Method for finish machining large-tolerance parts

A technology of parts and tolerances, which is applied in the field of finishing of parts with large tolerances, can solve the problems of unstable clamping and low clamping efficiency, and achieve the effects of improving production efficiency, stable clamping and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

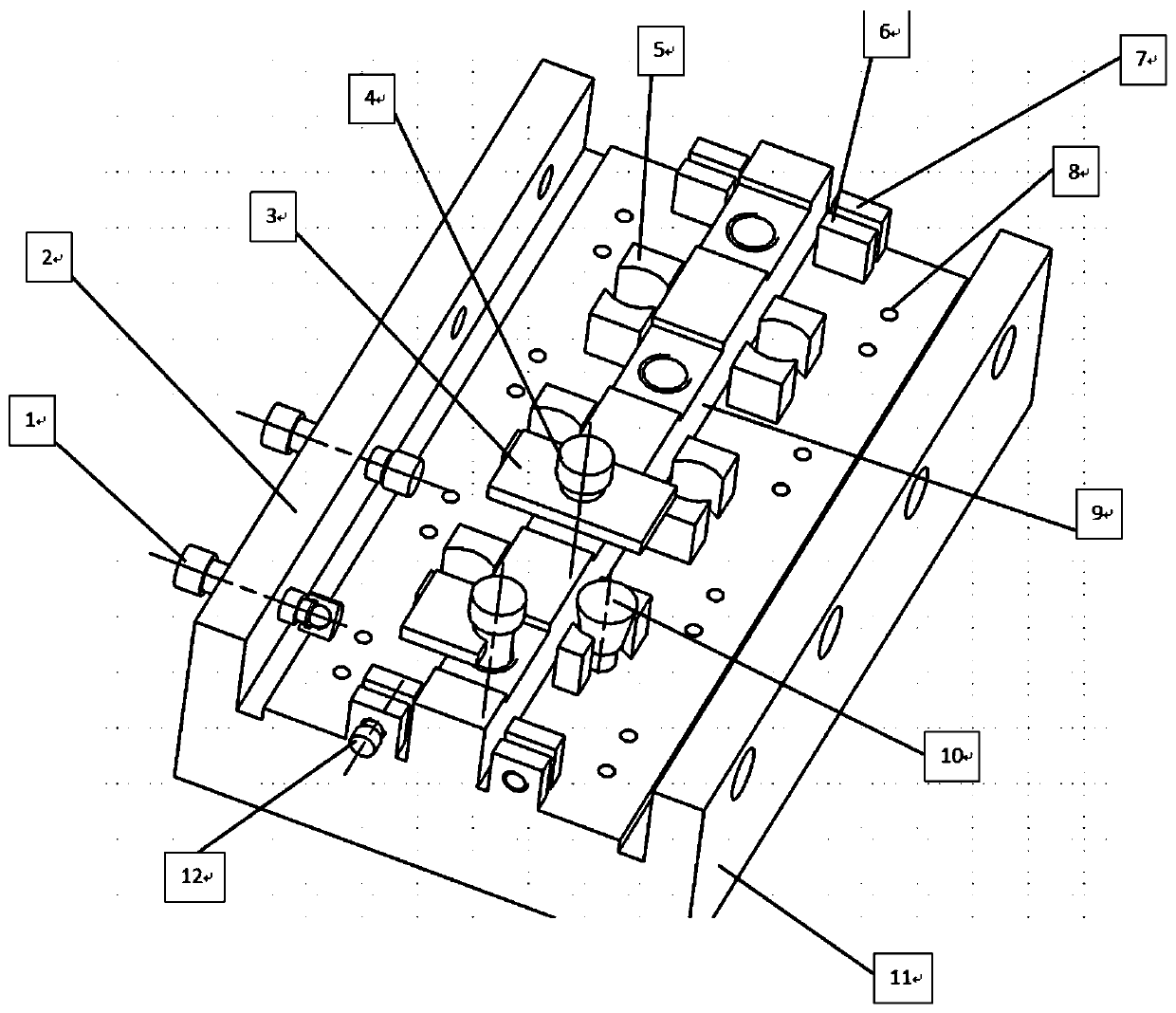

Image

Examples

Embodiment Construction

[0022] This part is the embodiment of the present invention, which is used to explain and illustrate the technical solution of the present invention.

[0023] A finishing method for large-tolerance parts, using a special elastic processing fixture, specifically includes the following steps:

[0024] Step 1. According to the size of the part to be processed, adjust the lateral deformation block A and the lateral deformation block B, so that the distance between two adjacent deformation blocks is less than 0.005-0.01 mm from the outer dimension of the part, and ensure that the clamping interference is not greater than 0.01 mm;

[0025] Step 2, using the machining center probe to measure and align the center between the lateral deformation block A and the lateral deformation block B;

[0026] Step 3, pressing the part to be processed between the lateral deformation block A and the lateral deformation block B, and compressing the axial direction of the workpiece through the axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com