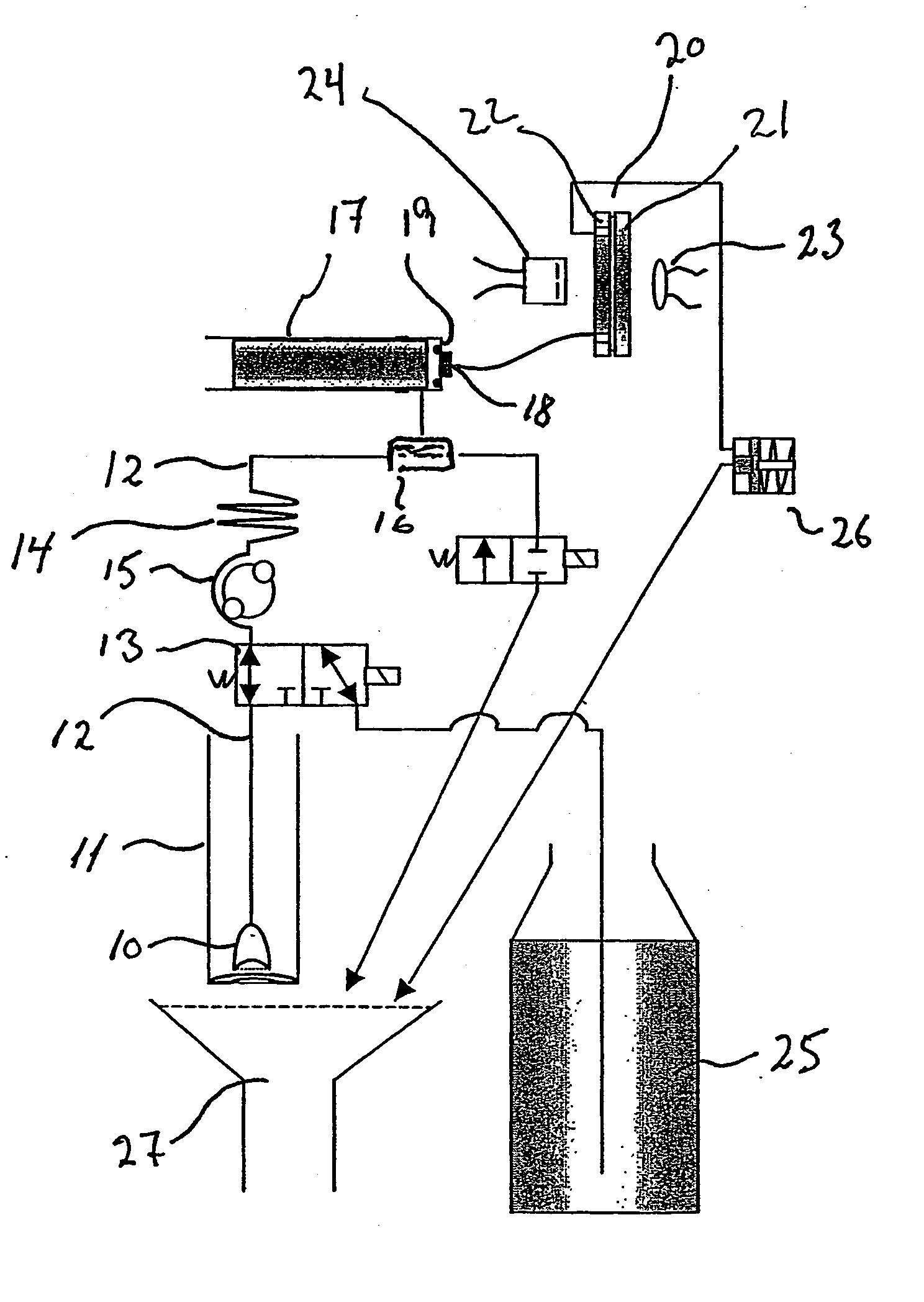

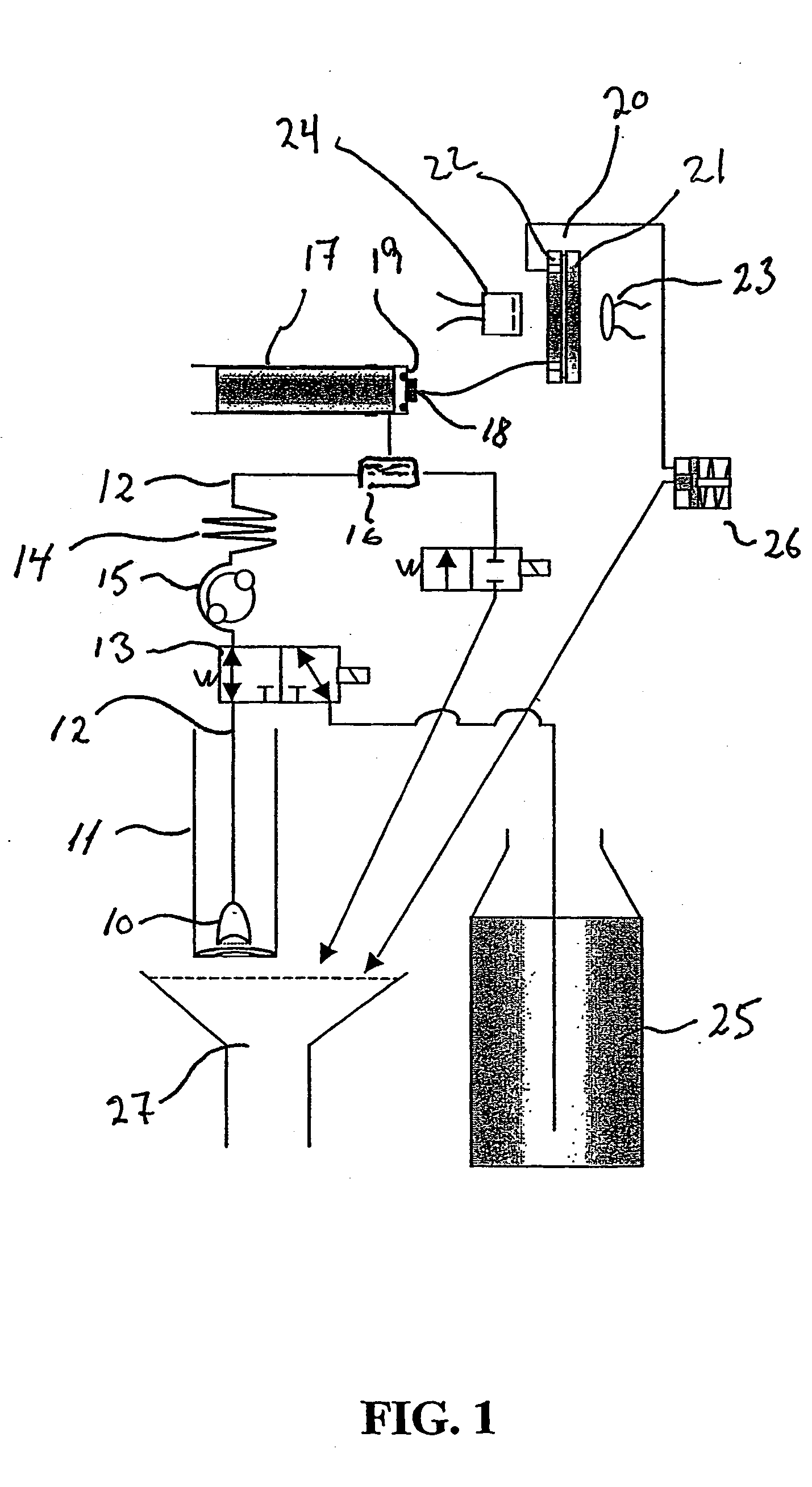

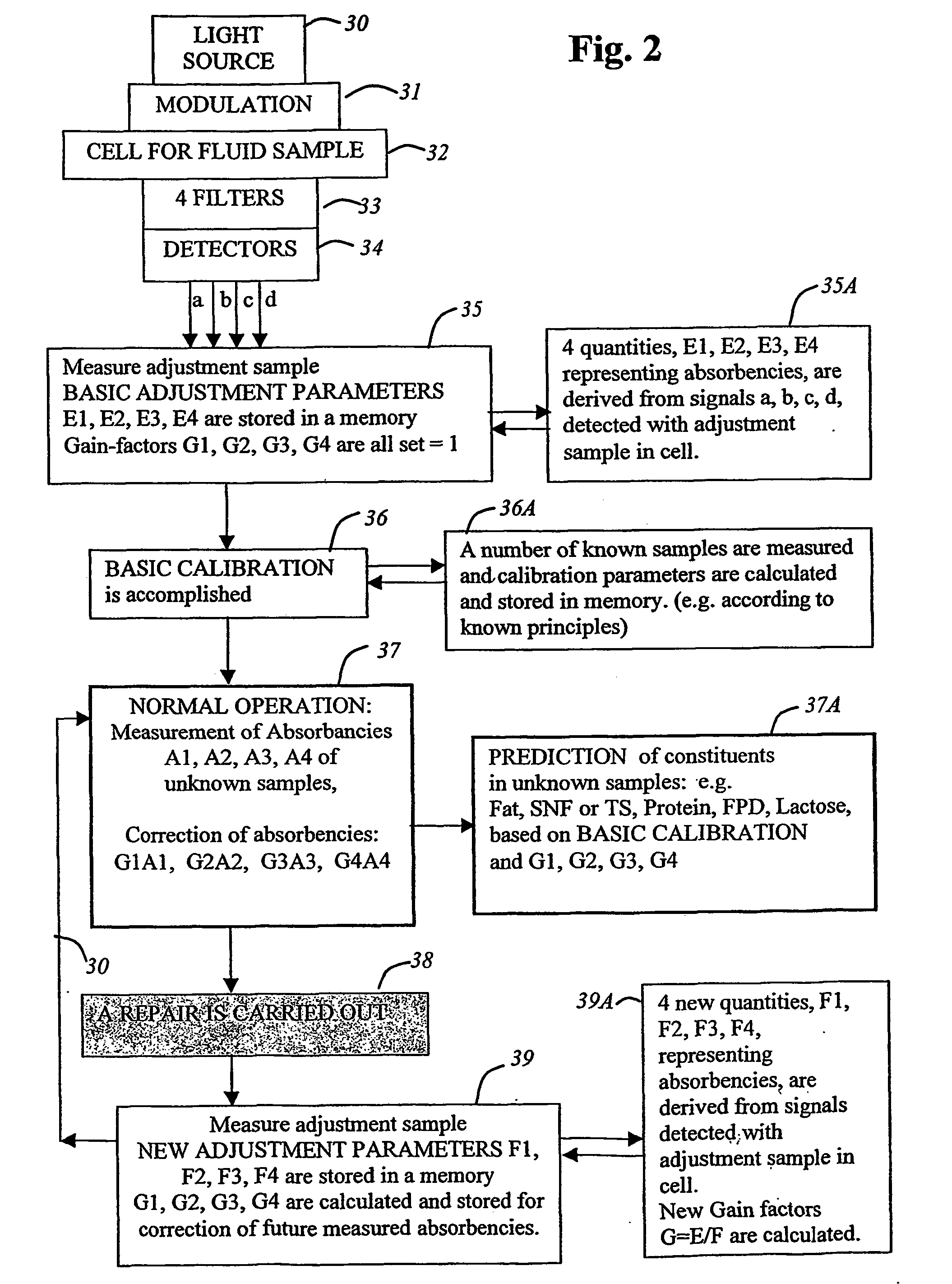

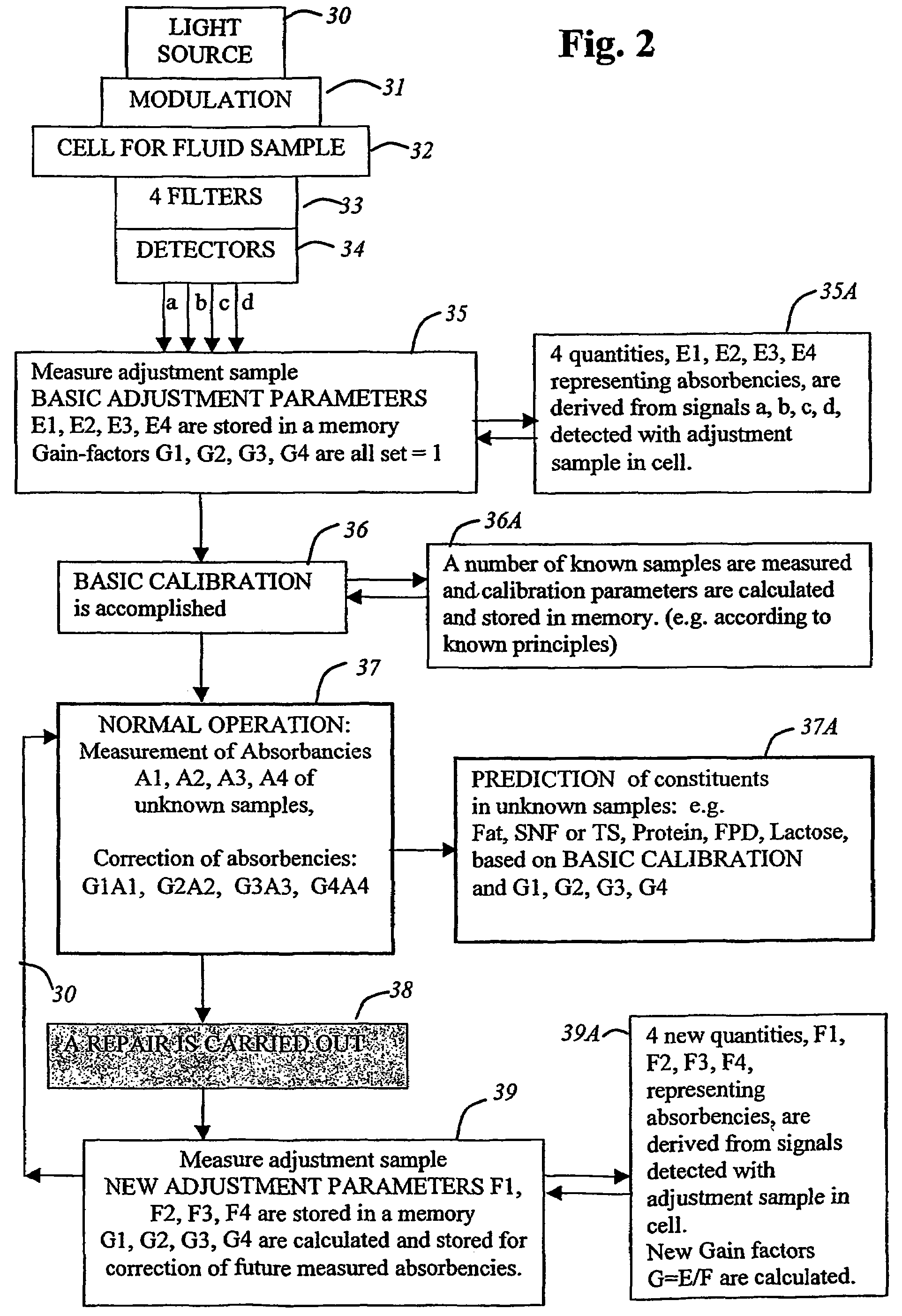

Method and a spectrometer for quantitative determination of a constituent in a sample

InactiveUS20050279924A1Avoid recalibrationEasy to handleRadiation pyrometrySamplingChemical compositionQuantitative determination

The present invention relates to a method of determining a constituent of a sample and more specifically, to a method of correcting an absorbance value for a spectrometer. The method is especially applicable in connection with spectrometric analysis instruments for quantitatively determining the chemical composition of fluids, e.g. the content of fat, protein lactose or urea, in food products, especially in raw milk or dairy products. The method is based upon a measurement of one or more selected ranges of a spectrum, providing an absorption spectrum of the product. The method may be applicable in connection with all spectroscopic instruments giving rise to specific ranges of a spectrum, such as UV, VIS, NIR, IR, NMR, MS, etc.). Typically, the spectrum will be a MID-IR absorption spectrum.

