Precision sliding table for multi-workpiece parallel vision measurement

A visual measurement, multi-workpiece technology, applied in measurement devices, instruments, optical devices, etc., can solve the problems of repeated camera calibration, inaccurate measurement positioning, low efficiency, etc., to achieve good flatness, wide application, stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

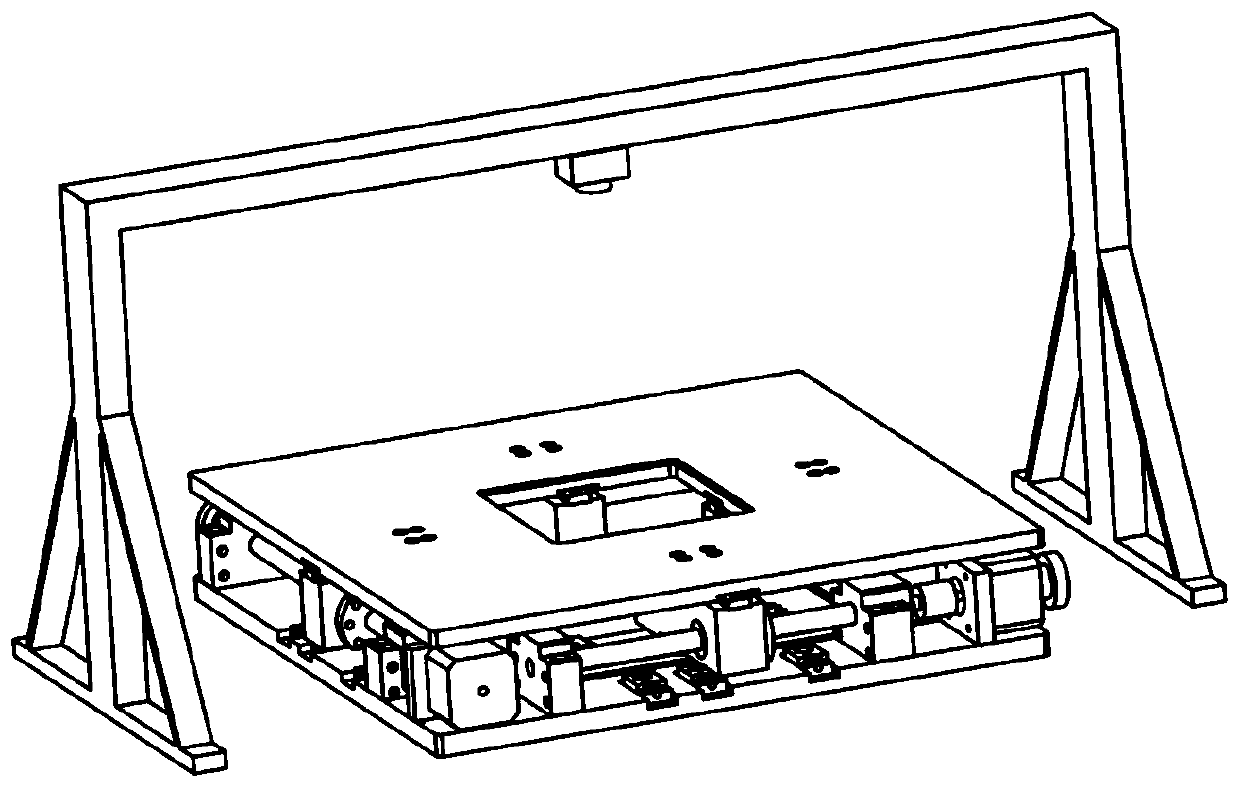

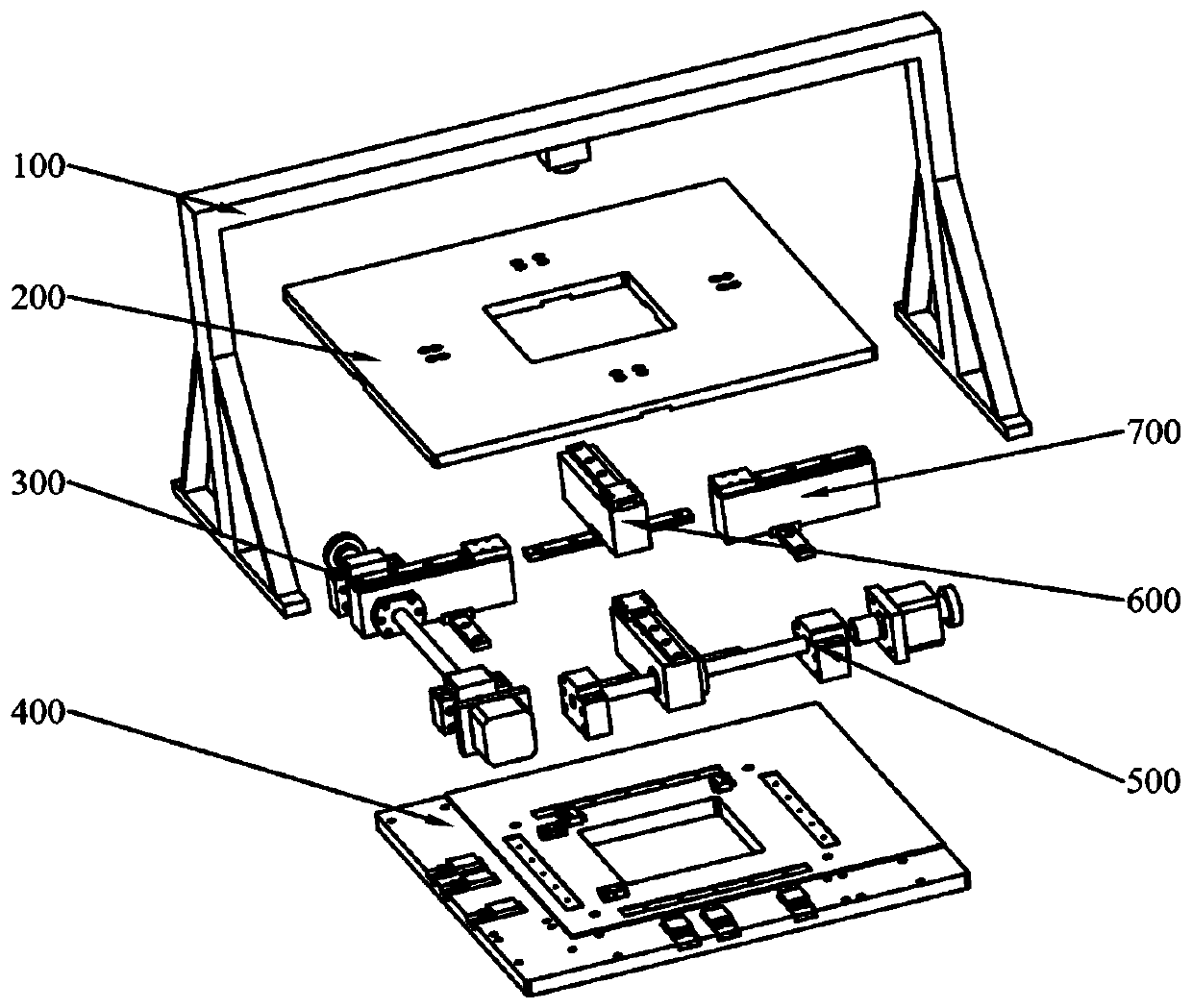

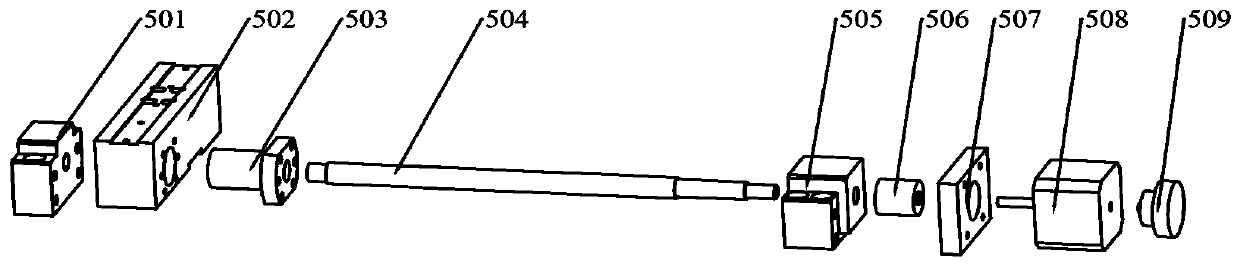

[0025] The structural composition of a precision slide table for parallel visual measurement of multiple workpieces includes: a gantry vision acquisition mechanism 100, a loading plate 200, an active radial screw nut mechanism 300, a fixing plate 400, an active axial screw nut mechanism 500, The driven axial slider mechanism 600 and the driven radial slider mechanism 700 are composed. The gantry vision acquisition mechanism 100 and the fixed plate 400 are arranged on the working platform; the active radial screw nut mechanism 300 and the active axial screw nut mechanism 500 are connected by bolts on the support seats 302, 501 and the fixed seats 308, 505 On the fixed plate 400, the drive motors 305, 508 are connected and fixed on the motor bases 306, 507 with screws, and the motor bases 306, 507 are connected on the fixed plate 400 by the screws on the bottom surface of the fixed plate 400, and the active radial screw nut mechanism 300 The lower part of the sliders 303 and 502...

Embodiment 2

[0030] In the present invention, the operation steps of a precision sliding table for parallel visual measurement of multiple workpieces are as follows:

[0031] Step I: Arrange and install the gantry vision acquisition mechanism 100 and the precision sliding table mechanism according to the measurement requirements, clamp multiple workpieces on the loading plate 200, drive the lead screws 504, 309 to rotate by the drive motors 508, 305, and move the slider to a position close to Switch sensors 409, 406, feedback the current position of the slider, complete the device reset, and the radial and axial operation modes are the same;

[0032] Step II: The driving motors 508 and 305 accept the operation command, drive the screw 504 and 309 to rotate through the coupling 506 and 307, the nut mechanism converts the rotation of the screw into the linear motion of the slider, and the drive shaft radial screw nut mechanism 500 The operation mode is the same as that of the active radial s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com