A precision control method for inertial group assembly

A control method and assembly precision technology, applied in the field of machining precision control of underwater vehicles, can solve problems such as strict reliability, increased inertial group maintenance costs, restrictions on the flexibility and rapid response of underwater vehicles, and achieve Improve processing accuracy, improve use flexibility and response speed, and save confirmation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] When the integrated navigation system is a combination of inertial navigation, Doppler log and acoustic correlation log, the specific steps of the inertial assembly precision control method provided by the present invention include:

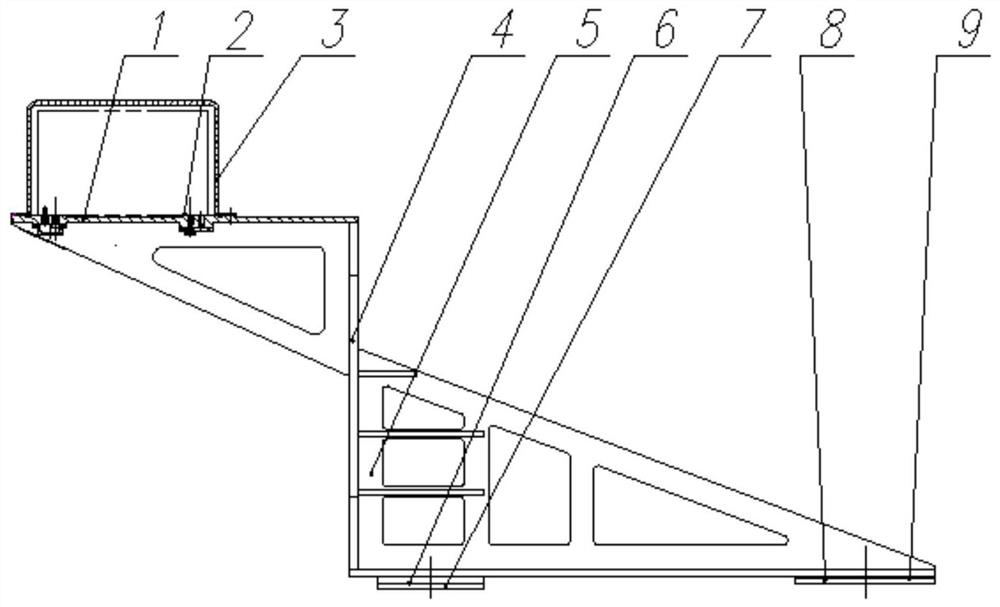

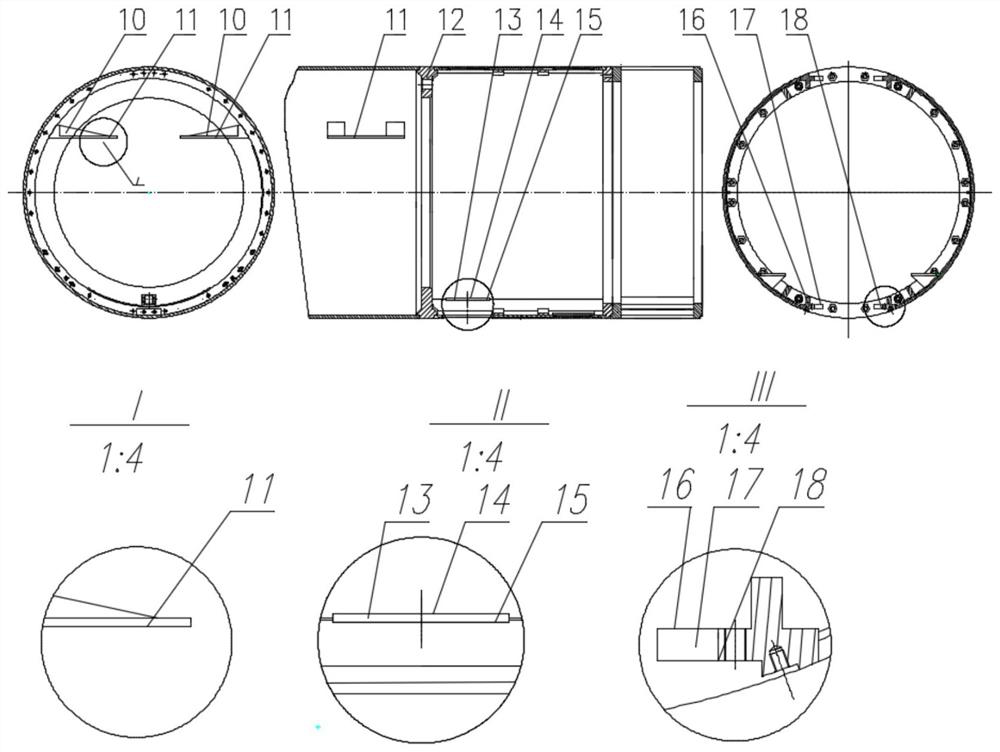

[0038] Step 1. One-time clamping and processing the inertial group on the carrier to install the positioning plate. First, the underwater vehicle carrier cabin section 12 that does not contain the inertial group mounting plate is clamped at a suitable position of the processing machine tool, such as figure 2 As shown, the inertial navigation mounting plate 10 in the carrier, the speed log transducer mounting plate 13 in the carrier and the sound-related speed log transducer mounting plate 16 in the carrier are processed to form the inertial navigation mounting surface 11 in the carrier and the speed log transducer installation in the carrier. Faces 14, 15, 17 and 18. During the above-mentioned processing process, the underwater vehicle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com