Owner:FOSS ANALYTICAL AS

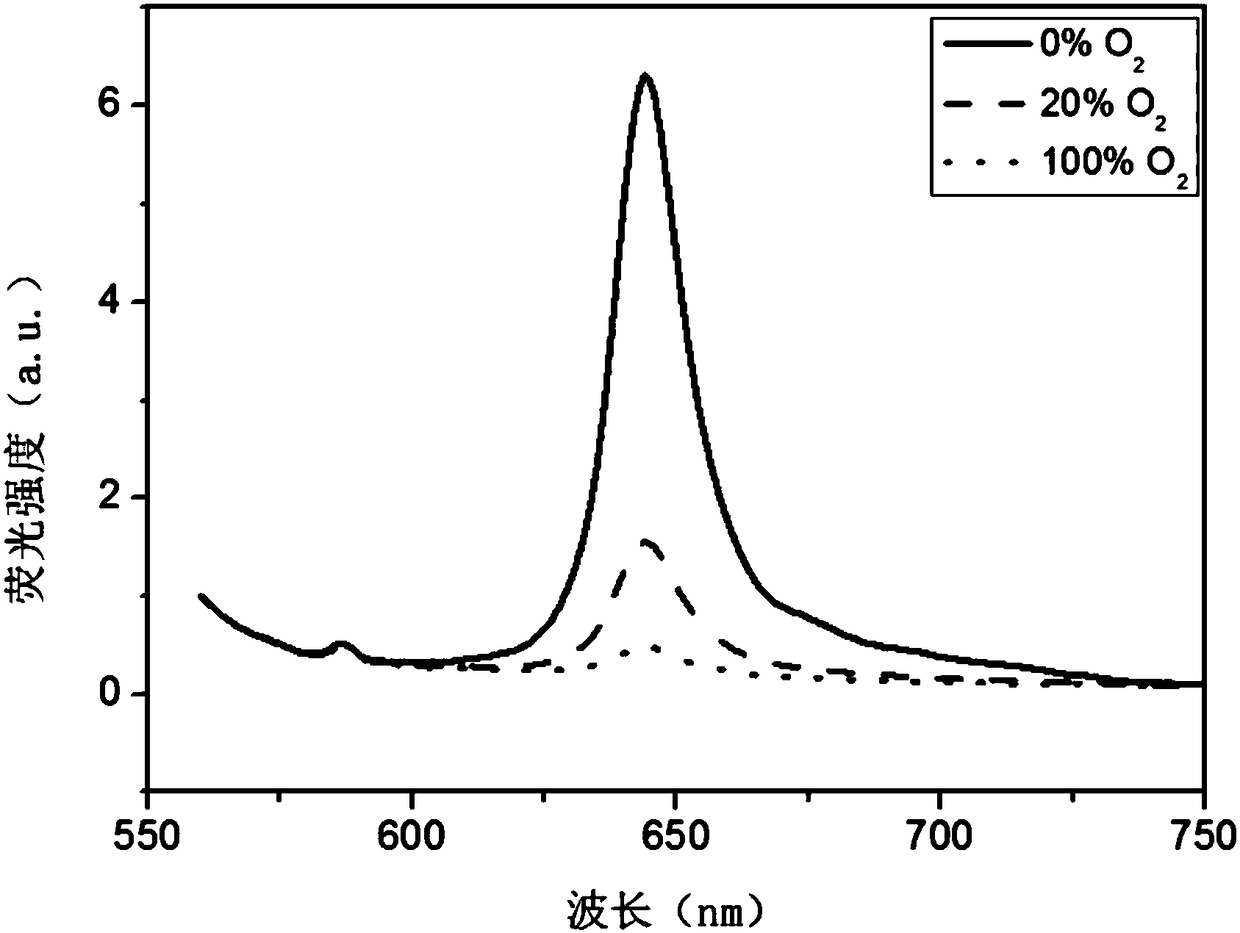

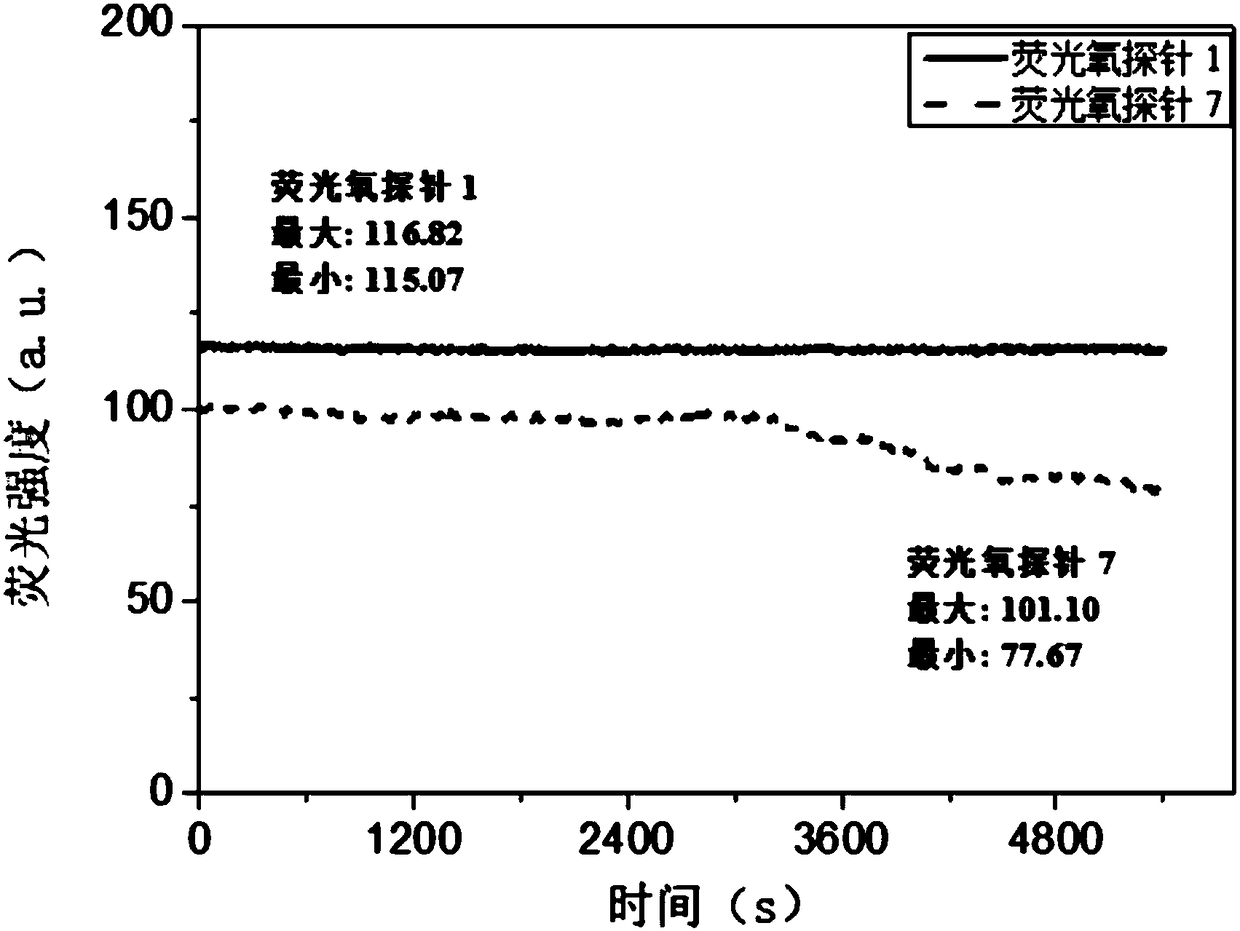

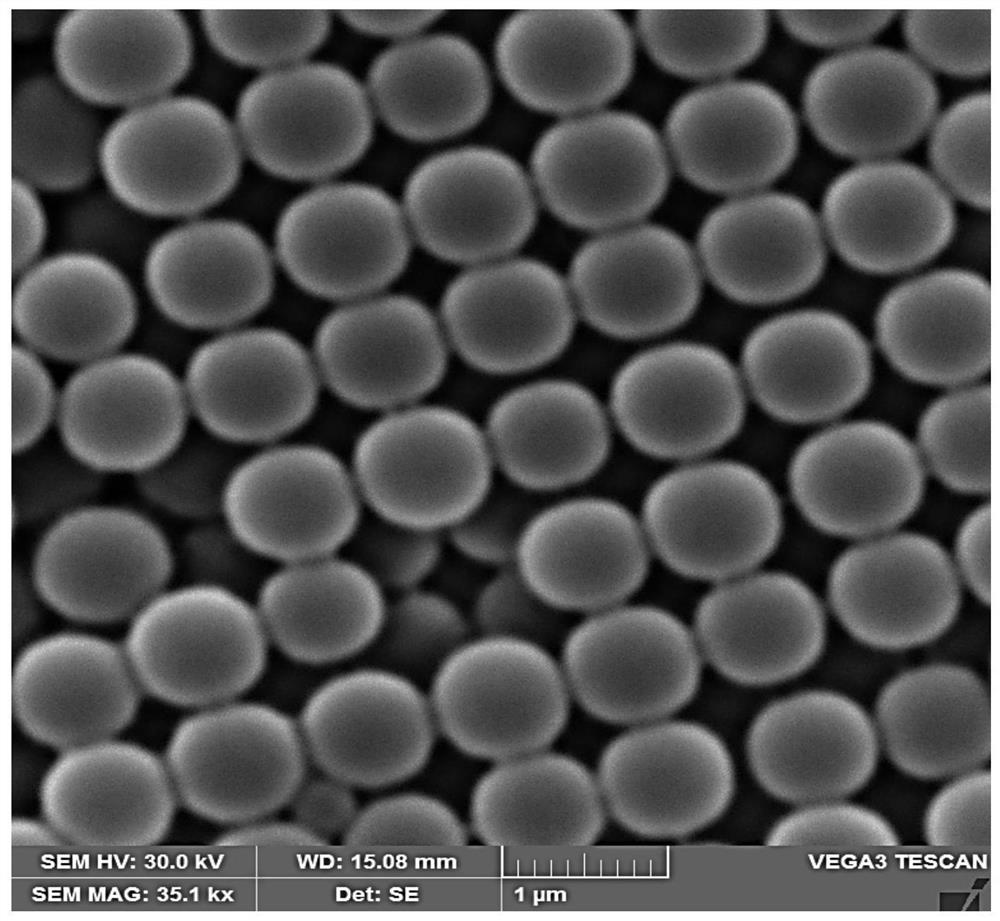

Fluorescent oxygen probe, and preparation method and use thereof

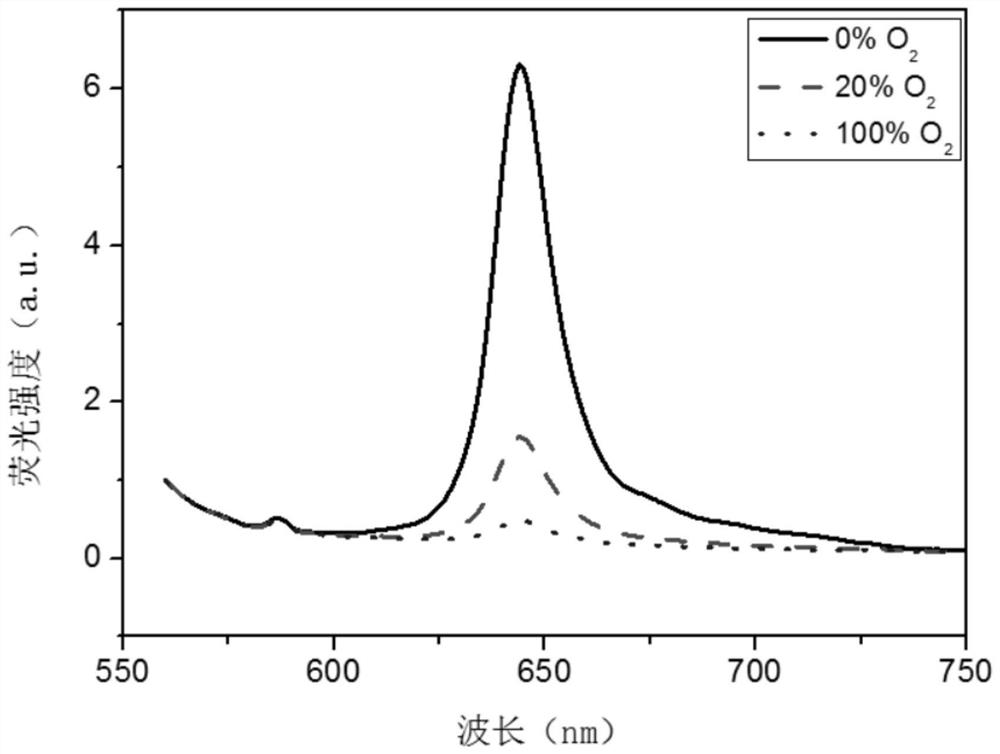

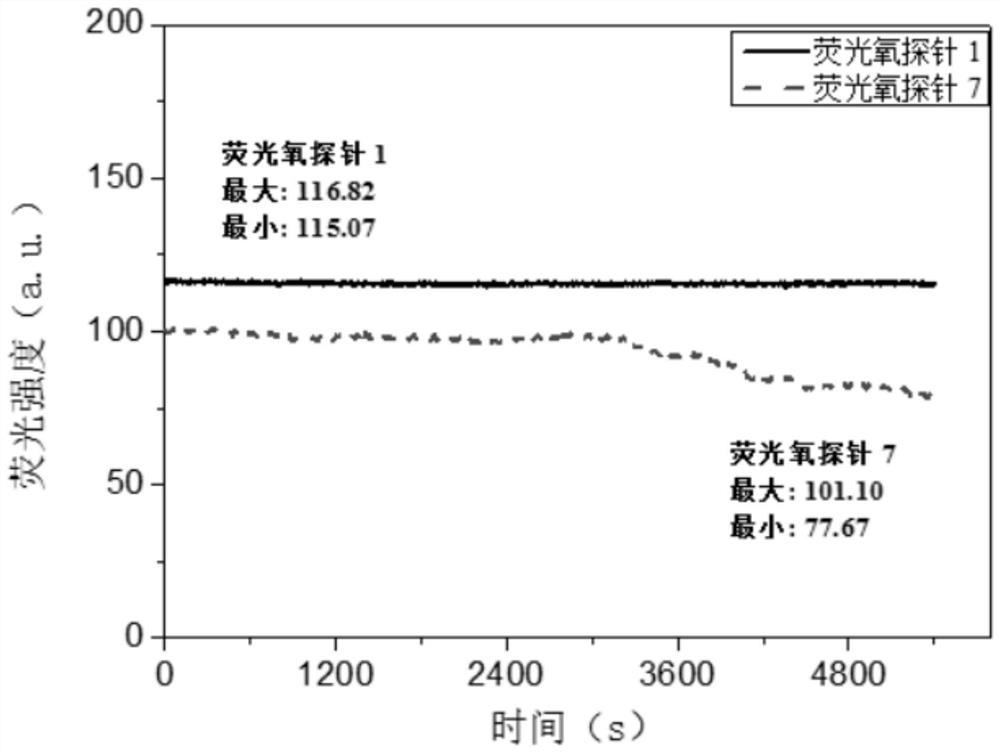

ActiveCN108333162AReduce detection errorPrevent metabolic breakdownFluorescence/phosphorescenceFluorescenceSelf-reference effect

The invention provides a fluorescent oxygen probe which includes polymer microspheres copolymerized with a reference probe compound, and a fluorescent oxygen probe compound uniformly dispersed in thepolymer microspheres copolymerized with the reference probe compound. The invention also provides a method for creatively preparing the fluorescent oxygen probe. By copolymerizing the reference probecompound and a polymerized monomer, the microspheres dispersed with the fluorescent oxygen probe compound are prepared and can be used as a fluorescent oxygen probe for use. The prepared fluorescent oxygen probe has a self reference effect, and the problem that a fluorescent probe needs to be recalibrated when a detection device is replaced in traditional fluorescence detection is avoided. In addition, the fluorescent oxygen probe has no high requirements on a detection environment and can be used for detecting the concentration of dissolved oxygen in a dynamic biological environment, such asa water body containing microorganisms, and the error of the detection result is less than or equal to 5% compared with that of a traditional electrochemical detection equipment.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

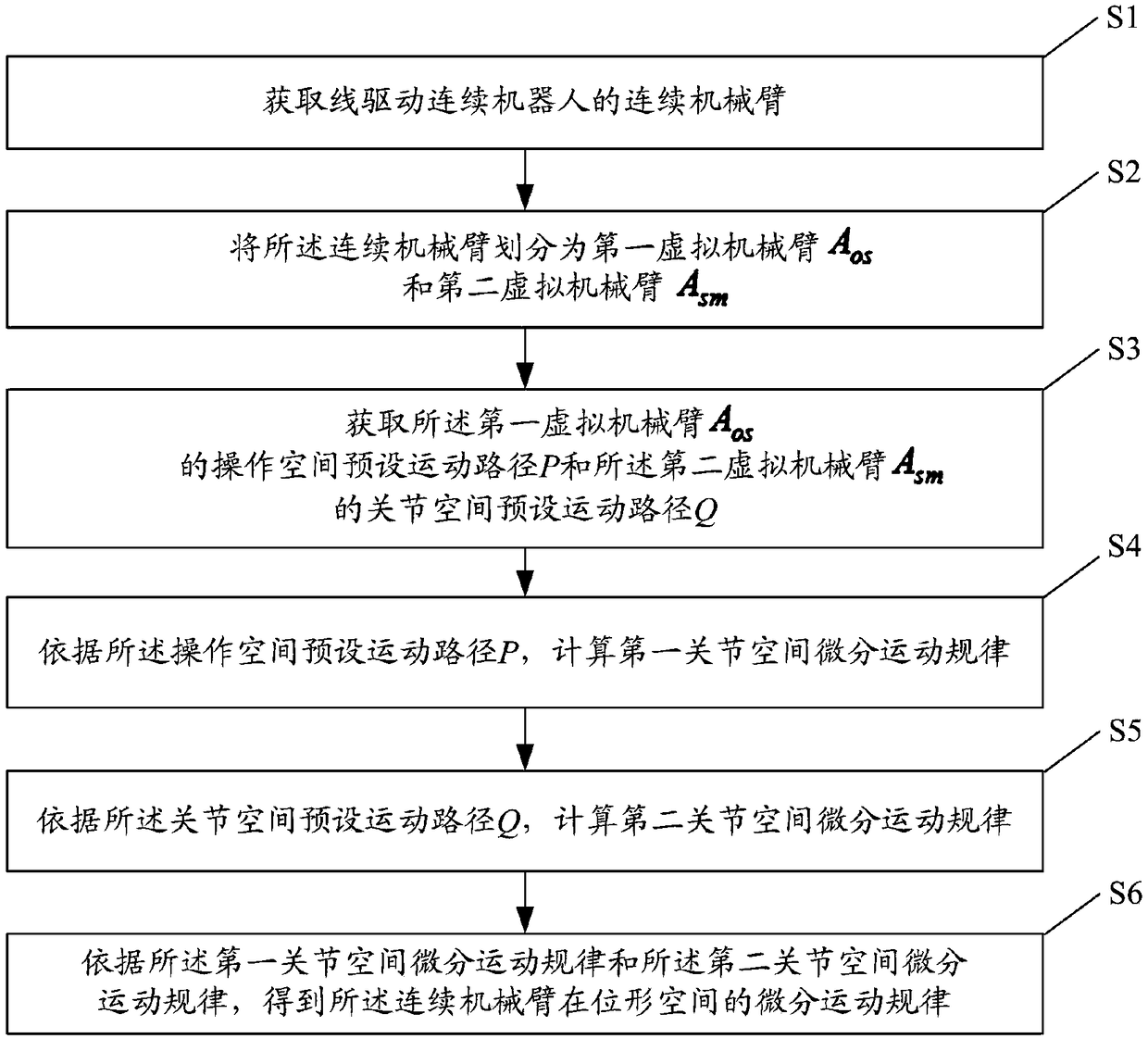

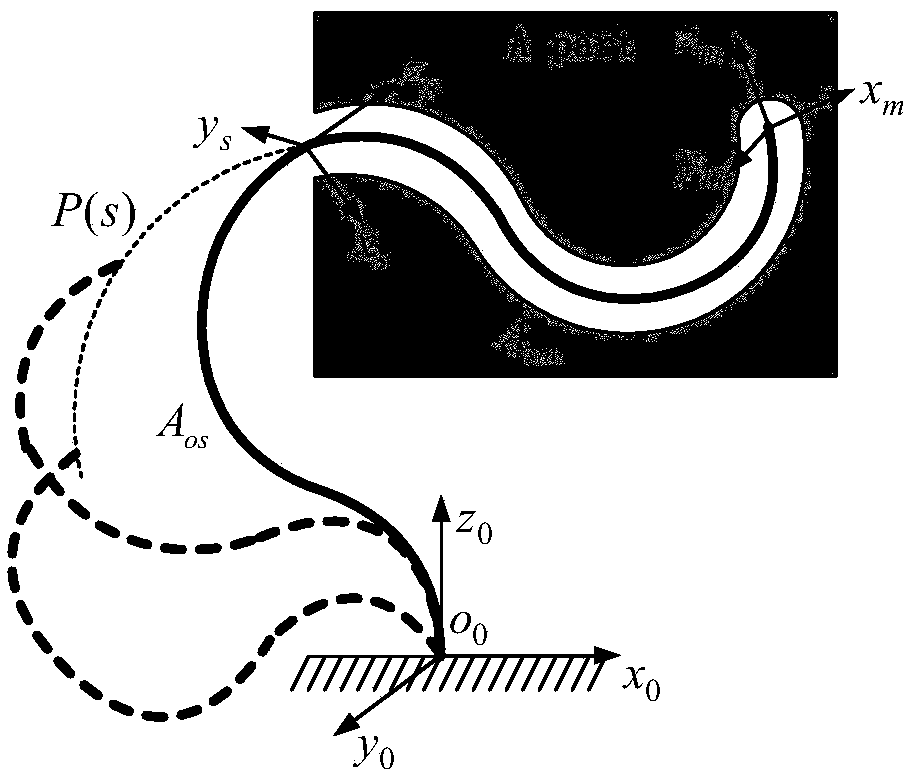

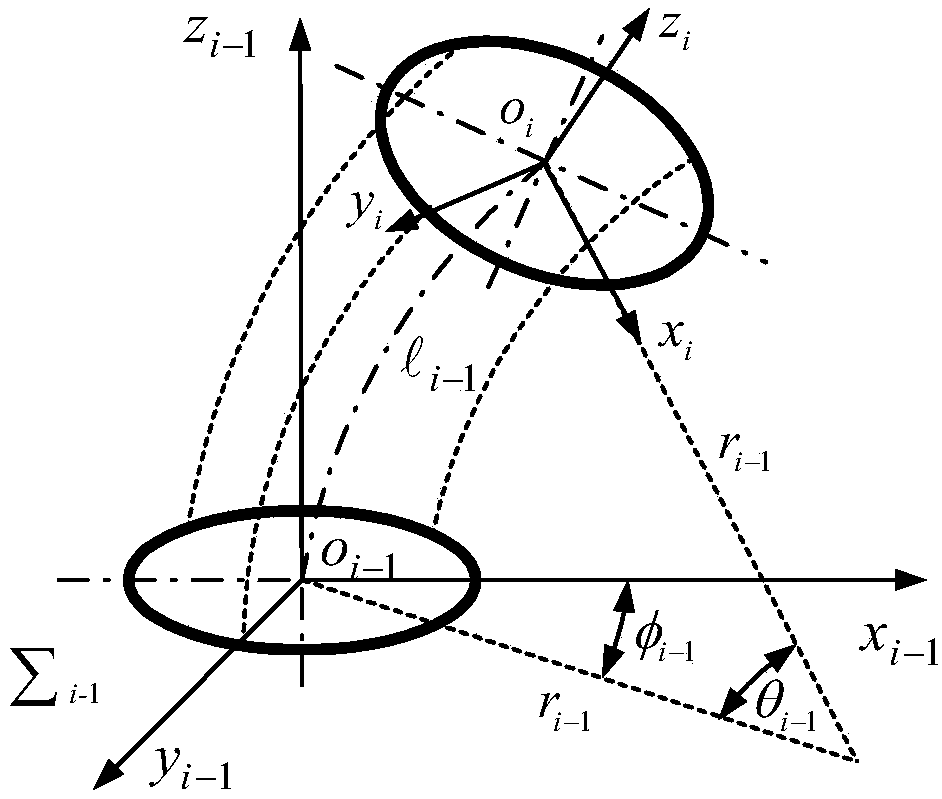

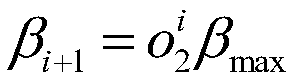

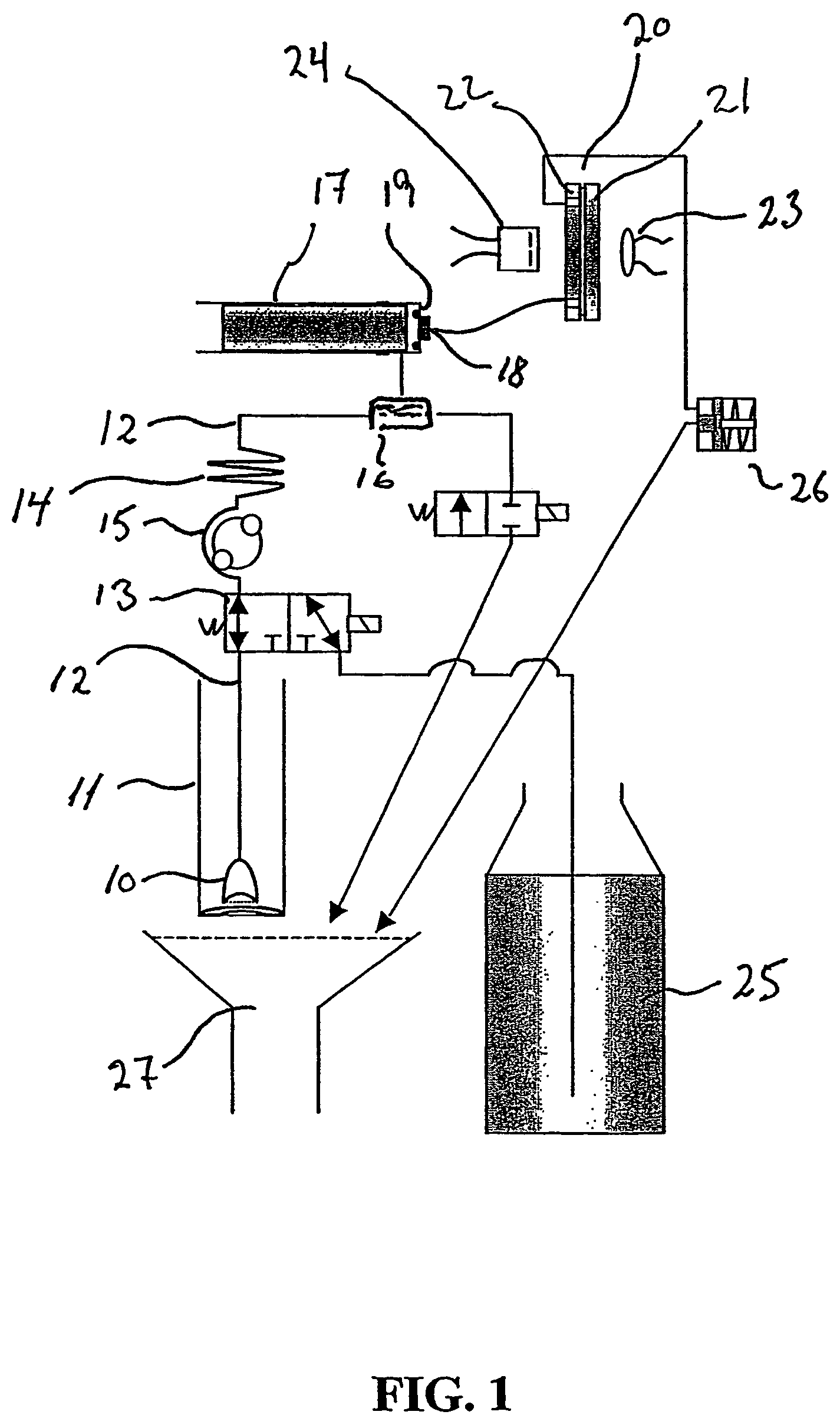

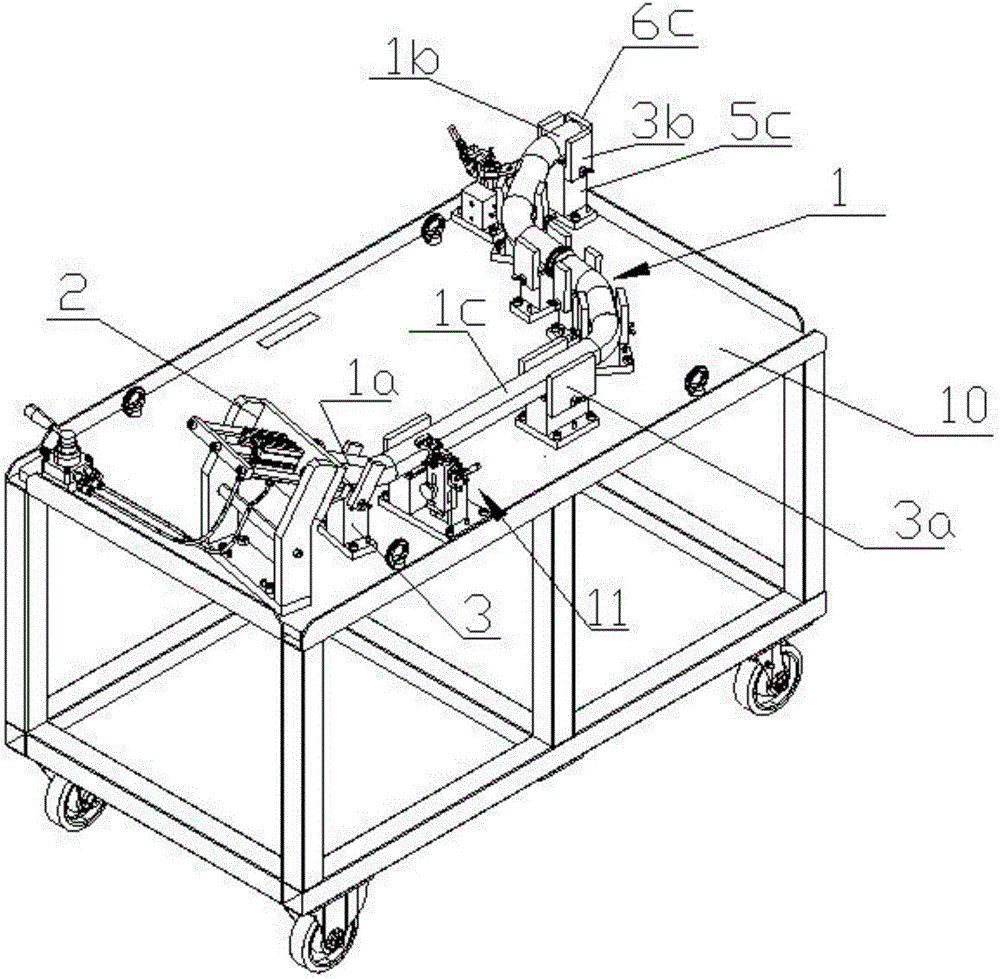

Method and system of planning of synergic movement of endoscopic operation of line-driven continuous robot

ActiveCN109434838AEnabling Safe Peeping OperationsImprove securityProgramme-controlled manipulatorConfiguration spaceJoint spaces

The invention discloses a method and system of planning of synergic movement of endoscopic operation of a line-driven continuous robot. The method comprises the steps that a continuous mechanical armof the line-driven continuous robot is obtained; the continuous mechanical arm is divided into a first virtual mechanical arm and a second virtual mechanical arm; an operation space preset movement path and a joint space preset movement path are acquired; a joint space differential movement rule of the first virtual mechanical arm under the condition of the operation space preset movement path anda joint space differential movement rule of the second virtual mechanical arm under the condition of the joint space preset movement path are calculated; and a differential movement rule of the wholecontinuous mechanical arm in the configuration space is calculated and used for achieving the synergic movement of the endoscopic operation of the line-driven continuous robot. By the adoption of themethod and system of planning of the synergic movement of the endoscopic operation of the line-driven continuous robot, planning of the synergic movement can be conducted in the operation space and the configuration space at the same time, the accidental contact or collision caused by configuration drifting can be avoided, the safety is high, and the working efficiency is high.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

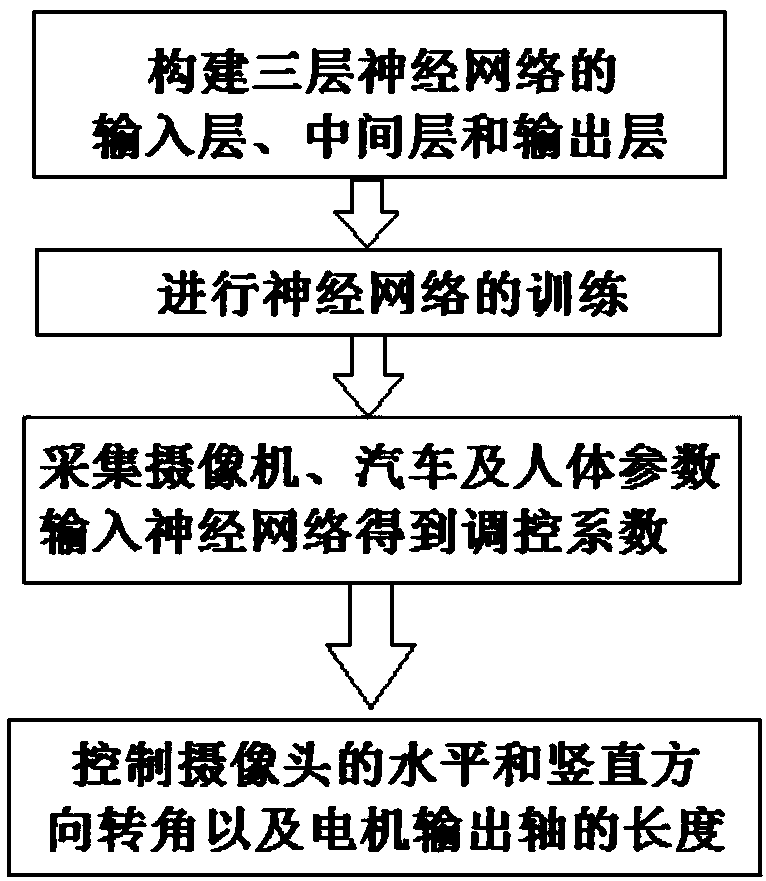

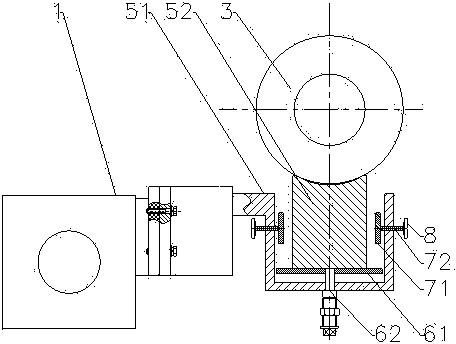

Driver feature point measuring device based on binocular vision and control method thereof

PendingCN108664043AAccurate measurementAvoid recalibrationUsing optical meansControl using feedbackMeasurement deviceDriver/operator

The invention discloses a driver feature point measuring device based on binocular vision, capable of detecting the running condition of an automobile and the characteristics of a driver, and changingthe position relation of the camera relative to the driver by adjusting the length of an output shaft of a motor and the rotation angle of a camera. The invention further provides a control method for driver feature point measuring based on binocular vision, and the positions of the two cameras and the length of the output shaft of the motor can be regulated and controlled on the basis of a BP neural network, so that the measuring precision and accuracy can be improved.

Owner:JILIN UNIV

Method and a spectrometer for quantitative determination of a constituent in a sample

InactiveUS7288767B2Avoid recalibrationEasy to handleRadiation pyrometrySamplingChemical compositionQuantitative determination

The present invention relates to a method of determining a constituent of a sample and more specifically, to a method of correcting an absorbance value for a spectrometer. The method is especially applicable in connection with spectrometric analysis instruments for quantitatively determining the chemical composition of fluids, e.g. the content of fat, protein lactose or urea, in food products, especially in raw milk or dairy products. The method is based upon a measurement of one or more selected ranges of a spectrum, providing an absorption spectrum of the product. The method may be applicable in connection with all spectroscopic instruments giving rise to specific ranges of a spectrum, such as UV, VIS, NIR, IR, NMR, MS, etc.). Typically, the spectrum will be a MID-IR absorption spectrum.

