Multi-directional adjustable knife changing mechanism of dividing and cutting machine

A technology of tool changing mechanism and slitting machine, which is applied in the direction of sending objects, thin material processing, transportation and packaging, etc. It can solve the problems of long disassembly process and achieve the effect of simple structure, avoiding recalibration and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

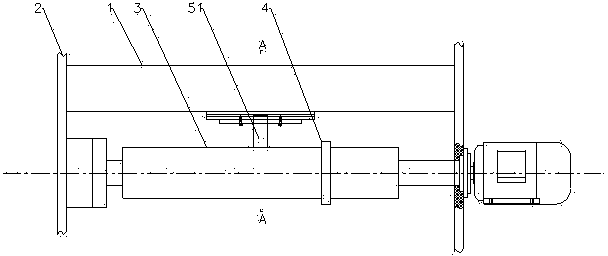

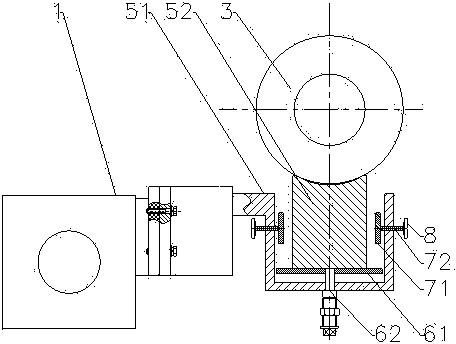

[0018] Such as figure 1 , figure 2 As shown, a multi-directional adjustable tool change mechanism for a slitting machine, the slitting machine includes a beam 1 and two wall panels 2, the beam 1 is fixed between the two wall panels 2, and there is a rotating device between the two wall panels 2 Slitting roller 3, is provided with annular cutting knife 4 on the slitting roller 3, is fixedly provided with on the beam 1 and is used for supporting the tool changing mechanism of slitting roller 3 when slitting roller 3 is changed, and the tool changing mechanism comprises support arm 51 With support platform 52, support arm 51 is a flat-bottomed U-shaped groove, and support platform 52 is arranged in the U-shaped groove, and is higher than the groove, and the bottom of the U-shaped groove is provided with a lifting mechanism for lifting support platform 52. The mechanism includes a carriage 61 arranged at the bottom of the U-shaped groove. Under the carriage 61, there is a thread...

Embodiment 2

[0020] On the basis of Embodiment 1, the surface of the support table 52 in contact with the cutting roller 3 is provided with an arc groove, and the arc groove matches the surface of the cutting roller 3 .

[0021] Specific usage method:

[0022] When the cutting knife needs to be replaced, first loosen the slitting knife 4 and move it to an end away from the motor. It can make the support table 52 support the slitting roller 3 by adjusting the lifting mechanism, and then adjust the translation mechanism to make the slitting The center of gravity of the roller 3 falls on the center of the supporting table 52 to ensure the stability of the slitting roller 3, then adjust the lifting mechanism so that the supporting table 52 can support the slitting roller 3 powerfully, and then open the fixing device at one end of the slitting roller 3 , replace the slitting knife 4, then fix it again, then adjust the lifting mechanism so that the support table 52 is away from the slitting roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com