Telescopic cutting device and heading machine

A telescopic cutting arm technology, applied in the direction of cutting machinery, slitting machinery, mining equipment, etc., can solve the problems of short telescopic stroke, large vibration of cutting head, complex structure of cutting telescopic mechanism, etc., and achieve reduction The effect of beating and strengthening support ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

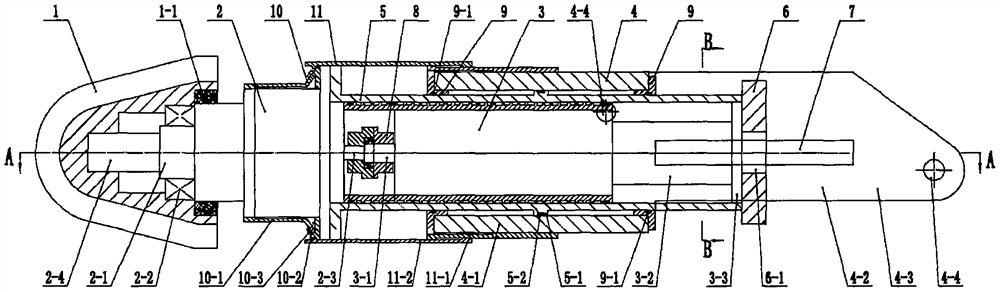

[0037] Embodiment one, with reference to the attached Figure 3 to Figure 5 , a telescopic cutting device, the carrier body is a cutting arm frame 4, the front part of the cutting arm frame 4 is provided with a cylindrical cylinder 4-1 coaxial with the motor 3, and the rear of the cutting arm frame 4 There are two groups of support lugs 4-2 at the top, each set of support lugs 4-2 is composed of two lug plates 4-3 parallel to the motor shaft, and the lug plates 4-3 are provided with hinged holes 4- 4. Two circular support guide sleeves 9 are set and fixed on the front and rear ends of the cylinder 4-1 respectively, and the inner hole of the support guide sleeve 9 is provided with a dust-proof sealing ring 9-1, and the cylindrical telescopic sleeve 5 can slide The sleeve is set between the front and rear support guide sleeves 9, a circular piston 5-1 that is slidingly fitted with the inner hole of the cylinder 4-1 is provided in the middle of the telescopic sleeve 5, and a pist...

Embodiment 2

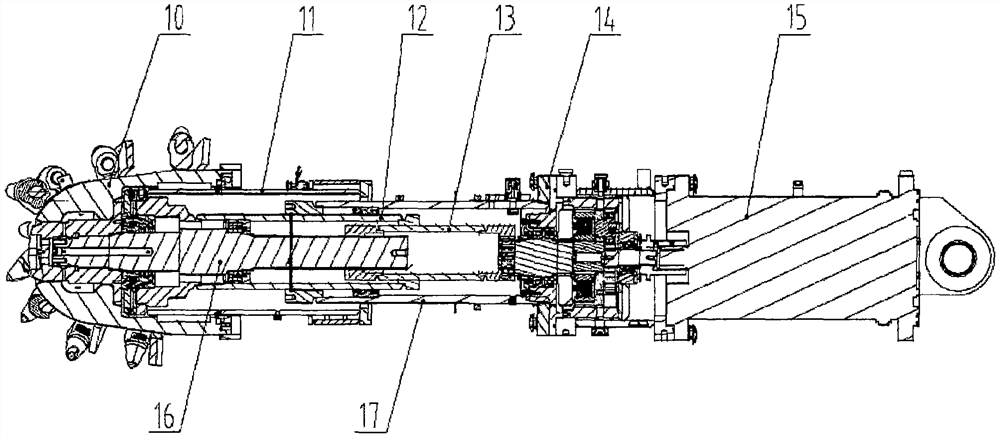

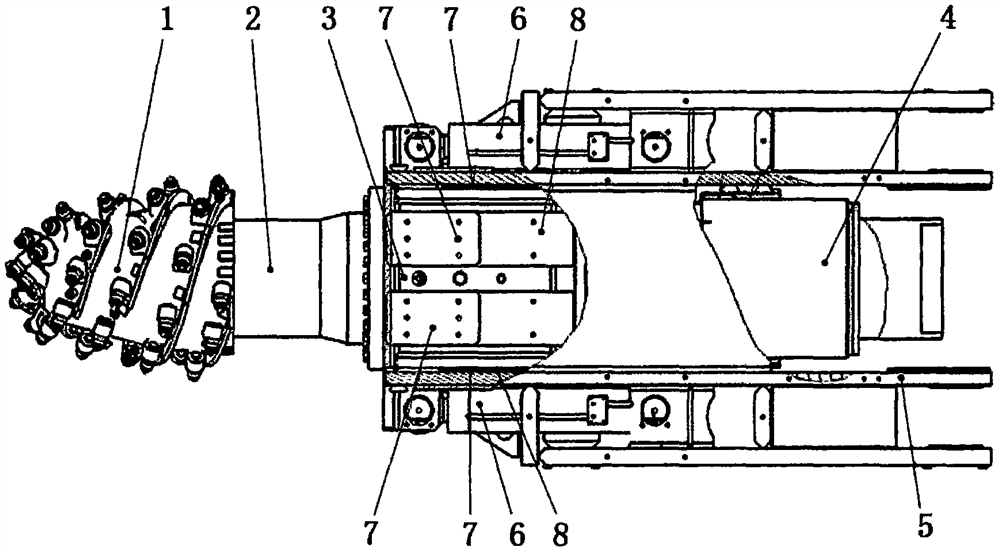

[0048] Embodiment two, referring to the attached Figure 7 to Figure 9 In this embodiment, the output shafts 2-4 of the reducer adopt a horizontal double output shaft arrangement. At this time, the output shafts 2-4 of the left and right reducers are fitted with two horizontally arranged cutting heads 1 . Adopting the arrangement of the transverse double cutting heads 1 can optimize the cutting force and reduce the lateral swing angle of the cutting boom 4 .

[0049] In order to further limit the overall length of the cutting device, in this embodiment, the connecting flange of the reducer 2 is placed in front, and the main part of the reducer 2 is also set in the telescopic sleeve 5. At this time, the connecting flange of the reducer 2 is also The ring casing 10 - 1 of the spray cooler 10 is welded and fixed to the casing of the speed reducer 2 .

[0050] The longitudinal guide rail 7 of this embodiment is an integral plate-like structure provided with a longitudinal groove-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com