Owner:FOSS ANALYTICAL AS

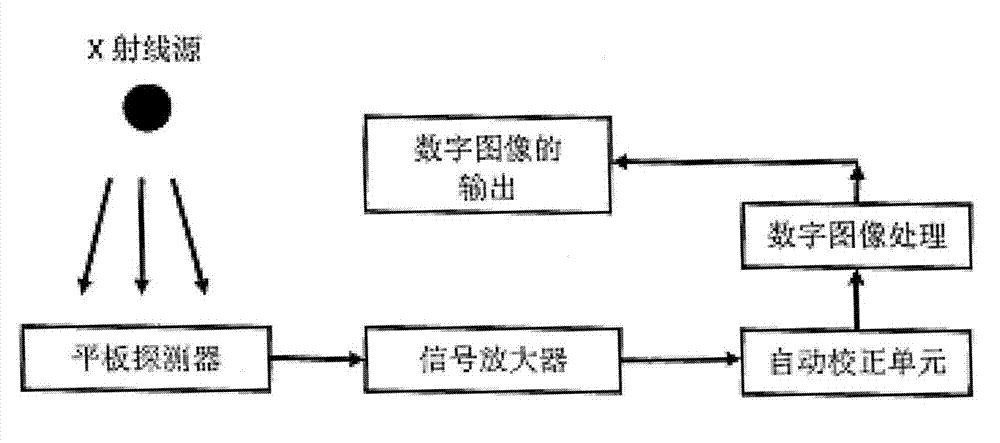

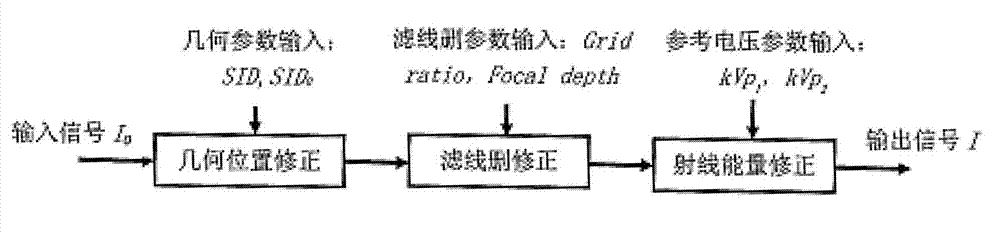

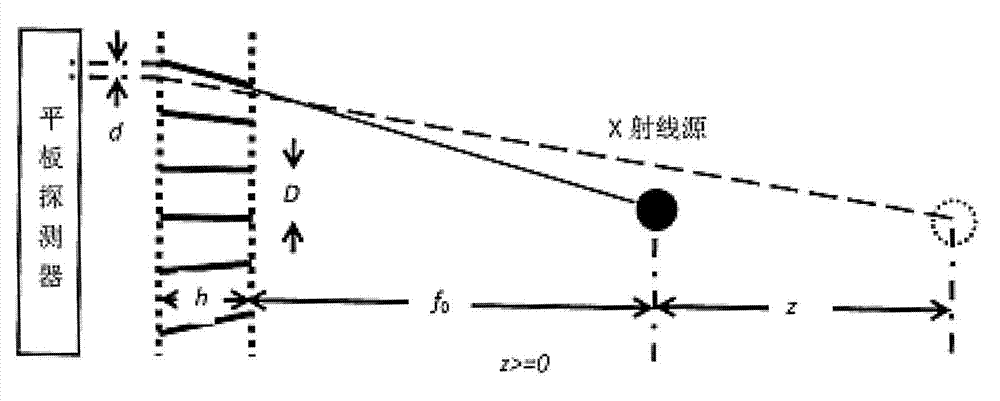

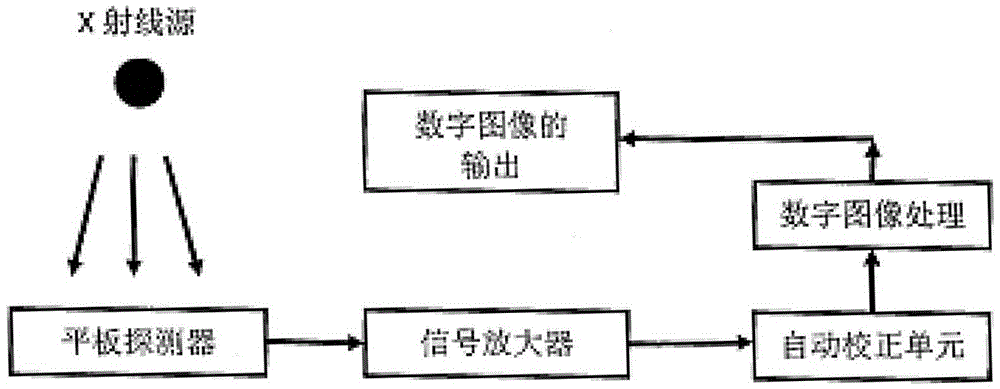

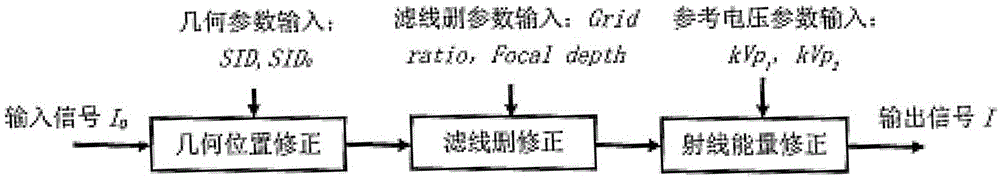

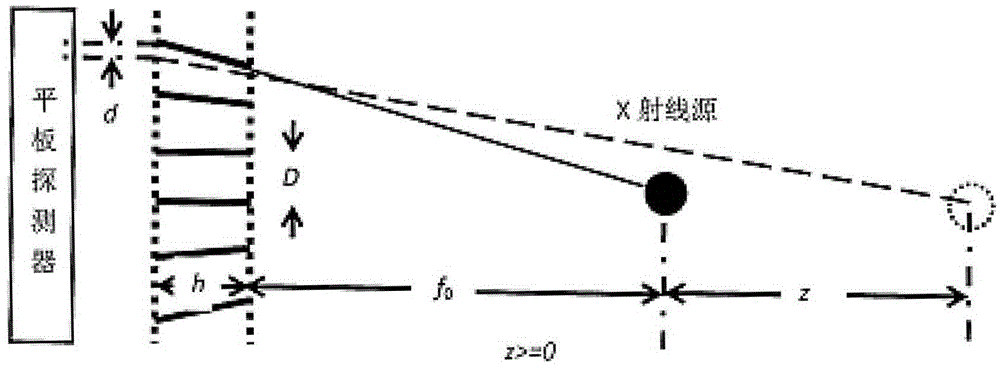

X-ray imaging method with automatic correction function

ActiveCN103091968AAvoid recalibrationRepeat calibration not requiredPhotographyFlat panel detectorAudio power amplifier

The invention discloses an X-ray imaging method with an automatic correction function. The method includes that first, the point light source of an X-ray source directly irradiates to a flat panel detector, and the flat panel detector receives image signals; second, the image signals are amplified through a signal amplifier and then enter into an automatic correction unit for correction, the relation between an output signal I (x, y) and an output signal I0 (x, y) of the automatic correction unit is that I (x, y) =G0(x, y)* S (x, y)* I0 (x, y), wherein the (x, y) is an image space coordinate, G0(x, y) is a sensitivity correction function of a detector, and S (x, y) is a system automatic correction function; and at last, corrected images are processed by a digital image processing unit and then output. According to the imaging system, under a changing condition, without the need for repeated correction, an optimal image can still be developed.

Owner:江西晟大康源医疗技术有限公司

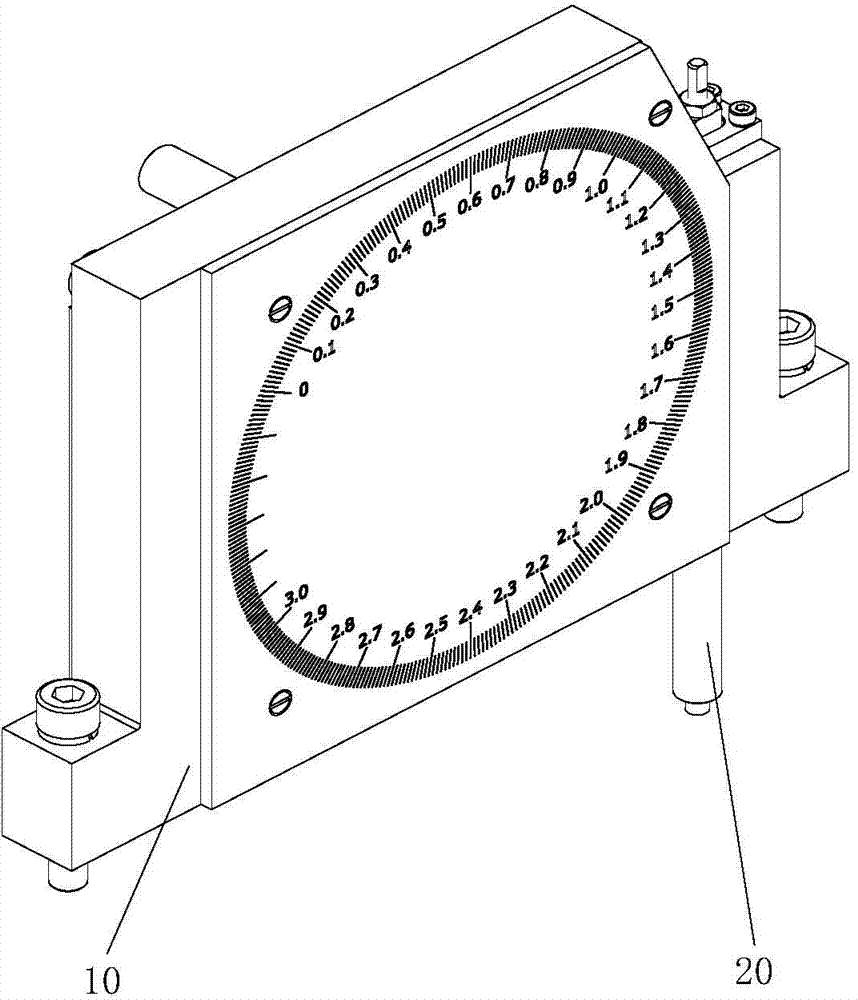

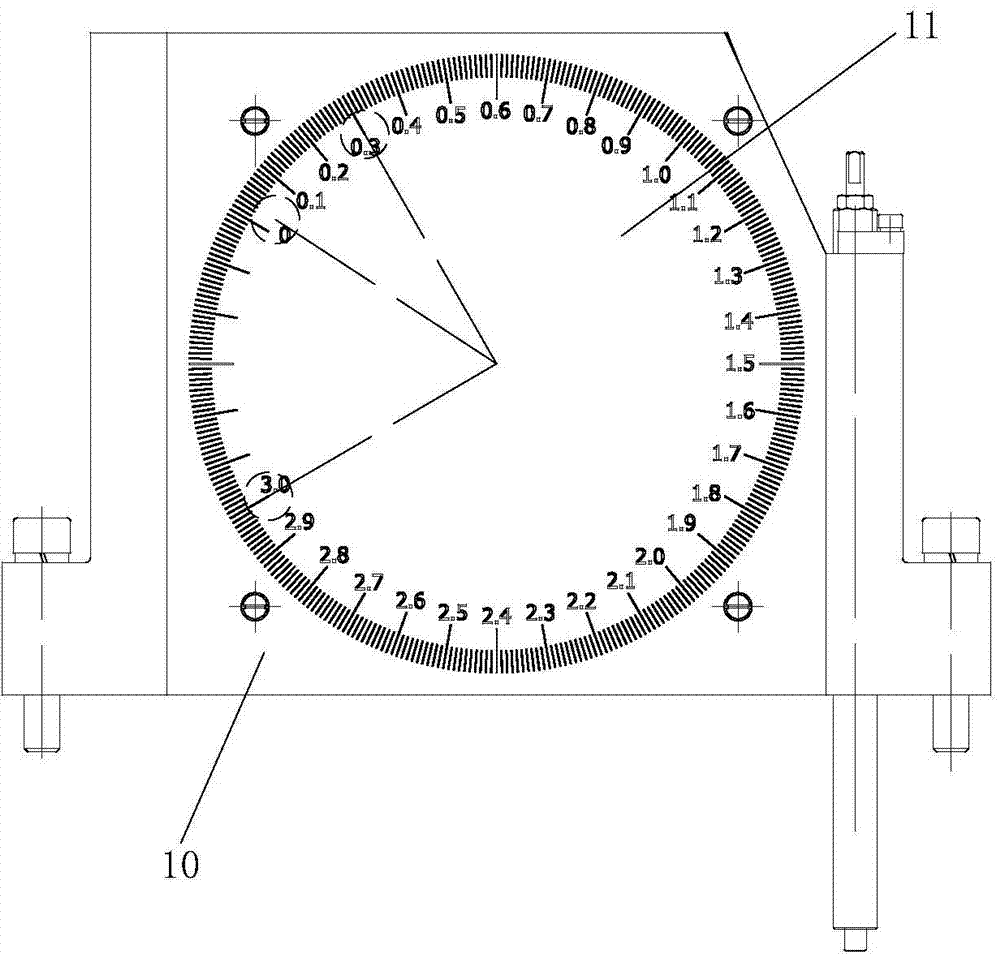

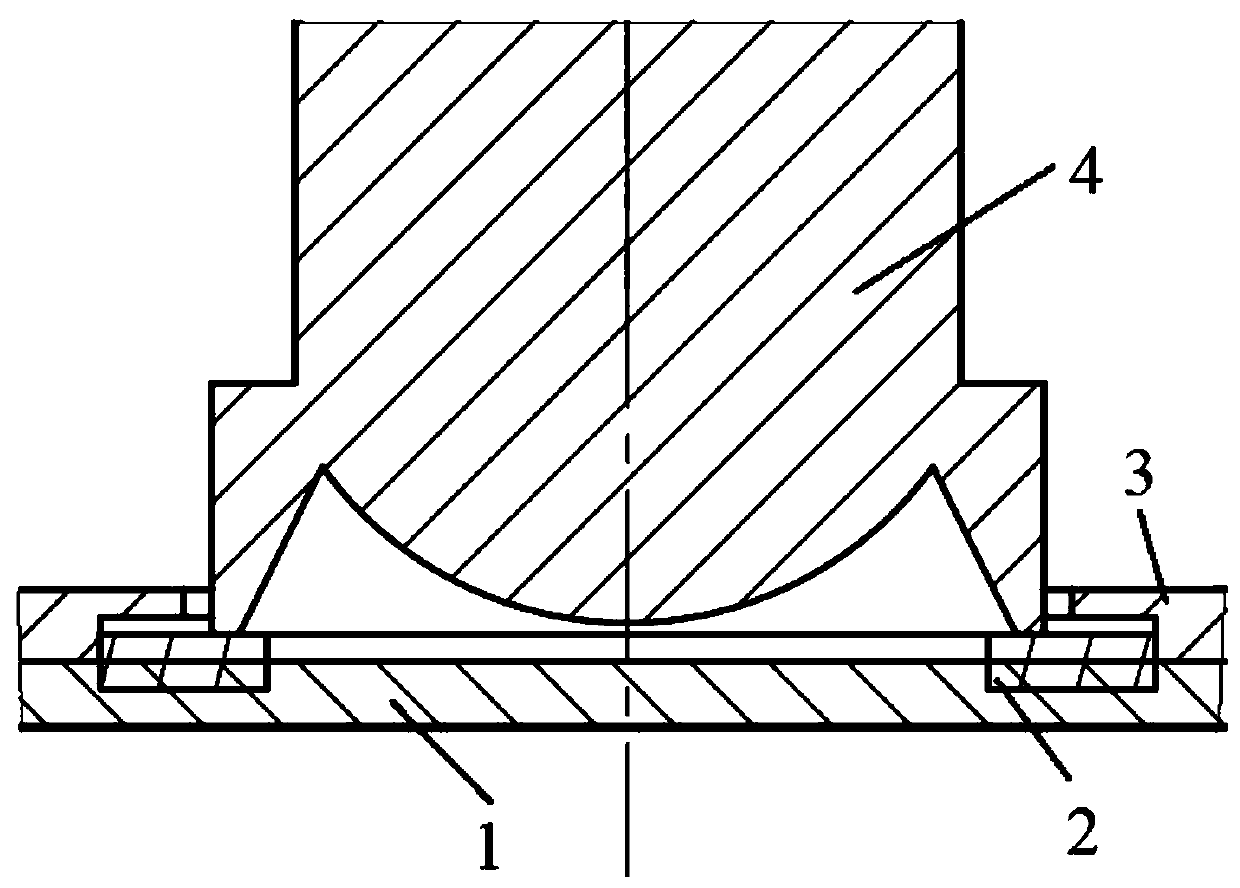

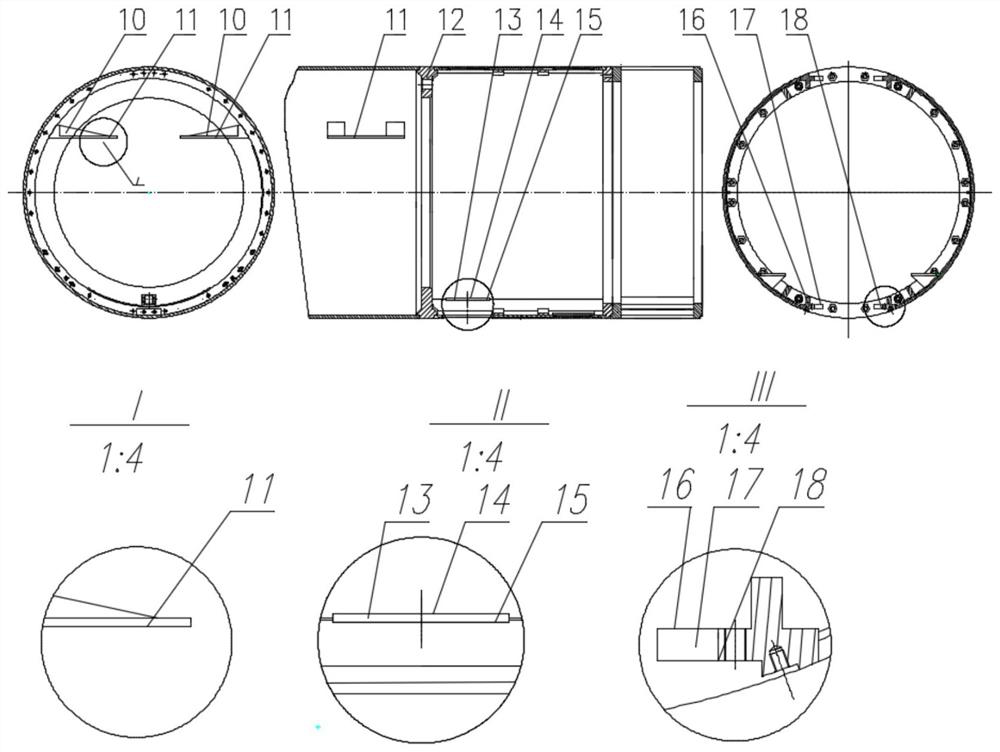

Gap measuring device for circle shear

ActiveCN104708496ASimple structureEasy to implementMeasurement/indication equipmentsShearing machine accessoriesCircular discMeasurement device

The invention discloses a gap measuring device for a circle shear. The gap measuring device for the circle shear comprises a shell, a rack, a gap measuring ejector pin, a first fan gear, a pointer shaft meshed with the first fan gear, a pointer fixed to the pointer shaft, a second fan gear meshed with the pointer shaft and an elastic piece. The rack drives the first fan gear to rotate when sliding relative to the shell, the first fan gear drives the pointer shaft to rotate so as to drive the pointer to rotate, and therefore the size of a gap is displayed. The second fan gear is driven by the elastic piece to sequentially drive the pointer shaft, the first fan gear, the rack and the gap measuring ejector pin, and then the gap measuring ejector pin is made to tightly eject a cutter shaft sleeve of the circle shear. According to the gap measuring device for the circle shear, due to the fact that the gap measuring ejector pin directly abuts against the cutter shaft sleeve of the circle shear in a connected mode, the displacement of the cutter shaft sleeve is directly measured, an error caused by a gap adjustment transmission device is avoided, the measurement precision of a shear edge gap value is improved, and abnormal shearing conditions are avoided.

Owner:WISDRI ENG & RES INC LTD

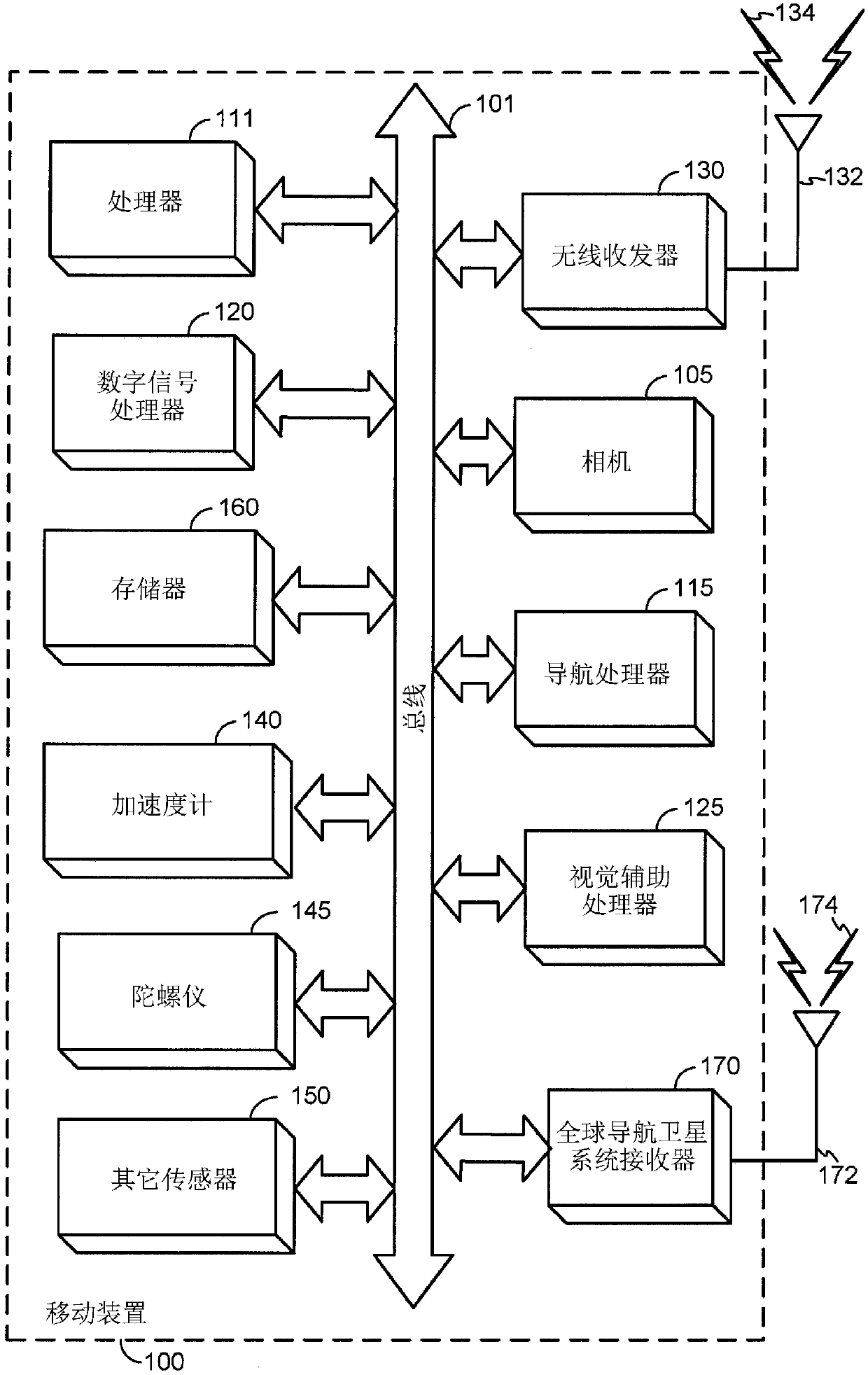

Cradle rotation insensitive inertial navigation

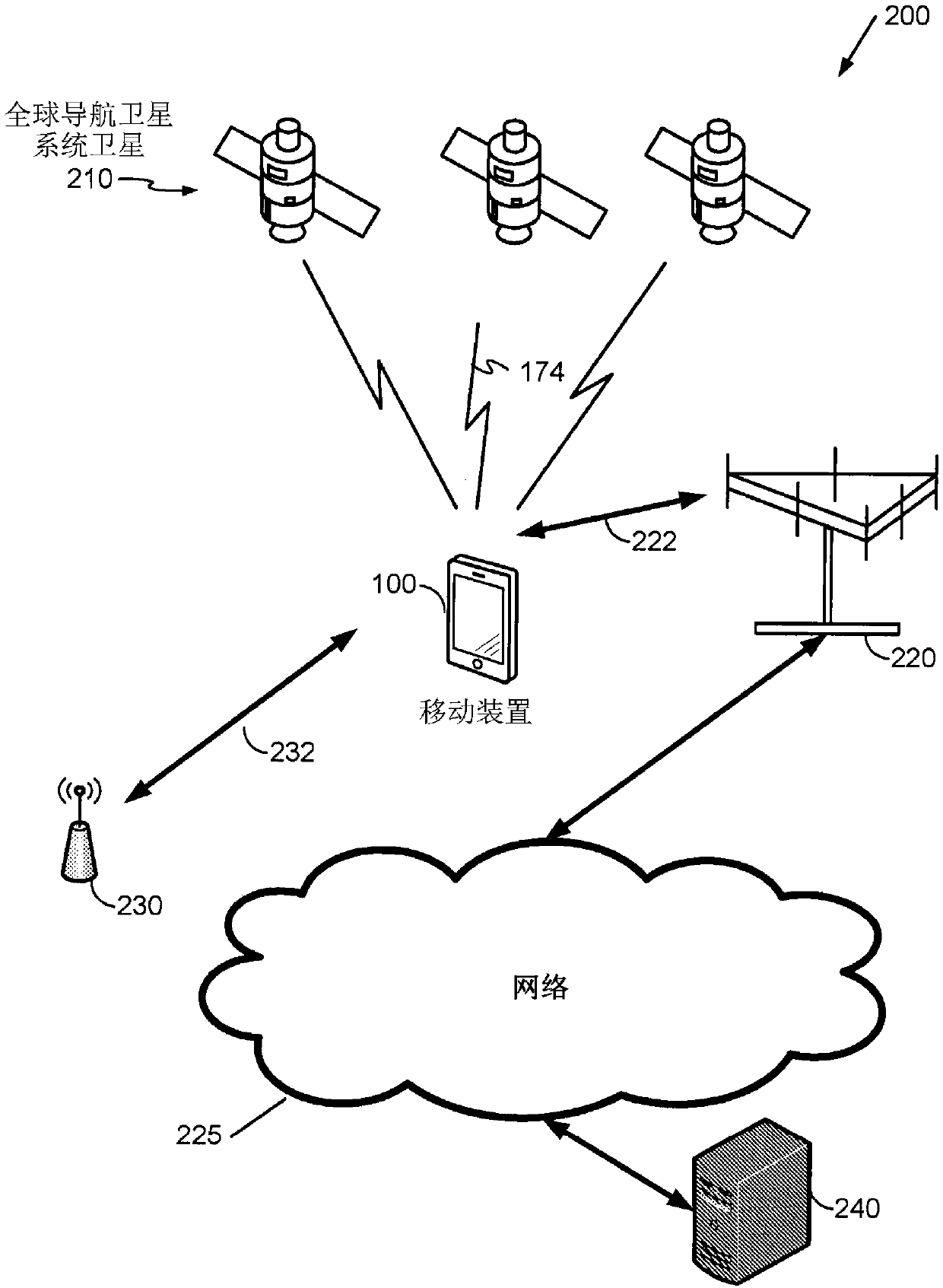

InactiveCN108419442AAvoid recalibrationIncrease usageImage enhancementImage analysisComputer graphics (images)Radiology

Techniques are provided which may be implemented using various methods and / or apparatuses in a mobile device to provide cradle insensitive inertial navigation. An example method for determining alignment changes between a first body frame and a second body frame according to the disclosure includes obtaining one or more images from an image capture device associated with the first body frame in response to detecting a change in alignment between the first body frame and the second body frame, determining a compensation information based on an analysis of the one or more images, and determininga position based on one or more inertial sensors and the compensation information.

