Fluorescent oxygen probe, and preparation method and use thereof

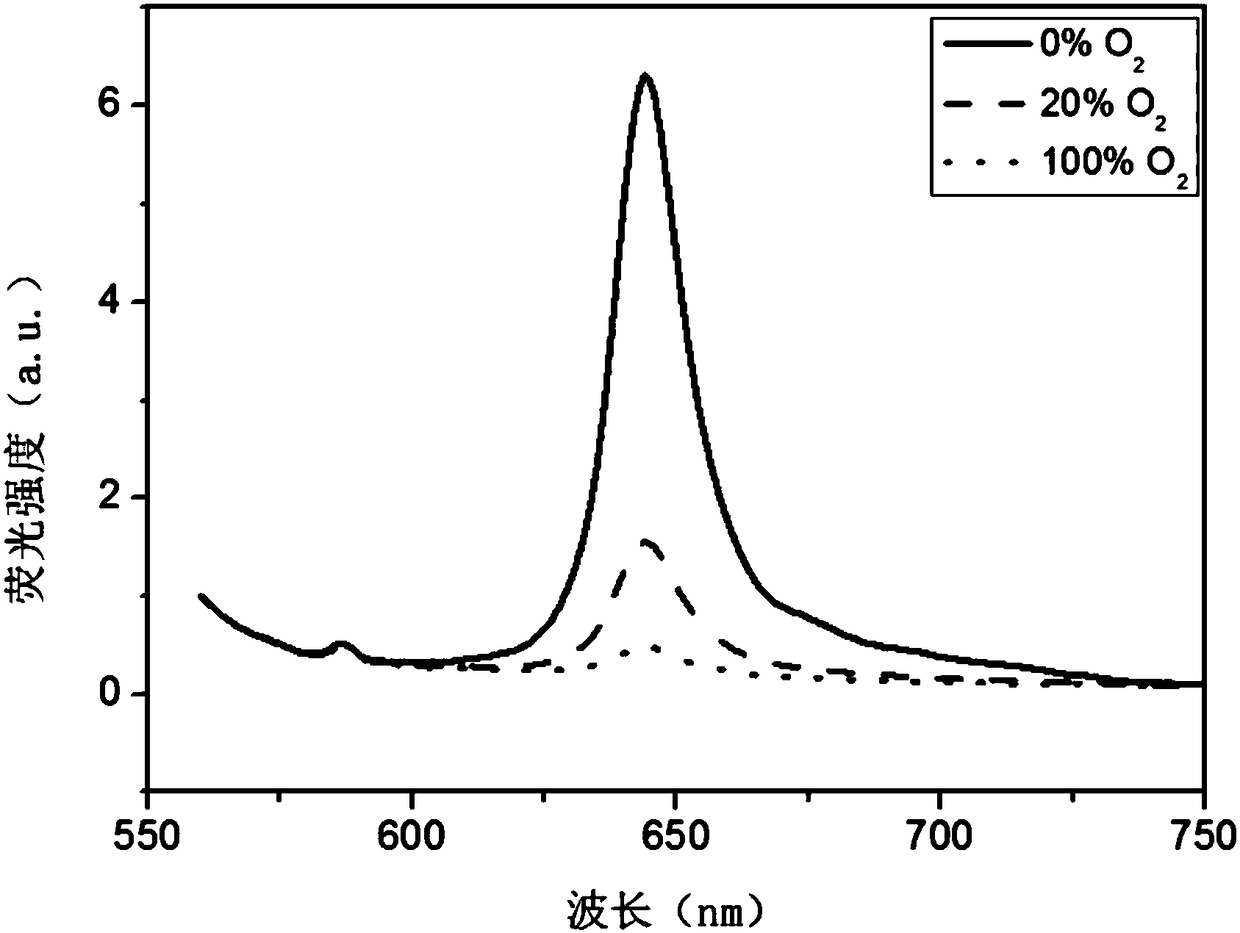

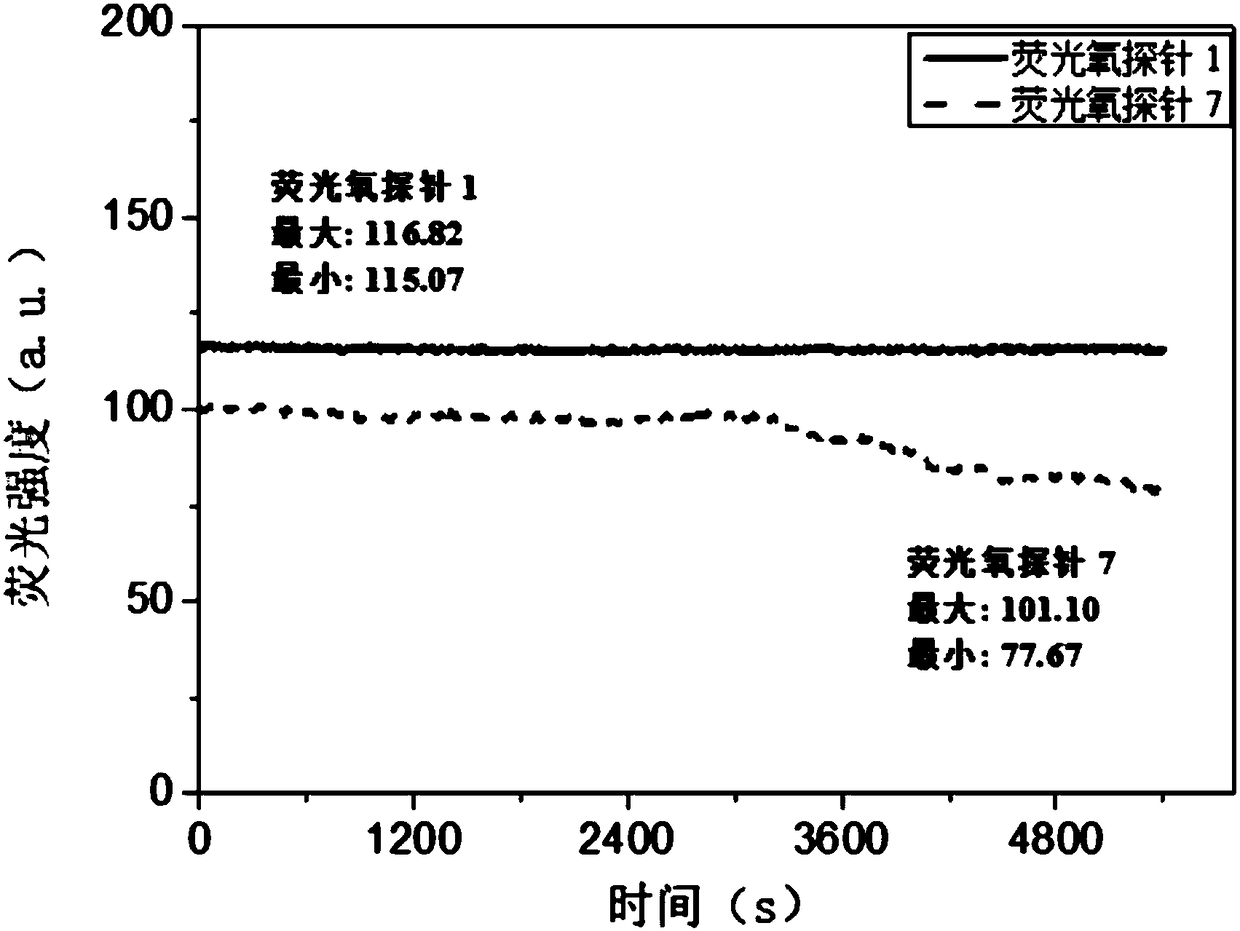

An oxygen probe and fluorescence technology, applied in the field of fluorescence detection, can solve the problems of deviation of detection results, decrease of fluorescence efficiency, complicated operation, etc., and achieve the effect of reducing detection error and preventing metabolic decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Fluorescent oxygen probe 1 was prepared by the following steps:

[0049] Synthesis of the reference probe compound rhodamine B acrylate: 400 mg of rhodamine B and 261 mg of triethylamine were dissolved in 20 ml of tetrahydrofuran to obtain rhodamine B solution, and then 2 mL of tetrahydrofuran with 135 mg of methacrylamide dissolved in 0 Slowly drop into the rhodamine B solution in an ice bath at ~5°C, stir overnight at room temperature to react, pour the product into excess water after the reaction, extract with dichloromethane to obtain an organic phase, wash the organic phase with pure water three times, Anhydrous MgSO 4 Dried to obtain the crude product, the crude product was separated by silica gel column chromatography, with dichloromethane and methanol in a volume ratio of 95:5 as eluent chromatography to obtain 300mg dark red viscous substance, which was the rhodamine acrylate B ester, the reaction yield is 70.10%.

[0050] The hydrogen nuclear magnetic resona...

Embodiment 2

[0054] Fluorescent oxygen probe 2 was prepared by the following steps:

[0055] The only difference with Example 1 is that the reference probe compound in step (1) is selected from (7-hydroxycoumarin) acrylate, the addition of the reference probe compound is 250mg, and the solvent of the reference probe compound is selected N,N-Dimethylformamide.

[0056] Example 2 Obtain the fluorescent oxygen probe 2.

Embodiment 3

[0058] Fluorescent oxygen probe 3 was prepared by the following steps:

[0059] The only difference from Example 1 is that tris(1,10-phenanthroline)ruthenium(II) is selected as the fluorescent oxygen probe compound in step (1), and the added amount of the fluorescent oxygen probe compound is 1 g.

[0060] Example 3 obtained the fluorescent oxygen probe 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com