Auxiliary device for installing connecting pipe of oil cooling pipe of cooler

A technology for installation assistance and oil-cooled tubes, which is applied to hand-held tools and manufacturing tools, can solve the problems of waste of human resources and low efficiency, and achieve the effects of accelerating production efficiency, avoiding repeated correction of angles, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

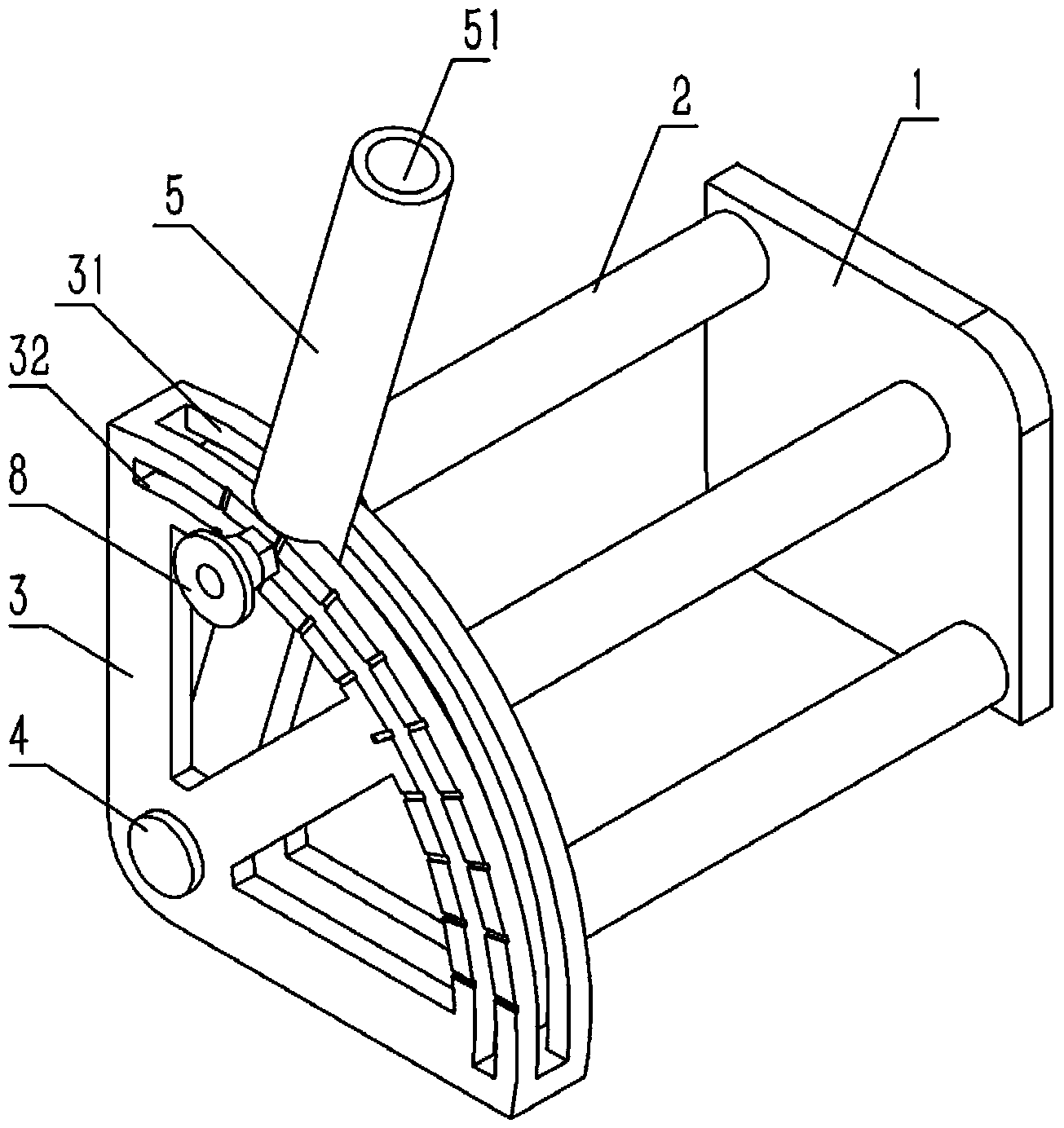

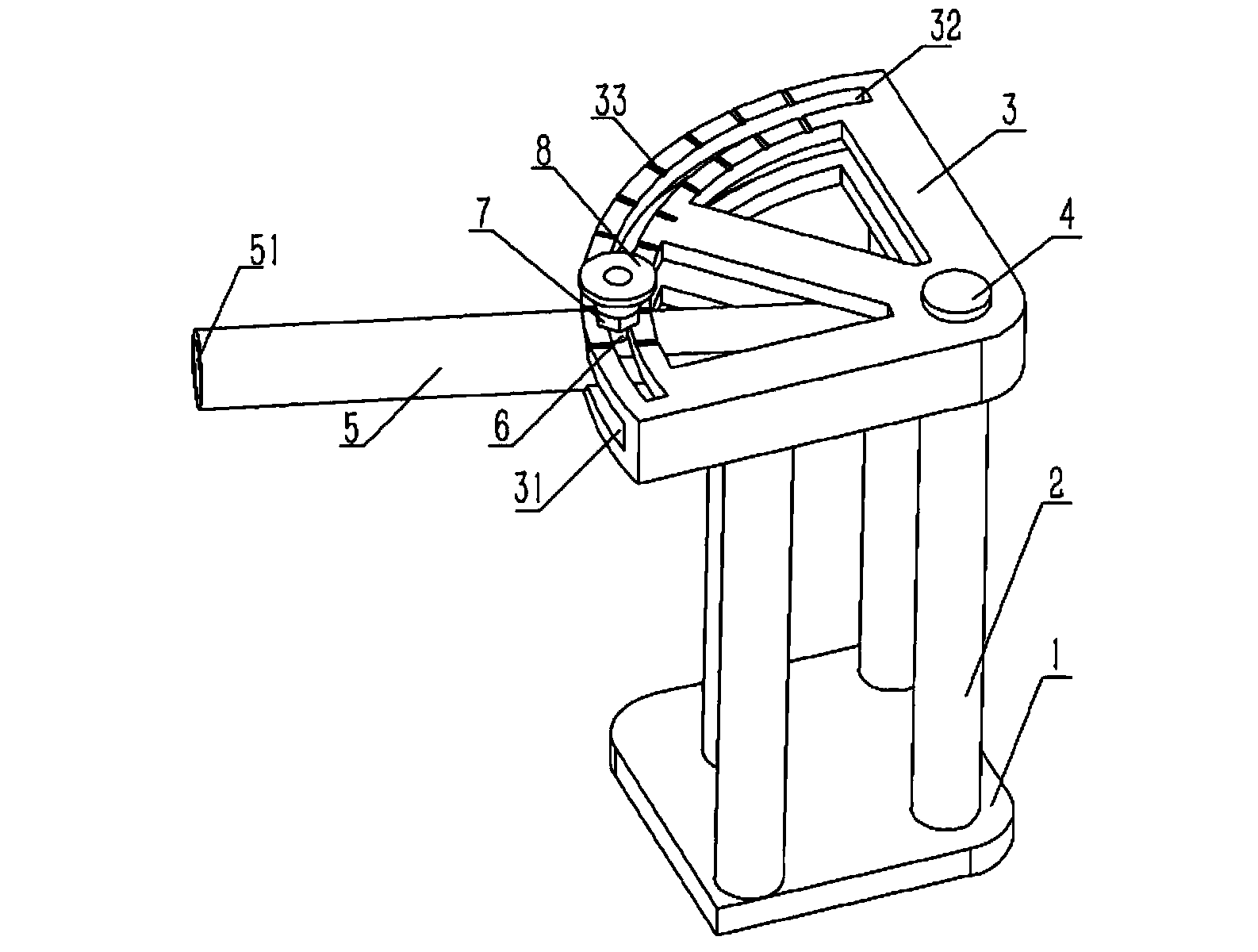