Owner:QUALCOMM INC

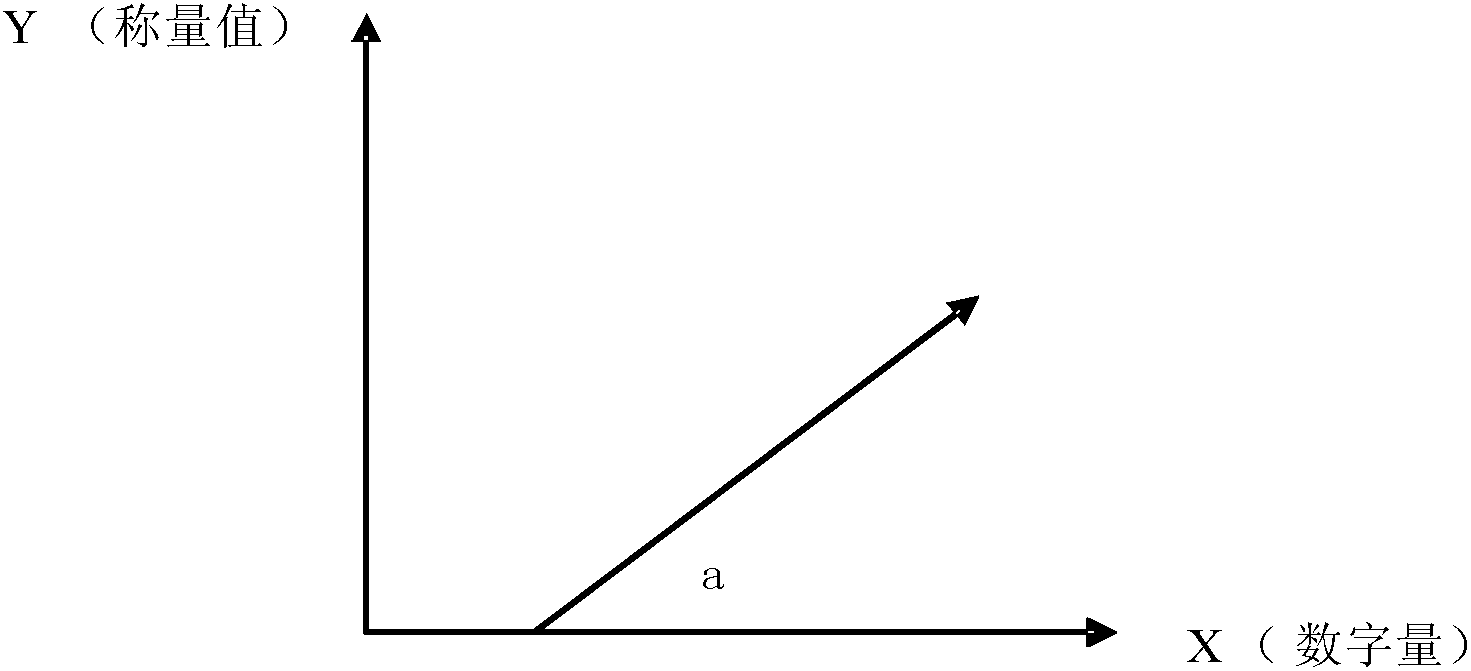

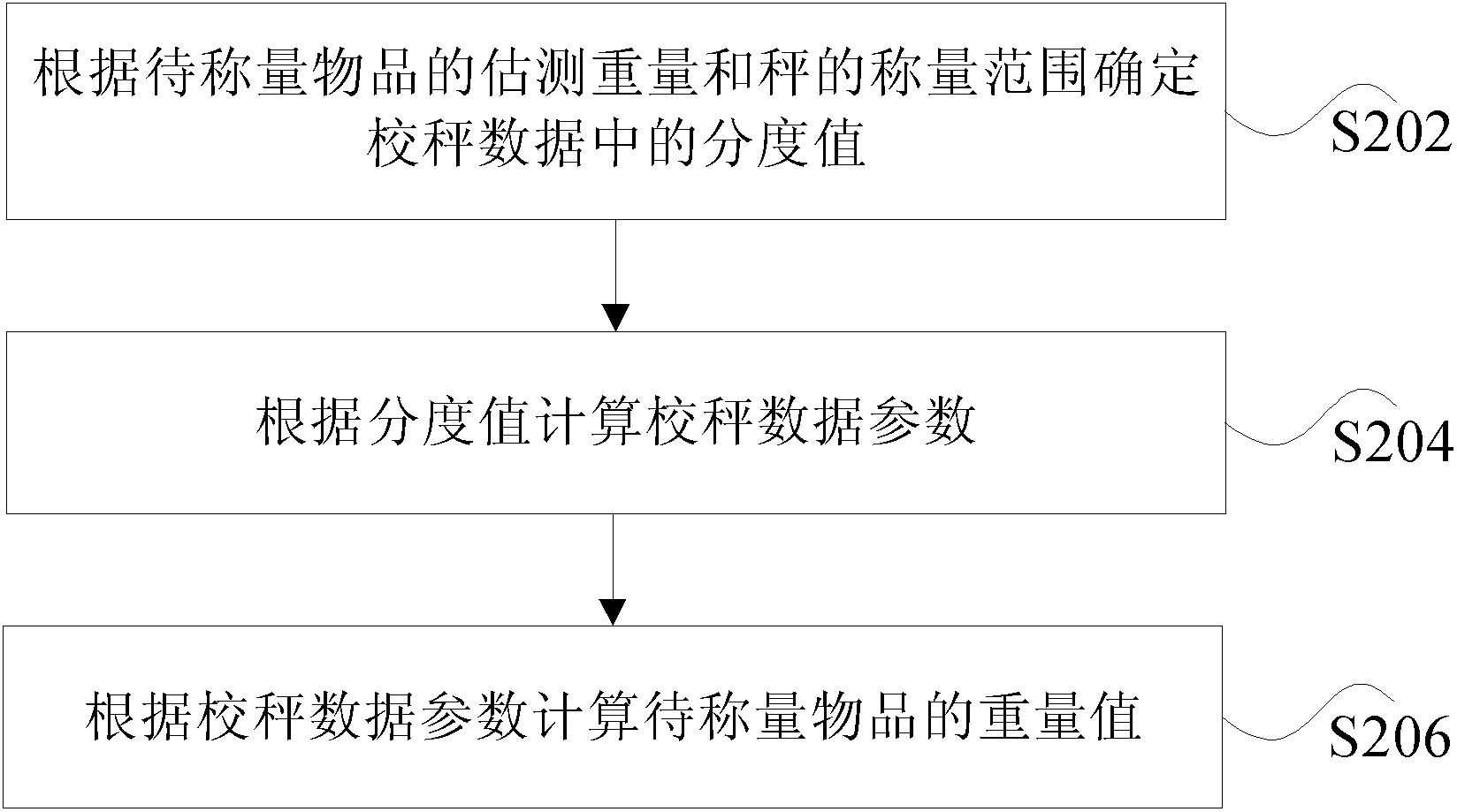

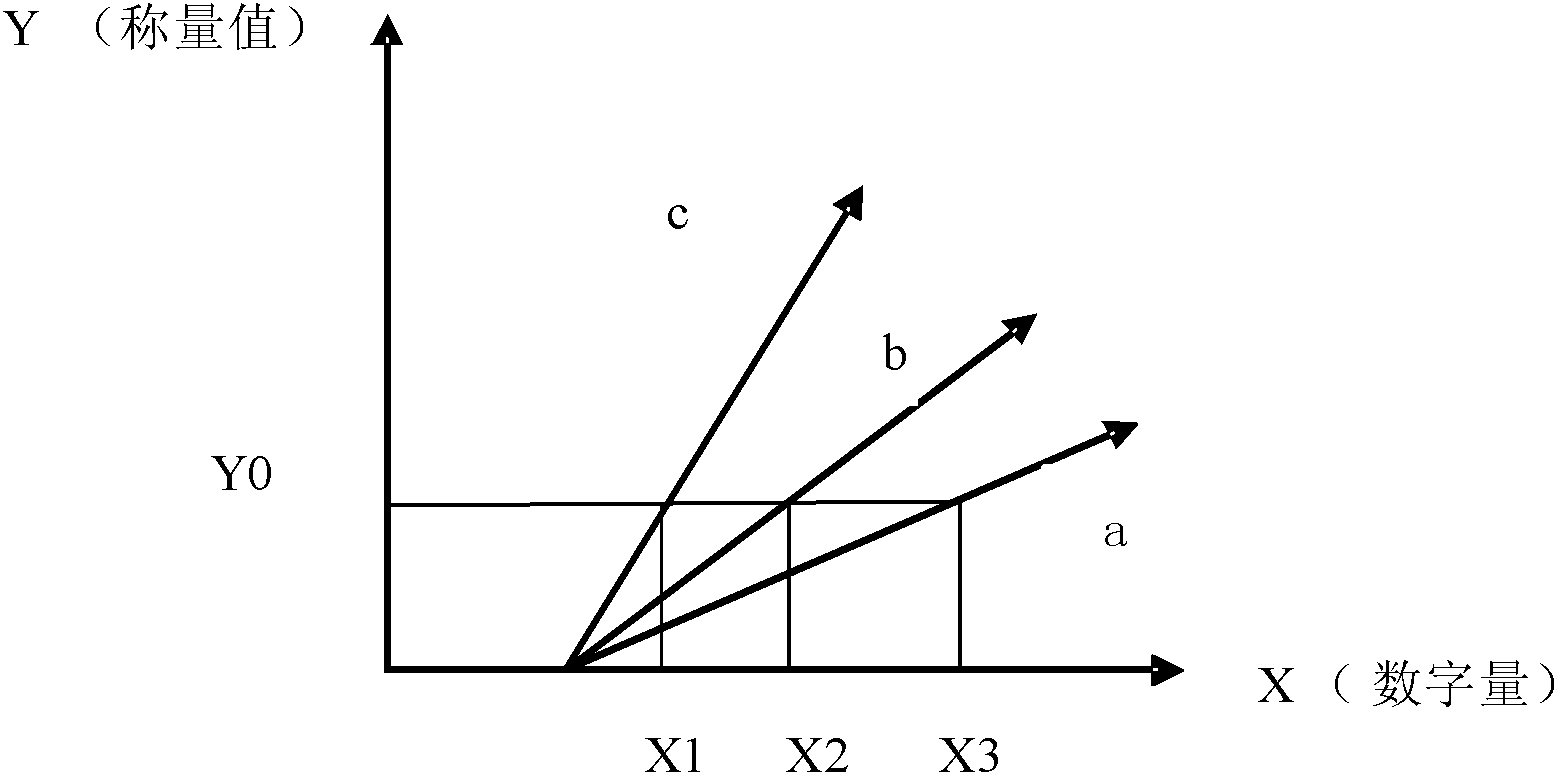

Method, device, system, lower computer and stirring station for weighing

InactiveCN102620803AAvoid recalibrationHigh measurement accuracySpecial purpose weighing apparatusEstimated WeightComputer science

The invention discloses a method, a device, a system, a lower computer and a stirring station for weighing. The method includes the steps of determining a division value in scale calibration data according to the estimated weight of a to-be-weighed article and a weighing range of a scale; calculating scale calibration data parameter according to the division value; and calculating the weight value of the to-be-weighed article according to the scale calibration data parameter. The method disclosed by the invention can avoid repeated scale calibration during the weighing process of the article, is time-saving and labor-saving, and can improve the measuring accuracy of the scale as much as possible on the premise of satisfying the metering range.

Owner:ZOOMLION HEAVY IND CO LTD

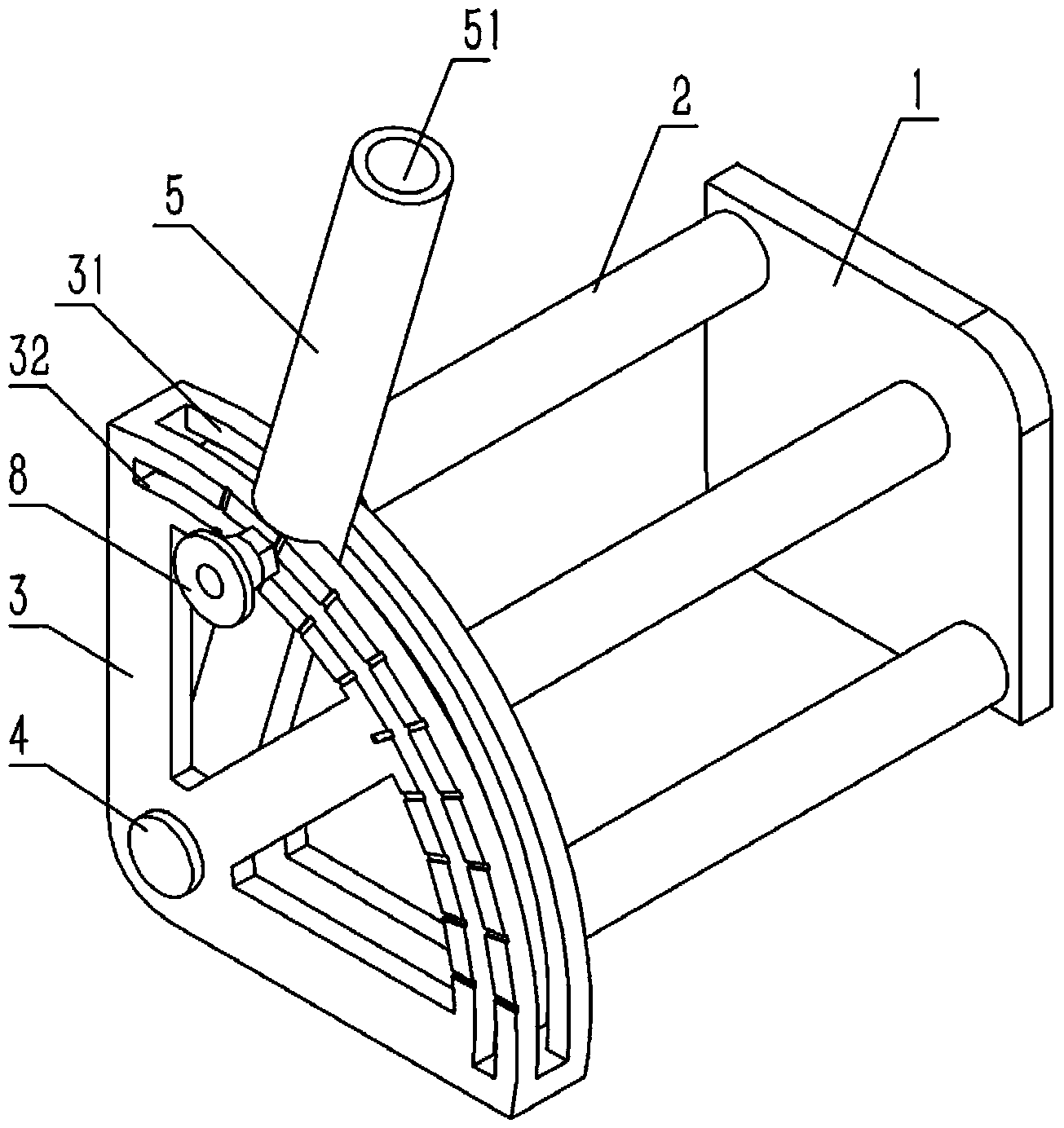

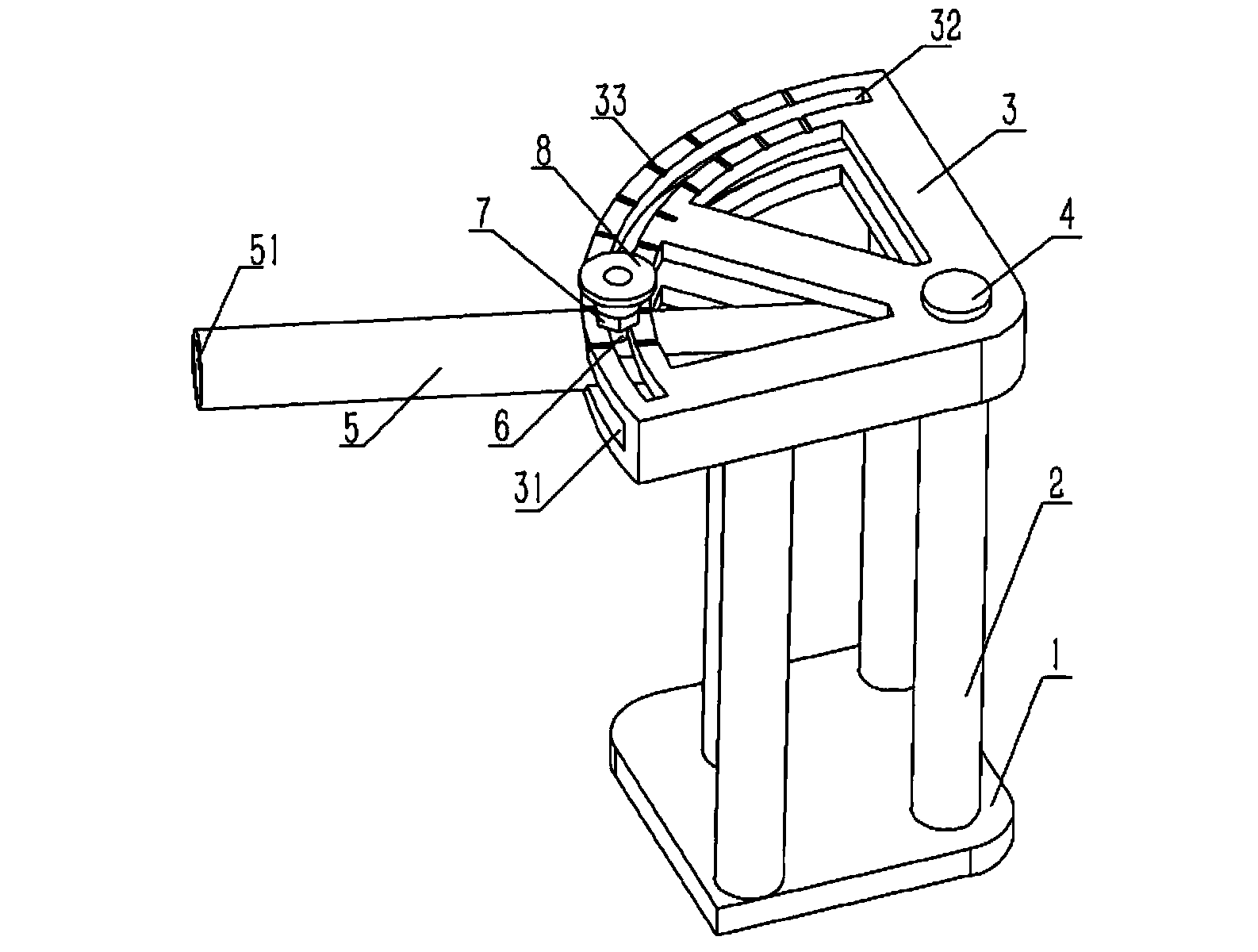

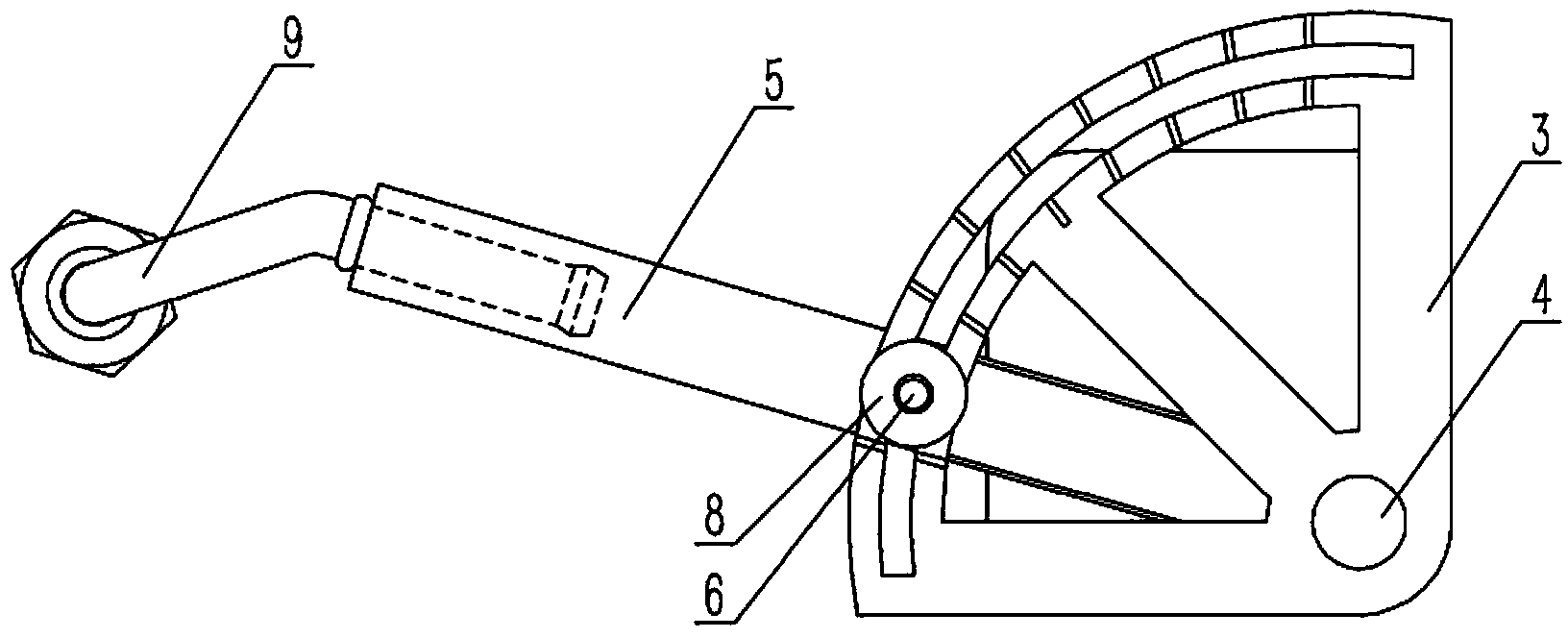

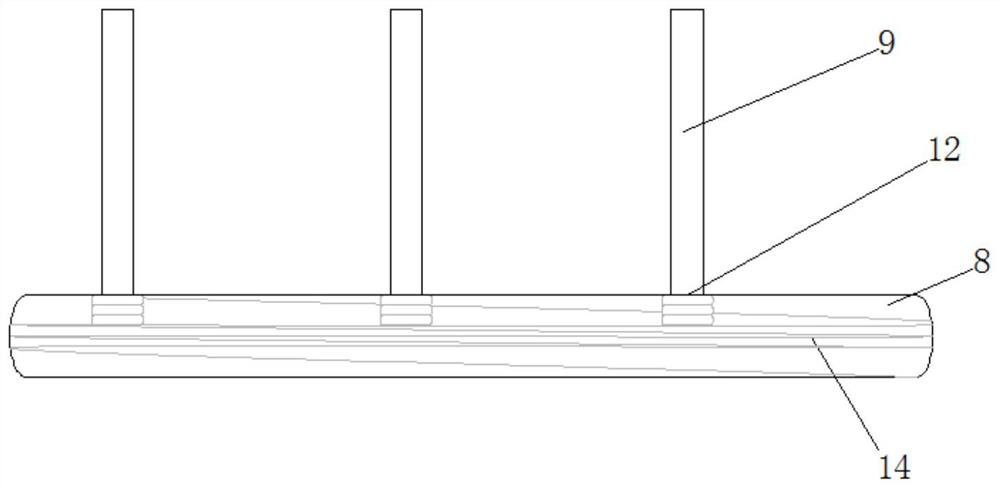

Auxiliary device for installing connecting pipe of oil cooling pipe of cooler

InactiveCN103448025AAvoid recalibrationSave resourcesMetal-working hand toolsEngineeringScrew thread

The invention relates to an auxiliary device for installing a connecting pipe of an oil cooling pipe of a cooler. The auxiliary device comprises a base which is fixed on a working platform; a support pillar is fixed on the base; a fan-shaped bracket is fixed at the upper end of the support pillar; a fan-shaped groove cavity which passes through the fan-shaped bracket and has an circular arc-shaped side is molded in the fan-shaped bracket; a fan ring-shaped groove which passes through the upper end surface and the lower end surface is molded on the fan-shaped bracket at the position close to the circular arc-shaped side of the fan-shaped groove cavity; one end of an auxiliary rod passes through the fan-shaped groove cavity of the fan-shaped bracket and is articulated on the fan-shaped bracket by a pin shaft; a slotted hole is molded on the other end surface of the auxiliary rod by lathing; the auxiliary rod is provided with a bolt; the bolt sequentially passes through the fan ring-shaped groove and the auxiliary rod which are arranged on the plane of the lower end of the fan-shaped bracket, and the fan ring-shaped groove on the plane of the upper end of the fan-shaped bracket, and is connected with a nut by screw threads; a handle is welded on the nut. After the auxiliary device is adopted, the connecting pipe can be installed only by one person, so that the resource can be saved; furthermore, the auxiliary device is fixed at the same position so as to adapt to the installation of connecting pipes with the same angle, so that the process that a worker repeatedly corrects the angle can be avoided, and the production efficiency is improved.

