Multistage diameter change milling cutter

A milling tool and milling technology, applied in the direction of milling cutting blades, milling cutters, manufacturing tools, etc., can solve the problems of insufficient tool rigidity, low cutting efficiency, serious interference, etc., to reduce cutting vibration, enhance applicability, and avoid interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

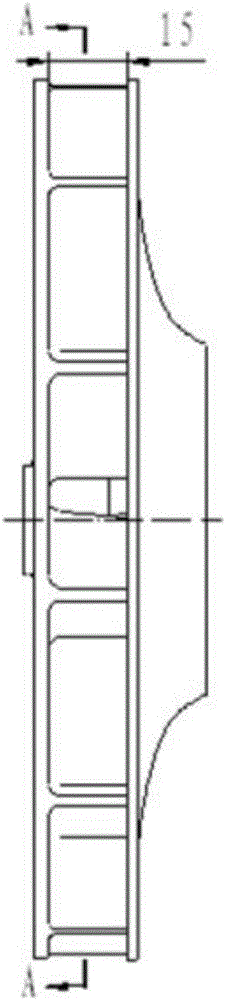

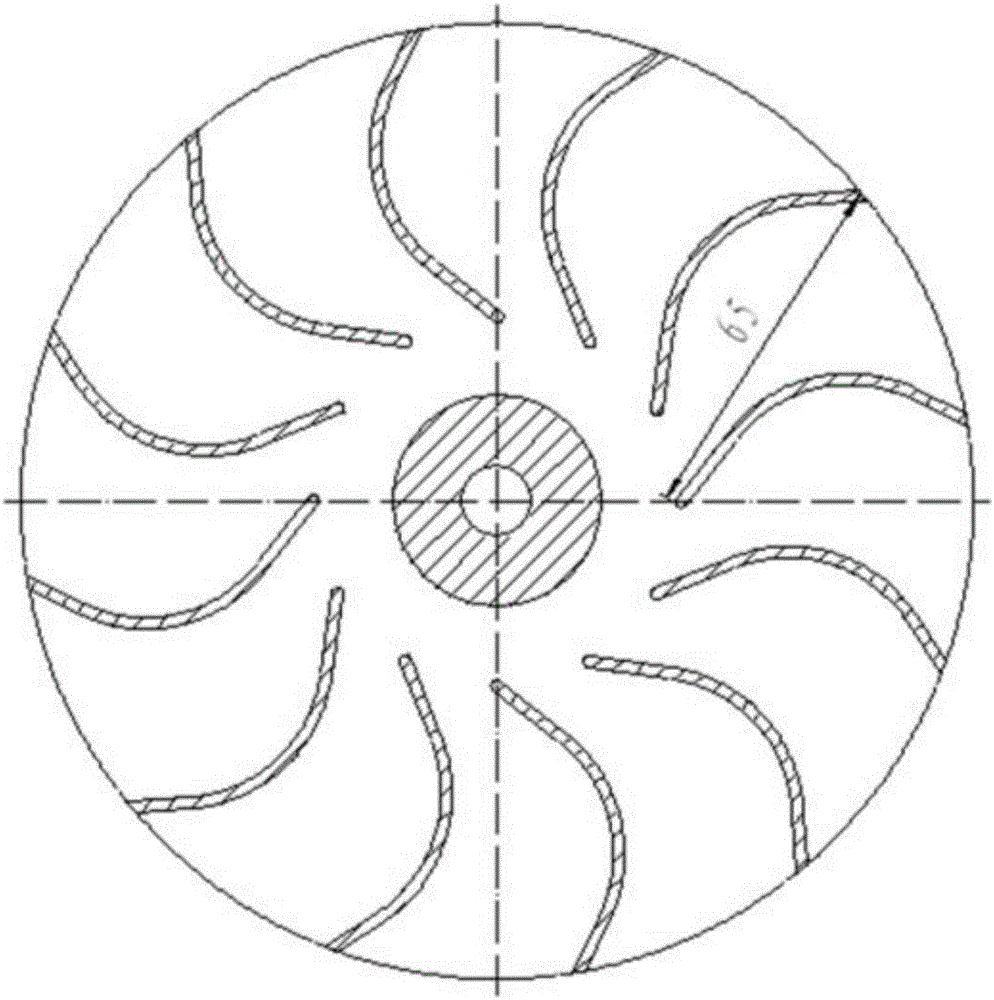

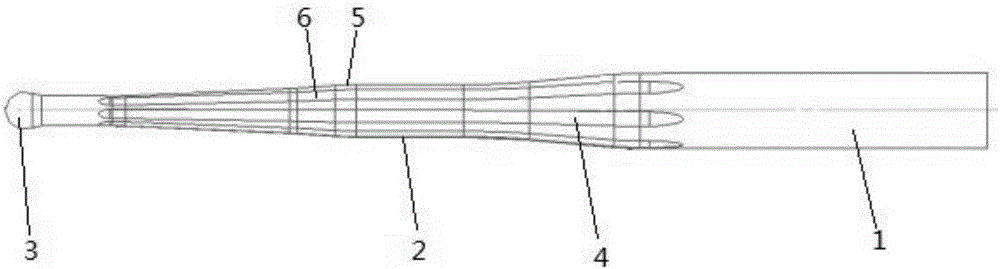

[0026] To be processed as Figure 1-2 For the impeller part shown, the thinnest part of the impeller blade is 1.2mm, and the thickest part is 1.8mm. It has a complex curved surface structure with a deep cavity, and the milling tool is prone to cutting vibration during manufacturing. Such as Figure 4 As shown, use a multi-stage variable diameter milling cutter with a diameter of ultrafine particle carbide ball head of Ф5mm, the first stage Ф4mm straight shank variable diameter, the second stage tapered diameter 5°, the third stage tapered diameter 8°, The fourth-stage reducing taper is 10°. The chamfer 5 set on the multi-stage variable diameter node is one place of R3mm, four places of R40mm, and one place of R100mm. The diameter of the cutter bar 2 at the junction of the cutter head 3 and the first-stage variable diameter is Ф4mm, and the diameter of the tool handle 1 is Ф10mm. The multi-stage variable-diameter cutter bar of the multi-stage variable-diameter milling tool is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com