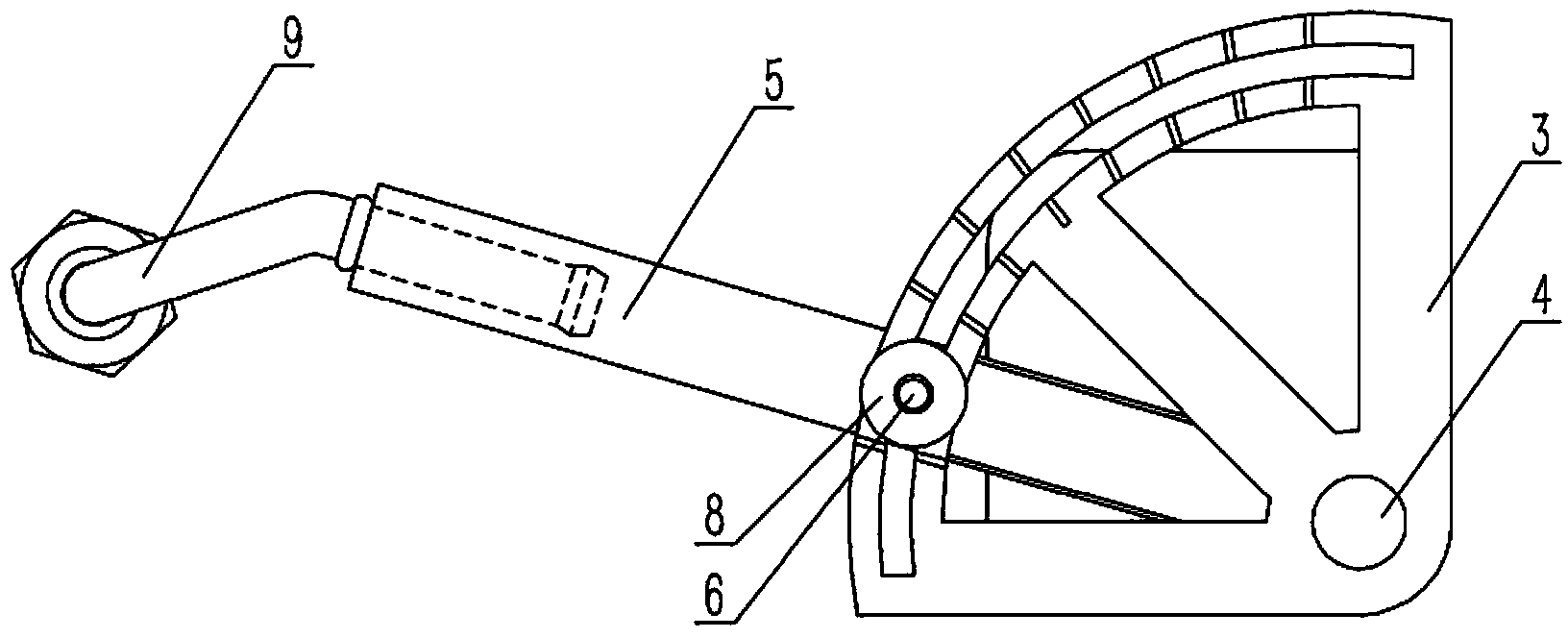

[0014] Example: see figure 1 , 2 As shown, a radiator oil cooling pipe connection installation auxiliary device includes a base 1, the base 1 is fixed on the workbench, the support column 2 is fixed on the base 1, the upper end of the support column 2 is fixed with a fan-shaped bracket 3, and the fan-shaped bracket 3 The inside is formed with a fan-shaped groove cavity 31 that runs through the arc side of the fan-shaped bracket 3, and a fan-shaped annular groove 32 that runs through the upper and lower end faces is formed on the fan-shaped bracket 3 near the arc side of the fan-shaped bracket 3, and one end of the auxiliary rod 5 passes through the fan-shaped bracket. 3, the fan-shaped cavity 31 is hinged on the fan-shaped bracket 3 through the pin shaft 4, and the other end surface of the auxiliary rod 5 is formed with a slot 51. The auxiliary rod 5 is provided with bolts 6, and the bolts 6 pass through the fan-shaped bracket in turn. The fan ring groove 32 on the lower plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com