Owner:SUZHOU CHENHAO TEXTILE TECH CO LTD

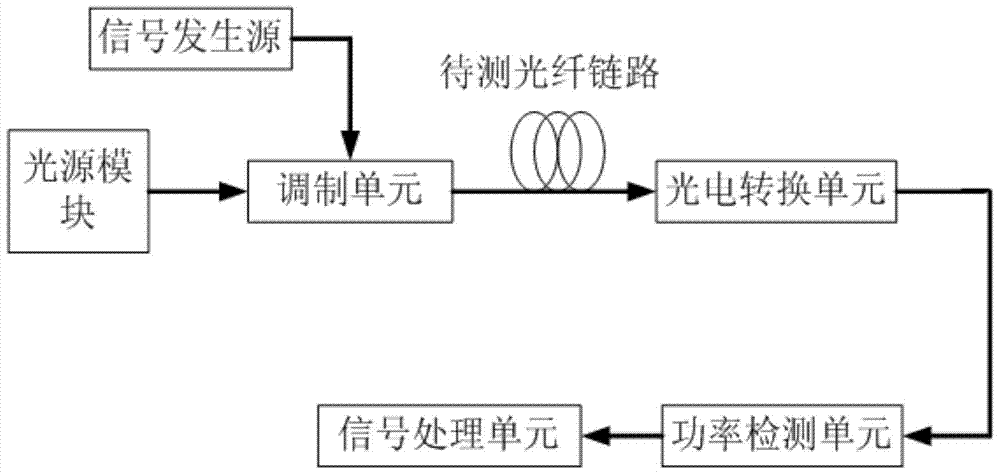

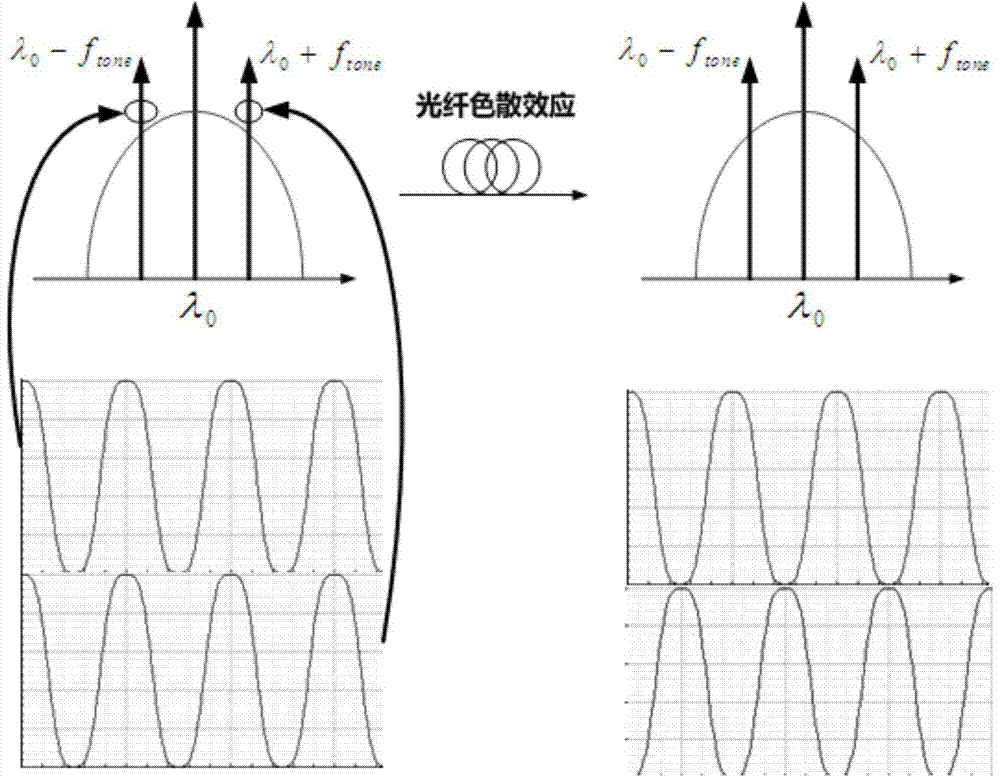

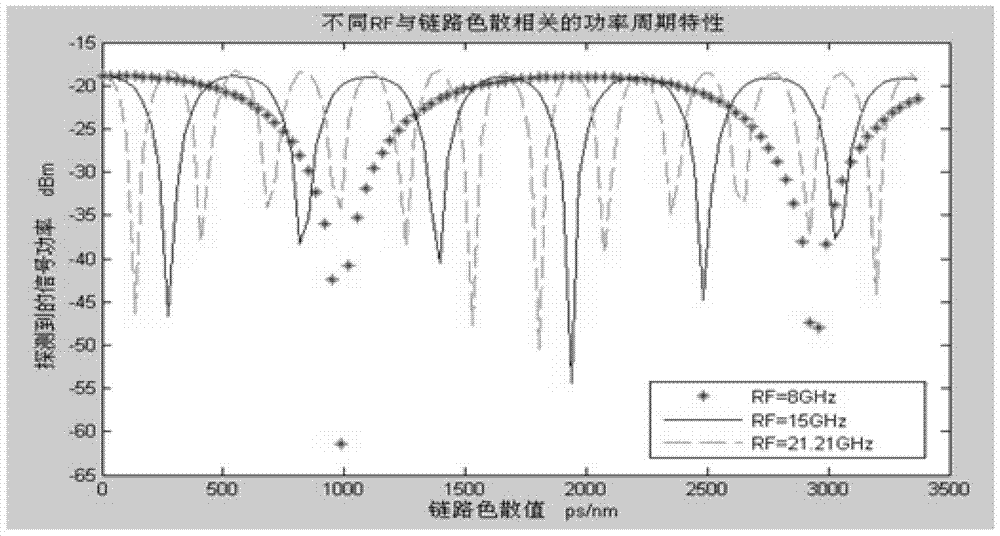

A Dispersion Measuring System

InactiveCN104243018BEasy to identifyAccurate measurementTransmission monitoring/testing/fault-measurement systemsContinuous lightFrequency spectrum

The invention belongs to the technical field of measurement, and discloses a dispersion measuring method. The dispersion measuring method is used for measuring a dispersion value of an optical fiber link and is characterized by comprising the following steps of generating an optical carrier signal through a stable and continuous light source, adopting a radio-frequency signal for modulating the optical carrier signal into a double-sideband optical spectrum, sending the double-sideband optical spectrum to the optical fiber link to be measured, conducting photovoltaic conversion on an optical signal at the output end of the optical fiber link to be measured to convert the optical signal into an electric signal, monitoring the power value of the electric signal in real time, adjusting the scanning frequency of the radio-frequency signal, determining the scanning frequency fnull generated when the power of the electric signal is the minimum, and calculating a dispersion value obtained when the scanning frequency fnull is generated. According to the dispersion measuring method, the double-sideband optical spectrum detects the optical signal and is sent to the optical fiber link to be measured and then converted into periodical power changes of the electric signal, accurate positioning is achieved, data sampling is optimized, and therefore the measuring precision is improved; then the measuring frequency is reduced, efficiency is improved, and the measurement range is extended.

Owner:武汉光盈科技有限公司

A fluorescent oxygen probe and its preparation method and application

ActiveCN108333162BAvoid recalibrationSelf-referencingFluorescence/phosphorescenceFluoProbesMicroorganism

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

Multi-use inspection tool for composite exhaust pipe assembly

ActiveCN103673819BAvoid recalibrationStable structureMechanical measuring arrangementsEngineeringExhaust pipe

The invention relates to detecting tools for exhaust pipes and discloses a detecting tool for diversified utilization of a combined type exhaust pipe assembly. The detecting tool comprises a fixing unit, a first detecting tool unit and a second detecting tool unit. The first detecting tool unit comprises a first base, a first supporting table, a detecting device and a pipe abutting table. The detecting device comprises a movable block and a fixed block, scale lines are formed in the fixed block, a pointer is arranged on the movable block, a line-shaped hole and a locating rod are arranged in the movable block, one side of the movable block is in slide connection with a side portion of the fixed block, and the other side of the movable block is in clamp connection with the fixed block. The second detecting tool unit comprises a second base, a second supporting table and a plurality of movable limiting blocks, and the two sides of the upper portion of the second supporting table are connected with a datum plane or a detection surface. The detecting tool is simple in structure and convenient to use; welding and debugging of the exhaust pipe assembly and detecting of the installation accuracy of the exhaust pipe assembly can be achieved through the detecting tool. Meanwhile, the detecting tool is also capable of carrying out vertical deviation detection on an exhaust pipe bracket installed on an exhaust pipe.

Owner:WUHAN HUIHENG IND

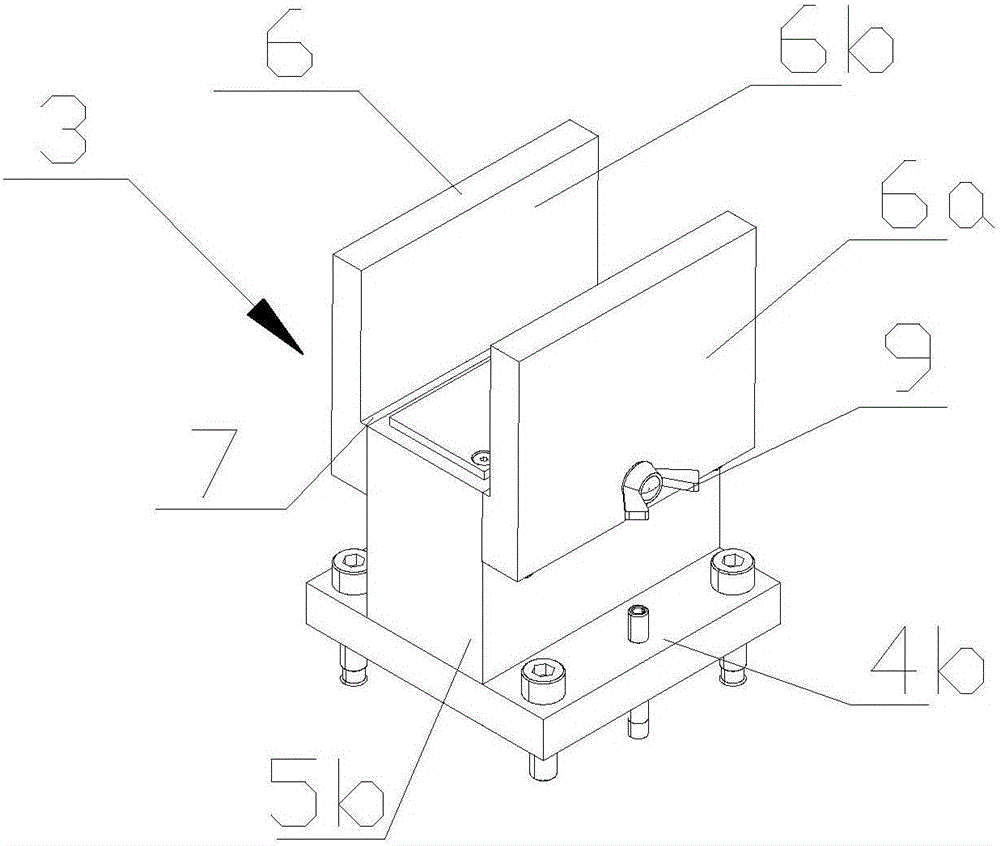

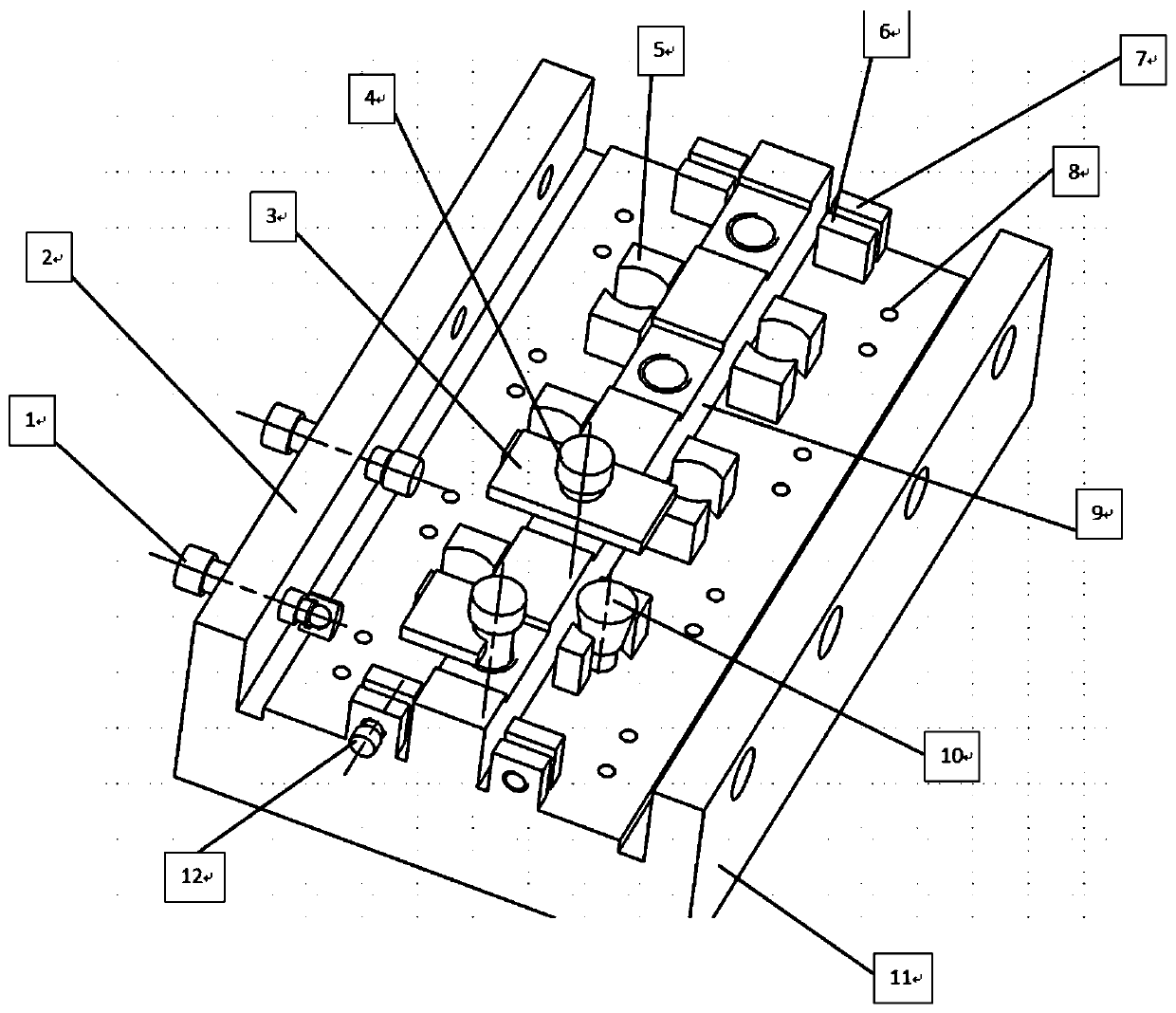

Machining method for through hole in angular combination device

ActiveCN109648257AHigh precisionAvoid interferencePositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to a machining process for a through hole in an angular combination device, in particular to a machining method for a through hole in an angular combination device. A machining clamp for the through hole in the angular combination device is adopted, and machining of the through hole in the angular combination device is achieved on a high-speed milling machine; a first combination part is positioned and clamped through an axial pressing bolt, an end face positioning block, a lateral pressing bolt and a lateral positioning block, and a through hole in the combination part is machined; and an axial positioning bolt is loosened, a second combination part is in inserted, angular combination is achieved, the pressing bolt is screwed, a tool is switched, a high-speed micro cutting milling method is adopted, and a through hole in the second combination part is machined. By means of the method, matching errors produced by through hole separated machining are well avoided,influences produced by different material cutting on a tool are avoided, the cutting movement phenomenon is reduced fundamentally, and the through hole machining quality is effectively improved.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

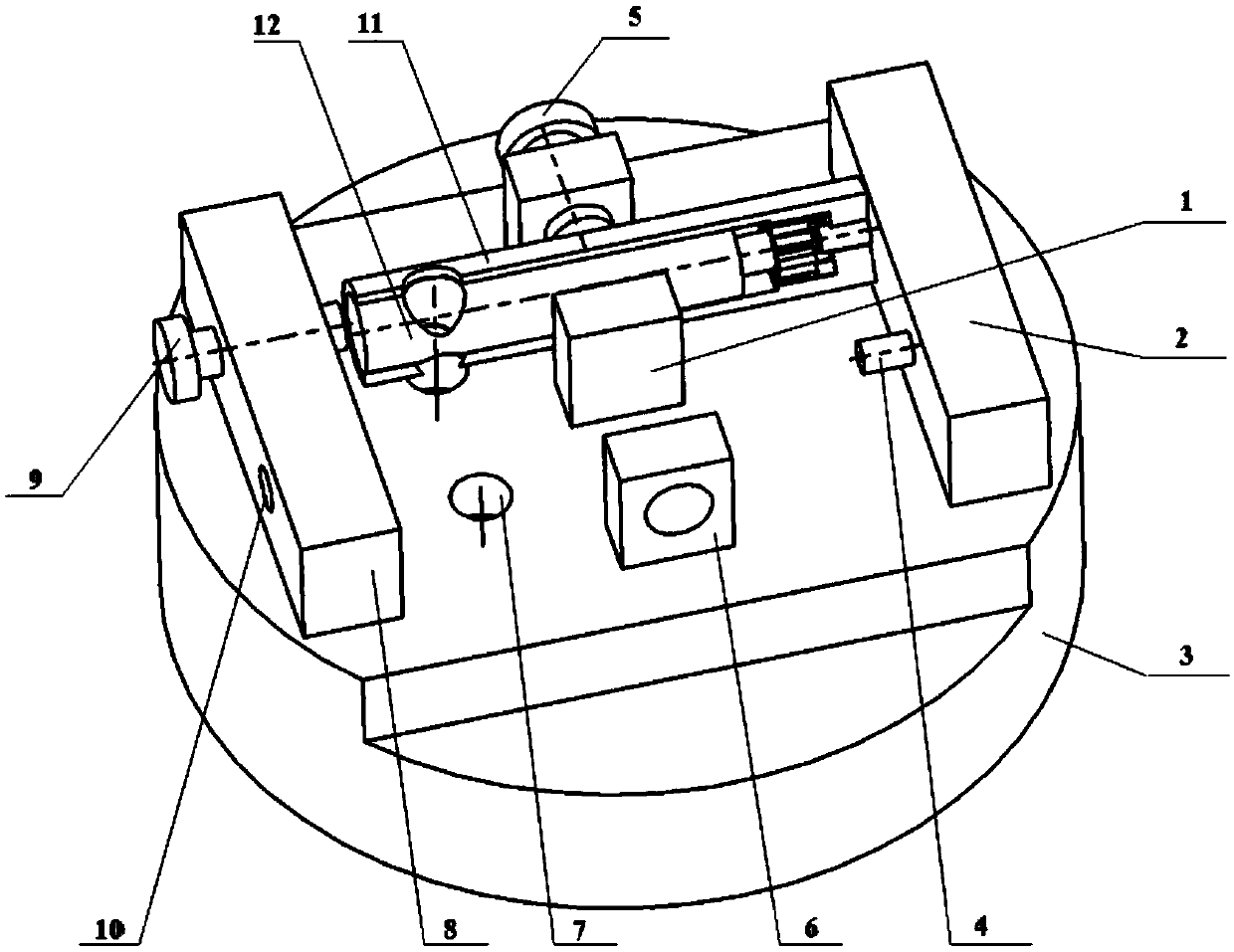

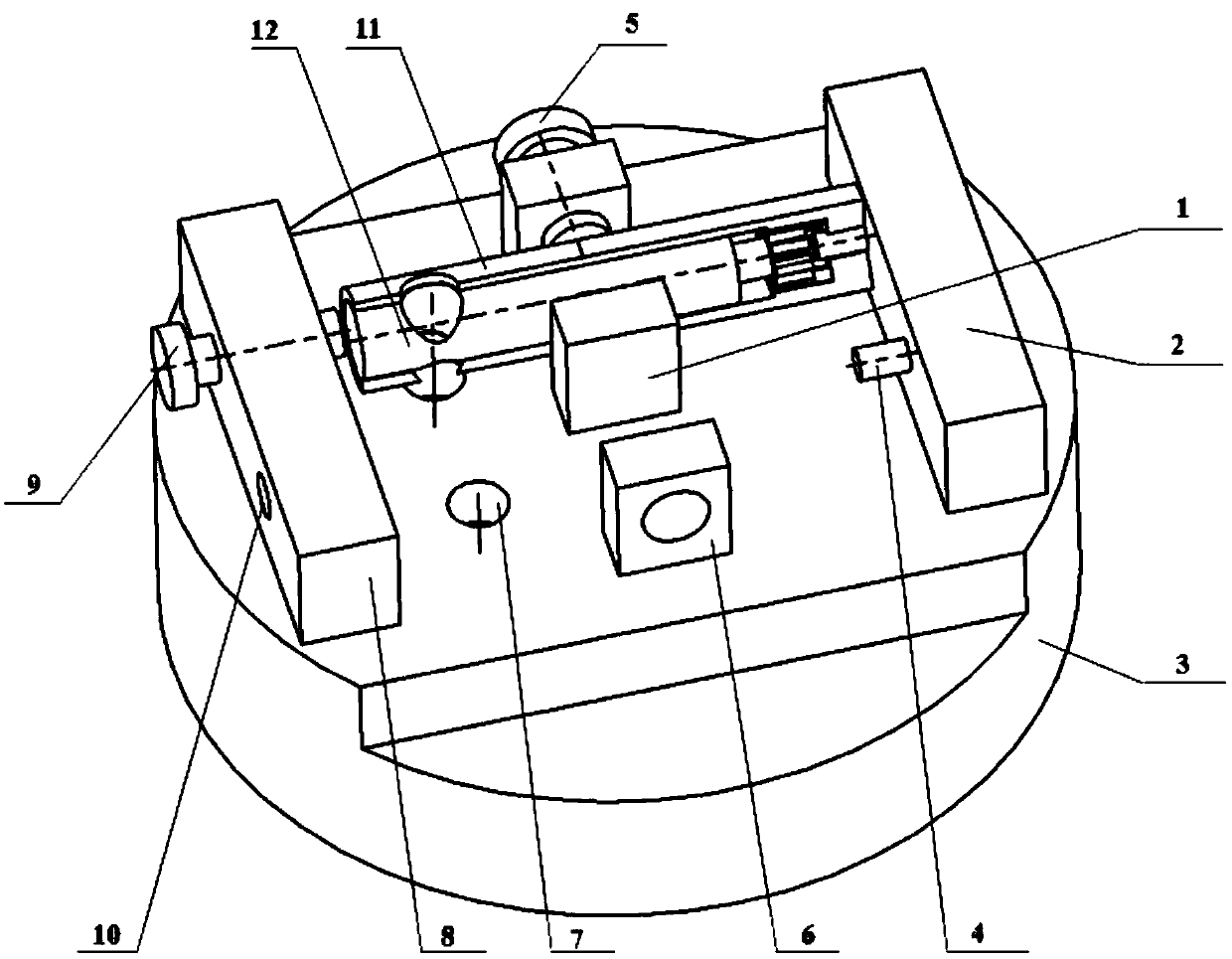

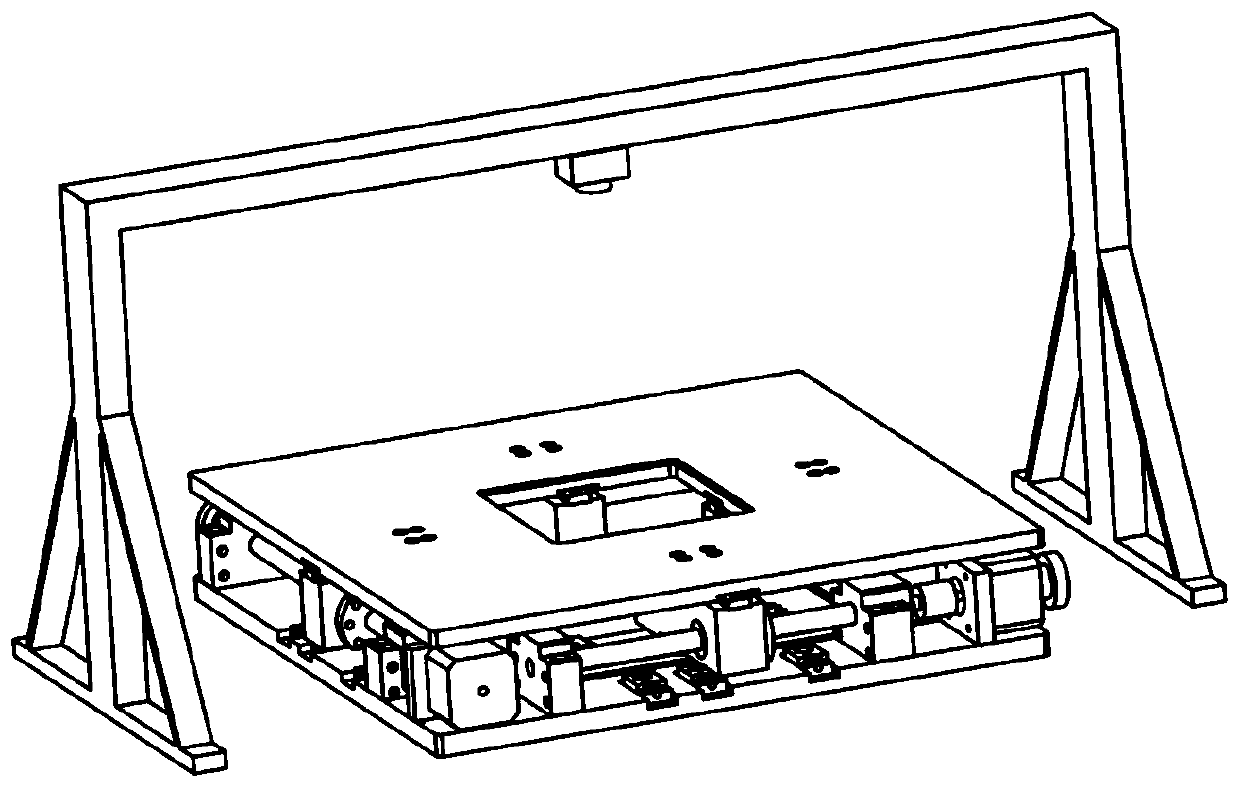

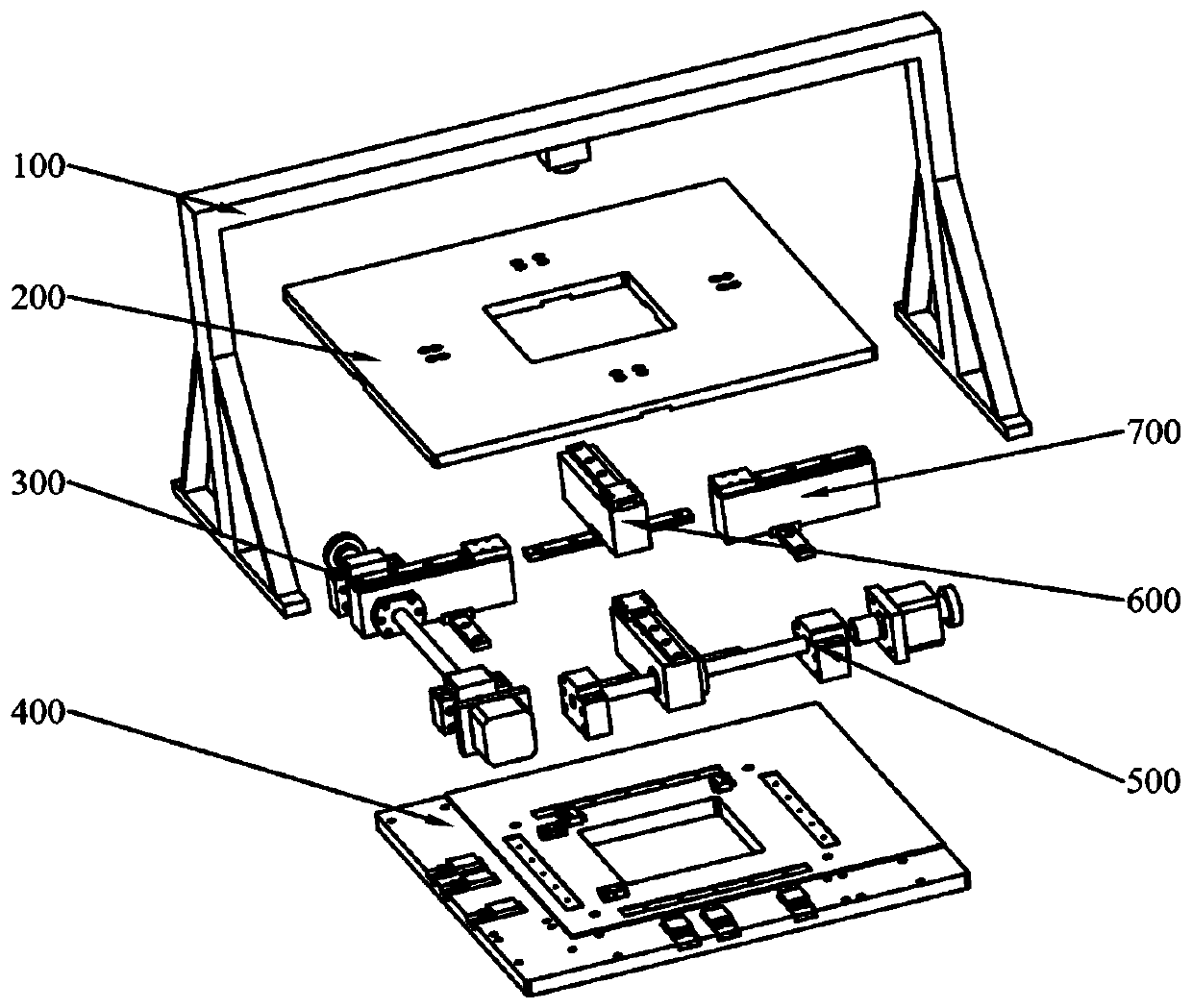

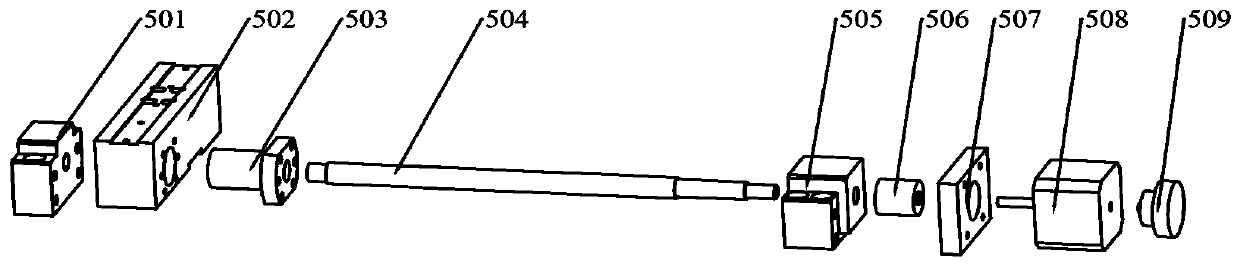

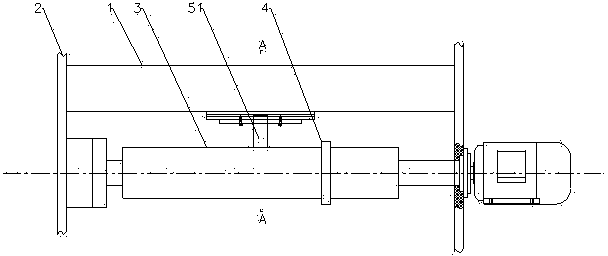

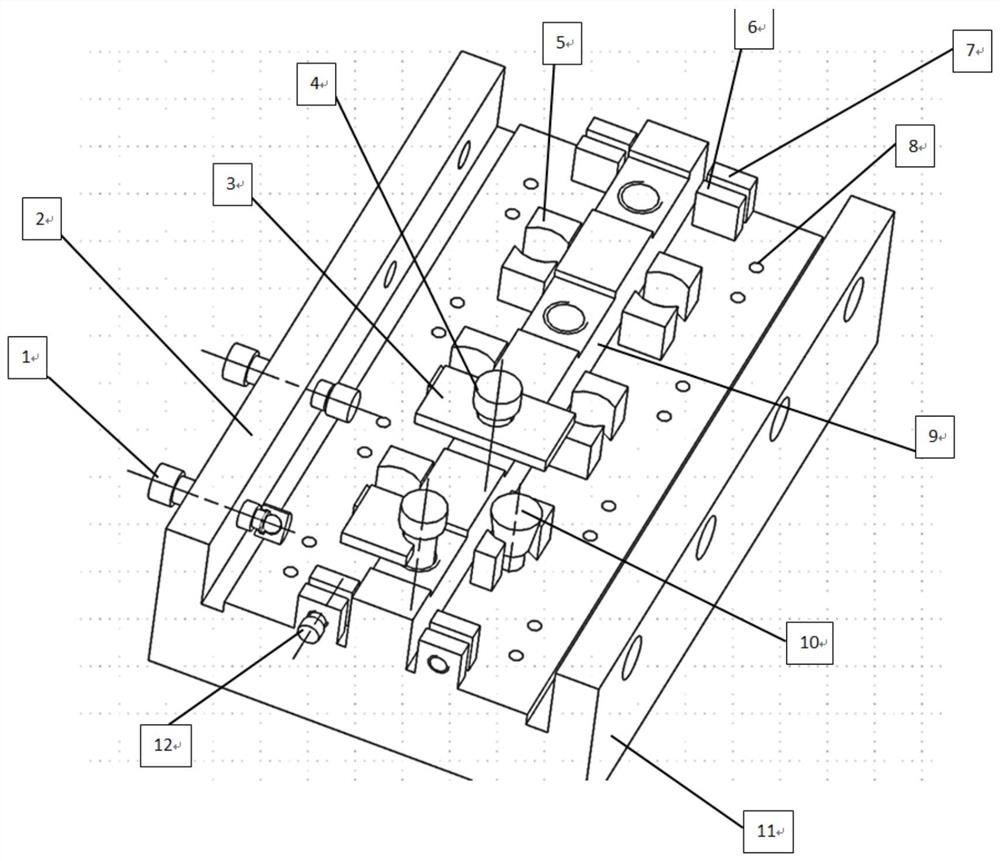

Precision sliding table for multi-workpiece parallel vision measurement

PendingCN110567375AAvoid recalibrationImprove measurement efficiencyUsing optical meansAutomatic controlEngineering

The invention discloses a precision sliding table for multi-workpiece parallel vision measurement. The precision sliding table comprises a portal frame vision acquisition mechanism 100, a carrying plate 200, a driving radial lead screw and nut mechanism 300, a fixing plate 400, a driving axial lead screw and nut mechanism 500, a driven axial sliding block mechanism 600 and a driven radial slidingblock mechanism 700; a portal frame and an acquisition camera are fixedly connected so as to form the portal frame visual acquisition mechanism 100; the loading plate 200 clamps a workpiece to finishprecise movement in an axial direction, a radial direction and a circumferential direction through the cooperative work of the driving axial lead screw and nut mechanism 500, the driving radial lead screw and nut mechanism 300, the driven axial sliding block mechanism 600 and the driven radial sliding block mechanism 700, so that the high-precision measurement and reconstruction of the workpiece are achieved. Driving motors on the lead screw and nut mechanisms achieve automatic control precision rotation through communication between an upper computer and a lower computer; hand wheels are arranged, so that manual adjustment is facilitated, and therefore, the adaptability of the precision sliding table to a working environment is good; the fixing plate 400 is provided with a proximity switch sensor and a limiting switch and used for feeding back the operation position of the workpiece in real time and achieving the self-protection of the device during work faults; and the carrying plate200 of the precision sliding table can clamp a plurality of workpieces simultaneously. The precision sliding table meets the task requirements of various visual acquisition modes including monocularvision measurement, binocular vision measurement and structured light measurement; and the precision sliding table has the advantages of high adaptability, high automation degree, and high practicability in the field of machine vision measurement.

Owner:HARBIN UNIV OF SCI & TECH

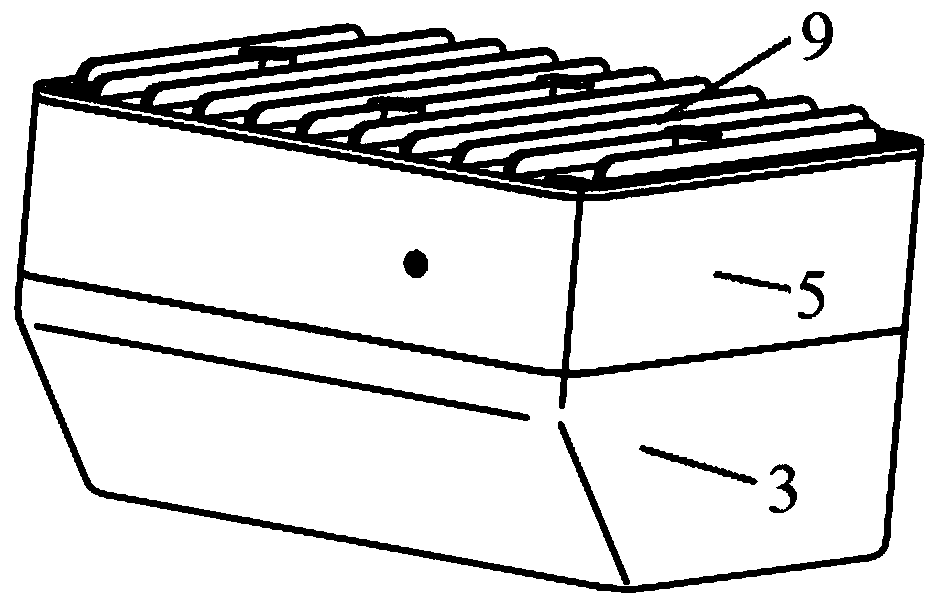

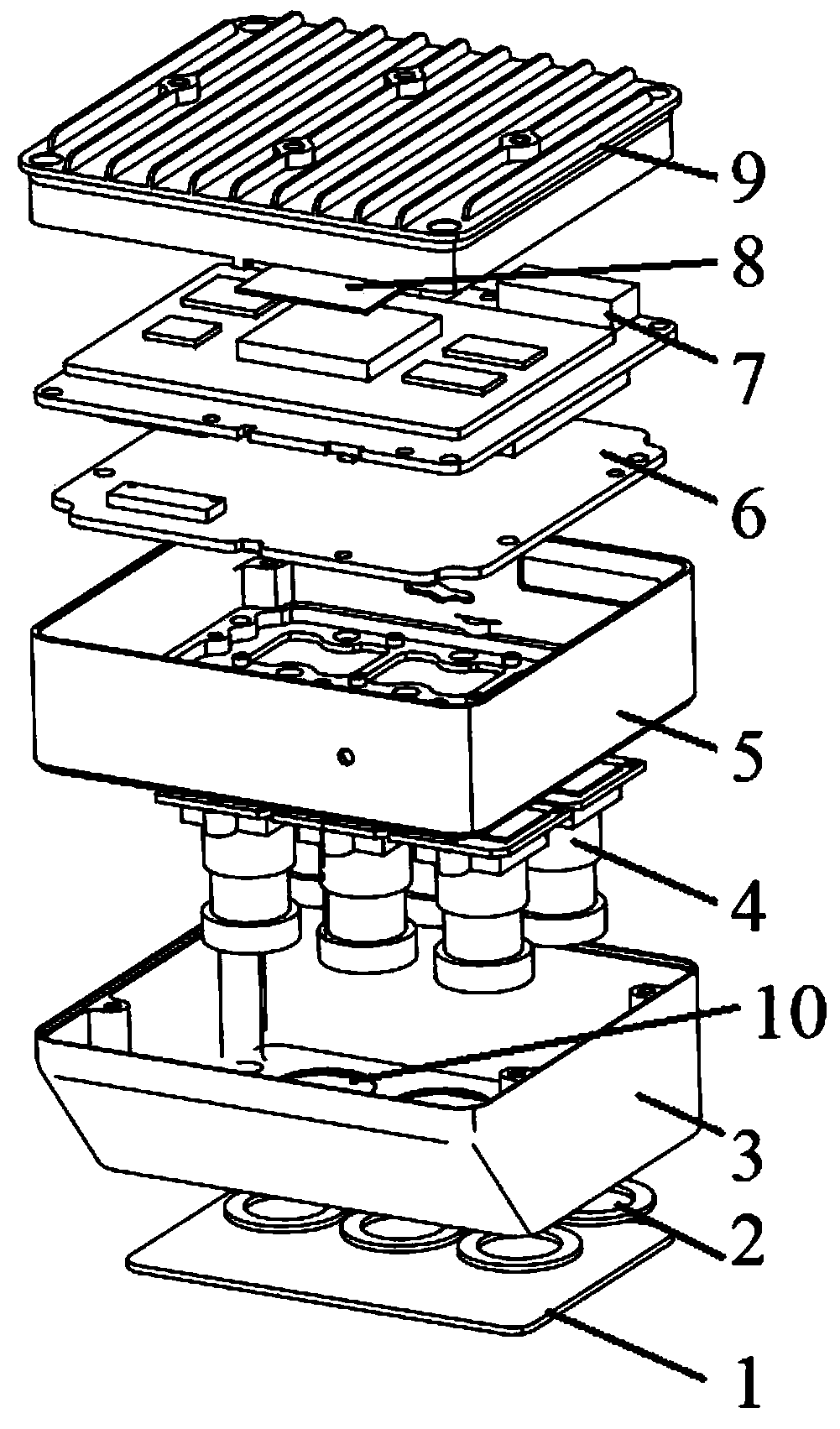

Multispectral camera and unmanned aerial vehicle

PendingCN111220272ACompact structureSmall volume and massAircraft componentsRadiation pyrometryUncrewed vehicleEngineering

The invention discloses a multispectral camera and an unmanned aerial vehicle. The multispectral camera comprises an annular middle housing, an upper housing and a lower housing, wherein the upper housing and the lower housing cover openings in the two ends of the middle housing respectively; an upper housing circuit board is fixed in the upper housing; a middle housing circuit board and a lens module electrically connected with the middle housing circuit board are fixed in the middle housing, and the middle housing circuit board is electrically connected with the upper housing circuit board;and lens glass is fixed to the outer side of a lens through hole of the lower housing. The whole system structure in the camera is split into three relatively independent modules, so that the difficulty of whole assembly and adjustment is reduced; the lens module is assembled in a modular manner, so that the influence of installation and adjustment errors can be reduced, and errors of optical parameter indexes of the lens module caused by installation, debugging, maintenance and the like of other parts can be avoided; other module assemblies are not influenced when debugging, maintenance and the like are carried out on the upper housing circuit board and on-board components, so that the frequency of parameter debugging and calibration is reduced, and the assembly production efficiency is improved.

Owner:YUSENSE INFORMATION TECH & EQUIP QINGDAO INC

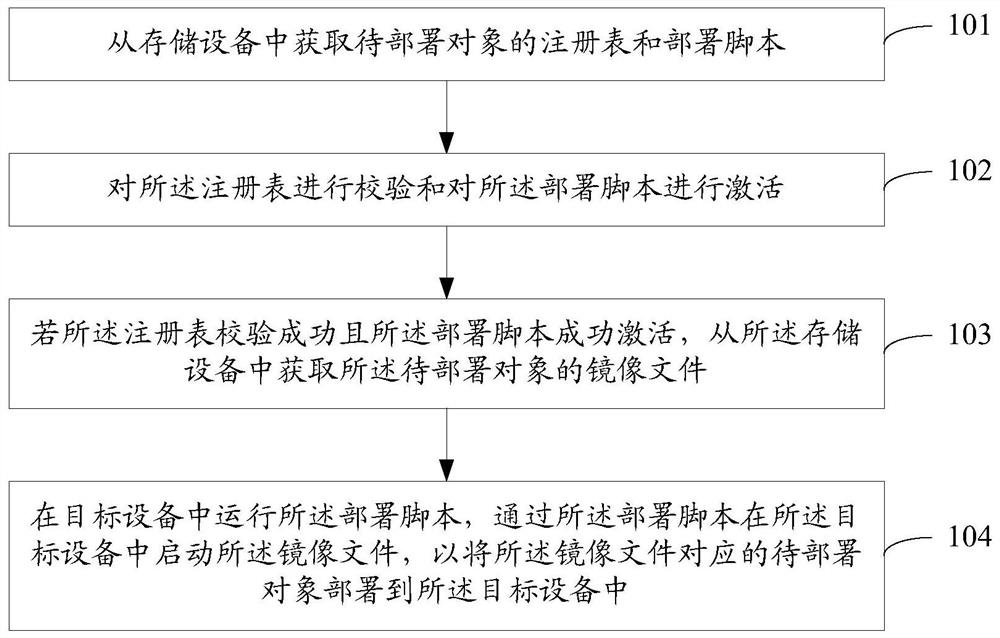

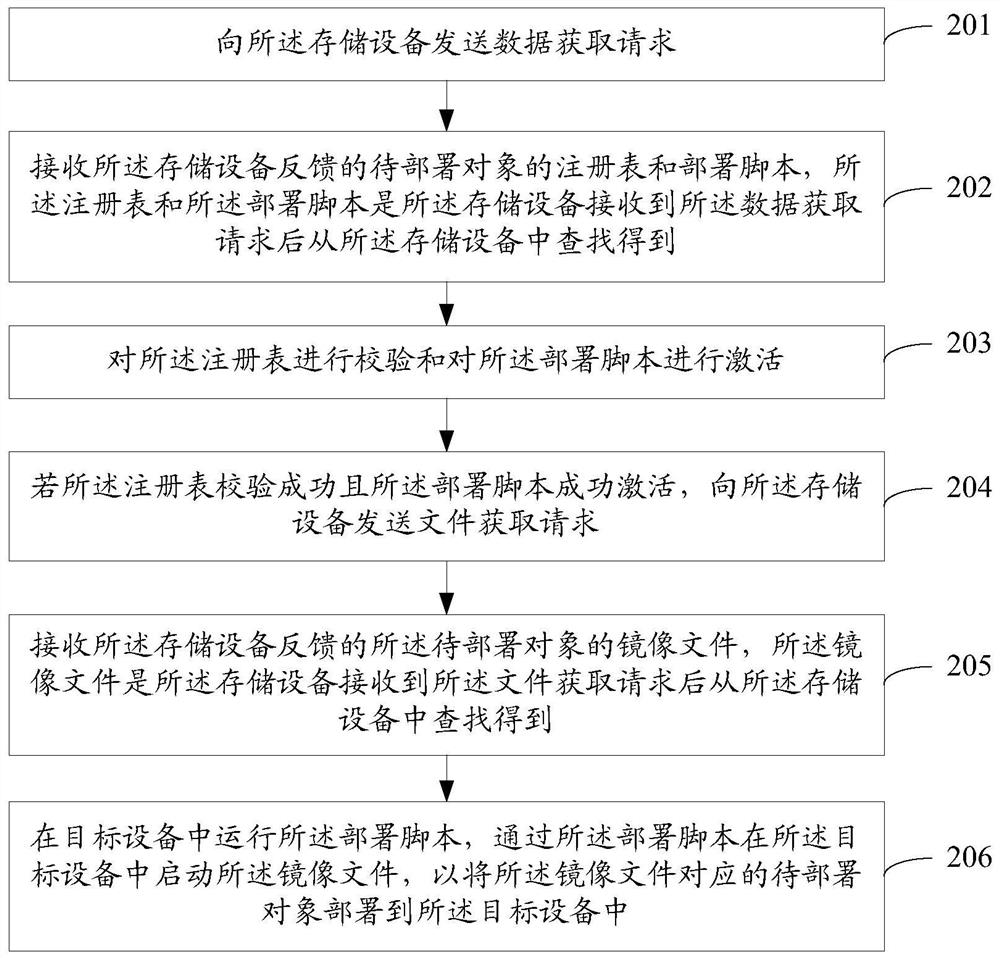

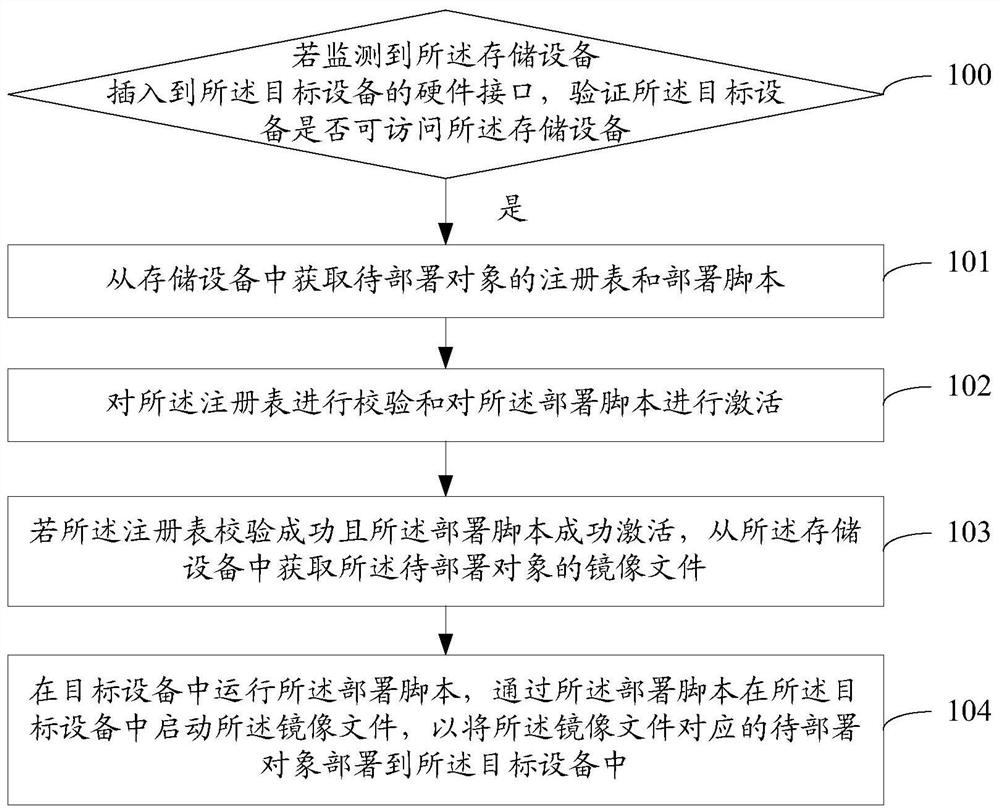

Object deployment method and device

ActiveCN111782222AOmit participationImplement automatic deploymentSoftware deploymentDeployment timeChecksum

The invention provides an object deployment method and device. The method comprises the following steps: acquiring a registry and a deployment script of a to-be-deployed object from a storage device,verifying the registry and activating the deployment script; if the registry is successfully verified and the deployment script is successfully activated, acquiring a mirror image file of a to-be-deployed object from a storage device, running the deployment script in a target device, and starting the mirror image file in the target device through the deployment script so as to deploy the to-be-deployed object corresponding to the mirror image file into the target device. According to the invention, automatic deployment of the to-be-deployed object from the storage device to the target device is realized, so a user participation link is omitted in the deployment process of the to-be-deployed object, deployment errors and repeated correction processes caused by wrong understanding of the user about the deployment process are prevented, and deployment time and deployment difficulty are reduced.

Owner:LENOVO (BEIJING) LTD

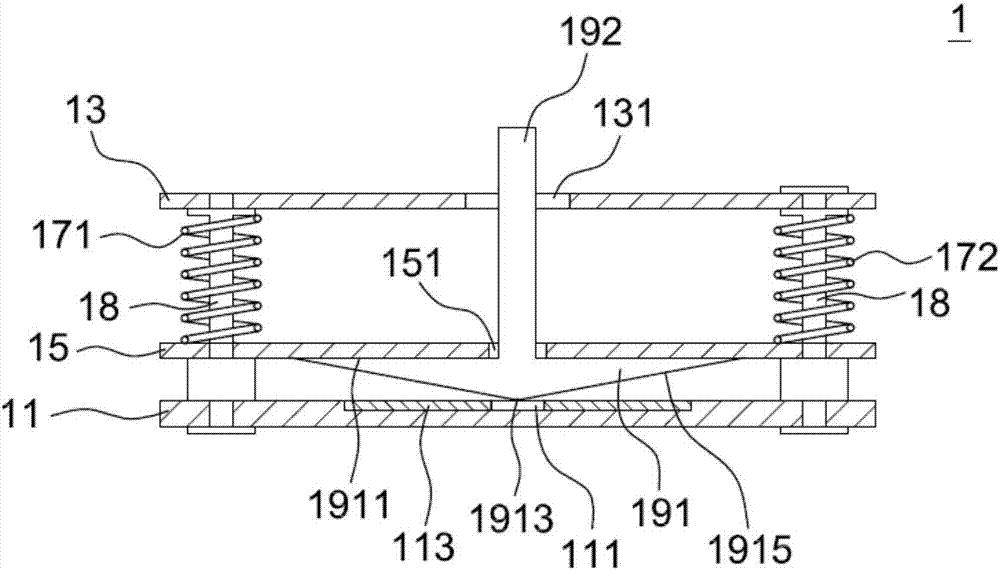

Method for finish machining large-tolerance parts

ActiveCN111015282APrecise positioningClamp firmlyPositioning apparatusMetal-working holdersMachine partsEngineering

The invention provides a method for finish machining large-tolerance parts. A special elastic machining fixture is used. The method includes the steps that 1, according to the size of to-be-machined parts, a lateral deformation block A and a lateral deformation block B are adjusted to make the distance between the two adjacent deformation blocks be smaller than the shape size of the parts by 0.005-0.01 mm, and it is ensured that the clamping interference magnitude is not greater than 0.01 mm; 2, the center between the lateral deformation block A and the lateral deformation block B is measuredand aligned by using a machining center probe; 3, the to-be-machined parts are pressed into the position between the lateral deformation block A and the lateral deformation block B, and the axial direction of workpieces is compressed through an axial positioning device; and 4, finish machining is conducted. According to the method, the elastic machining fixture is adopted, positioning is accurate,clamping is stable, repeated correction and clamping are avoided, the same product is used permanently after being subjected to one-time centering, cutting vibration is reduced, the accuracy of the parts is improved, the professional requirements for operators are reduced, and the production efficiency is improved; and the method can be applied to machining processes such as turning, milling anddrilling of plane machining, and wide application is achieved.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

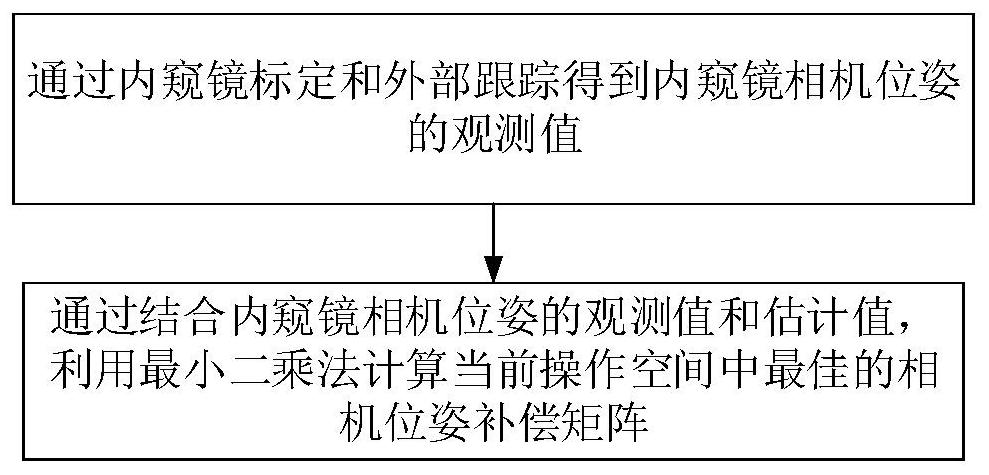

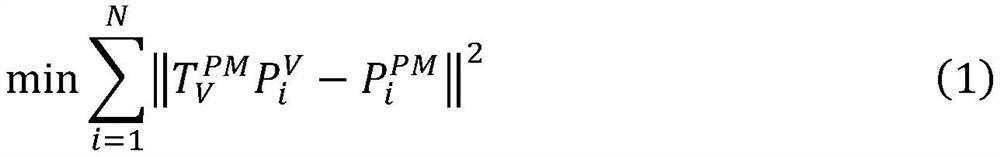

Endoscope augmented reality error compensation method and device

PendingCN113470184AIncreased sensitivityCompensate for pose errorsImage enhancementImage analysisNuclear medicineEndoscopy

According to an endoscope augmented reality error compensation method and device, the AR fusion precision is remarkably improved, a camera pose error caused by rotation of an endoscope tube can be accurately compensated, an AR fusion error of the system is kept at a low level, recalibration of an endoscope camera is avoided through application of a compensation model, and the sensitivity to system positioning noise and corner recognition noise in an image is high. The method comprises the following steps: (1) obtaining an observation value of the pose of an endoscope camera through endoscope calibration and external tracking; (2) calculating an optimal camera pose compensation matrix in the current operation space by using a least square method by combining the observation value and the estimation value of the pose of the endoscope camera;.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

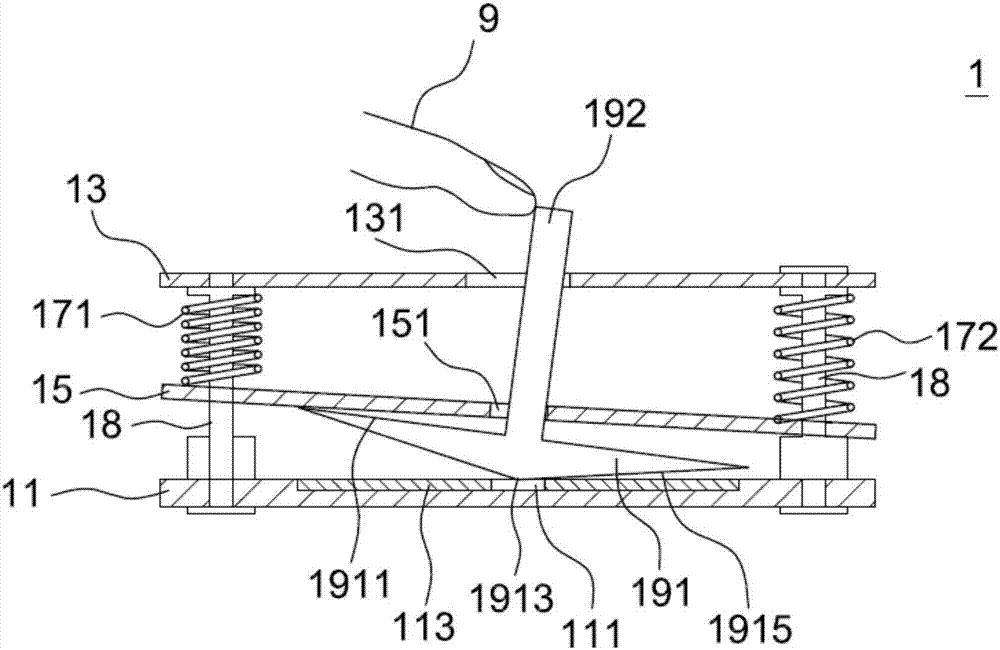

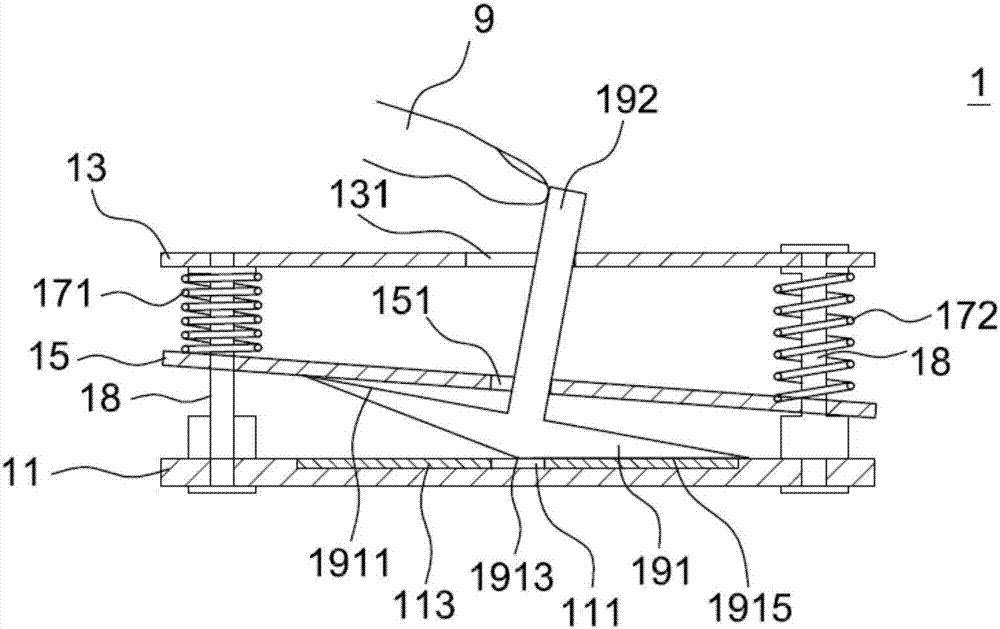

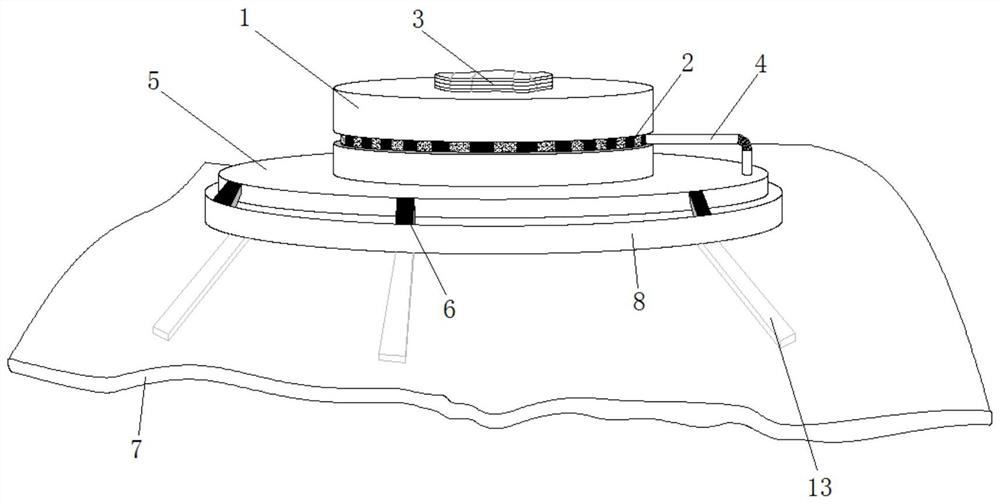

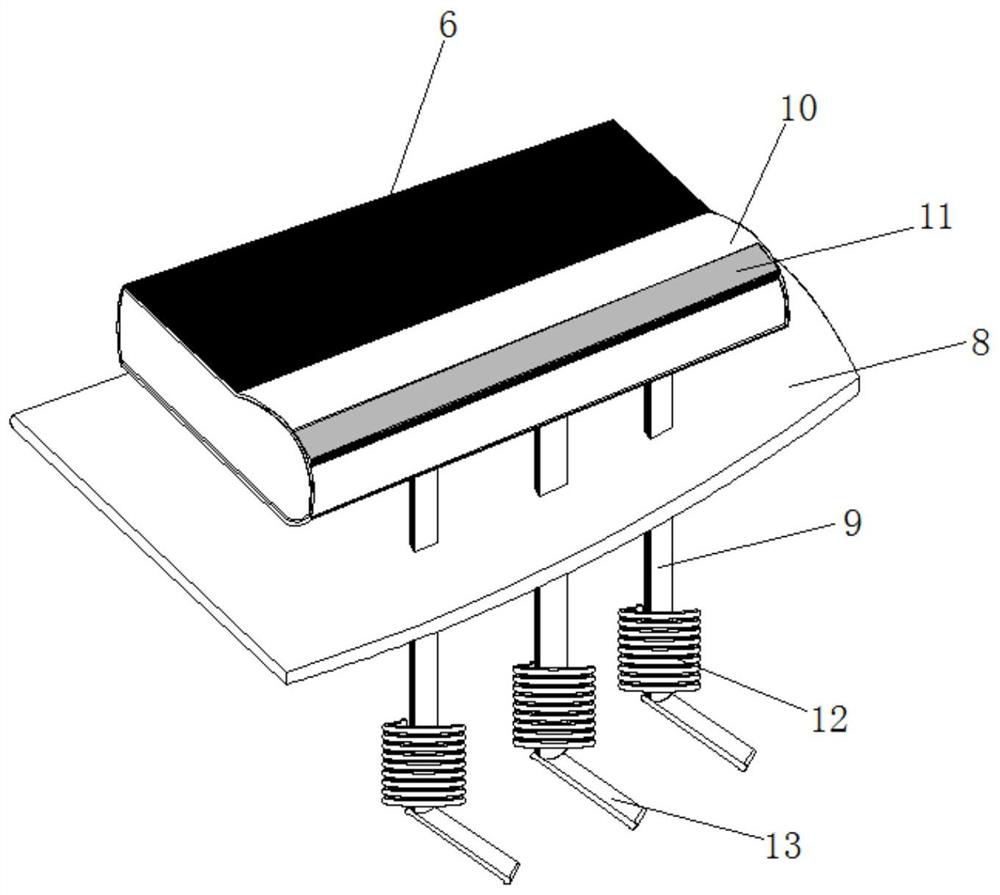

Capacitive rocker device

ActiveCN105224103BAvoid recalibrationIncrease the operating areaInput/output processes for data processingCapacitanceMechanical engineering

The invention provides a capacitive joystick device including a substrate, a fixed plate, a movable member, a plurality of elastic elements, a cone and an operation stick. The substrate includes a ground region and a capacitance sensing region. The fixed plate includes a first opening. The movable member includes a second opening. The elastic elements are symmetrically disposed between the fixed plate and the movable member. The cone is disposed between the movable member and the substrate, and includes a base, a vertex and a lateral surface. The base presses against the movable member. The vertex is disposed on the ground region of the substrate. The lateral surface is aligned with the capacitance sensing region of the substrate. The operation stick extends from the base of the cone and passes through the first opening and the second opening.

Owner:PIXART IMAGING INC

Online teaching auxiliary equipment capable of automatically changing photographing angle along with body movement

InactiveCN111970446AShorten the timeSave adjustment timeTelevision system detailsColor television detailsAssistive equipmentBody movement

The invention relates to the technical field of online teaching equipment. The invention further discloses online teaching auxiliary equipment capable of automatically changing the photographing anglealong with body movement. The online teaching auxiliary equipment comprises a main body, wherein a movable seat penetrates through the top side of the main body, a movable disc is movably connected to the bottom of the main body, a chassis is fixedly connected to the bottom side of the movable disc, a base plate is fixedly connected to the bottom side of the chassis, a rocker penetrates through the base plate, a movable rod is movably connected to the end, close to the chassis, of the rocker, and a compression spring penetrates through the side wall of the movable rod. When a movable ball passively extrudes the outer side wall of the non-toppling body on the side, the non-toppling body inclines towards the other side, a magnetic block can roll to the lowest position on the inner side wallof the non-toppling body, the magnetic block attracts the magnet to the back side of the movable seat, the movable seat is driven to rotate, the front face of the movable seat is rotated to the position right opposite to a teacher, the rotating angle can be automatically adjusted, the magnetic block can accurately right correspond to the front face of the teacher, and repeated correction of manual adjustment is avoided.

Owner:杭州伟博思文化传播有限公司

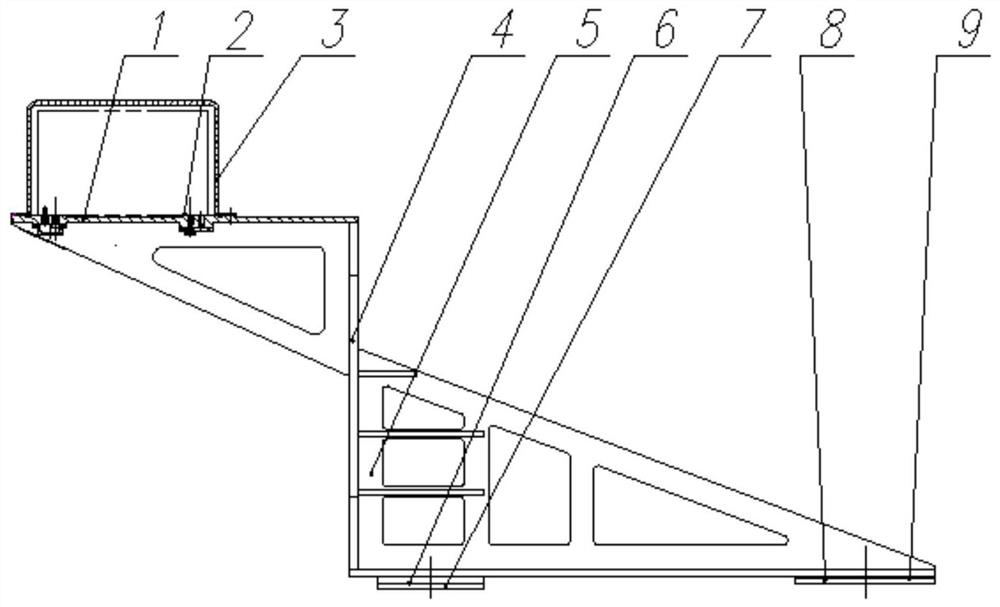

Multi-directional adjustable knife changing mechanism of dividing and cutting machine

ActiveCN104003237AEasy to operateAvoid recalibrationArticle deliveryEngineeringMechanical engineering

The invention relates to the technical field of cutting devices, in particular to a multi-directional adjustable knife changing mechanism of a dividing and cutting machine. The dividing and cutting machine comprises a beam, two wall boards, an annular dividing and cutting knife and a knife changing mechanism, the knife changing mechanism comprises a support arm and a support platform, the support arm is a U-shaped groove with flat bottom, the support platform is mounted in the U-shaped groove and higher than the groove, a lifting mechanism for lifting the support platform is mounted at the bottom of the U-shaped groove, and a translation mechanism capable of regulating the support platform in the horizontal direction is mounted at the side wall of the U-shaped groove. The multi-directional adjustable knife changing mechanism of the dividing and cutting machine is capable of enabling the support platform to support a dividing and cutting roller firstly through regulating the lifting mechanism; the whole knife changing process is easy to operate, the user does not need to demount the whole dividing and cutting roller to change the knife, the re-correction for the dividing and cutting roller is avoided, the structure is simple, the use is facilitated, and the changing efficiency is high.

Owner:CHANGZHOU WUJIN GUANGYU EMBOSSING ROLLER MACHINERY

A precision control method for inertial group assembly

ActiveCN109649575BEnsure that the shape and position tolerances meet the requirementsGuaranteed positioning accuracyVessel designingControl engineeringProcess engineering

The invention discloses a method for controlling the assembly precision of an inertial group. The inertial group installation positioning surface on the carrier is processed by one clamping, and the calibration special tooling whose accuracy meets the requirements is produced, and the installation position of the inertial group on the carrier is determined by the calibration special tooling. At the same time, the inertial group can be calibrated underwater by using the special tooling for calibration, so that the inertial group can be accurately assembled to the carrier without re-calibration, which reduces the calibration cost during the use of underwater vehicles and saves the confirmation of navigation accuracy. Time, improving the flexibility and quick response of the underwater vehicle. In addition, a set of special tooling for calibration can be used to prepare the installation holes of multiple sets of carriers, which simplifies the processing procedure, improves the processing accuracy, and reduces the production cost.

Owner:CSIC NO 710 RES & DEV INST

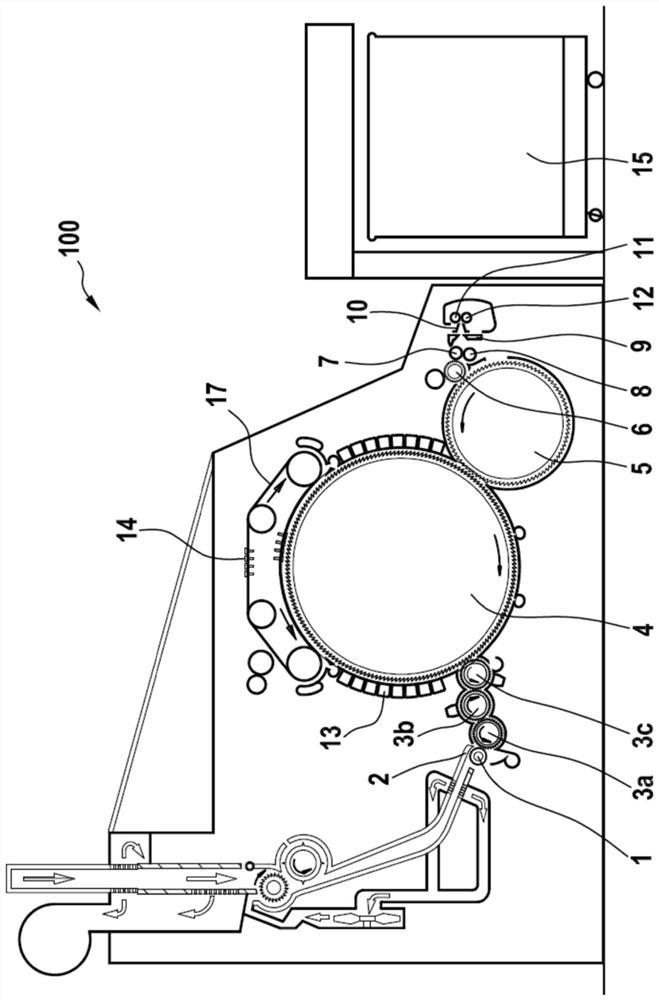

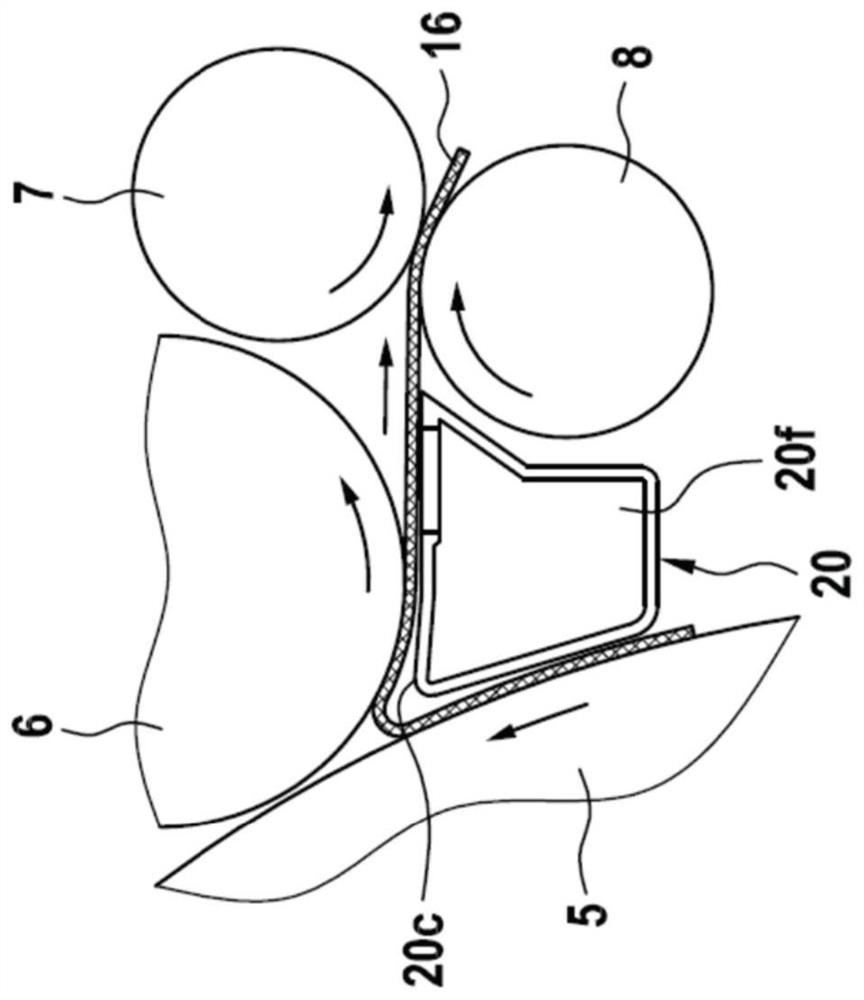

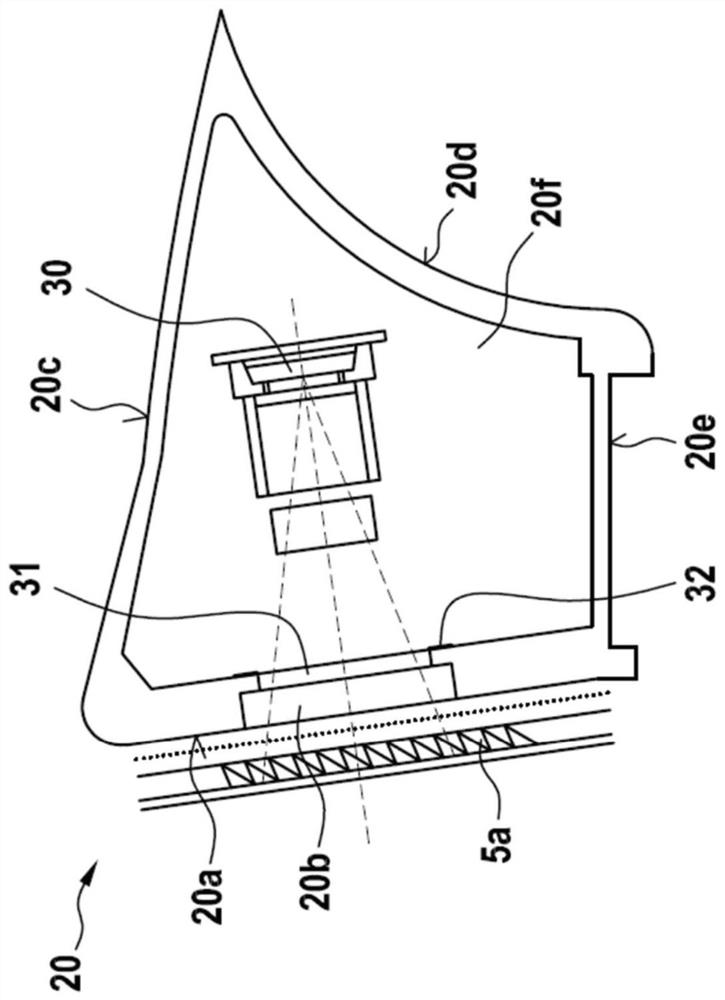

Carding machine with device for detecting interfering particles

PendingCN112048785AExtended service lifeAvoid failureSafety devices for fibre treatmentCarding machinesPhysicsEngineering

The invention relates to a carding machine (100) having a device for detecting interfering particles, in particular waste parts, agglomerates, crumbs, slubs and / or impurities in a carded fibrous web (16), said device comprising at least one sensor (30) arranged in a web guide element (20), wherein the web guide element (20) is arranged in the transition of the doffer (5) to the stripping roller (6), and wherein the at least one sensor (30) detects the fibrous web (16) on the doffer (5).

Owner:特吕茨施勒集团欧洲公司

X-ray imaging method with automatic correction function

ActiveCN103091968BAvoid recalibrationRepeat calibration not requiredPhotographyFlat panel detectorAudio power amplifier

The invention discloses an X-ray imaging method with an automatic correction function. The method includes that first, the point light source of an X-ray source directly irradiates to a flat panel detector, and the flat panel detector receives image signals; second, the image signals are amplified through a signal amplifier and then enter into an automatic correction unit for correction, the relation between an output signal I (x, y) and an output signal I0 (x, y) of the automatic correction unit is that I (x, y) =G0(x, y)* S (x, y)* I0 (x, y), wherein the (x, y) is an image space coordinate, G0(x, y) is a sensitivity correction function of a detector, and S (x, y) is a system automatic correction function; and at last, corrected images are processed by a digital image processing unit and then output. According to the imaging system, under a changing condition, without the need for repeated correction, an optimal image can still be developed.

Owner:ZHEJIANG KANGYUAN MEDICAL DEVICE

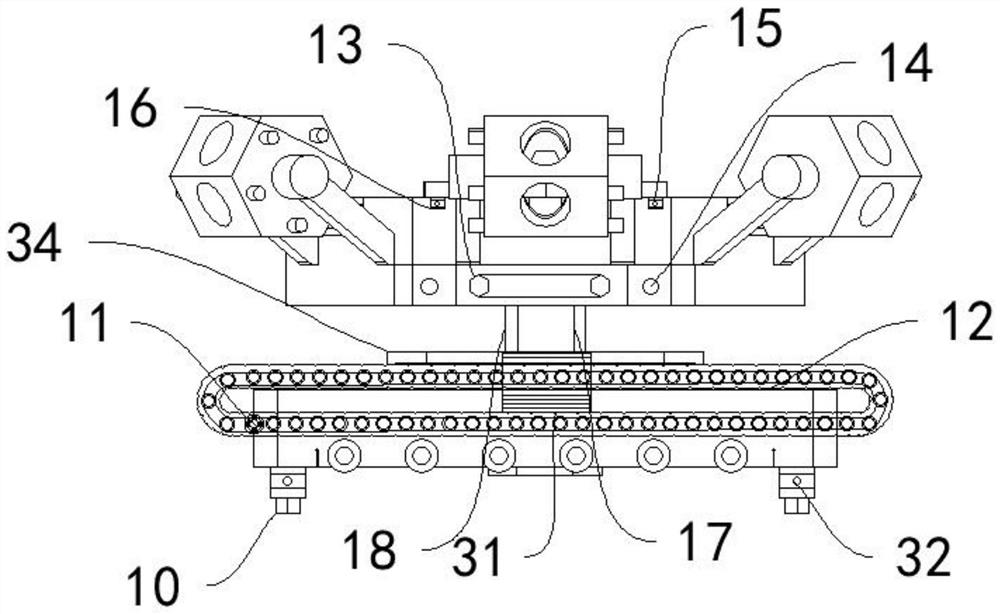

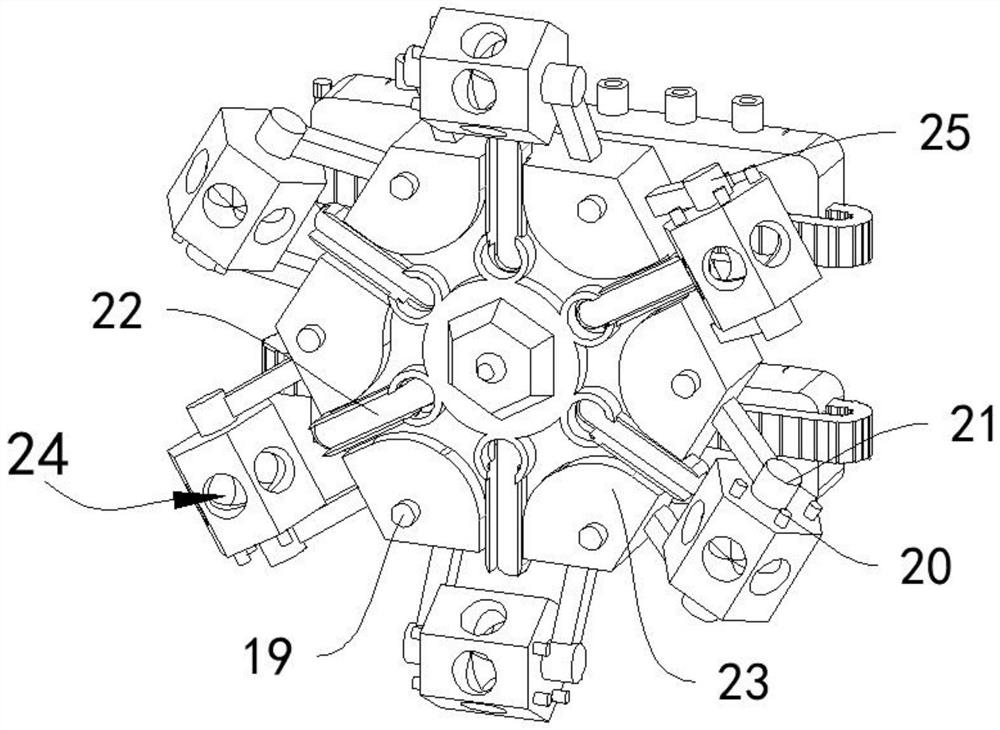

Cutter positioning device for woodworking processing

ActiveCN114523532AIncrease flexibilityAvoid shakingRotary cutting toolsMachine toolWoodworking machinery

The invention provides a tool positioning device for woodworking machining, and relates to the technical field of woodworking machining, the tool positioning device comprises a rotary working disc, a bearing frame and a tool positioning box, the rotary working disc is arranged above the bearing frame, a center control end is arranged at the top of the rotary working disc, and the center control end is fixedly connected with the top of the rotary working disc; a placing hole is formed in the outer side of the center control end, and an induction lamp is arranged at the top of the outer end of the rotary working disc. In order to perform different processing on woodworking materials, different cutters are stored according to processing requirements by rotating a plurality of groups of placing holes in a working disc, the cutters are driven by a telescopic cylinder device to enter a cutter positioning box, the directions of the cutters are controlled to process wood, and the wood is processed by the movement of a transmission crawler belt and the movement of an adjusting chassis. The whole device can be close to machine tool parts conveniently, machining flexibility is improved, and different cutters are called for machining through rotation of the rotary working disc in order to meet different machining procedures.

Owner:SHUNDE POLYTECHNIC

A Finishing Method for Parts with Large Tolerance

ActiveCN111015282BPrecise positioningClamp firmlyPositioning apparatusMetal-working holdersMechanical engineeringPhysics

The invention provides a finishing method for parts with a large tolerance, which uses a special elastic processing fixture, including: 1. According to the size of the part to be processed, adjust the lateral deformation block A and the lateral deformation block B, so that two adjacent deformation blocks The distance between them is less than 0.005-0.01mm of the outer dimension of the parts, ensuring that the clamping interference is not greater than 0.01mm; 2. Use the machining center probe to measure and find the center between the lateral deformation block A and the lateral deformation block B; 3. Press the part to be processed between the lateral deformation block A and the lateral deformation block B, and press the axial direction of the workpiece through the axial positioning device; 4. Finishing. The invention adopts an elastic processing fixture, which has accurate positioning, stable clamping, avoids repeated correction and clamping, the same product can be used permanently at one time, reduces cutting vibration, improves parts precision, reduces professional requirements for operators, and improves production efficiency. It can be applied to processing procedures such as turning, milling, and drilling of plane processing, and is widely used.

Owner:JINCHENG NANJING ELECTROMECHANICAL HYDRAULIC PRESSURE ENG RES CENT AVIATION IND OF CHINA

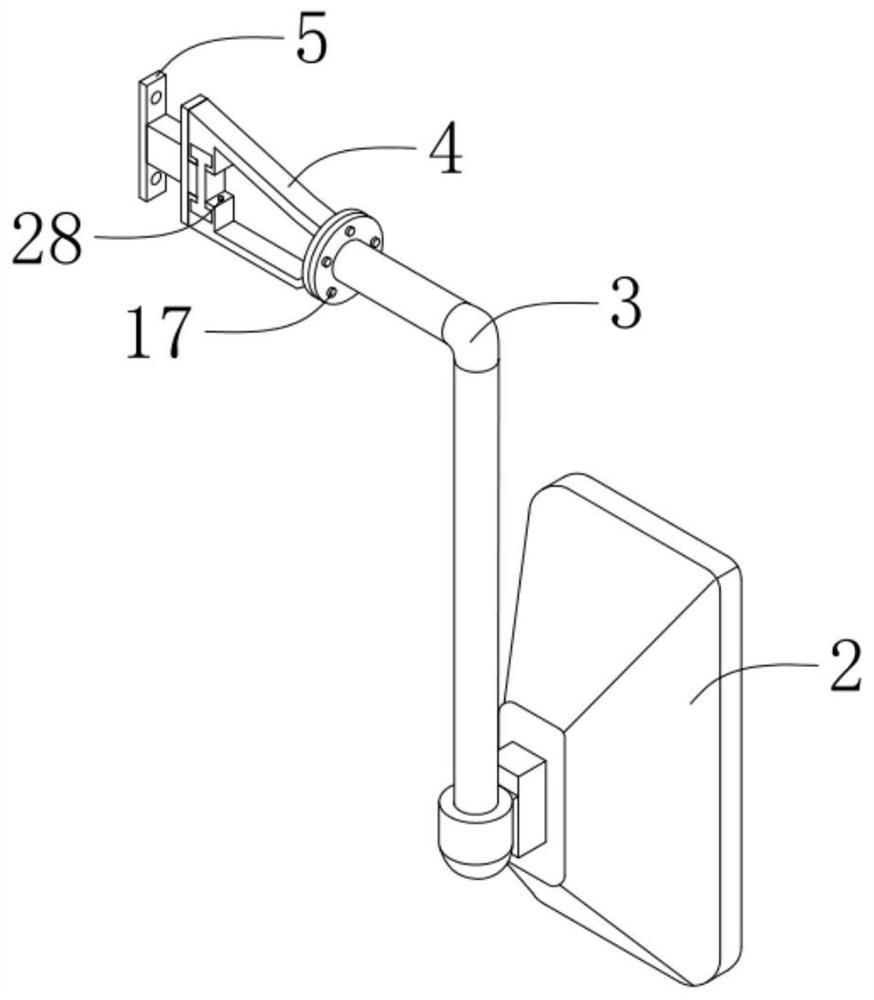

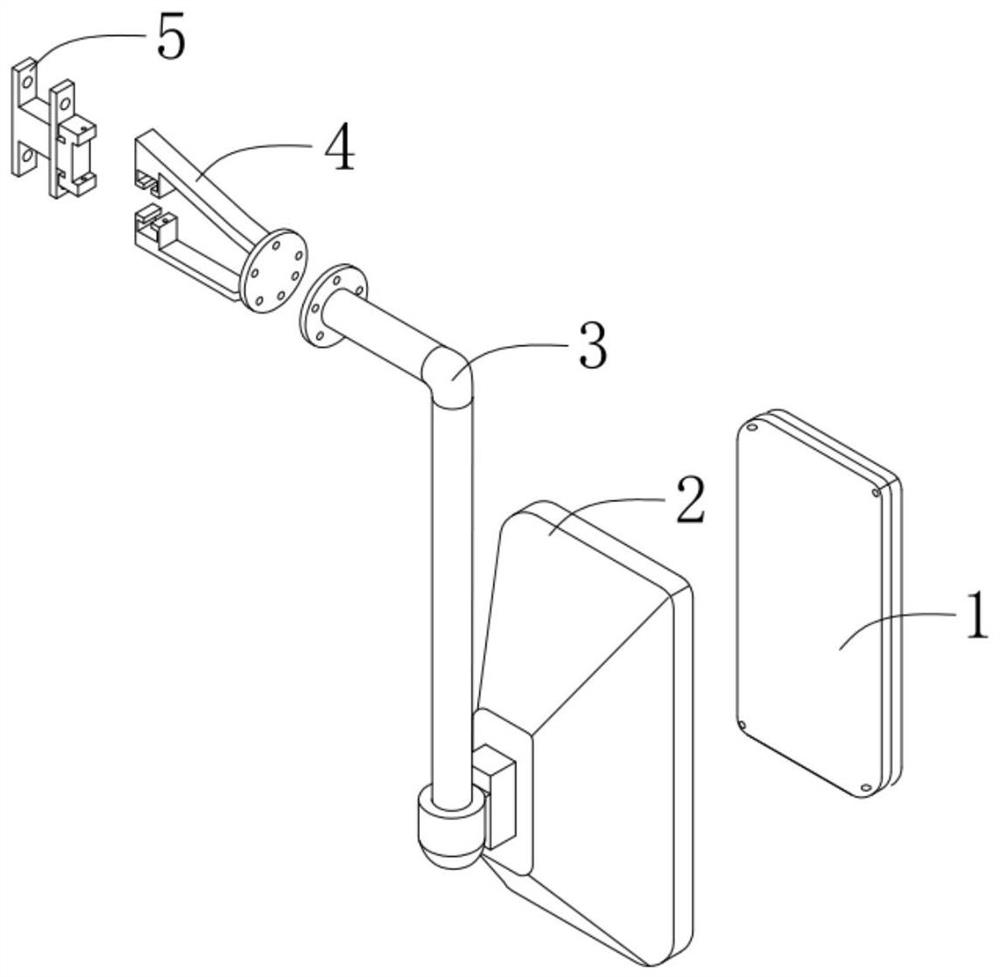

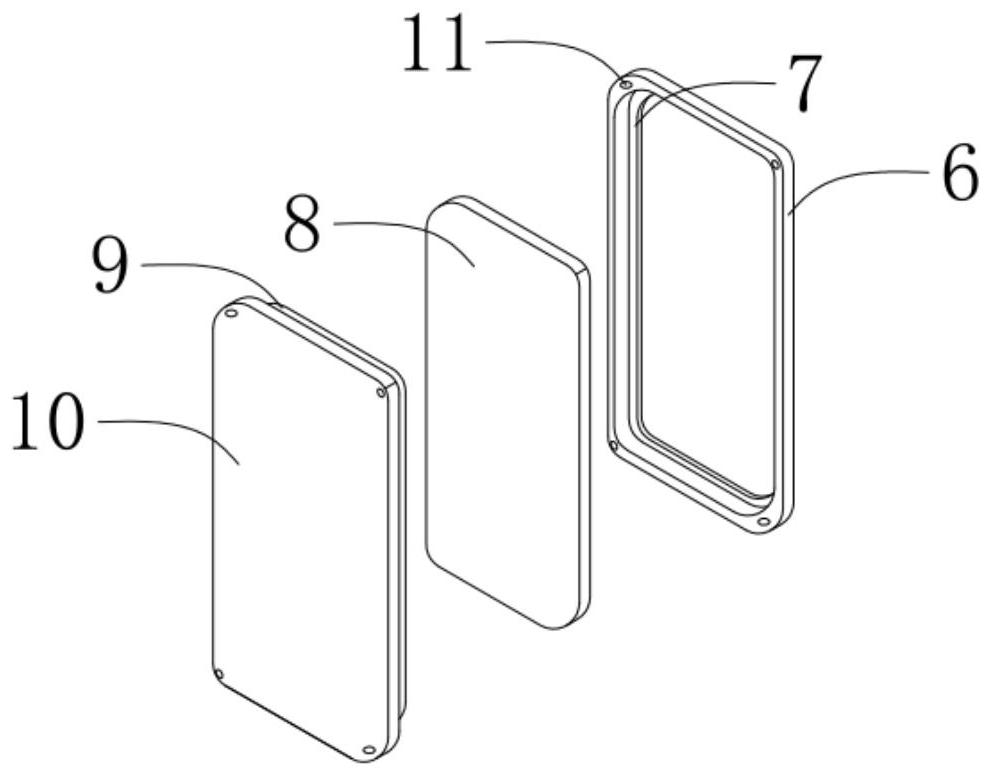

Sugarcane harvester rearview mirror system

PendingCN114734915AAvoid scratchingFlexible adjustmentHarvestersOptical viewingRear-view mirrorStructural engineering

The invention discloses a sugarcane harvester rearview mirror system, which comprises a rearview mirror body, a rearview mirror protection device, a mirror rod, a connecting piece and a mounting seat, and is characterized in that the rearview mirror body comprises a rectangular butt joint frame, a frame type limiting check ring, a rearview mirror, a rectangular abutting plate and a rectangular butt joint plate; the rearview mirror protection device comprises a frame type clamping ring, an isosceles trapezoid cover shell and a rectangular fixing block, the rectangular fixing block is connected with the mirror rod through a universal ball head, and the connecting piece comprises a second butt-joint disc fixed to the first butt-joint disc in a threaded connection mode, a first special-shaped positioning rod with an inverted-T-shaped groove and a second special-shaped positioning rod with an inverted-T-shaped groove. The mounting base comprises two inverted-T-shaped inserting blocks, a connecting block, a rectangular vertical plate and an inverted-T-shaped fixing block. The universal ball head is additionally arranged between the mirror rod and the rearview mirror, an operator can flexibly adjust the rearview mirror according to the operation condition, the visual angle of the operator is clear, observation is convenient, and the protective device is additionally arranged on the periphery of the rearview mirror, so that the mirror surface can be effectively prevented from being scraped and collided by the outside.

Owner:常州中兴塑业有限公司

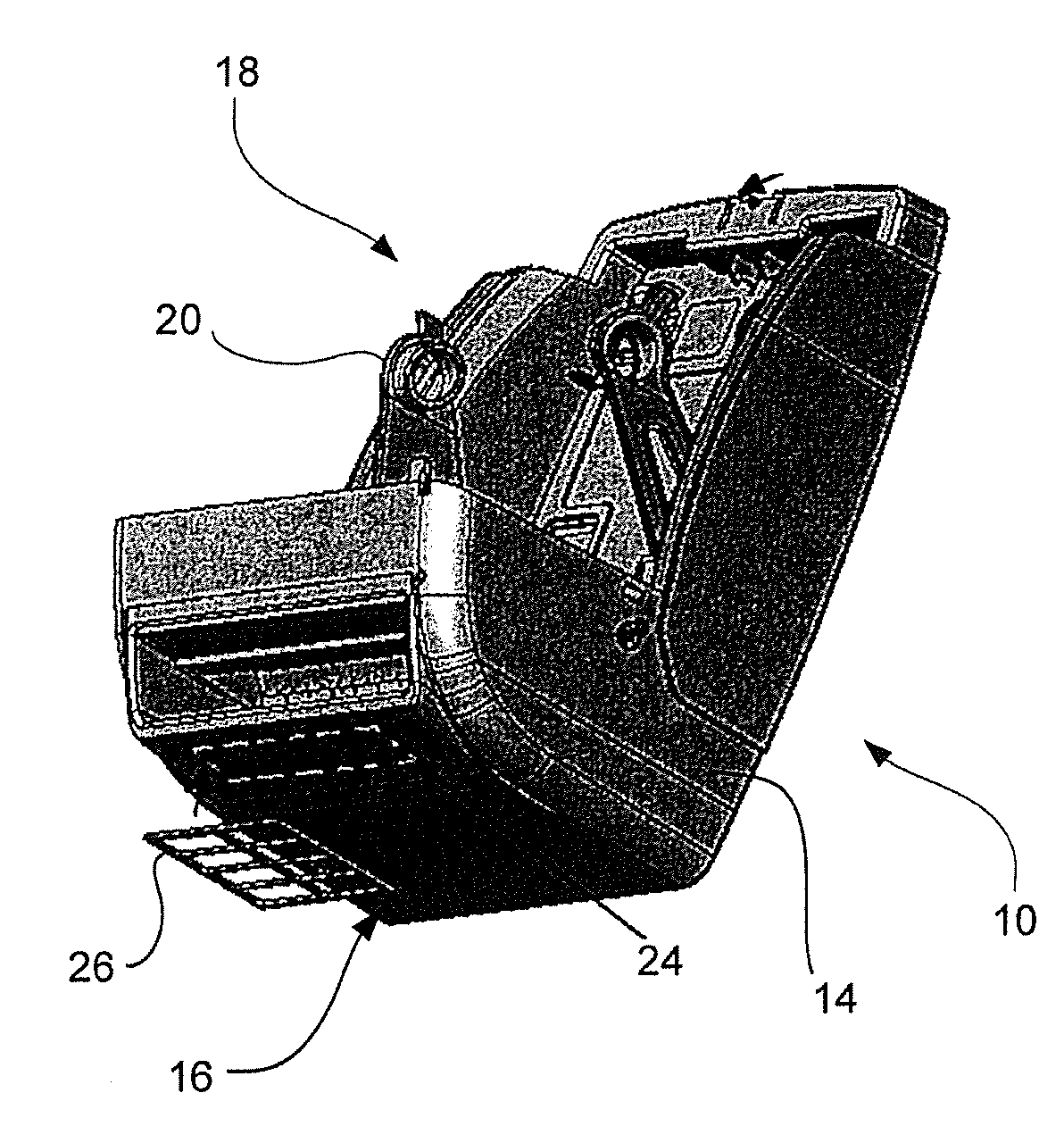

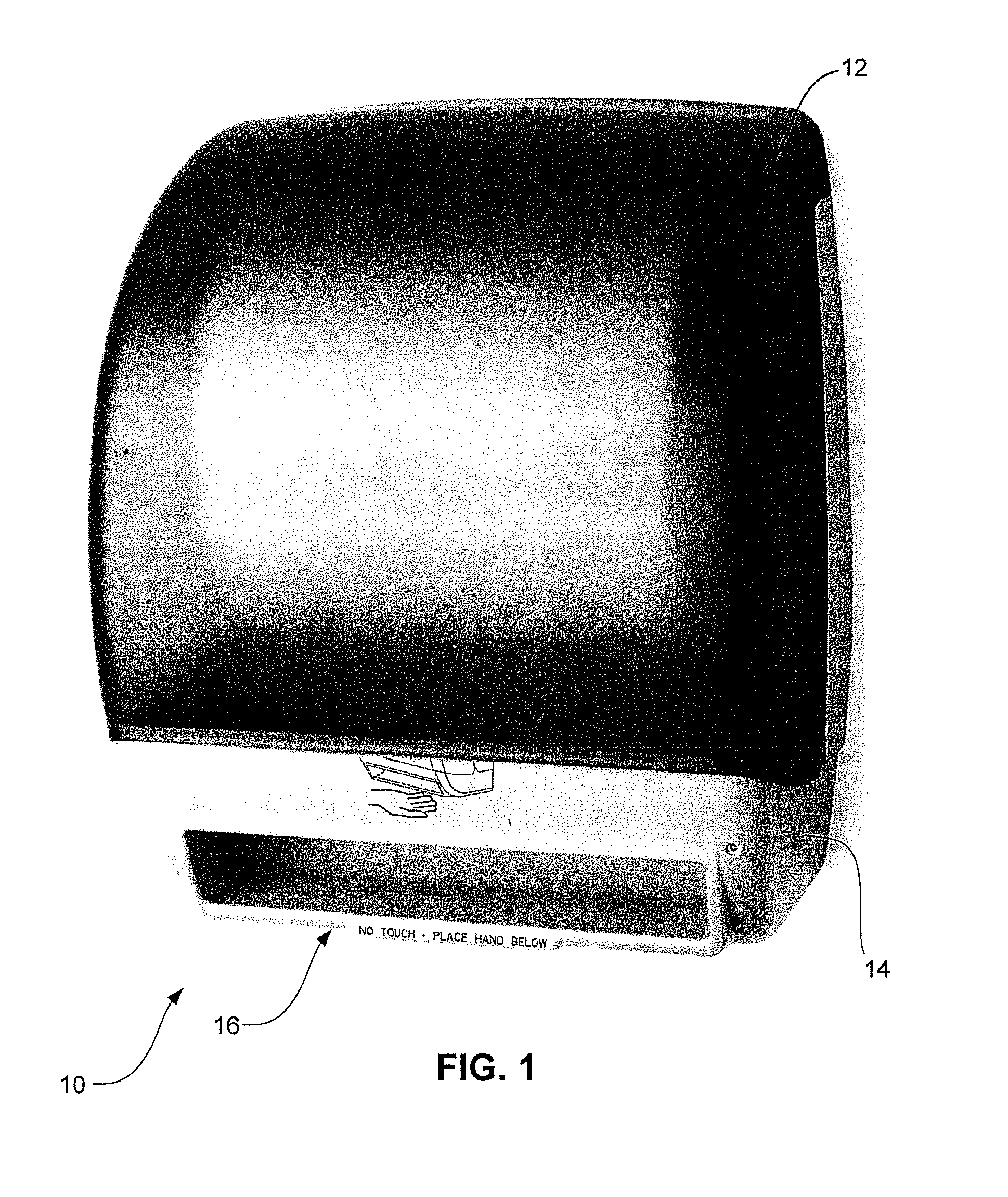

Sensor protector

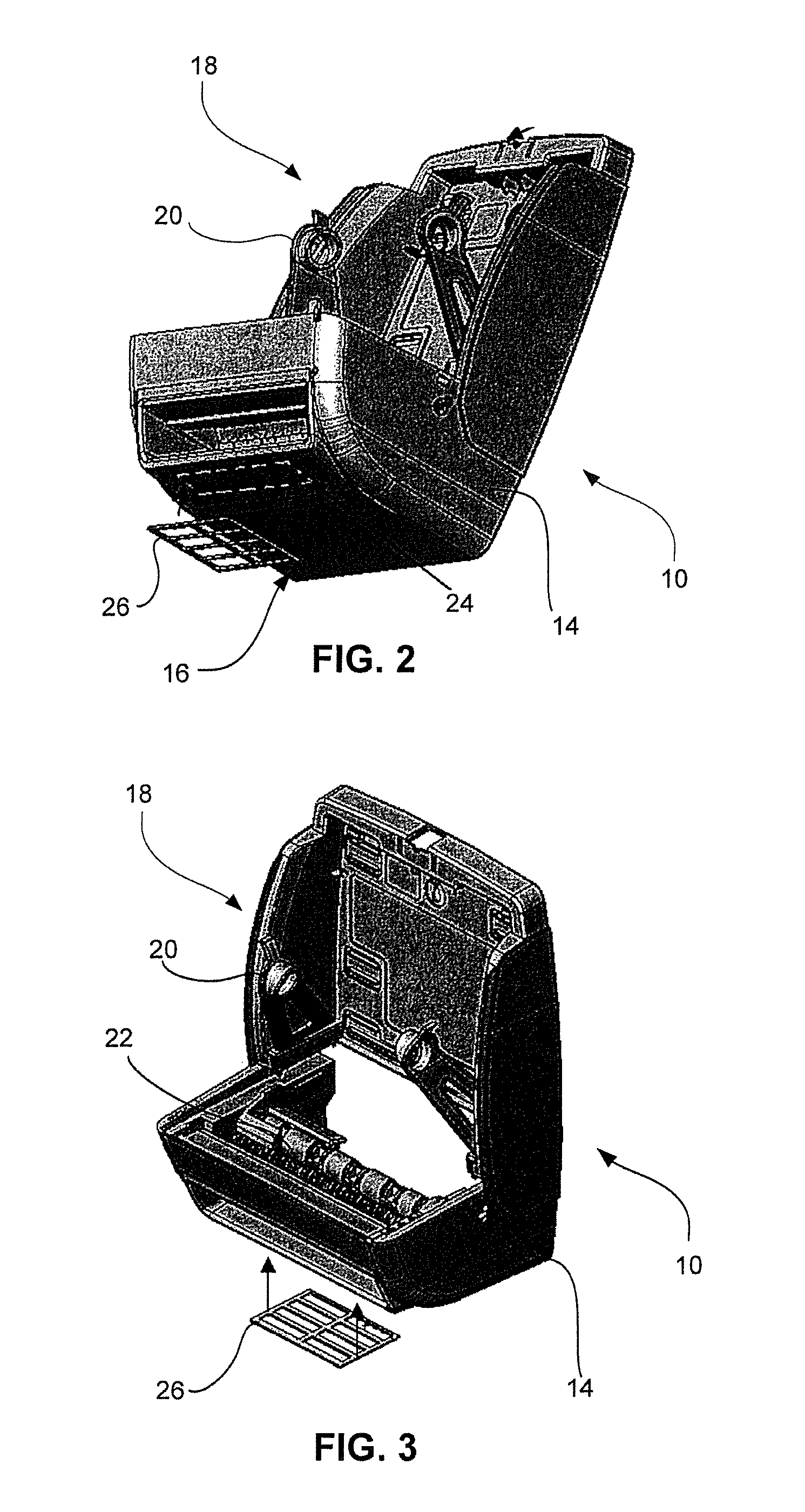

ActiveUS8631967B2Reduce needReduces and eliminates and amountFilament handlingCoin-freed apparatus detailsCapacitive sensingEngineering

Owner:BOBRICK WASHROOM EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com